Study Experimental of Cooling Tower Forced Draft With Variation

of Ratio Obstacle in Film Filler

Achmad Syifa'urromli, Arrad Ghani Safitra and Fifi Hesty

Politeknik Elektronika Negeri Surabaya, Institut Teknologi Sepuluh Nopember, Kampus Jl. Raya ITS, Keputih, Kec.

Sukolilo, Kota SBY, Jawa Timur 60111, Indonesia

Keywords: Cooling Tower, Forced Draft, Filler Ratio Obstacle, Efficiency, Performance.

Abstract: This study aims to build and test the Cooling Tower of the Forced draft type. Cooling Tower is a heat

exchanger that functions to cool water with high temperatures from the condenser and remove heat into free

air or atmosphere in the power plant. It aims to bring the water back to its normal temperature or original

condition. To cool, supplier components are needed, one of which is filler. The filler is a very influential

compoent, because the contact between liquid (hot water) and gas (cooling water) occurs in fillers with heat

transfer of conduction. This research was conducted by changing or varying the type of obstacle ratio. The

variation of the filler film is to calculate the ratio of the resistance area and surface area of the filler film with

a variation value of 1 without filler, a variation of 2 times 0.31 , with the type of material used which is

Steinleesstell 0.75 mm. The results showed their effectiveness of 0.47 and 2.43 and the resulting efficiency

of 29.53% and 54.48%.

1 INTRODUCTION

The cooling system plays an important role in

maintaining the temperature of the production

machine so that it can work optimally. An example of

a cooling system is a cooling tower which is a heat

exchanger to lower the temperature the of

wateairflowir flow. One type of cooling tower is a

forced draft cooling tower (Mugisidi et al., 2021). In

the forced draft type, hot water flows down through a

barrier in the form of ,filler and from under the

airflowir flow is blown. The performance of cooling

towers is greatly influenced by filler materials (fillers)

both in the form of arrangements and types of raw

materials (fillers).

The type of filling material used in the cooling

tower has an important point because it provides a

surface area factor that affects the efficiency

especially the thermal performance of the charging

zone of 70% of the heat dissipation capacity

depending on the charging zone (E. Novianarenti et

al., 2019).

Research on the type of cooling tower type forced

draft is still rare because many studies use cooling

tower type wet and type induced draft. Many wet-

type studies are widely used toperformanceomancy

values and NTU values ( Mirabdolah Lavasani et al.,

2014).

The factor that affects the rate of heat transfer

from hot water to air as a cooling medium is when the

two fluids meet in the filler. Filler functions as a

barrier and breaker of water droplets and slows down

the motion of waterfalls so that the contact time

between fluids is longer and the contact area is also

greater, it will increase the amount of heat transfer

that occurs. Some of the studies that have been carri

ouof support for cooling towers include varying the

composition of fillers to obtain cooling tower

performance characteristics (Pita & Sob, 2020),

For the cooling tower performance, several things

must be considered, including the value of the heat

transfer rate,number of trans the fer units (NTU), and

the effectiveness of the cooling tower. In previous

studies, cooling tower induce drafts developed

variations in filler shapes with variations in straight,

zigzag, and wavy fillers and resulted in highest efthe

fectiveness in wave filler variations (Eky

Novianarenti & Setyono, 2019).

This research will compare cooling tower forced

draft by comparing cooling towers without fillers

(empty) with cooling towers containing fillers which

have a obstacle ratio value of 0.31. The data taken are

the discharge of incoming water, the temperature of

Syifa’urromli, A., Safitra, A. and Hesty, F.

Study Experimental of Cooling Tower Forced Draft With Variation of Ratio Obstacle in Film Filler.

DOI: 10.5220/0011710700003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 25-30

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

25

water in and out, the temperature of wet and dry air in

and out, and the speed of air. After data collection,

data processing is carried out to obtain calorific

values, effectiveness values, NTU values, efficiency

and evaporation that occur.

