The Analysis of Modern Diagnostic and Monitoring Devices for the

Traction Power Supply System

Alexandr Agunov, Ilya Terekhin, Olga Stepanskaya, Ivan Baranov and Erbol Abishov

State Transport University of Emperor Alexander I, St. Petersburg, Russian Federation

Key words: Monitoring, grounding, diagnostics, grounding system of contact line poles, traction power supply, high-

speed transport, low-maintenance system.

Abstract. In the process of a new modern device developing for diagnostics and real-time monitoring of the ground

system, in order to take into account, the existing features of high-speed traffic development, the present

modern diagnostic devices for the traction network of high-speed railway transport were investigated. The

existing devices and methods of diagnostics and monitoring of the traction power supply elements of railways

are discussed in the article. The basic operation principles of the used devices have been analyzed and the

analysis of their advantages and disadvantages are considered in the present paper. The presented analysis

allows us to studied not only the trends in the development of diagnostics and monitoring systems, but also

to make a conclusion about the future prospects for their implementation and refinement.

1 INTRODUCTION

Based on the Strategy for the Development of Rail

Transport in the Russian Federation through 2030, an

increase in the range of high-speed and high-speed

traffic, the weight of trains and the reliability of the

current system are being implemented. The risks of

traction network failures increase with the increase in

speed; train traffic disruptions lead to significant

economic losses. Restoration work takes a

considerable amount of time, as the damaged sections

become more extensive. The classical way to ensure

high reliability indicators is to provide redundancy and

increase the safety margin. So, at speeds over 160

km/h, it is forbidden to operate the contact wire with

wear and tear exceeding 20 % of the nominal cross

section. At the same time, on the lines with low speed

it is allowed to wear out 30 %. There is a similar

situation with the tension of contact wires and cables

that are part of the contact suspension system. Despite

the positive effect of increasing the tension on the

quality of current collection, it is limited to about 50 %

of the yield strength of the material.

The reasons described above have led to the fact

that the operation of the contact line nowadays

involves the replacement of contact wires much earlier

than reaching their critical wear and tear, and also

leads to a decrease in the dynamic performance of the

current collection system. Problems related to the

increase of permissible speeds and service life of

contact wires in conditions of transition to high-speed

traffic, when designing high-speed lines, are extremely

topical.

During operation, the contact line regulation

characteristics specified by the project are capable of

exceeding the permissible values as a result for the

effects of electric rolling stock (ERS), climatic

conditions and current loads, which leads to failures.

To ensure quality and reliable current collection, it is

necessary to constantly monitor the state of the contact

line and traction network as a whole. Improvement of

contact line operation technologies using the

permanent diagnostics and monitoring system helps to

reduce the need for JSCo "Russian Railways" in

traction network elements with increased strength

characteristics and increase it’s replacement periods

and will ensure the possibility of high-speed traffic on

the sections with standard design solutions.

According to the "Strategy for Scientific and

Technological Development of Russian Railways

Holding Company for the period until 2025 and for the

perspective until 2030," one of the most important

tasks in rail transport is to improve the quality of

traction network maintenance through the use of

software and hardware complexes that can allow

monitoring and diagnostics of traction network

elements in autonomous mode. Autonomous

Agunov, A., Terekhin, I., Stepanskaya, O., Baranov, I. and Abishov, E.

The Analysis of Modern Diagnostic and Monitoring Devices for the Traction Power Supply System.

DOI: 10.5220/0011587200003527

In Proceedings of the 1st International Scientific and Practical Conference on Transport: Logistics, Construction, Maintenance, Management (TLC2M 2022), pages 359-363

ISBN: 978-989-758-606-4

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

359

diagnostic and monitoring devices combined into the

system will improve the quality of diagnostics and

monitoring, as well as reduce the need for highly

qualified personnel and virtually eliminate the human

factor (Burkov, 2021).

2 MATERIALS AND METHODS

Traction network monitoring and diagnostic devices

form a set of special equipment that can be divided into

mobile and stationary. Mobile devices are the

laboratory wagon and various manual devices for

control of traction power supply system elements.

