Ergonomic Design of Weaving Yarn Spinning Machine from Doyo

Leaf Fiber

Dwi Cahyadi

1

, Suparno

2

, Ratna Wulaningrum

3

, Imam Rojiki

4

and Ferry Bayu Setiawan

2

1

Design Department, Politeknik Negeri Samarinda, Indonesia

2

Machine Department, Politeknik Negeri Samarinda, Indonesia

3

Accounting Department, Politeknik Negeri Samarinda, Indonesia

4

Pokan Taqak, Indonesia

Keywords: Ergonomic, Anthropometric, Spinning Machine, Doyo Leaf Fiber.

Abstract: The manufacture of woven yarn has been tested through a prototype by designing a yarn spinning machine

whose principle is almost the same as other natural fiber spinning machines. The design of the existing doyo

fiber spinning machine still has shortcomings in the shape and size of the machine that is not ergonomic so

that it can affect the safety, comfort and even productivity of workers. This study aims to overcome these

problems where the machine to be developed will be more ergonomic by using worker anthropometric data.

The results of the study using ergonomic analysis from the application of anthropometric data for adult women,

50th percentile, Indonesian ethnic groups aged 18-45 years, obtained ergonomic sizes and shapes than before.

Changes in the dimensions of the machine have a length of 125 cm, a width of 45 cm, a height of 95 cm, a

fiber entry hole height of 75 cm. This machine has a footrest with a height of 25 cm with a tilt angle of 45

degrees

1 INTRODUCTION

Doyo plants are plants that are often found in the

province of East Kalimantan, Indonesia. Since

ancient times, the doyo plant has been used by the

Dayak tribe in the West Kutai area, East Kalimantan

Province, where the fiber from the doyo leaves is used

as a woven material to make clothes for traditional

events. The material in the form of woven yarn is

obtained from doyo leaf fibers which have been

specially treated before becoming yarn and are

handicrafts with cultural and historical value.

The process of making doyo leaf fiber into woven

yarn is a production process that is usually done by

women and takes a long time because it is done

manually. With current technological advances, the

manual production process of making woven yarn is

carried out by designing a yarn spinning machine

whose principle is almost the same as other natural

fiber spinning machines.

The design of the Doyo woven fiber spinning

machine has been made in a prototype, but it still has

several shortcomings, one of which is the shape of the

machine that is not ergonomic and can cause

accidents for workers from the production process.

The shape and size of the doyo leaf fiber spinning

machine into woven yarn that is not ergonomic and

does not match the user's anthropometric body size

can affect the safety, comfort and even productivity

of workers. This study aims to overcome these

problems where the machine that will be developed

later becomes more ergonomic, namely prioritizing

the principles of safety, and comfort and according to

the body size or anthropometry of workers. The

contribution of this research will provide input to the

machine manufacturing industry so that the design of

the machine, especially the spinning machine which

is designed to have more ergonomic elements and

without leaving its main function.

2 LITERATURE REVIEW

2.1 Doyo Weaving

Doyo weaving is derived from the leaf fiber of the

doyo plant which has the Latin name (Curliglia

Latifolia) which is a type of pandan with strong fiber

Cahyadi, D., Suparno, ., Wulaningrum, R., Rojiki, I. and Setiawan, F.

Ergonomic Design of Weaving Yarn Spinning Machine from Doyo Leaf Fiber.

DOI: 10.5220/0011712600003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 77-81

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

77

and grows wild in the interior of Kalimantan as the

main ingredient for doyo weaving (Purbasari and

Rahardja, 2018, Meilita et al., 2020, Indriastuti,

2021).