2 EXPERIMENTAL APPARATUS

AND PROCEDURE

The cooling tower made is a forced draft type cooling

tower. With cooling air conditions using a fan /

blower. The hot fluid used is water by raising the

temperature to a temperature of 60 °C with a heater

of 1000 watts. The hot fluid is then pumped into the

cooling tower with a cooling tower size of 0.15 x 0.15

x 1.1 m.

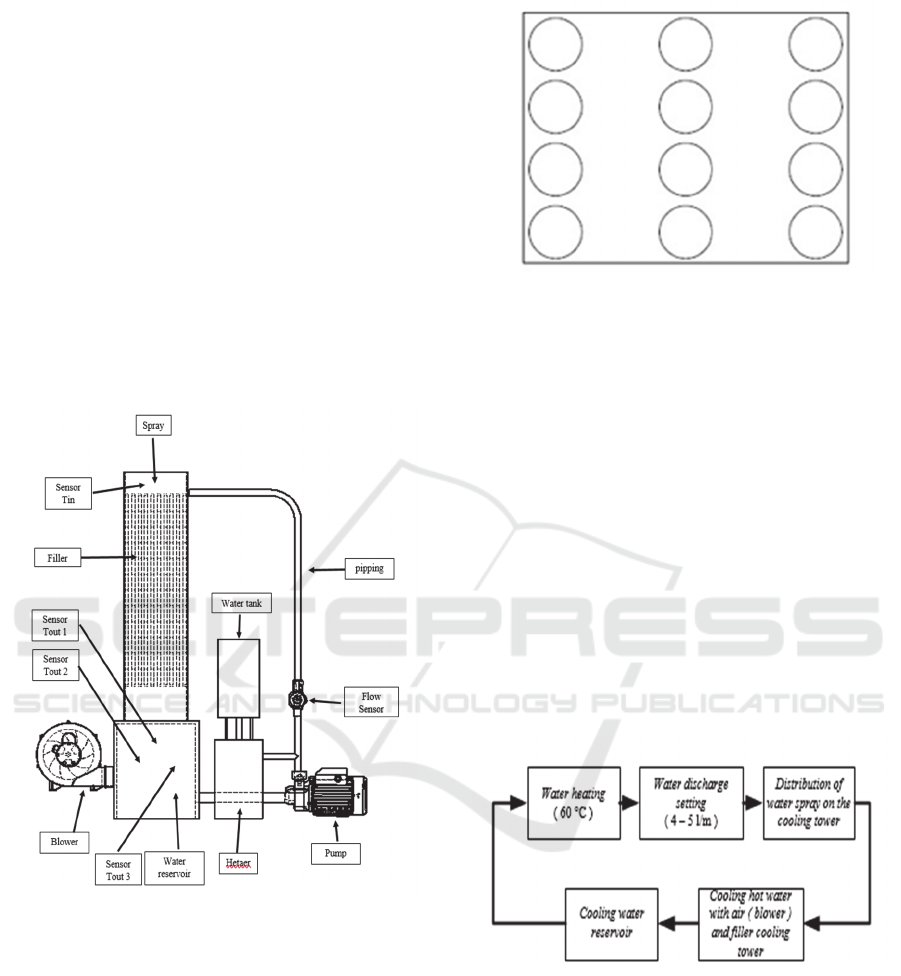

Figure 1: Scheme Cooling tower.

Seen As seenig.1 there is a filler in the cooling

tower which functions as a barrier to the flow of hot

fluid (hot water) and cold fluid (air). The fifillersed

has dimensions of 0.13 x 0.1 m with a total of 6 filler

layers and has 8 levels and the type of material used

is an aluminum plate with a thickness of 0.75 mm.