Stationary devices are used for continuous real-time

monitoring of certain parameters. Information from

stationary devices is transmitted via various

communication channels, such as: optoelectronic,

radio channels, mechanical (via insulating element)

and optical. Processing and analysis of output signals

from sensors installed on traction network elements

are performed according to specially developed

algorithms for each of them, as well as the program

responsible for combining, storing and transmitting

these signals.

2.1 Mobile Diagnostic Devices

The problem of mobile devices is that they have to

perform diagnostics on functioning lines, along which

the ERS movement is carried out stable. In addition,

manual measurements aren’t sufficiently effective,

since they require several bypass of diagnosed sections

of different lengths, and give insufficiently accurate

results.

One of the most effective mobile devices is a

complex of automated control of contact line

parameters. Them equipped with a diagnostic

laboratory wagon, on the roof for which a measuring

current collector and an observation tower with

measuring equipment are installed. Apart from

determining voltage to the type and magnitude in

contact line, special devices make it possible to

measure and register the deviations of the contact line

parameters that go beyond the set norms for all the

contact line objects, and on this basis they

automatically generate a report on the assessment of

the technical condition of the contact line on the track

section under diagnosis. The design of the observation

tower provides a wide and sufficient view for the

measuring and control systems installed on it for video

and thermal monitoring as well as ultraviolet

diagnostics.

The system of speed control of contact wire is also

known (Contact network control systems, tvema.ru)

