Expert-based Classification of Worker Assistance Systems in

Manufacturing Considering the Human

Benedikt G. Mark

1a

, Matteo De Marchi

1b

, Erwin Rauch

1c

and Dominik T. Matt

1,2 d

1

Free University of Bozen-Bolzano, Industrial Engineering and Automation (IEA), Universitätsplatz 5, 39100 Bolzano, Italy

2

Fraunhofer Italia Research, Via A. Volta 13/a, 39100 Bolzano, Italy

Keywords: Industry 5.0, Smart Manufacturing, Worker Assistance Systems, Operator 4.0, Sustainable Manufacturing.

Abstract: The transformation process of manufacturing industry into a more digitalized world is a key challenge of the

fourth industrial revolution. Advantages of new technologies must be used effectively, and therefore

employees need to be prepared to deal with these new technologies and the complexity and speed that today's

production entails. Worker assistance systems offer the possibility to simplify the interaction between humans

and complex machines and to reinforce physical and cognitive skills of employees. Although worker

assistance systems are available on the market, methods focusing on the classification of appropriate worker

assistance systems for specific work tasks and worker types are missing. This work presents an expert-based

classification of worker assistance systems in manufacturing based on classification attributes and capabilities.

1 INTRODUCTION

In addition to the Digital Transformation in

production, sustainability in manufacturing is playing

an increasing role (Despeisse & Acerbi, 2022). This

is also reflected in the relatively new term "Industry

5.0", which according to the definition of the

European Commission aims to make production more

sustainable, more resilient and more human-centered

(EC, 2021; Anvari, 2021). Assistive technologies can

play a major role in production, especially in the area

of social sustainability (Zimmer et al., 2022). By

means of assistance systems, work processes can not

only be made more ergonomic and safer (Gualtieri et

al., 2020), but at the same time human skills (Sony &

Mekoth, 2022) and diversity in manufacturing can be

increased. However, many companies are currently

faced with the challenge of obtaining a

comprehensive overview of existing worker

assistance systems on the market and selecting the

most suitable aid systems for internal work processes

from the wide variety available. There are currently

only isolated studies on the potential of individual

worker assistance systems (Zigart & Schlund, 2020;

a

https://orcid.org/0000-0001-8211-4682

b

https://orcid.org/0000-0001-7965-4338

c

https://orcid.org/0000-0002-2033-4265

d

https://orcid.org/0000-0002-2365-7529

Tropschuh et al., 2022), which often makes it difficult

to compare the systems with one another. The

problem tackled in this study is how to facilitate the

selection and comparison of worker assistance

systems based on their specific characteristics.

Thus, in this paper, an expert-based classification

of worker assistance systems regarding classification

attributes and capabilities is presented. Actually no

similar concept for the classification of worker

assistance systems in manufacturing can be found;

therefore the results of this work represent an original

and novel contribution to the scientific body of

knowledge. The goal is to create an first concept of a

reliable database, which makes it possible to compare

and later also select worker assistance systems for

certain purposes. Once such a concept to create a

database is established, relevant or newly developed

systems can be added and continuously further

evaluated in the future to ensure topicality. For the

evaluation purpose, a web platform was

programmed/configured that makes a user-friendly

evaluation possible.

The paper is structured as follows. First, in

Section 2 a theoretical background is given with a

184

Mark, B., De Marchi, M., Rauch, E. and Matt, D.

Expert-based Classification of Worker Assistance Systems in Manufacturing Considering the Human.

DOI: 10.5220/0011591200003329

In Proceedings of the 3rd International Conference on Innovative Intelligent Industrial Production and Logistics (IN4PL 2022), pages 184-191

ISBN: 978-989-758-612-5; ISSN: 2184-9285

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

review and summary of available worker assistance

systems. Afterwards classification attributes and

capabilities are distinguished. In Section 3 the

procedure for setting up an expert based database for

worker assistance systems is discussed. Section 4

shows the results of a first pilot implementation of

such an expert based database concept before ending

with a short summary and conclusions in Section 5.

2 BACKGROUND

In the following, the worker assistance systems to be

evaluated as well as the classification attributes and

capabilities are presented.

2.1 Worker Assistance Systems

As for the systems to be evaluated, those were chosen

from the identified systems in the systematic

literature review (SLR) of Mark et al. (2021), that are

either already established/industrialized and used in

industry for some time (I) or not yet used (or since a

shorter period), and therefore still under research (R).

This leads to the resulting systems that are presented

in Table 1.

Table 1: Evaluated worker assistance systems in the expert-

based database.

Worker

Assistance S

y

ste

m

Explanation Readiness

Telemanipulator/

Balancer/ Lifting

Ai

d

System that is used to transport

workpieces between workplaces.

I

Eye Tracking Technology for measuring the point

of eye gaze or the motion of an eye

relative to the head.