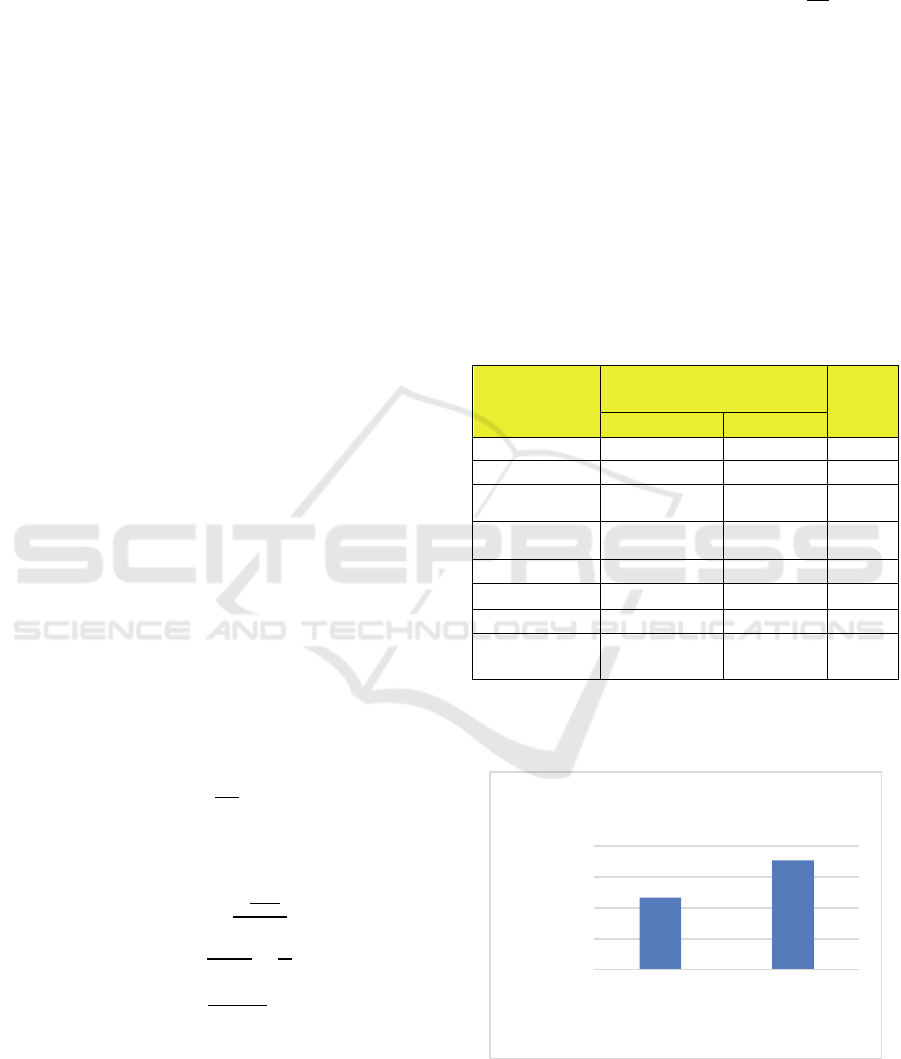

Figure 2: Filler ratio 0.31.

In fig.2 is an image of one filler layer with a

anbstacle ratio of 0.31. The obstacle ratio is obtained

by adding obstacles (rounds on fig.2) with

dimensions of 21 mm in diameter and 3 mm

invulnerability using acrylic with an amount of 24

pieces (front layer and back layer), and the ratio value

is obtained by a comparison of the area of the total

obstacle divided by the total area of 1 filler layer.

In fig.1 there is the placement of sensors used for

data retrieval and data processing. For the

temperature sensor, namely using a thermocouple

sensor, for the water discharge sensor using a flow

meter ,and everything is connected to the Arduino.

Data collection includes the temperature of the heated

fluid in and out, the discharge of hot fluid flow, the

temperature of wet bulbs in and out, the dry

temperature out and in, and the speed othe f incoming

wind.

Figuro 3: retrievalrival process.

On fig. 3, namely the stages for data retrieval for

data processing. The first stage ensures that the

cooling tower and filler used are perfectly installed,

fill the water into the heater and then heat the water

by adjusting the temperature set point to a

temperature of 60 waiting and wait for the water

temperature to reach the set point value, then turn on

the pump and blower and adjust the valve opening

with a range of 4-5 l / min. do data collection, data

collection is carried out as much as 10-12 times data

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

26

collection with the condition that if the water

temperature decreases and the temperature wett is

always lower, then the next data collection can be

continued. After all the data retrieval on variation 1 is

done, turn ofpertains peraltans and replace them with

the second variation.