Along with the development of fashion and

handicraft products today, doyo weaving is widely

used not only as clothing used in traditional events,

but has developed into fashion products and other

handicraft materials such as wall hangings,

tablecloths and others because has the uniqueness of

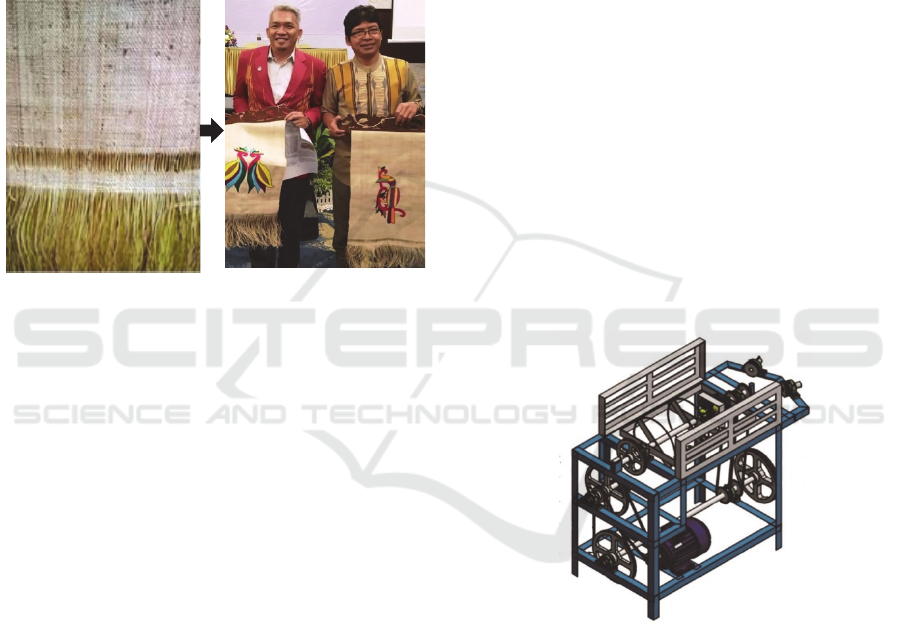

its own natural ingredients as shown in Figure 1

(Cahyadi et al., 2019b)

Figure 1: Utilization of doyo weaving for formal clothes

and wall decoration.

2.2 Ergonomics and Anthropometry

Ergonomics can be regarded as a field of science that

is oriented towards the interaction between humans

and their environment, covering the cognitive,

physical, and organizational fields. Ergonomics also

studies humans in relation to the work they do to

make them safer, more comfortable and productive

(Wignjosoebroto, 1995, WHO, 1972, Nurmianto,

1998).

Ergonomics will emphasize the importance of

safety, comfort and human well-being and overall

system performance. One of the fields in physical

ergonomics is anthropometry. Anthropometry is used

as a standard for determining dimensions in product

manufacturing and development (Lehto and Landry,

2013).

Anthropometry is the measurement of the human

body that can be used as a basis for determining the

size of the minimum or maximum limits of products,

equipment or ergonomic machines based on ethnicity,

gender, disability, body position and posture during

activities, as well as the type of work performed.

designing a product such as equipment, machinery

and furniture adapted to the user's anthropometry can

provide maximum benefits (Lee et al., 2018a, Lee et

al., 2018b, Adnan and Dawal, 2019, Wang and Cai,

2020)

The use of the latest anthropometric data will

produce products, equipment or workstations that are

more in line with the size of the human body as its

current user (Castellucci et al., 2016, Cahyadi et al.,

2019a). Some software applications use

anthropometric data to determine the size of products

and ergonomic equipment, one of which is

Mannaquin Pro (Cahyadi, 2014).

2.3 Yarn Spinning Machine

The combined flow spinning and forming technique

is widely used because of the high flexibility it

provides for producing complex machine tool parts

especially in the automotive industry (Das et al.,

2010). For machines the manufacture of yarn from

plants such as flax, mesta, and sisal can be done

through the help of mechanical processing and the

intervention of a number of machines. Therefore, it

becomes important to explore all spinning

technologies for low-cost yarn production. In the

process of making single yarns it can be assisted by

coating several materials to improve some yarn and

fabric properties such as hairiness, strength,

elongation, evenness and abrasion resistance

(Yurtaslan and Yilmaz, 2016, Wongkasema and

Aksornpimb, 2015, Seisarina, 2021)

Figure 2: Prototype of doyo leaf fiber spinning machine

(Seisarina, 2021).

Figure 2 is a prototype machine for spinning

Doyo leaf fiber into a woven thread. Doyo leaf fiber

spun machine has specifications of length 130 cm,

width 46 cm, height 115 cm with a single phase

electric motor, 220 V, 250 watts, 1400 rpm. This doyo

leaf fiber spinning machine has a maximum capacity

of 4900 cm/hour, an increase of 59.67% compared to

manual spinning.

This spinning machine is able to shorten the

stages of the process of making doyo leaf fiber rope,

namely by eliminating the pre-processing process.

This is because the doyo leaf fiber can be directly fed

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

78

to the twisting and spinning process. This spinning

machine produces the best doyo leaf fiber rope with a

maximum capacity at a ratio of 18:5:1 rotational

speed of the twisting shaft, spinning shaft and pulling

roller, 750 rpm main shaft rotation and 100 cm length

of agel (Seisarina, 2021). In using this machine, in

addition to using personal protective equipment,

workers are still at risk in using the machine. The

open form of the machine, the machine design that

does not match the user's anthropometry and the

shape that has sharp angles can pose a safety risk and

work accidents.