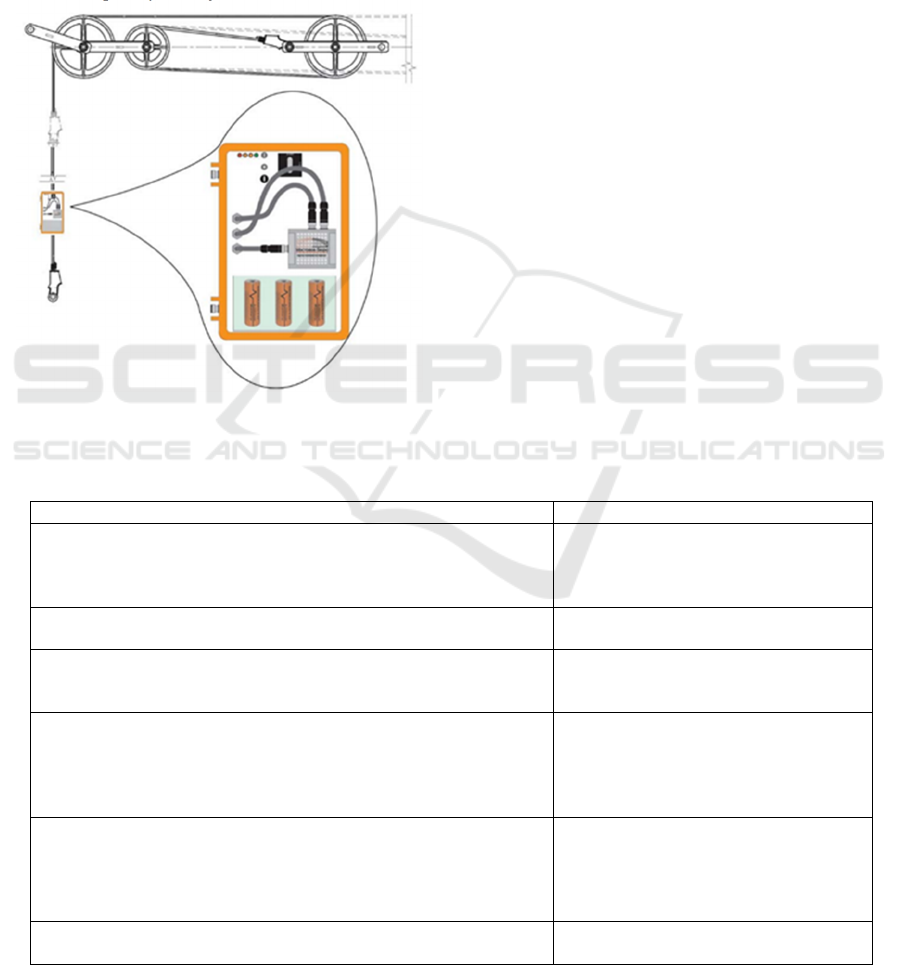

Fig. 1 - one of modern developments. Sensors perform

all measurements in a non-contact manner, and the

recorded parameters are processed by the information-

computer equipment of the complex. Parameters are

measured in relation to the level of top of rail heads

and their position in the plot plan. At the same time,

the hardware complex registers the reduction of

contact wire on aerial frog and the height of

registration fitting set relative to it, measures the force

of current collector pressing on the contact wire, as

well as registers hits on the current collector, tension

of contact wire and breaking loose of current collector.

Diagnostic results, including registered deviations

from the required standard parameters of the contact

line, are displayed in the form to graphs on the

monitors of the operator's hardware complex and

saved to electronic storage devices. Measurement

results for the thermal imaging and ultraviolet camera

are recorded separately. All recorded readings are

linked to the recorded parameters of speed sensors and

the distance travelled, as well as to the points of contact

wire fixation.

Figure 1: System for speed control of contact wire.

2.2 Stationary Diagnostic Devices

Currently on the JSCo «Russian Railways» range, the

most widespread stationary diagnostic and remote

monitoring system (SDRM) of the contact line

contains various sensors for recording parameters for

the technical condition of the contact line elements,

which include the carrying cable (CC), contact wire

(CW), consoles, strings, load-compensating devices

placed on the anchored poles of the contact line.

Stationary data acquisition and transmission devices

are installed along the entire length for the contact line

section on the CC and CW behind the rollers of the

load-compensating units and/or above the load of the

load-compensating unit placed on the anchored poles

of the contact line, Fig. 2. Each device for transmitting

and collecting information contains a certain list of

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

360

sensors for measuring parameters to the technical

condition of the contact line elements, a

microprocessor device for analog-digital processing an

information from the sensors, an autonomous power

supply, a device for wireless communication between

the device and an intermediate information storage

device SDRM placed at the nearest station, which is

connected by a wire and/or wireless communication

with a single information storage device on the

condition of the contact line elements of the railway

network (Nepomnyashchij, RU2444449C1).

Figure 2: Information collection and transfer device SDRM.

However, a complete transition to stationary

devices has not yet been organized and is difficult. In

order to control the parameters of the contact line with

detection of pre-fault conditions, it is planned to use a

combined monitoring and diagnostic system

consisting of mobile diagnostic devices (laboratory

wagons), diagnostic tools on the ERS, stationary

monitoring devices installed along the entire line area,

as well as a unitary system for data collection and

analysis. Stationary devices provide diagnostics and

monitoring for a number to certain parameters,

including movement of compensating device weights,

tension of contact suspension wires, temperature of

contact wires, conditions of ice formation, vibration

and inclination of contact line poles, etc (Eurasia news,

eav.ru).

3 RESULTS AND DISCUSSION

The main disadvantage of the existing systems for

monitoring the state of the contact line with the help

for mobile diagnostic devices is that these

measurements are carried out periodically, and the

observation time is short enough, which does not

provide an opportunity to monitor the stress and strain

state of the components to the contact line. Also, the

presence of optical devices has a negative impact on

all the above, as it significantly reduces the reliability

of the described method.

Table 1: Frequency of inspections, checks and measurements of grounding devices.

Name of work on the scope of maintenance for grounding devices Periodicity

1. Inspection of all visible elements for the grounding device,

checking the contacts strength, the correctness of installation, no

mechanical damage; tightening loose bolted contacts, elimination of

detected faults

Twice a year (spring and autumn)

2. Selective opening of the ground to inspect the elements of

the

g

roundin

g

device in the

g

roun

d

once every 5 years

3. Measuring the resistance of the grounding device (if it's

value is normalized)

After installation, no later than 6

months after commissioning, and

thereafter at least once ever

y

3

y

ears

4. Measuring the grounding resistance of structures and

devices connected to the rail circuits (if necessary to control their

values in the condition of the influence on the operation of the rail

circuits for signals and interlocks and protection against electrical

corrosion)