3 ANALYSIS METHOD

The performance of the cooling tower can be known

by the following equations and can also be analyzed

with the approach of the value of the range and the

value of the approach. And the equations used are as

follows the range

Range

Range is the value of the difference between the

temperature of the heat fluid entering and leaving the

cooling tower, and if the difference in value is high,

the coolong tower can be said to be effective in

performance, and the formula is (H et al., 2014) :

Range (°C) = [T

in

- T

out

] (1)

Approach

Approach is the value of the difference between

the temperature of the hot fluid out of the cooling

tower and the twet bulbure of the wetbulb in, the

lower the value, the better the performance of the

cooling tower. and the formula is (H et al., 2014) :

Approach (°C) = [T

out

– T

wet, in

] (2)

The paradeterminingeded in determing the value

of heat transfer rate (q), effectiveness ε) , number of

a transfer unit (NTU), efficiency, and evaporation loss

are the following values: temperature water inlet ( T

in

), temperature water outlet ( T

out

), Temperature wet-

bulb in and out ( T

wetin

and T

wetout

), temperature dry in

and out ( T

dryin

and T

dryout

), water mass flow rate ( m

,

),

and inlet air flow rate (V)

Inlet air Characteristic

From fig.4 it is used to find the value of the

calculation value of the inlet air characteristic which

includes realtive humirelativen), absolute humidity

(ωin), the rate of incoming moist air ( m

,

moist in

),the rate

of w ater vapor in the air (m

,

vin

), the flow rate of dry

air masses(m

,

dry air

)And from fig4. Can be used to find

relative humidity by using temperature dryin ( T

dryin

)

and temperature wet in ( T

wetin

)(Singh & Das, 2016)

Absolute humidity (ω

in

) the formula is (3).

ω

in

= 0,622

p

v, in

p - p

v,in

(3)

p

v, in

= ϕ

in

× p

g,in

(4)

The rate of incoming moist air

(

ṁ

𝒎𝒐𝒊𝒔𝒕 𝒊𝒏

the

formula is (5).

Figure 4: Psychometric chart.

m

moist,in

= ρ

air

× V × A

u

(5)

Based on table A-2 of Stoecker's book the nature

of humid air at measured temperatures (T

dryin

) to find

a specific volume (m³/kg) so that Pudara = 1/v.

The flow rate of dry air masses((ṁ

the

formula is (6).

m

v,in

=

m

moist,in

1

ω

in

+1

(6)

h

air,in

= C

p

T

1

+ω

in

h

v,in

(7)

and the h

vin

value is obtained using a psychometric

chart table at T

dryin

temperature.

The flow rate of dry air masses (

ṁ

𝒅𝒓𝒚 𝒂𝒊𝒓

the

formula is (8).

m

dry air

= m

moist,in

- m

v,in

(8)

Outlet Air Characteristics

On the calculation of the outlet air

chareteristicharacteristics Fig. 4, by using the dry out

temperature ( T

dry out

) and wet out temperature ( T

wetout

)parameters to find out the value of the relative

humidity(

ϕ

out

, while to find other parameters using

the following equations: (Singh & Das, 2016).

ω

out

= 0,622

p

v, out

p - p

v,out

(9)

p

v, out

= ϕ

out

× p

g,out

(10)

how to find

p

g,out

by using the A-2 stoecker table

Mass flow vapour out vaporrmula is

m

v,out

= ω

out

𝑥 𝑚

dry air

(11)

Study Experimental of Cooling Tower Forced Draft With Variation of Ratio Obstacle in Film Filler

27

Mass flow rate evaporation m

evap

the formula is

(12).

m

evap

= m

v,out

- m

v,in

(12)

Mass flow rate outlet moist air (m

moistout

) the

formula is (13).

m

moist,out

= m

moist,in

+ m

evaporation

(13)