R

Portable

Com

p

ute

r

Technical system that technically

su

pp

orts worker in manufacturin

g

.

I

Wearable Sensor Devices that can measure health

related metrics and other personal

data.

R

Ergonomic

Manual

Workplace

The Ergonomic Manual Workplace

can be seen as an aggregation of

different technologies to increase

ergonomics, e.g., by a height-

adjustable tabletop, bright light, and

enough space to be adaptable to the

em

p

lo

y

ee.

I

AI Based

Intelligent

Personal Assistant

Artificial intelligence or software

agent that helps the operator while

interacting with computers or

machines.

R

Computer

Assisted

Instructions

Computing device combined with a

monitor to show e.g., instruction

manuals.

I

Physiological

Sensor – Galvanic

Skin Response

(GSR)

Measures a change in the electrical

resistance of the skin which is caused

by emotional stress.

R

Intelligent Hand

Tracking

System that uses two depth cameras

to track the hand movements of the

worker on the works

p

ace.

R

Smart Phone Device that can be used during

industrial manufacturing to see

instruction manuals and receive

notifications.

I

Voice Control A voice control that can be

individually adapted to the user and

the industrial workin

g

environment.

R

Tablet Digital device that can be used for

showing instruction manuals during

industrial manufacturin

g

.

I

RGB Camera Camera equipped with standard

CMOS sensor through which colored

ima

g

es are ac

q

uired.

I

Augmented

Reality (AR)

Technical system that superimposes

a computer generated picture on the

user's current view of the real world.

R

Passive

Exoskeleton

Different supporting

structures/mechanisms for

supporting the musculature of the

arm.

I

Collaborative

Robot

System that is also known as "Cobot"

which is capable of learning diverse

tasks to assist human.

I

Physiological

Sensor – Heart

Rate

(

HR

)

Measures the speed of the heartbeat

by the number of beats per minute.

R

Active

Exoskeleton

Active support for the human body. R

Smart Scan Glove System that combines a gloves,

smartphone, and Bluetooth to

su

pp

ort workers durin

g

their work.

R

Object Positioning

Tracking System

System that detects the position of

items (e.g., a drill) which are

e

q

ui

pp

ed with the trackin

g

s

y

stem.

R

Projection-Based

Assistance System

Technical system that projects e.g.,

instruction manuals on the

work

p

lace.

I

Mobile Robotic

Assistant

Mobile platform/robot with high

accurac

y

and flexibilit

y

.

I

Smart Watch Industrial smart watch that can be

used for diverse kind of applications,

e.

g

., assembl

y

or maintenance.

R

Infrared Camera System that is used to recognize the

operator and their intention by e.g.,

hand

g

estures.

I

Virtual Reality

(VR)

Technical system that simulates

experiences that can be similar or

also different from real life.

R

2.2 Classification Attributes and

Capabilities

When it comes to worker assistance systems, a first

step is to classify each system. The classification

approach is divided into two different branches. The

first branch focuses on attribute categories to describe

the characteristics and interaction of the worker

assistance systems. According to previous research

published in Mark et al. (2021) they consist of 50

attributes with 147 values grouped into five

categories, namely (i) human worker, (ii) work

environment, (iii) workplace, (iv) task/process, and

(v) performance. Examples for classification

attributes can be e.g., gender, scope of application,

humidity, light condition, type of information

transfer, type of task.

The second branch presented in Mark et al. (2021)

focuses on 23 capability parameters which are also

Expert-based Classification of Worker Assistance Systems in Manufacturing Considering the Human

185

divided into five categories, namely (i) skills, (ii)

relevant senses, (iii) cognitive abilities, (iv) physical

abilities, and (v) personal attributes. These categories

are later used to assess each worker assistance system.

3 PROCEDURE AND

STRUCTURE OF THE EXPERT-

BASED DATABASE

In this section, the procedure and structure applied for

the classification of the attributes and capabilities via

a developed prototype web platform are explained.

The selection of an expert-based approach is

explained and the web platform itself is shown

together with the used traffic light colour coding for

classification as well as the Likert scale for the

capability rating.

3.1 Expert-based Approach

In order to collect necessary data for the

establishment of a database, two different approaches

resulted to be possible. One is to collect the data

through experiments with all identified assistance

systems and the other is to let the assistance systems

be evaluated by experts. The SLR of Mark et al.

(2021) showed that experiments were conducted with

some worker assistance systems in the existing

literature, but only a few systems were considered in

experiments and additionally only specific aspects

could be investigated (such as the preferred user

acceptance for two different systems). Further, the

setup and conduction of extensive empirical testing

and comparison of each of the worker assistance

systems in Table 1 resulted to be unrealistic in sense

of effort, cost and time required. For this reason, it

seemed to be most reasonable to have the individual

systems be evaluated by experts in the field.