3 METHOD

The research on the design of this doyo leaf fiber

spinning machine uses ergonomic analysis using

anthropometric data that is adjusted for workers. This

doyo leaf fiber spinning machine is specially

designed for standing position work. So that

ergonomic analysis in determining the safety and

comfort of workers will pay attention to the type of

work standing.

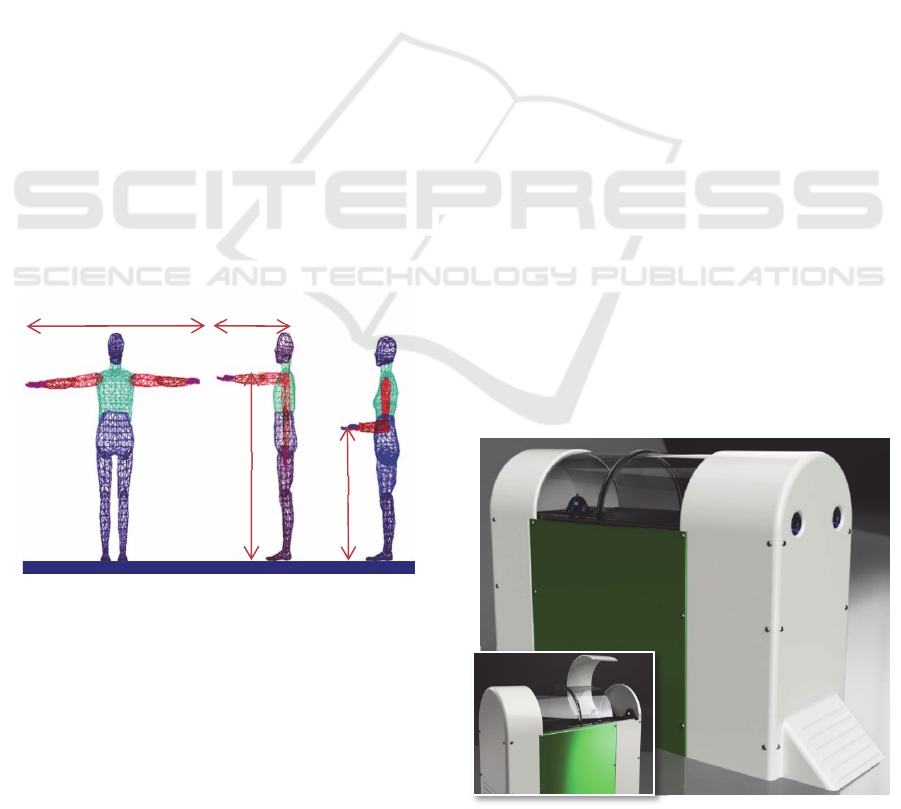

Anthropometric data used as the basis for

determining the size of the machine uses the sex of an

adult female, aged 18-45 years with an average adult

female size of 50 percentile, from the Indonesian

ethnic group. Data obtained from Indonesian

anthropometric data (Indonesia, 2022). The data that

will be used are shoulder height, forward hand reach,

side arm span, and elbow height as seen in figure 2.

Figure 3: Anthropometric measurements.

4 RESULT AND DISCUSSION

To design an ergonomic doyo leaf fiber spinning

machine design, anthropometric data is used as a

measure that suits the user. The size of the machine

height is taken from the anthropometric data of

shoulder height (SH). From Indonesian

anthropometric data, the average shoulder height of

adult women is 129.2 cm. This value is the maximum

value for the height of the machine, so in the design

of this machine the height used is 95 cm from the

floor.

For the size of the width of the machine, the

anthropometric data used is the size of the forward

hand reach (FHR). This value is the maximum value

for the width of the machine, so in designing this

machine the width used is 45 cm.

The length of the machine uses side arm reach

(SAR) anthropometric data. From Indonesian

anthropometric data, it was found that the average

side arm reach for adult women is 155.7 cm. This

value is the maximum value for the width of the

machine, so in designing this machine the length used

is 125 cm.

In the design of this machine, the fiber to be spun

enters through the machine through two parallel holes

before being spun by the machine. The hole for

inserting this fiber has a diameter of 3 cm according

to the shape of the fiber. Hole height for more

ergonomics should be measured at elbow height to

optimize work and avoid fatigue too quickly. In this

design, the height of the hole for fiber entry uses

anthropometric data from elbow height (EH).

From Indonesian anthropometric data, the

average elbow height of adult women is 97.6 cm. This

value is the maximum value for the height of the fiber

entry hole into the machine, so in the design of this

machine the height of the hole and from the floor is

75 cm.

