Seeding Phase of Restaurant Wastewater Treatment with and

without Addition of Bioballs

Herawati Budiastuti

a

, Silmi Nurul Ulya

b

, Yanti Rachmawati

c

, Tifa Paramitha

d

,

Emma Hermawati Muhari

e

and Laily Isna Ramadhani

f

Chemical Engineering Department, Politeknik Negeri Bandung, Jl. Gegerkalong Hilir, Bandung, Indonesia

Keywords: Bioballs, Parameters, Restaurant Wastewater, Seeding Phase.

Abstract: Until now, industrial wastewater and domestic wastewater, including restaurant wastewater have not been

managed optimally in Indonesia. A prototype of activated sludge reactor with and without bioballs has been

designed and constructed in 2021 but due to several obstacles in operating this aerobic treatment system

equipment and ineffective attachment of microorganisms, this research was conducted. The reactor added

bioballs (RB) and another reactor without addition of bioballs (RWB) were used to treat the restaurant

wastewater from a food industry in Bandung, Indonesia. Parameters observed were MLVSS, COD, and

reactor pH. Seeding phase could be conducted successfully in both reactors. The maximum MLVSS in the

RB was 79,003 mg/L whereas in RWB was 79,132 mg/L. The COD removal in RB decreased from the highest

value of 7,895 mg/L to 4,668 mg/L whereas in RWB decreased from the highest value of 11,941 mg/L to

5,026 mg/L. The values of pH were in the range of 8.3 to 8.6 in both reactors. It means that the function of

bioballs as attachment media for microorganism during the seeding phase has not been shown, however, the

seeding phase in both reactors could be continued to the next phase, which is the acclimatization phase.

1 INTRODUCTION

The food and beverage industry is one of the fastest

growing industries in Indonesia because this industry

is a strategic business in meeting everyone's basic

needs. The development of the food and beverage

industry is accompanied by an increase in the

discharge of wastewater from this industry and

similar industries into water bodies. Until now,

wastewater from industry and domestic purposes

originating from household waste has not been

managed optimally in Indonesia. Domestic

wastewater includes used washing water, kitchen and

toilet wastewater, in which this type of wastewater is

the biggest contributor to water pollution that must be

handled especially because of its high organic matter

contents (Amri and Wesen, 2013; Ramadhani et al.,

2020).

a

https://orcid.org/0000-0001-9971-9717

b

https://orcid.org/0000-0003-4762-7305

c

https://orcid.org/0000-0001-6739-7127

d

https://orcid.org/0000-0002-8904-7846

e

https://orcid.org/0000-0003-2351-0305

f

https://orcid.org/0000-0002-0365-4937

In compliance with the Regulation of the Minister

of Environment and Forestry of the Republic of

Indonesia Number: P.68/Menlhk/Setjen/Kum.1/8/

2016 (Minister of Environment and Forestry of the

Republic of Indonesia, 2016), concerning domestic

wastewater pollution, there are still many food and

beverage industries, and small and medium-sized

industries whose effluent waste does not meet the

specified quality standards. Domestic wastewater

pollution parameters consist of COD, BOD, TSS, pH,

ammonia, oil and fat parameters and total coliform.

The fulfilment of domestic wastewater quality

standards will be realized when the wastewater is

treated before being discharged into water bodies.

One of the food industries in Bandung, Indonesia

has tried to treat its industrial wastewater by adding a

grease trap to catch the oil and grease in its

wastewater, but in its biological processing,

68

Budiastuti, H., Ulya, S., Rachmawati, Y., Paramitha, T., Muhari, E. and Ramadhani, L.

Seeding Phase of Restaurant Wastewater Treatment with and without Addition of Bioballs.

DOI: 10.5220/0011712300003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 68-72

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

inconsistent results in meeting wastewater quality

standards have been found. The biological treatment

used is activated sludge treatment where

microorganisms that decompose organic compounds

in wastewater grow suspended in an activated sludge

reactor owned by this industry (Sukmana and Rifa’i,

2020).

One of the wastewater treatment methods

containing high concentrations of organic compounds

such as wastewater owned by the food and beverage

industry is aerobic biological treatment. The aerobic

biological treatment method that is widely used by

industry in Indonesia is the activated sludge treatment

system (Sudarman et al., 2020).

To streamline the performance of microorganisms

in the activated sludge treatment system, it is

necessary to add bioballs as media for attaching

aerobic bacteria. Thus, the performance of

microorganisms that grow in suspension can be

assisted with microorganisms that grow attached to

the bioballs. Decomposition of pollutants in

wastewater becomes more effective with the presence

of bioball media as a breeding ground for

microorganisms (Said and Utomo, 2007).