Therefore, experts were contacted who are

currently working or have been working in the past

with the respective systems either in research or

industry.

3.2 Web Platform for Evaluation

In order to ensure a structured evaluation of the

worker assistance systems, a prototypal web platform

was developed. This was selected since it has several

advantages compared to an evaluation with other

formats, e.g., Excel datasheets or phone calls. On the

one hand, the well-structured web platform represents

a user-friendly way and makes it possible to guide the

evaluator through the evaluation process by first

explaining the aim of the evaluation, how to do it, and

the final evaluation itself. On the other hand, having

a web platform makes it possible to organize the huge

amount of data in a structured way for further

processing. In addition, the evaluation can be done

from everywhere, which was important especially in

times of Covid-19 pandemic restrictions.

On the landing page of the web platform, without

registering and creating an account, first information

are given on the home page of the web platform.

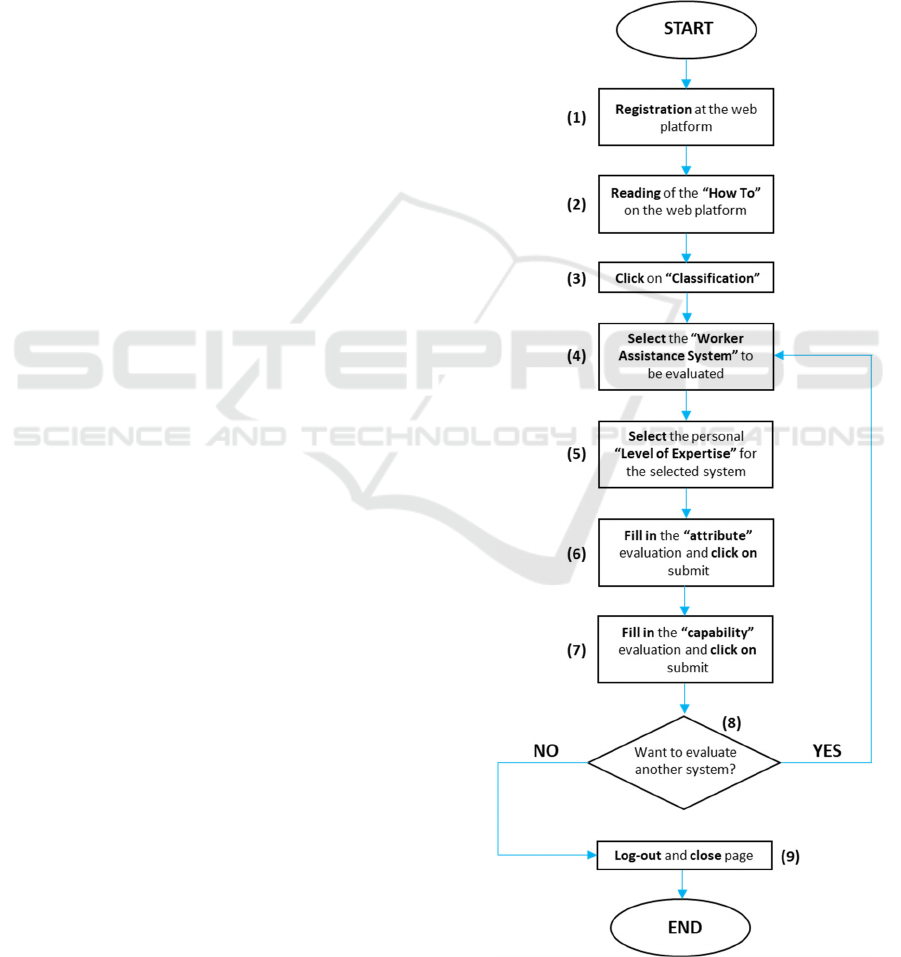

Figure 1: Process flow diagram for system evaluation.

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

186

By clicking on the button “Why” the user gets further

clarification concerning the developed concept and

the purpose of the evaluation (“About”). By clicking

on the button “How”, the user is sent to the “How to”

page which provides the user with necessary

information on how to do the attribute classification

and capability evaluation as an expert. The process

flow diagram in Figure 1 shows the process the

evaluator needed to go through in order to evaluate a

system. First, by clicking on “Register”, the user

creates an account on the web platform (1). After the

“How to” has been read (2), the user may click on

“Classification” (3), which occurs in the main bar

after the user logged in. Now, the user is able to

choose the worker assistance system to be evaluated

(4). Afterwards, the level of expertise of the evaluator

regarding the previously selected system needs to be

inserted (5). What follows is the evaluation of the

classification attributes (6) and capability parameters

(7) which can both be confirmed by clicking on the

submit button. After one system has been evaluated,

there is the possibility to continue with further

systems the user is familiar with (8) or log-out and

close the session (9).