Water Characteristics

The result of the difference between the inflow rate

(

𝑚

and the magnitude of the evaporation rate m

evap

and the formulated as follows (14).

m

wout

= m

win

- m

evap

(14)

and how to find (

𝑚

i.e. by using the conversion

from discharge (l/m) to (kg/s)

Heat mass transfer or kalor

q = m

win

× h

win

-

m

wout

× h

wout

(15)

enthalpy values are searched using tables A-2

properties of saturated water (liquid vaporliquid-

vaporwater temperatures in and

Maximum Kalor

q

max

=

m

win

× h

win

-

m

wout

× h

wwb

(16)

h

wwb

is the enthalpy obtained from the temperature

of the water outlet (T

out

) coupled with the wetbulbin

temperature (T

wetin

) in then divided by 2.

Effectiveness

Effectiveness is a comparison between the actual

heat released by the cooling tower and the maximum

heat that the cooling tower may be able to remove and

formulated such as (17).(ghani saitra et al., 2016;

Ramkrishnan & Arumugam, 2013).

ε =

q

q

max

(17)

Number of Transfer Unit (NTU)(Jaber & Webb,

1989)

NTU = -

ln

1 - ε

1 - εm

*

1 - m

*

(18)

m

*

=

m

moistin

m

moistout

×

C

s

C

p

(19)

C

s

=

h

win

- h

wout

T

in

- T

out

(20)

Evaporation loss

is the evaporation loss per mass conditioned

subduction every 1 °C at each unit of time.

Evaporation loss usually represents the efficiency of

cooling towethe r and the heat of equipment. There is

a formula to calculate evaporation loss

volume:(Tower, n.d.) (21)

Evap loss = 0.00085 × 1.8 × circulating rate

m

3

hr

×

T

w,in

-T

w,out

4 RESULT AND DISCUSSION

After data collection, data processing can be carried

out to determine the performance of the cooling tower

which is influenced by the obstacle ratio on the filler

film which includes data: range and approach,

maximum calorific value and calorific value,

effectiveness and Number of Transfer Unit (NTU), as

well as efficiency values and evaporation loss.

Table 1: Data Process Result.

PARAMETER

variation of filler

U

NIT

No Filler 0,31

Range 7,34 11,45 °C

Approach 17,52 13,38 °C

Q 2,47 4,18

kJ/

s

Q max 5,29 5,91

kJ/

s

efektivitas 0,47 0,71

NTU 0,87 2,33

efisiensi 29,53 54,48 %

evaporation

loss

5,0064466

88

8,51735

8735

ml

C/min

Based on the results of data processing above Tab.