At commissioning and thereafter at

least once every 5 years (direct

current) and at least once every 10

years (alternating current)

5. Checking serviceability of protective devices of the

grounding circuit:

airgap

diode, diode-spark grounders

airgap type IPV-CNII

once every 3 months

twice a year

once a yea

r

6. Checking the serviceability of the grounding circuits by

electrical measurement

once a year

The Analysis of Modern Diagnostic and Monitoring Devices for the Traction Power Supply System

361

Continuous monitoring systems that are used do

not allow you to properly assess the tension of wires

and cables traction network in the online mode, or

require changes in the construction of the control

object.

Both versions of diagnostic and monitoring

systems have the ability to control only one parameter

- the force in wires and cables. In addition, the

described systems do not provide the possibility of

continuous diagnosis and monitoring of the state of

traction network elements, but most importantly, they

do not provide the possibility of rapid prediction of

pre-fault and failure situations. At the moment, many

of these disadvantages have been solved in the

developments (Efanov, RU2701887C1; Navik, 2016).

However, even before it’s final and full-fledged

implementation, certain improvements are needed.

Along with the development of the optimal system for

diagnostics and monitoring of the contact suspension

elements, the issue of diagnostics and monitoring of

other elements in the traction network, in particular,

such an important element of traction power supply as

the grounding system, remains unresolved.

According to (Ministry of Railways of Russia,

1993) (Table 1) it can be concluded that the frequency

of checking the grounding system devices is not great

and consists mainly of visual inspections, which,

combined with the human factor, creates a high

probability of untimely detection of faults in the

grounding system.

This maintenance procedure inevitably leads to

high labor costs for it’s implementation, and often

misses the real pre-fault states of the grounding system

elements. This leads to failures and, as a consequence,

to disruptions in train traffic, and in the worst cases can

lead to disasters.

One of the important and problematic nuances is

the resistance of the contact line poles groups, which

affects the operation of the relay protection.

Operational information about the technical

condition of the traction network elements, including

the grounding system, will allow technicians to

eliminate pre-fault conditions in time.

Means of continuous diagnostics and monitoring

are currently sufficiently equipped only facilities of

railway automation and telemechanic, the fault of

which is registered less than 3% of failures that caused

violations of train traffic and safety of people (Efanov,

2016). However, it’s mainly necessary to provide

means of continuous diagnostics and monitoring of the

following objects: traction network and track railway

line, which aren't redundant.

For quite a long time there has been a need to

introduce continuous monitoring and diagnostic

systems of the traction network on railways, because

it's elemention failures lead to disruption of train

traffic, threaten the safety of passengers and

maintenance personnel, and also have a negative effect

on adjacent objects.

It should be noted that, according to a preliminary

estimate, the cost of implementing the monitoring and

diagnostics system will be less than 10-15 % of the

cost of capital building of the traction network. The

costs of the diagnostics and continuous monitoring

system can be divided into two components: the cost

of technological equipment: sensors, accumulators,

autonomous power supplies, etc. and the hardware

complex of centralization: data transmission channels,

automated workplaces, servers, etc. Application of the

continuous monitoring and diagnostics system will

contribute to almost complete elimination of critical

damage for traction network elements, leading to a

threat to human safety and disruption of train traffic.

Obviously, the quality and safe operation of

electrified railways directly depends on the reliable

operation of all components of railway infrastructure

and ERS. Thus, an effective means of ensuring high

reliability as well as preventing pre-failure states are

systems for continuous monitoring and diagnostics of

railway infrastructure facilities, including grounding

systems.

On the Department "Electrical Power Supply of

Railways" of the Emperor Alexander I St. Petersburg

State Transport University is working on a modern

diagnostic and real-time monitoring device for the

grounding system, which in combination with the

traction power supply system without grounding the

contact line poles on the traction rail will create a low-

maintenance grounding system and allow for control

within the digital substation.