3.3 Evaluation Step 1: Morphological

Box Approach and Traffic Light

Colour Coding for Attribute

Classification

In step 6 of Figure 1 a morphological box approach

and traffic light colour coding is used. The

morphological box approach is a creativity technique

that was first introduced by Fritz Zwicky in 1976

(Erdenberger, 2008; Post, 2021). It can be used to

present different attributes regarding a problem,

method, or product and makes it possible to evaluate

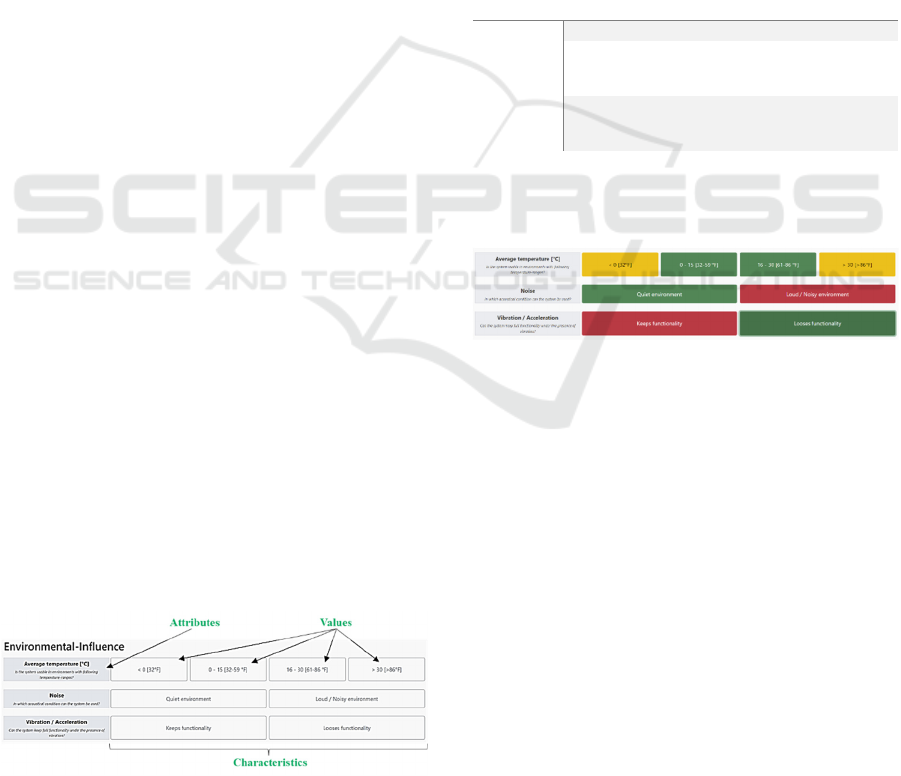

non-related attributes in a structured way. Figure 2

shows an excerpt of the web platform in which the

morphological box approach was applied. On the left

side the attributes are listed (e.g., average

temperature), and the characteristics, in form of

different values (e.g., <0 [32°F]), are shown on the

right.

Figure 2: Excerpt of the morphological box approach used

on the web platform.

For the evaluation of the classification attributes a

traffic light colour coding was used. It is a system

which can be utilized to indicate the status of

variables by applying the colours green, orange and

red, similar to traffic lights. This system is already

used in product labelling (e.g., food and drink (Trudel

et al., 2015) where it shows among others the amount

of fat, sugar, and salt or in performance monitoring

(e.g., project management). Table 2 explains the

meaning of the colours in the scope of this work and

the translation of each colour into a number which

will be of importance in the following chapters.

Within the web platform, the colour (i) green can be

applied by clicking once, (ii) orange by clicking

twice, and (iii) red by clicking thrice.

Table 2: Traffic light colour coding and the meaning of the

colours.

Colour Meaning Value

Green Yes (if the answer is “true”) 1

Orange Possibly (if the “possibility” can be

seen for implementation under

certain circumstances)

0.5

Red No (if the answer is “false” and the

system is not applicable for the

underlying value)

0

Figure 3 shows an excerpt of the morphological

box by having applied the traffic light colour coding

for showing the status of each value.

Figure 3: Excerpt of the morphological box approach with

traffic light colour coding.

3.4 Evaluation Step 2: Likert-Scale for

Capability Rating

After having filled in the classification evaluation in

step 6 (in Figure 1), step 7 follows with the capability

evaluation. For this purpose, a Likert scale is used. It

is a psychometric scale, named after the psychologist

Rensis Likert and is commonly used for

questionnaires in research (Kriksciuniene et al.,

2019). Speaking about survey research, it is the most

widely used method for scaling responses. In this

second step of the evaluation, it is necessary to rate

the enhancement of the respective worker assistance

systems regarding the predefined capability

parameters. Therefore, a Likert scale from 0 (no

enhancement at all) to 3 (maximum enhancement)

was used. An excerpt of the evaluation page provided

on the web platform can be seen in Figure 4. The

Expert-based Classification of Worker Assistance Systems in Manufacturing Considering the Human

187

respective rate can be selected by clicking on the

dedicated white circles.