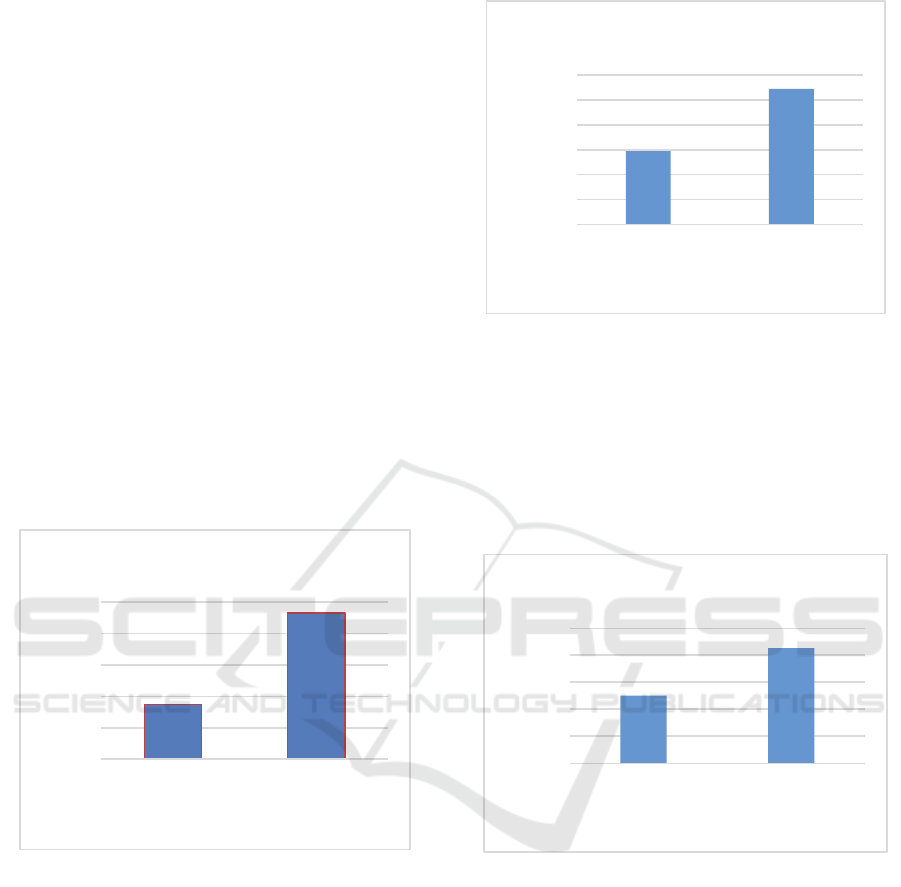

1 can be known to be graphed as shown below.

Figure 5: Graph of the effectiveness of Obstacle ratio

variation.

Effectiveness is a depiction of the performance of

the cooling tower which can be seen from the range

0,47

0,71

0,00

0,20

0,40

0,60

0,80

NoFiller 0,31

EFFECTIVENESS

OBSTACLE RATIOVARIATION

EFFECTIVENESS

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

28

value and approach value. The greater the value of the

resulting range value, the cooling tower can be said to

be effective but also must pay attention to the

approach value also because the smaller the value of

the approach, the cooling tower can be called an

effective cooling tower. The range and approach

values of the cooling tower without fillers are 7.34 °C

and 17.52 °C and can be seen from Tab.1 that with

the addition of fillers at the obstacle ratio level of 0.31

resulting in range and approach values of 11.45 °C

and 13.38 °C, this indicates that fillers with a obstacle

ratio level of 0.31 can improve the performance of

this cooling tower.

Figure 5. is to illustrate that the effectiveness of

the cooling tower, with an empty condition and with

a filler condition whose variation in the ratio of the

obstacle is 0.31 . It can be seen that the effectiveness

value has increased quite significantly due to the

obstacles that occur in the cooling tower due to the

filler. With an effectiveness value of no filler of 0.47

and with filler an obstacle ratio level of 0.31 resulted

in a value of 0.71.

Figure 6: Graph of the NTU of obstacle ratio variation.

From fig.6 is a graphic depiction of the number of

transfer unit (NTU) values which show that in cooling

towers nilia NTU is so small because the transfer of

heat resistance is so small that it can be seen that it is

only worth 0.87, while for cooling towers with fillers

with an obstacle ratio of 0.31 it produces a value of

2.33, this is due to the contact of hot fluid and cold

fluid in the installed filler so that the energy transfer

that occurs between 2 fluids is increasing.

Figure 7: Graph of Efficiency of obstacle ratio variation.

From fig.7 is a graph of the cooling efficiency of

the tower. The cooling efficiency of the tower without

filler only resulted in 29.53% and the efficiency of the

cooling tower filled with a filler ratio of 0.31 resulted

in an efficiency of 54.48%. This is caused by the

exhaustion of the inlet temperature and outlet

temperature of the cooling tower.

Figure 8: Graph of Evaporation loss of obstacle ratio

variation.

Figure 8 is a graph of evaporation loss from

cooling towers. Evaporation loss is a condition where

the evaporation loss (fluid volume) at a temperature

change (°C) in a unit of time. Evaporation loss usually

describes the efficiency of cooling towers and the

heat of equipment. As seen on fig 8. The evaporation

loss value in the cooling tower without filler is 5.0064

(mL°C/min) and the nilia evaporation loss in the

cooling tower with a filler ratio of 0.31 which is

8.5174 (mL°C/min) there is an increase caused by the

contact between the hot fluid and the cold fluid more

and more due to the filler.