In the design of this machine, a foot rest will also

be added which serves to rest the feet so that they are

not too tired when working in a standing position. The

foot rest is designed to form a triangle with a footrest

that has a tiered shape to rest one foot while working.

Footrest height is 25 cm with 45 degree angle.

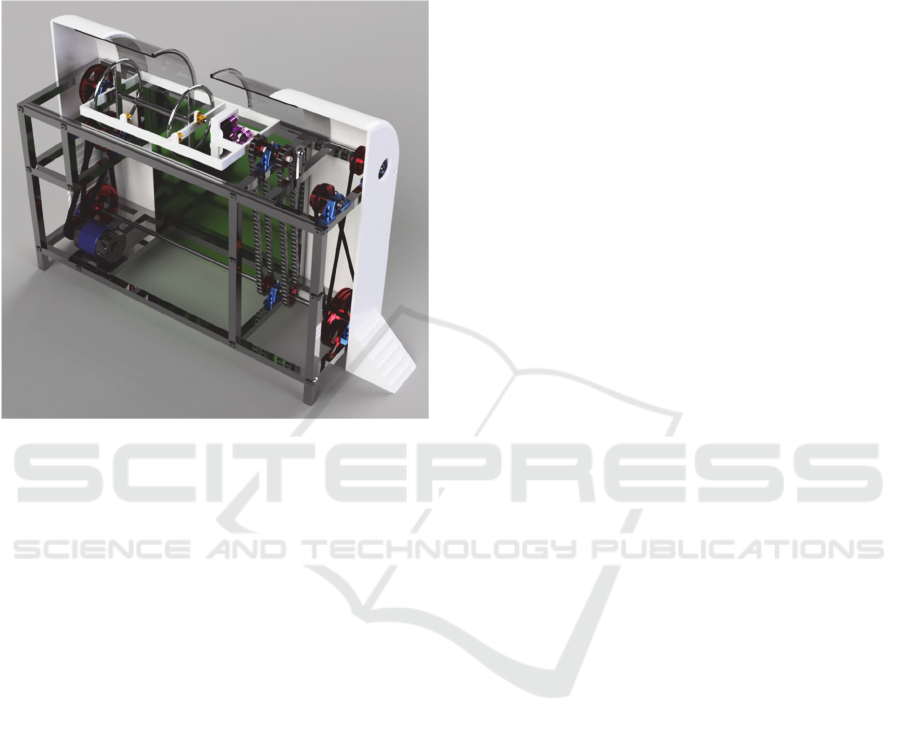

Figure 4: Perspective view of the machine.

S

E

SAR

FHR

Ergonomic Design of Weaving Yarn Spinning Machine from Doyo Leaf Fiber

79

With a more ergonomic size in accordance with

this worker's anthropometry, the design of the

machine designed will experience changes in terms of

size and shape that are more ergonomic and aesthetic.

The machine design is shown in the figure 4 and

figure 5.

Figure 5: Half cover view of the machine.

Some improvements from the design of this machine

design as a technical research contribution are:

1. Aesthetic machine design by making curves

and avoiding sharp shapes than before.

2. The machine designed has measurements such

as height, length and width of the machine that

are more ergonomic than the previous

machine according to the size of the

Indonesian human body as the worker.

3. The hole where the fiber enters has two holes

75 cm high parallel to the position of the hand

when standing. These holes are made to create

a more directional pull during the fiber

spinning process.

4. The design of the machine that has a

transparent cover will make it easier for

workers to see the process when the machine

is working. The transparent cover can be

opened or closed again to make it easier for

workers to pick up the spun yarn and clean the

machine.

5. The design of the machine has a footrest to

reduce worker fatigue on the feet when

working standing position.

Thus the design of the yarn spinning machine

from Doyo leaf fiber has an ergonomic shape that

makes workers safer, more comfortable and easier to

do their work so that in the end it will lead to an

increase in work productivity.

5 CONCLUSIONS

In this research, the design of the yarn spinning

machine from Doyo leaf fiber was developed to make

the machine more ergonomic so that it has a level of

safety and comfort in its use. By using anthropometric

data of adult women, 50th percentile, ethnic groups

of Indonesia aged 18-45 years. Changes in the

dimensions of the machine have a length of 125 cm,

a width of 45 cm, a height of 95 cm, the height of the

hole for the entry of fiber is 75 cm.

In addition, this machine has a foot rest with a

height of 25 cm with 45 degree angle. This size is

adjusted to the worker's anthropometry which is

supported by an ergonomic shape by avoiding sharp

corners to make it safer, more comfortable and in the

end will also increase work productivity.