Bioball media has several advantages, including

its ability to minimize the occurrence of clogging and

can maintain good aeration (Astuti and Ayu, 2019).

In addition, bioballs are lightweight, easy to wash

again, and have a fairly large specific area, and they

are easy to install (randomly) so that the small

Wastewater Treatment Plant (WWTP) package is

very suitable (Said and Utomo, 2007). Based on these

previous studies, a prototype activated sludge reactor

with bioball has been designed and constructed in

2021 (Paramitha et al., 2021). However, due to

several obstacles in the operation of the aerobic

treatment system equipment and the results of

ineffective attachment of microorganisms, this

research is proposed.

The complete final results of this study are

expected to provide input for the food and beverage

industry in solving the problem of inconsistent results

in meeting wastewater quality standards of their

domestic wastewater treatment. In addition, the

results of this study can be used to increase the

competence of chemical engineering students of

Politeknik Negeri Bandung, in terms of wastewater

treatment practices by using treatment system

technology that is more up to date.

2 METHODS

2.1 Preparation of Equipment and

Materials

The main equipment in this research is a prototype set

of activated sludge system with bioballs (RB) and a

set of activated sludge system without bioballs

(RWB). Each reactor system completed with a

feeding tank of 9.1 L and an aeration tank of 15.7 L.

The number of bioballs added in the RB was 150

pieces. The diameter of bioball is 3 cm with its

surface area of 200 – 235 m

2

/m

3

. Aerators used in

both reactors were Resun 9906 type. By applying

these aerators, the DO in both reactors could be

maintained > 2 mg/L (Budiastuti et al., 2021).

Supporting equipment includes measuring flask,

volume pipette, beaker glass, hotplate and stirrer,

burette, Erlenmeyer, glass funnel, porcelain cup,

desiccator, oven, furnace, and pH meter. Hach tubes,

and Hach COD digester were used to measure the

COD of the samples.

The chemicals used as nutrients for

microorganisms include glucose, KNO

3

, and

KH

2

PO

4

. The materials used in the analysis process

include K

2

Cr

2

O

7

, 98% H

2

SO

4

, ferrous ammonium

sulphate (FAS), ferroin indicator, KH

2

PO

4

, K

2

HPO

4

,

Na

2

HPO

4

, MgSO

4

.7H

2

O, FeCl

3

.6H

2

O, CaCl

2

, NaOH,

HCl, aquadest, and filter paper.

Wastewater from a restaurant in the Bandung

area, Indonesia was used to represent the food

industry wastewater, while activated sludge as the

source for starter of microorganisms was obtained

from activated sludge of a food industry in West Java,

Indonesia.

2.2 Seeding Stage

The seeding process was carried out by growing

microorganisms to be suspended and attached to the

surface of the bioballs. The seeding process was

carried out in a natural way, namely by flowing

restaurant wastewater into an aeration tank that does

not contain bioballs and an aeration tank contains

bioballs to form a biofilm layer that will cover the

bioballs. The volume of activated sludge used was

2.75 L for RB and 3.235 L for RWB. To obtain the

hydraulic retention time (HRT) in each reactor system

of 6 days, the feeding rate in each reactor system was

adjusted to the active volume of RB and of RWB.

The seeding process took 12 days with HRT of 6

days. Initial nutrition for microorganisms given was

400 mg COD/L. Nutrients were made synthetically

by mixing glucose with nitrogen and phosphorus

Seeding Phase of Restaurant Wastewater Treatment with and without Addition of Bioballs

69

sources in the form of KNO

3

and KH

2

PO

4

at a ratio

of 100:5:1 (Hamza et al., 2019). Sampling was carried

out once a day followed by checking of pH,

temperature, DO, and MLVSS. In addition, the

operating temperature was not specially maintained

to make it easier for related industries when applying

this technology.

2.3 Analysis Stage

The analysis carried out during the seeding stage, and

also acclimatization, and main experimental stages

was pH, MLVSS, COD, and TSS. Determination of

pH was using a pH meter, MLVSS using the

gravimetric method, COD using the SNI

6989.73:2009 method, TSS using the SNI 06-6989.3-

2004 method. The success indicator of this research

is the increase of MLVSS as representation of the

growth of microorganisms. Reactor pH is at the range

of neutral pH. In addition, the removal of organic

compounds in the form of COD were also observed.