0,873

2,327

0

1

1

2

2

3

NoFiller 0

NTU

OBSTACLERATIOVARIATION

NTU

29,53

54,48

0

10

20

30

40

50

60

NoFiller 0,31

EFFICIENCY(%)

OBSTACLERATIOVARIATION

EFFICIENCY

5,0064

8,5174

0

2

4

6

8

10

NoFiller 0,31

evaporationloss(mL.C/min)

OBSTACLERATIOVARIATION

EVAPORATIONLOSS

Study Experimental of Cooling Tower Forced Draft With Variation of Ratio Obstacle in Film Filler

29

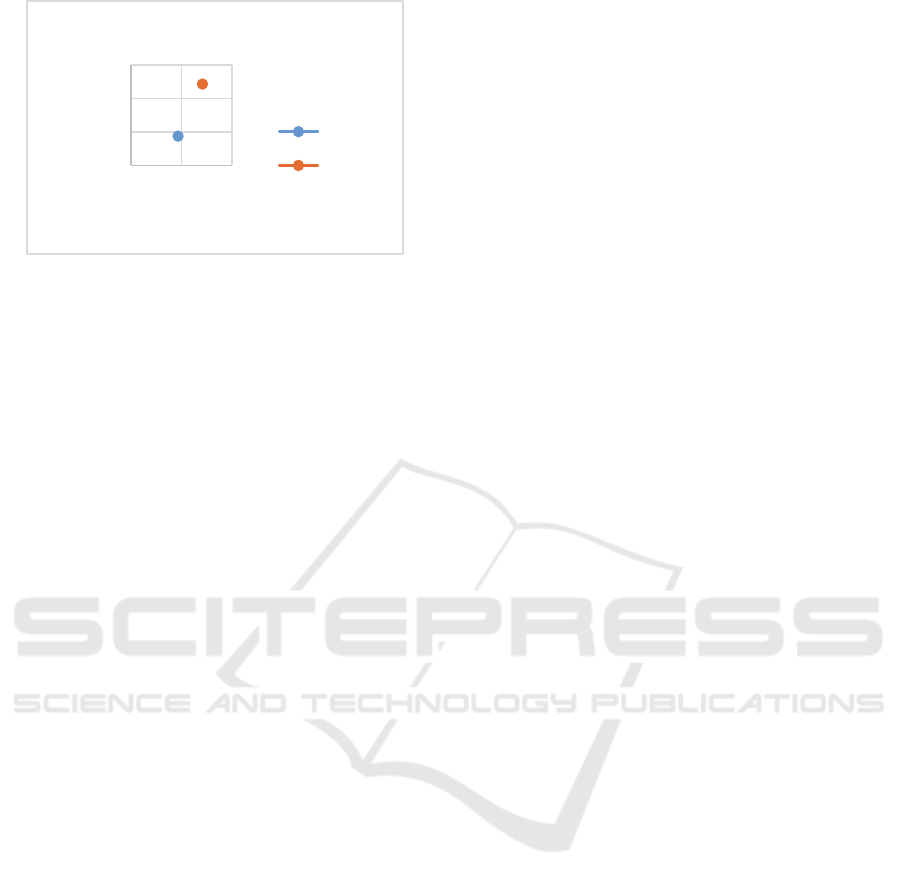

Figure 9: Graph of the NTU of Effectiveness.

Figure.9 shows a graph of the value of the NTU

cooling tower against the value of the effectiveness of

the cooling tower. The NTU value is directly

proportional to the effectiveness value, because the

higher the heat transfer value or energy transfer in a

cooling tower, the higher the effectiveness value of

the cooling tower. It can be seen here that with the

influence of the addition of fillers (variations in

obstacle ratio) the effectiveness value increases. At

the time of cooling tower without filler, it was seen in

fig.9 NTU was valued at 0.87 with an effectiveness of

0.47, while when the cooling tower was filled with

filler with an obstacle ratio of 0.31 NTU was worth

2.43 and the effectiveness value was 0.71. Therefore,

fillers in cooling towers are very important for their

role to improve the performance in cooling towers.