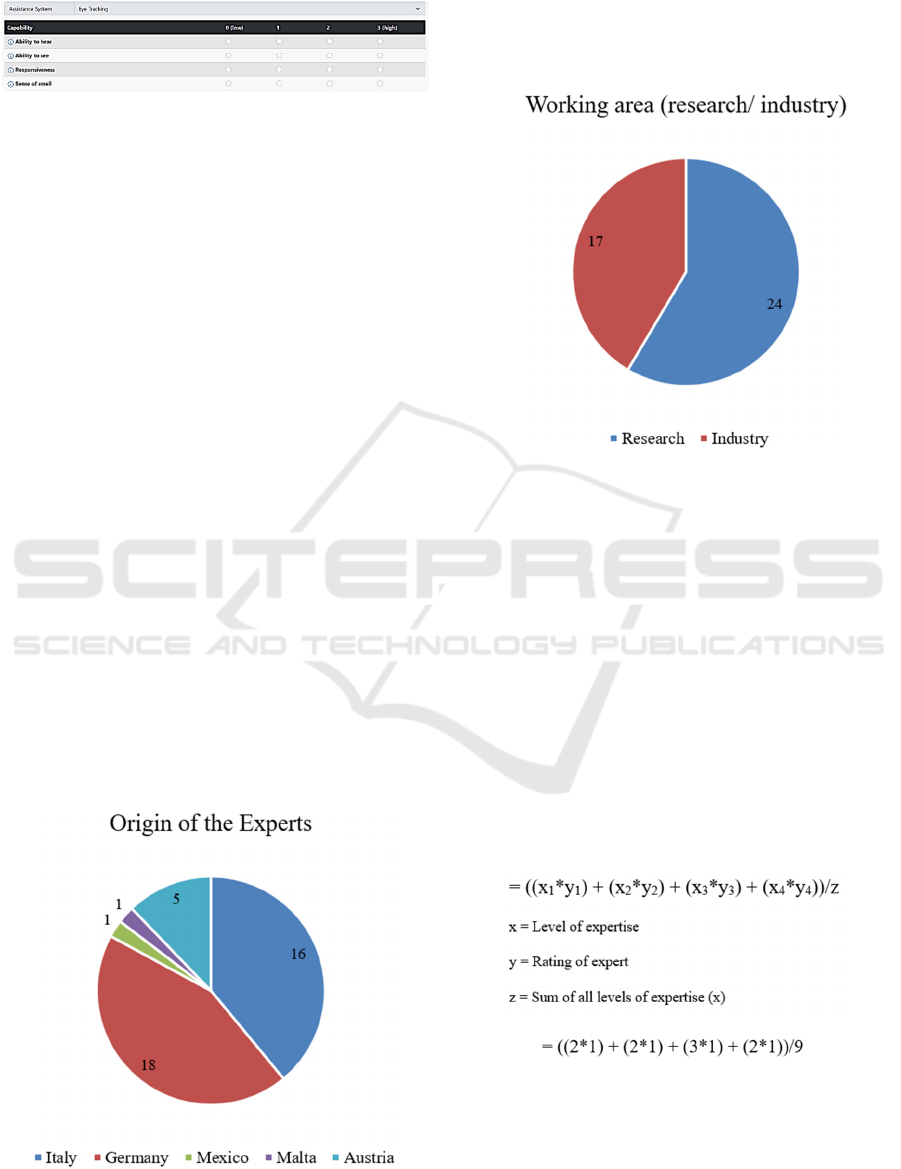

Figure 4: Excerpt of the Likert-scale used for the parameter

evaluation.

4 REALIZATION

In this Section, the realization of the expert-based

evaluation database is presented. Therefore, more

information about the expert evaluation itself is

given, the examination of both the attribute data as

well as the capability data are shown and finally

discussed in an encompassed manner.

4.1 Expert Evaluations

The method developed here represents a novel way of

looking at worker assistance systems in a unified way.

This uniformity allows for subsequent selection based

on various relevant parameters. The purpose of the

methodology is to ensure that the evaluations of

systems continue to evolve over the coming years and

that new systems are included in the methodology.

This allows the values to be based on an increasingly

well-founded and large data set. The purpose of the

expert evaluation carried out here is to build up an

holistic database with trustworthy data. By the time a

sufficient number of votes for the worker assistance

systems had been reached (79 system ratings), 41

experts from research and industry, and different

countries had participated.

Figure 5: Origin of the experts.

Figure 5 shows the origin of the experts, whereas

Figure 6 presents the belonging of the experts either

to research or industry. The experts could be

identified through the systematic literature review as

well as through case study reports and the personal

network.