3 RESULTS AND DISCUSSION

3.1 Raw Material Characteristics

This study used the main raw materials, namely

activated sludge and restaurant wastewater. The

restaurant wastewater used is cloudy yellow in

colour, emits a distinctive odour from food residue, is

runny, and has sediment originating from food scraps

that are carried away. Restaurant wastewater was

previously tested with COD (Chemical Oxygen

Demand) parameters and the value was 9000 mg/L.

Therefore, pre-treatment was carried out by diluting

restaurant wastewater to 1000 mg/L and 3000 mg/L

respectively as feed during the operation stage.

Restaurant wastewater that had been diluted was put

into a refrigerator, this was done so that no chemical

or physical changes occur during the research

process. The characteristics of the restaurant

wastewater used in this study are listed in Table 1.

Table 1: Wastewater characteristics.

Characteristics COD

(

m

g

/L

)

pH TSS

(

m

g

/L

)

Restaurant wastewater

P.68/Menlhk/Setjen/

Kum.1/8/2016

9,000

100

3.24

6 - 9

83

30

3.2 Seeding Phase – Reactor with

Bioballs (RB)

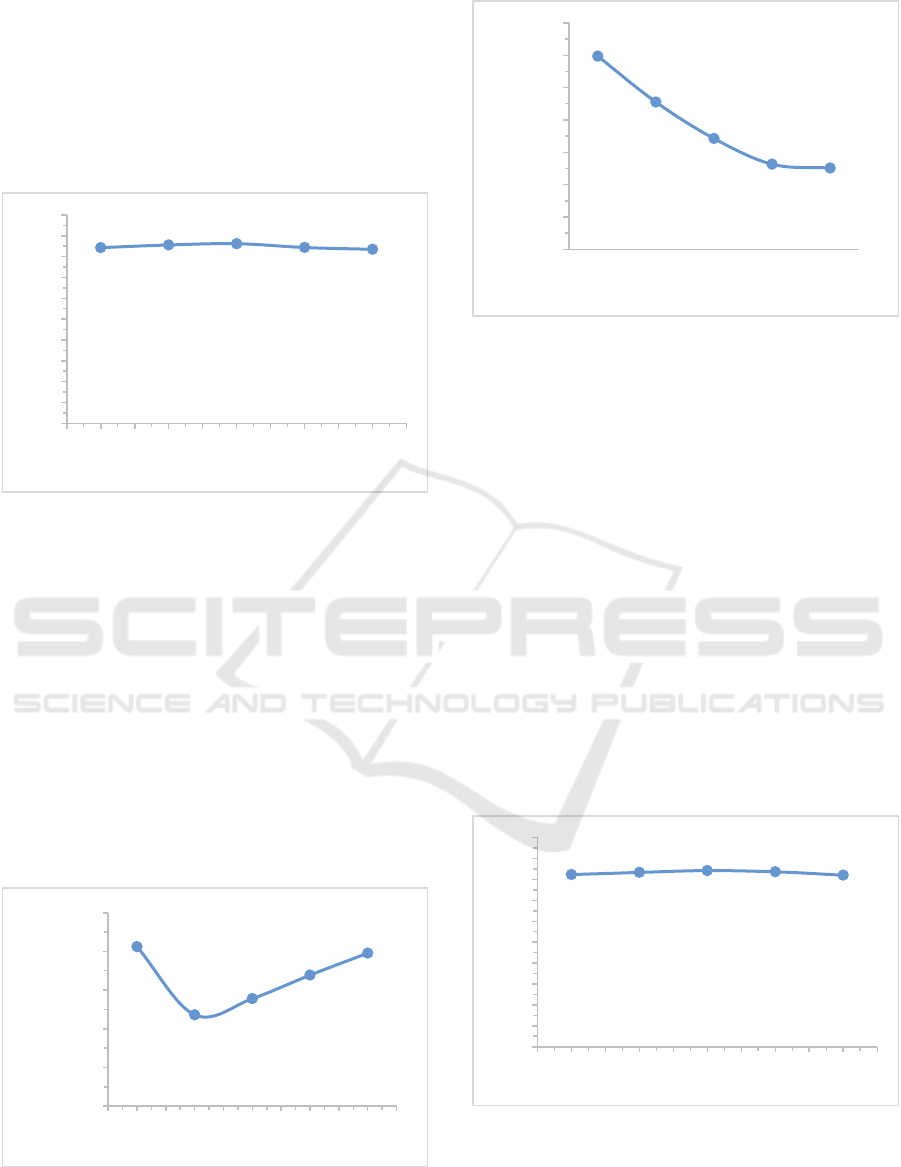

MLVSS in RB during the seeding stage showed an

upward trend (Figure 1). The highest MLVSS value

was found on the 9th day of 79,003 mg/L, while the

lowest MLVSS was on the 5th day of 57,911 mg/L.