5 CONCLUSION

Based on the results of experiments and data

processing on each variation in the obstacle ratio, it

can be concluded that:

1. Filler ( obstacle ratio ) in the cooling tower

is a very important influence, because it can improve

the performance of the cooling tower.

2. The effectiveness and efficiency of the

cooling tower can be seen from the range and

approach values.

3. The addition of filler ( obstacle ratio )

affects the efficiency and effectiveness of cooling

tower which have increased with successive values :

54.48 % and 0.71 values.

4. The higher the NTU value of the cooling

tower, the highger the value of uts effectiveness.

REFERENCES

ghani saitra, A., hesty sholihah, F., & nabilah fauziyah, I.

(2016). karakteristik menara pendingin tipe induced

draft dengan bahan isian kain flanel. Seminar Nasional

Sains Dan Teknologi Terapan IV 2016.

H, A. T., S, D. L., & Sutjahjono, H. (2014). ANALISIS

BEBAN KALOR COOLING TOWER INDUCED

DRAFT COUNTERFLOW DENGAN BAHAN

PENGISI BAMBU WULUNG ( Heat Load Analysis Of

Induced Draft Counterflow Cooling Tower With

Bamboo Filler Wulung ) Abstrak Pendahuluan Metode

Penelitian.

Jaber, H., & Webb, R. L. (1989). Design of cooling towers

by the effectiveness-NTU method. Journal of Heat

Transfer, 111(4), 837–843.

https://doi.org/10.1115/1.3250794

Mirabdolah Lavasani, A., Namdar Baboli, Z.,

Zamanizadeh, M., & Zareh, M. (2014). Experimental

study on the thermal performance of mechanical

cooling tower with rotational splash type packing.

Energy Conversion and Management, 87, 530–538.

https://doi.org/10.1016/j.enconman.2014.07.036

Mugisidi, D., Heriyani, O., Gunawan, P. H., & Apriani, D.

(2021). Performance improvement of a forced draught

cooling tower using a vortex generator. CFD Letters,

13(1), 45–57. https://doi.org/10.37934/cfdl.13.1.4557

Novianarenti, E., Setyono, G., & Safitra, A. G. (2019).

Experimental Study of the Performance Characteristic

an Induced Draft Cooling Tower with Variates Fillings.

IOP Conference Series: Materials Science and

Engineering, 462(1). https://doi.org/10.1088/1757-

899X/462/1/012027

Novianarenti, Eky, & Setyono, G. (2019). Peningkatan

Performansi Cooling Tower Tipe Induced Draft

Counter Flow Menggunakan Variasi Bentuk Filler.

R.E.M (Rekayasa Energi Manufaktur) Jurnal, 4(1).

https://doi.org/10.21070/r.e.m.v4i1.1766

Pita, M., & Sob, P. B. (2020). Experimental study on the

performance of a vertical plate packing cooling tower

at various air flow rates. Proceedings of 2020 IEEE

11th International Conference on Mechanical and

Intelligent Manufacturing Technologies, ICMIMT

2020, 22–26.

https://doi.org/10.1109/ICMIMT49010.2020.9041232

Ramkrishnan, R., & Arumugam, R. (2013). Experimental

study of cooling tower performance using ceramic tile

packing. Processing and Application of Ceramics, 7(1),

21–27. https://doi.org/10.2298/pac1301021r

Singh, K., & Das, R. (2016). An experimental and multi-

objective optimization study of a forced draft cooling

tower with different fills. Energy Conversion and

Management, 111, 417–430.

https://doi.org/10.1016/j.enconman.2015.12.080

Tower, S. C. (n.d.). 7. cooling tower.

0,87

2,43

0,00

1,00

2,00

3,00

0,00 0,50 1,00

NTU

EFFECTIVENESS

NTU - EFFECTIVENESS

NoFiller

0,31

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

30