ACKNOWLEDGEMENTS

Acknowledgments to the Direktorat Jendral

Pendidikan Vokasi, Kementerian Pendidikan,

Kebudayaan, Riset dan Teknologi of Indonesia for

the funding support provided through the Higher

Education Vocational Product Research Program,

also to the Samarinda State Polytechnic and Pokan

Taqak who have helped a lot in the process of finding

research data.

REFERENCES

ADNAN, N. & DAWAL, S. Z. M. 2019. Applied

anthropometric for wheelchair user in Malaysia.

Measurement, 136, 786-794.

CAHYADI, D. 2014. Aplikasi Mannequin Pro Untuk

Desain Industri Leutikaprio.

CAHYADI, D., FIBRIANIE, E., IRWAN, M.,

SUSANDARI, H. & TANTRIKA, C. F. M. Design of

workstation in the home industry of Amplang crackers

production. iCAST-ES, 2019. Journal of Physics:

Conference Series

CAHYADI, D., SOEPRPATO, E. F., HIDAYANTO, A. F.,

NIZAORA, D., HIDAYAT, H., ERWINSYAH &

SUKMAWATI. Design Men's Bag for Starter Kit in a

New Normal Life During the Covid-19 Pandemic

Using Doyo Weaving and Tumpar Embroidery

Proceedings of the 2nd Borobudur International

Symposium on Science and Technology (BIS-STE

2020). Advances in Engineering Research.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

80

CASTELLUCCI, H. I., CATALÁN, M., AREZES, P. M.

& MOLENBROEK, J. F. M. 2016. Evidence for the

need to update the Chilean standard for school furniture

dimension specifications. International Journal of

Industrial Ergonomics, 56, 181-188.

DAS, P., NAG, D., DEBNATH, S. & NAYAK, L. 2010.

Machinery for extraction and traditional spinning of

plant fibres. Indian Journal of Traditional Knowledge,

9.

INDONESIA, A. 2022. Available:

https://antropometriindonesia.org [Accessed 17 Juli

2022].

INDRIASTUTI, H. 2021. Ulap Doyo : Produk Regiosentris

Kalimantan Timur, Sidowarjo, JP Publishing.

LEE, W., YANG, X., JUNG, D., PARK, S., KIM, H. &

YOU, H. 2018a. Ergonomic evaluation of pilot oxygen

mask designs. Appl Ergon, 67, 133-141.

LEE, Y., KIM, Y. M., LEE, J. H. & YUN, M. H. 2018b.

Anthropometric mismatch between furniture height and

anthropometric measurement: A case study of Korean

primary schools. International Journal of Industrial

Ergonomics, 68, 260-269.

LEHTO, M. & LANDRY, S. J. 2013. Introduction to

Human Factors and Ergonomics For

Engineering, CRC Press

MEILITA, YUWONO, E. C. & YUSUF, V. 2020.

Perancangan Strategi Promosi Kain Tenun Ulap

Doyo Pemayuq. Jurnal DKV Adiwarna, 1.

NURMIANTO, E. 1998. Ergonomi Konsep Dasar

dan Aplikasinya, Guna Widya.

PURBASARI, M. & RAHARDJA, A. 2018. Warna

Tenun Doyo Sebagai Expresi Masyarakatnya

(Tanjung Isuy-Kutai Barat). Dimensi, 14.

SEISARINA, M. 2021. Rancang Banung Mesin

Pemintal Serat Daun Doyo. Diploma,

Politeknik Negeri Samarinda.

WANG, C. Y. & CAI, D. C. 2020. Hand tool handle

size and shape determination based on hand

measurements using a contour gauge. Human

Factors and Ergonomics in Manufacturing &

Service Industries, 30, 349-364.

WHO 1972. INTRODUCTION TO ERGONOMICS

WORLD HEALTH ORGANIZATION

WIGNJOSOEBROTO, S. 1995. Ergonomi, Studi

Gerak dan Waktu, PT. Candimas Metropole.

WONGKASEMA, S. & AKSORNPIMB, P. he

Development of a Carding Machine and a

Twisting Silk Machine for Eri Silk.

International Symposium on Intelligent

Manufacturing and Automation, 2015. Procedia

Engineering.

YURTASLAN, Ö. & YILMAZ, D. 2016. A Study for

The Modification of A Yarn Twisting Mechine

With an Air Nozzle. EKSTİL ve

KONFEKSİYON, 26.

Ergonomic Design of Weaving Yarn Spinning Machine from Doyo Leaf Fiber

81