4 CONCLUSION

Development of the real-time diagnostics and

monitoring system for the railway traction network is

associated with the improvement of monitoring

technologies, reduction in the cost of hardware and

equipment and increase in the established level to the

quality of system operation. At the same time,

equipping railways with continuous monitoring

systems creates favorable conditions for the

development of digital railway space (digital railway)

(Rozenberg, 2016).

The development of data transmission networks at

signal transmitting elements, which include diagnostic

devices of the permanent monitoring system of the

traction network, on long railway sections is

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

362

accompanied by the creation of a system of wireless

transmission of diagnostic information in real time.

Any diagnostic and monitoring devices for the railway

infrastructure, including grounding systems equipped

with radio transmitters, can be connected to such a

system. At the same time, there will be no need to

provide the services of contractors in terms of

communication (Ivanov, 2016). At the same time, a

real-time digital diagnostic data transmission system

will allow the use of cloud-based storage and

transmission technologies in the railway transport, for

example, diagnostic and monitoring results can be

transmitted on the portable devices of the nearest

service personnel to the diagnostic and monitoring

object. Stationary workstations with a large number of

hardware and computers can be eliminated, and

monitoring results can be displayed in a separate

module of the automatic train control system. The

reduction in equipment will reduce the cost of

diagnostic and monitoring systems for various railway

infrastructure facilities.

However, scientists engaged in the development of

continuous monitoring systems for railway

infrastructure facilities have not yet been able to solve

the problem associated with the use of diagnostic data

not only for maintenance tasks, but also to transfer

information about deviations from established

standards onboard devices for ERS, which would

allow in conditions of critical violations of train safety

to make different decisions to counteract dangerous

situations: from lowering the pantograph in dangerous

areas to a complete train stop.

The development of the continuous monitoring and

diagnostics system for railway traction network

elements allows to judge about the prospects of it's

widespread implementation, as well as to conclude that

with it’s help the transition to Smart grid technology -

smart power supply networks - is possible (Madrigal,

2017).

The development of continuous traction network

monitoring technology, as well as the creation of low-

maintenance technical diagnostic tools, will enable the

optimization of all electrified railways in the future.

REFERENCES

Burkov, A. T., Mukhamedjanov, М. F., 2021. Logical

control of the catenary maintenance in the current

collection system at intensive train traffic. Modern

Technologies. System Analysis. Modeling. 1 (69). pp.78–

88.

Contact network control systems. https://tvema.ru/625.

Nepomnyashchij, V. G., Osadchij, G. V., Pristenskij, D. N.

RU2444449C1 Method and system of diagnostics and

remote monitoring of railway overhead contact system.

Bridge bureau.

Innovative contact network solutions for high-speed lines.

Eurasia news. http://eav.ru/publ1.php?publid=2017-

11a04.

Efanov, D. V., Gross, V. A., Romanchikov, A. M.

RU2701887C1 System and method for continuous

monitoring of state of contact network of rail.

LokoTekh-Signal.

Navik, Petter, Ronnquist, Anders, Stichel, Sebastian A,

2016. Wireless railway catenary structural monitoring

system: Full-scale case study. Case Studies in Structural

Engineering. 6, pp. 22-30.

Instructions for grounding power supply devices on

electrified railways. Moscow: Ministry of Railways of

Russia, 1993. 69 p.

Efanov, D. V., 2016. Concurrent checking and monitoring

of railway automation and remote control devices.

Sankt-Peterburg, p. 171.

Rozenberg, E. N., 2016. The digital railway is the near

future. Automation, communication, informatics. 10. pp.

4–7.

Ivanov, A. A., Legon'kov, A. K., Molodcov, V. P., 2016.

Transfer of data from moving equipment devices with

APK-DK equipment in the absence of a physical line and

round-the-clock duty. Transport automation. 2(1). pp.

65–80.

Madrigal, M., Uluski, R., Gaba, K. M., 2017. Practical

Guidance for Defining a Smart Grid Modernization

Strategy. Int. Bank for Reconstruction and Development.

The World Bank, USA, Washington DC. p. 152.

The Analysis of Modern Diagnostic and Monitoring Devices for the Traction Power Supply System

363