The increase in MLVSS in RB occur gradually from

day 5 to day 9. If we consider the increase in MLVSS

from the first day, during 9 days of operation the

MLVSS which represents the concentration of

microorganisms has increased by 7,226 mg/L or by

10%. The next test parameter is COD (Chemical

Oxygen Demand) which is a parameter of oxygen

demand needed by microorganisms in degrading

organic compounds in wastewater. The following is

the COD curve for RB during the seeding process

(Figure 2).

Figure 1: MLVSS during the seeding process (RB).

Figure 2: COD concentration during the seeding process

(RB).

Based on Figure 2 the COD value of RB during

the seeding stage showed a decrease trend starting

from the third day. The COD RB value, which was

71777

62857

57911

67536

79003

0

20000

40000

60000

80000

100000

012345678910

MLVSS(mg/L)

Days

5428

7895

6979

5875

4668

0

2000

4000

6000

8000

10000

12000

14000

012345678910

COD(mg/L)

Days

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

70

initially 5,428 mg/L to become 4,668 mg/L on day 9

shows a decrease efficiency of about 14%. The next

test parameter on RB is pH. The following is the pH

curve of the seeding process (Figure 3). Based on

Figure 3 the pH in the seeding process in RB is in the

range of 8.43-8.62. This proves that the pH obtained

is still within the safe limit of neutral pH, which is in

the range of 6-9.

Figure 3: pH during the seeding process (RB).

3.3 Seeding Phase – Reactor without

Bioballs (RWB)

Based on Figure 4 the MLVSS value in the RWB

during the seeding stage showed an increase. The

increase in MLVSS is an increase in the quantity of

microorganisms. The highest value of MLVSS in

RWB on day 1 was 82,472 mg/L and the lowest value

on day 3 was 47,211 mg/L. Even though there was a

decrease in MLVSS in the first 3 days, the MLVSS

value on the following days increased. For this

reason, it is necessary to look at the decrease in the

COD value (Figure 5) with a decrease in MLVSS of

about 4% for 9 days of operation.

Figure 4: MLVSS during the seeding process (RWB).

Figure 5: COD during the seeding process (RWB).

Based on Figure 5 the COD value in RWB during

the seeding stage showed a decrease. The COD value

in RWB was 11,941 mg/L to 5,026 mg/L with a

decreasing efficiency of 57.91%, even though on the

7th and 9th days the COD values were relatively

constant with a difference of only 4.8%. The next

parameter is pH during seeding in RWB which is

shown in Figure 6. The pH obtained is still within the

safe limit of neutral pH, which is in the range of 6-9.

From the result parameters observed in both RB and

RWB, both system of reactors are ready to be

continued to the next stage, which is the

acclimatization stage. During the seeding phase, the

function of bioballs to be used as media attachment of

microorganisms has not been shown. It will be

observed during the acclimatization process and the

main experiment, as further processes which can

show the real function of bioballs addition in this

system.

Figure 6. pH during the seeding process (RWB).

Paramitha et al. (2021) found the same

observation that during the seeding phase, addition of

bioballs has not shown its function. During 15 days

of operation, the MLVSS in the activated sludge

8,43

8,56

8,62

8,44

8,35

0

1

2

3

4

5

6

7

8

9

10

012345678910

pH

Days

82472

47211

55618

67790

79132

0

20000

40000

60000

80000

100000

012345678910

MLVSS(mg/L)

Days

11941

9106

6855

5266

5026

0

2000

4000

6000

8000

10000

12000

14000

012345678910

COD (mg/L)

Days

8,24

8,34

8,43

8,37

8,21

0

1

2

3

4

5

6

7

8

9

10

012345678910

pH

Days

Seeding Phase of Restaurant Wastewater Treatment with and without Addition of Bioballs

71

reactor increased from 585 mg/L to become 1,120

mg/L whereas MLVSS in the activated sludge reactor

added bioballs increased from 380 mg/L to become

1,065 mg/L. The removal efficiencies in the form of

COD removal were almost the same in both reactor

types.

Another group of researchers (Temitope and

Abayomi, 2022) observed that degradation of

restaurant wastewater treated by a different method,

i.e. electro coagulation resulted in low percentages in

COD removal. During operation of 30 minutes of

retention time only 12.58% removal efficiency was

obtained. During operation of 60 and 90 minutes of

retention time, removal efficiencies were only

21.13% and 25.83%, respectively. They obtained

better improvement of COD removal by increasing

the retention time, however, still low results were

obtained.