Figure 6: Working area (research/ industry).

4.2 Examination of Attribute Data and

Discussion

Microsoft Excel was used to examine the huge

amount of data. An algorithm was developed to

structure the around 14.000 lines of data and insert it

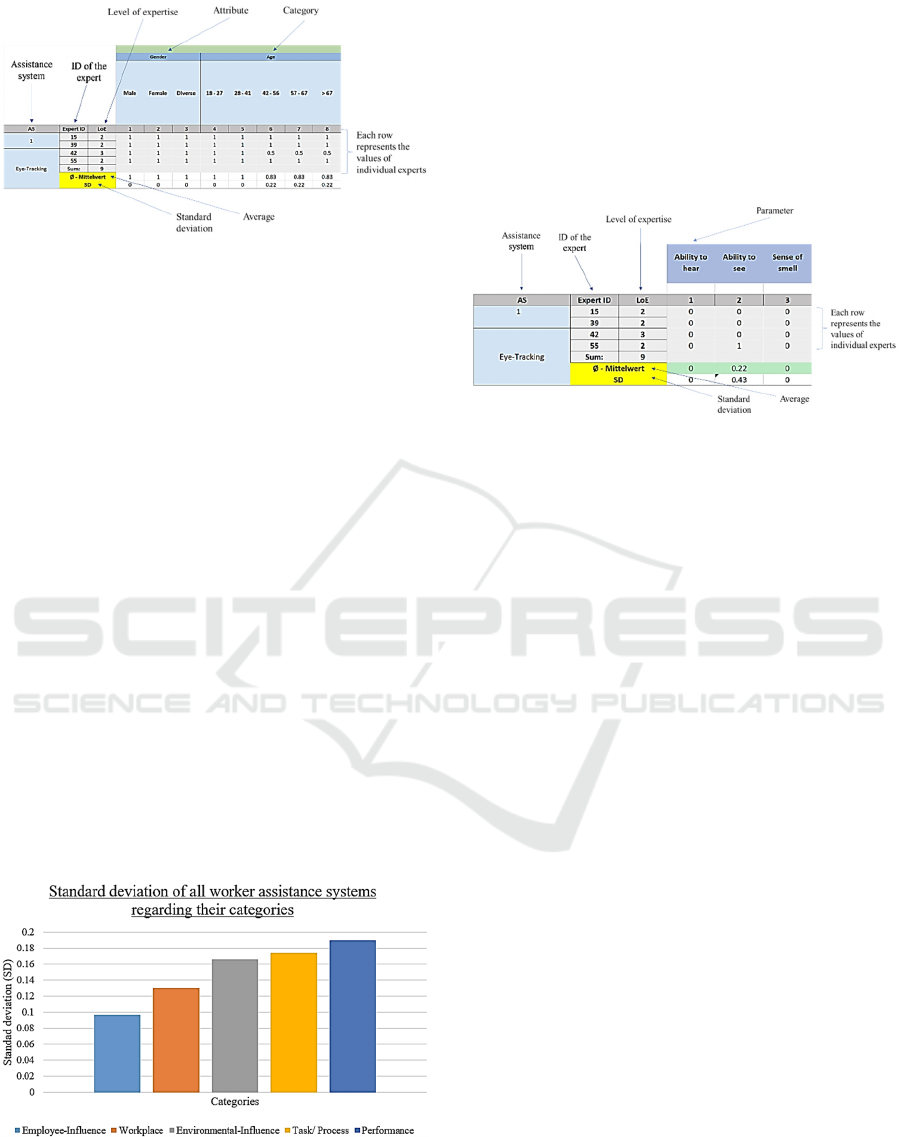

into a template form. Figure 7 shows an excerpt of the

examination spreadsheet. With the collected data for

each worker assistance system the arithmetic mean

and standard deviation was built. In order to consider

the level of expertise of each evaluator, the selected

value was taken into account when building the

arithmetic mean. The following Equation 1 explains

the formula applied and Equation 2 shows how the

first average value was calculated from Figure 7.

(1)

(2)

By examining the data collected through the

expert evaluations together with the comments that

were given by the experts, the 50 attributes could be

assessed and relations to individual worker assistance

systems could be drawn.

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

188

Figure 7: Simplified excerpt of the examination Excel

(attributes data).

Figure 8 shows the average standard deviations of

each of the individual categories. It can be seen that

all standard deviations are rather low, but a trend can

be noticed. It confirms the higher variance of task and

performance related categories compared to others.

The values of the category attributes “employee-

influence” (12 attributes) and “workplace”

(7 attributes) are lower compared to the values of the

attributes “environmental-influence (8 attributes),

“task/ process” (12 attributes) and performance

(11 attributes). An explanation could be the

following: Worker assistance systems that until some

time ago might have been seen as individual

assistance systems got further developed in different

directions. The resulting systems can no longer be

seen as sub-categories of the original systems but

more as newly resulting and further developed

systems. As example can be mentioned the

collaborative robot, which now has many different

versions that differ especially in terms of task/

process and performance rather than workplace,

environment, or employee. The attributes of the

categories workplace, environment, and employee

are more constant when advancing a system.