4 CONCLUSIONS

Seeding of restaurant wastewater treatment can be

conducted successfully in both reactors, with (RB)

and without bioballs (RWB). The maximum MLVSS

in the RB was 79,003 mg/L whereas in RWB was

79,132 mg/L. The COD removal in RB decreased

from the highest value of 7,895 mg/L to 4,668 mg/L

whereas in RWB decreased from the highest value of

11,941 mg/L to 5,026 mg/L. The values of pH were

in the range of 8.3 to 8.6 in both reactors. It means

that the function of bioballs as attachment media for

microorganism has not been shown. However, based

on the research results parameters, the seeding phase

in both reactors could be continued to the next phase,

which is the acclimatization phase.

ACKNOWLEDGEMENTS

Financial support throught the Applied Research

Scheme No. B/66.5/PL1.R7/PG.00.03/2022 and

supporting equipment provided by Politeknik Negeri

Bandung are greatly appreciated.

REFERENCES

Amri, K., Wesen, P. (2013). Pengolahan Air Limbah

Domestik Mengunakan Biofilter Anaerob Bermedia

Plastik (Bioball). Jurnal Ilmiah Teknik Lingkungan. 7

(2): 55-66.

Astuti, A.D., Ayu, D.I. (2019). Treatment of Tofu Industry

Wastewater using Biorector Anaerobic-Aerobic and

Bioball as Media with Variation of Hydraulic Retention

Time. Reaktor. 19(1): 18-25.

Budiastuti, H., Rismawati, R., Nurfauziah, L., Ramadhani,

L.I., Muhari, E.H. (2021). Tofu Wastewater Treatment

by Using Sequencing Batch Reactor (SBR) with

Variation of Feeding Rates. Rekayasa Hijau: Jurnal

Teknologi Ramah Lingkungan. 5(3): 197-207.

Filliazati, M., Apriani, I., Zahara, T.A. (2013). Pengolahan

Limbah Cair Domestik dengan Biofilter Aerob

Menggunakan Media Bioball dan Tanaman Kiambang.

Jurnal Teknologi Lingkungan Lahan Basah. 1(1): 1-

109.

Hamza, R.A., Zaghloul, M.S., Iorhemen, O.T., Sheng, Z.,

Tay, J.H. (2019). Optimization of Organics to Nutrients

(COD:N:P) Ratio for Aerobic Granular Sludge Treating

High-strength Organic Wastewater. Science of The

Total Environment, 650 (2): 3168-3179.

Minister of Environment and Forestry of the Republic of

Indonesia, No..:P.68/Menlhk/Setjen/Kum.1/8/2016

(https://jdih.maritim.go.id/en/peraturan-menteri-

lingkungan-hidup-dan-kehutanan-no-

p68menlhksetjenkum182016-tahun-2016, accessed on

11 February 2022).

Paramitha, T., Sukmana, A.F., Rifa'I, A.F., Budiastuti, H., ;

Sudarman, R. (2021). Treatment of Canteen

Wastewater by Activated Sludge added Bioballs.

Proceedings of the 2nd International Seminar of

Science and Applied Technology (ISSAT 2021). 207:

333-338.

Ramadhani, L.I, Rahmaningsih, Y.D, Amanda, N.R.,

Budiastuti, H. (2020). The combination of anaerobic-

aerobic and coagulation flocculation method using

tamarind seed as natural coagulant for tofu wastewater

treatment. IOP Conf. Series: Materials Science and

Engineering, IOP Publishing, 830 (2020) 022012: 1-7.

Said, N. I., Utomo, K. (2007). Pengolahan Air Limbah

Domestik dengan Proses Lumpur Aktif yang Diisi

dengan Media Bioball. JAI 2007. 3(2): 160-174.

Sudarman, R. Budiastuti, H., Djenar, N.S., Pangalo, E.S.,

Nurhasyim, A. (2020). Penyisihan Kadar Amoniak

dalam Limbah Cair Industri Pupuk Menggunakan

Sequencing Batch Reactor. Jurnal Fluida 13(2): 65-72.

Sukmana, A.F., Rifa'I, A.F. (2020). Pengolahan Air

Limbah Kantin PT Nutrifood Indonesia Plant Sentul

Menggunakan Reaktor Biofilter Aerobik. Politeknik

Negeri Bandung.

Temitope, A.A., Abayomi, E.T. (2020). A preliminary

Study on the Treatment of Restaurant Wastewater using

Electrocoagulation Technique. Journal of Degraded

and Mining Lands Management. 7(1): 2029-2033.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

72