Figure 8: Standard deviations of all worker assistance

systems regarding their categories.

4.3 Examination of Capability Data

and Discussion

Similar to the attribute related data, Microsoft Excel

was used to examine the huge amount of data

regarding the capability evaluations and an algorithm

helped to structure the data. Figure 9 shows an

excerpt of the examination Excel.

Figure 9: Simplified excerpt of the examination Excel

(capability data).

4.4 Resulting Matrix and Prototype

Implementation of an Expert-based

Database for Existing Worker

Assistance Systems

In this section, the resulting matrix of the (i)

classification attributes and (ii) capability parameters

is explained and shown with variables.

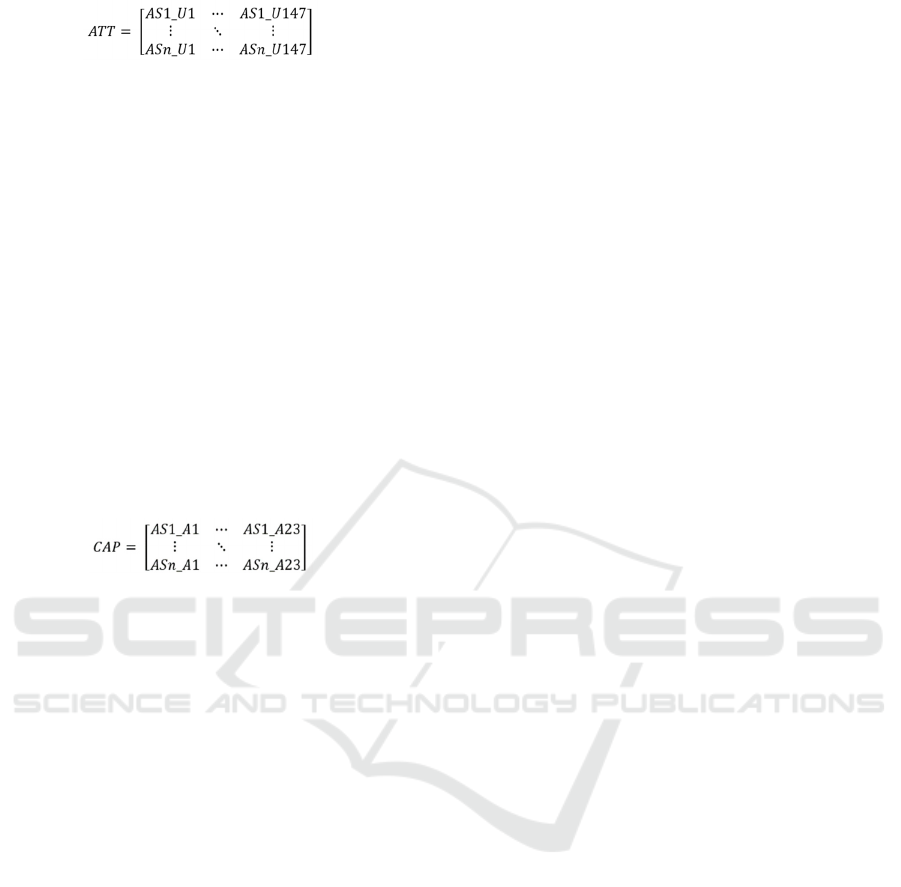

As for the evaluations of the (i) classification

attributes, a matrix ATT (Equation 3) results, which

consists in an evaluation regarding so called Use (U),

that describe the applicability of the individual

attributes regarding the assistance system. These U

(in total 147 characteristic values to be evaluated)

were evaluated for each assistance system from 0

over 0.5 to 1 (red, orange, green), whereas 0 stands

for “No” (if the answer is “false” and the system is

not applicable for the underlying value), 0.5 stands

for “Possibly” (if the “possibility” can be seen for

implementation under certain circumstances), and 1

stands for “Yes” (if the answer is “true”). Appendix 5

shows the values for one assistance system

(dictionary form; key:value pair). It can also be

written in form of the following matrix (Equation 3;

with variables). The matrix ATT lists the applicability

of the 147 characteristics in x direction (U1-U147). In

y direction the different assistance systems (AS)

evaluated by experts are shown (AS1-ASn). ASn

stands for the possible position of the individual

assistance systems (index).

Expert-based Classification of Worker Assistance Systems in Manufacturing Considering the Human

189

(3)

Similar to the evaluation of classification

attributes, the evaluation of (ii) capability parameters

can be presented in a matrix form. The assessment of

the identified assistance systems consists in an

evaluation regarding so called Assistance (A), which

describes the support/enhancement that the individual

assistance systems can provide based on the

capability parameters. These A were evaluated for

each assistance system from 0 to 3, whereas 0 stands

for “assistance system cannot give any support” and

3 for “maximum support”. This results in a list with

values for A for each of the evaluated assistance

systems. It can also be written in form of the

following matrix (with variables). The matrix CAP

(Equation 4) lists the 23 parameters in x direction

(A1-A23). In y direction the different assistance

systems evaluated by experts are shown (AS1-ASn).

ASn stands for the possible position of the individual

assistance systems (index).

(4)

The data are saved to serve as a database in

Microsoft Excel as well as in python dictionary

format (key:value pair) for further processing. This

database provides the basis that can be filled in with

future assistance systems to be included in the

selection and classification method.

5 CONCLUSIONS

The goal of this expert-based evaluation is to create a

prototype of an expert based database which makes it

possible to compare different worker assistance

systems between each other and to select an

appropriate aid systems for certain circumstances and

situations. Based on a first set of data provided by 41

international experts in the field a prototype of such a

database could be realized.

With the enabled database or using the approach

for setting up the expert based database further

research can be done to continuously add other

assistance systems and to test its applicability in real

industrial case studies where a selection of aid

systems is needed. For the validation, a web platform

was programmed/configured that makes a user-

friendly expert evaluation possible. The results

proved the possibility to evaluate different worker

assistance systems in a holistic manner.

ACKNOWLEDGEMENTS

The research is a result of the project titled:

Assist4Work: Social sustainability in production

through age-appropriate and disability-friendly

workplace design using assistance systems, grant

number TN200J.

REFERENCES

Anvari, A. R. (2021). The integration of LARG supply

chain paradigms and supply chain sustainable

performance (A case study of Iran). Production &

Manufacturing Research, 9(1), 157-177.

Despeisse, M., & Acerbi, F. (2022). Toward eco-efficient

and circular industrial systems: ten years of advances in

production management systems and a thematic

framework. Production & Manufacturing Research,

10(1), 354-382.

EC (2021). Industry 5.0: Towards more sustainable,

resilient and human-centric industry. [Online].

Available: https://research-and-innovation.ec.europa.

eu/news/all-research-and-innovation-news/industry-

50-towards-more-sustainable-resilient-and-human-

centric-industry-2021-01-07_en

Erdenberger, A. (2008). Der Morphologische Kasten als

Designmethode für Pauschalreisen, Seminararbeit

[Online]. Available: https://www.grin.com/document/

114923.

Gualtieri, L., Rojas, R. A., Ruiz Garcia, M. A., Rauch, E.,

& Vidoni, R. (2020). Implementation of a laboratory

case study for intuitive collaboration between man and

machine in SME assembly. In Industry 4.0 for SMEs

(pp. 335-382). Palgrave Macmillan, Cham.

Kriksciuniene, D., Sakalauskas, V., and Lewandowski, R.

(2019). Evaluating the Interdependent Effect for Likert

Scale Items, in Lecture Notes in Business Information

Processing, vol. 373, Business Information Systems

Workshops, W. Abramowicz and R. Corchuelo, Eds.,

Cham: Springer International Publishing, pp. 26–38.

Mark, B.G., Rauch, E., and Matt, D.T. (2021). Worker

assistance systems in manufacturing: A review of the

state of the art and future directions, Journal of

Manufacturing Systems, 59, 228–250.

Post, F. (2021). How to use a Morphological Box for

product or business development, [Online]. Available:

https://fabianpost.com/morphological-box/ (accessed:

Oct. 18 2021).

Sony, M., & Mekoth, N. (2022). Employee adaptability

skills for Industry 4.0 success: a road map. Production

& Manufacturing Research, 10(1), 24-41.

Tropschuh, B., Windecker, S., & Reinhart, G. (2022).

Study-based evaluation of accuracy and usability of

wearable devices in manual assembly. Production &

Manufacturing Research, 10(1), 569-582.

Trudel, R., Murray, K.B., Kim, S., and Chen, S. (2015). The

impact of traffic light color-coding on food health

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

190

perceptions and choice, Journal of Experimental

Psychology: Applied, 21(3), 255–275.

Zigart, T., & Schlund, S. (2020, July). Evaluation of

augmented reality technologies in manufacturing–A

literature review. In International Conference on

Applied Human Factors and Ergonomics (pp. 75-82).

Springer, Cham.

Zimmer, M., Al-Yacoub, A., Ferreira, P., Hubbard, E. M.,

& Lohse, N. (2022). Experimental study to investigate

mental workload of local vs remote operator in human-

machine interaction. Production & Manufacturing

Research, 10(1), 410-427.

Expert-based Classification of Worker Assistance Systems in Manufacturing Considering the Human

191