Analysis of the Effect of Double Waste Valves in Series Arrangement

and Compressor Tube Layout on the Performance Efficiency of

2 Inch Hydraulic Ram Pump

Rafael Mado, Alexius Leonardo Johanis, Frans Mangngi and Irene Budayawati

Mechanical Engineering Department, State Polytechnic of Kupang, Lasiana, Kupang, Indonesia

Keywords: Hydraulic Ram Pump, Layout, Double Waste Valve, Efficiency, Performance, Series Arrangement.

Abstract: Water is an absolute necessity for the survival of life because without water there will be no life in this

world. For areas that are close to water sources or are located close to springs, the need for water is not a

problem. The laws of physics say that water flows from a higher place to a lower place, but the fact is that

the land surface is not always flat; there are hilly and bumpy areas. For areas that are higher than the water

source, it will be difficult to get a continuous supply of water. One of the efforts to get water supply for

areas that are higher than the spring is to use a water pump. The types of pumps commonly used today are

electric-powered water pumps and fuel-powered water pumps. In urban areas, the need for fuel and

electricity is not a problem, but in rural areas, the availability of fuel and electricity is very scarce and

expensive. The hydraulic ram is the answer to this problem. One of the efforts to increase the efficiency of

hydraulic ram pump performance is by increasing the number of waste valves arranged in series. The

problem is, is there any effect of the arrangement of the double waste valve series on the performance

efficiency of the 2-inch hydraulic ram pump at the Input-Compressor-Waste-Waste (ICWW) position, the

Input-Waste-Waste-Compressor (IWWC) position, and the Input-Waste-Compressor-Waste position.

(IWCW)? The purpose of this research is to design, manufacture, and test the arrangement of the double

valve series of hydraulic ram pumps at three different positions (ICWW, IWWC, and IWCW) using a 3000

ml compressor tube. So, it could be seen the optimal performance efficiency of the hydraulic ram pump.

The method used is a site survey, literature study, and action method with the design of the hydraulic ram

pump installation, as well as observing the effect of using a double exhaust valve in series at the ICWW,

IWWC, and IWCW positions on the efficiency of the 2-inch hydraulic ram pump performance. The results

of this study indicate that the largest pumping discharge occurs in the IWCW pump arrangement (Input-

Waste-Compressor-Waste) with a waste valve weight of 367 grams; at input 180 liters/minute produces

output 0.131 liters/second and at input 170 liters/minute produces output 0.107 liters/second. The greatest

efficiency also occurs in the IWCW pump arrangement (Input-Waste-Compressor-Waste) with a waste

valve weight of 367 grams; at the input of 180 lt/min by 132% and at the input of 170 lt/min by 110%

(according to D'Aubuison Efficiency).

1 INTRODUCTION

Water is an absolute necessity for the survival of

life, because without water there will be no life in

this world. Especially for areas that are close to

water sources or are located under springs, water

demand is not too much of a problem. Areas where

the land surface is higher than the water source will

have difficulty getting a continuous water supply.

One of the efforts to meet water needs, especially

in locations higher than the springs, is to use a water

pump. The type of pump that is commonly used

today is a water pump powered by an electric motor

or a fuel oil engine which is difficult to obtain in

remote rural areas. The solution is to use a hydraulic

ram pump, because a hydraulic ram pump works

without the use of fuel or electricity.

The problem is whether to increase the number

of waste valves (double waste valves) arranged in

series at the Input-Waste-Waste-Compressor

(IWWC), Input-Compressor-Waste-Waste (ICWW)

and Input-Waste-Compressor-Waste (IWCW)

positions. , can increase the efficiency of the 2 inch

hydram pump performance.

158

Mado, R., Johanis, A., Mangngi, F. and Budayawati, I.

Analysis of the Effect of Double Waste Valves in Series Arrangement and Compressor Tube Layout on the Performance Efficiency of 2 Inch Hydraulic Ram Pump.

DOI: 10.5220/0011729800003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 158-163

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Various studies have been carried out in an effort

to improve the efficiency of the hydraulic ram pump

performance, such as (Asep Supriyanto et al., 2017)

conducted a study entitled “Pengaruh Variasi Jarak

Sumbuh Katub Limbah dengan Sumbuh Tabung

Udara Terhadap Efisiensi Pompa Hidram”, in which

the results showed that the variation of the shortest

distance (0.25 m) get an output discharge of 0.0041

m³/second with an efficiency of 14%.

(Aris Eko Sulistiawan, et al., 2006), also

conducted a study entitled “Pengaruh Berat Katub

Limbah dan Ketinggian Discharge Terhadap Kerja

Pompa Hidram”. The results showed that, the best

capacity at the west of the waste valve is 200 grams

with a value of 7.75 liters/minute at 3 meters

discharge, volumetric efficiency is 52.961% and

pump efficiency is 60.623%.

Another study conducted by (Muhamad Jafri et

al., 2017), entitled “Analisa Beda Tinggi Katub

Limbah dan Variasi Diameter Pipa Inlet Terhadap

Unjuk Kerja Pompa Hidram Ukuran Dua Inchi”.

The results showed that the minimum efficiency of

59.15% was obtained at a valve height difference of

15 cm and an inlet pipe diameter of 3 inches, while

the highest efficiency was obtained at 95.29% at a

different valve height of 10 cm and an inlet pipe

diameter of 2 inches.

(Muhamad Fajri et al., 2015), also conducted a

study entitled “Pengaruh Diameter Katub Limbah

dan Jarak Antara Katub Limbah dengan Katub

Penghantar Terhadap Efisiensi Pompa Hidram. The

results showed that the highest efficiency obtained

was 79.7535% at a waste valve diameter of 0.041

meters and a distance between valves of 0.130

meters.

From previous studies, no researcher has raised

the issue of the number of waste valves used in

increasing the efficiency of hydraulic ram pump

performance.

The purpose of this study was to design and

manufacture a hydraulic ram pump and to test the

use of a double valve in series arrangement in three

positions: Input-Waste-Waste-Compressor (IWWC),

Input-Compressor-Waste-Waste (ICWW) and Input-

Waste-Compressor-Waste (IWCW).

The main issue that will be raised in this research

is the use of new and renewable energy in meeting

the needs of clean water for rural communities,

especially those that have not been reached by the

State Electricity Company.

The results of this study are expected to solve the

problems mentioned above, so that people can take

advantage of the natural resources that are around

them (river water), for their daily needs such as

drinking water, watering plants and giving water to

their livestock. Thus the standard of living of the

people will be better.

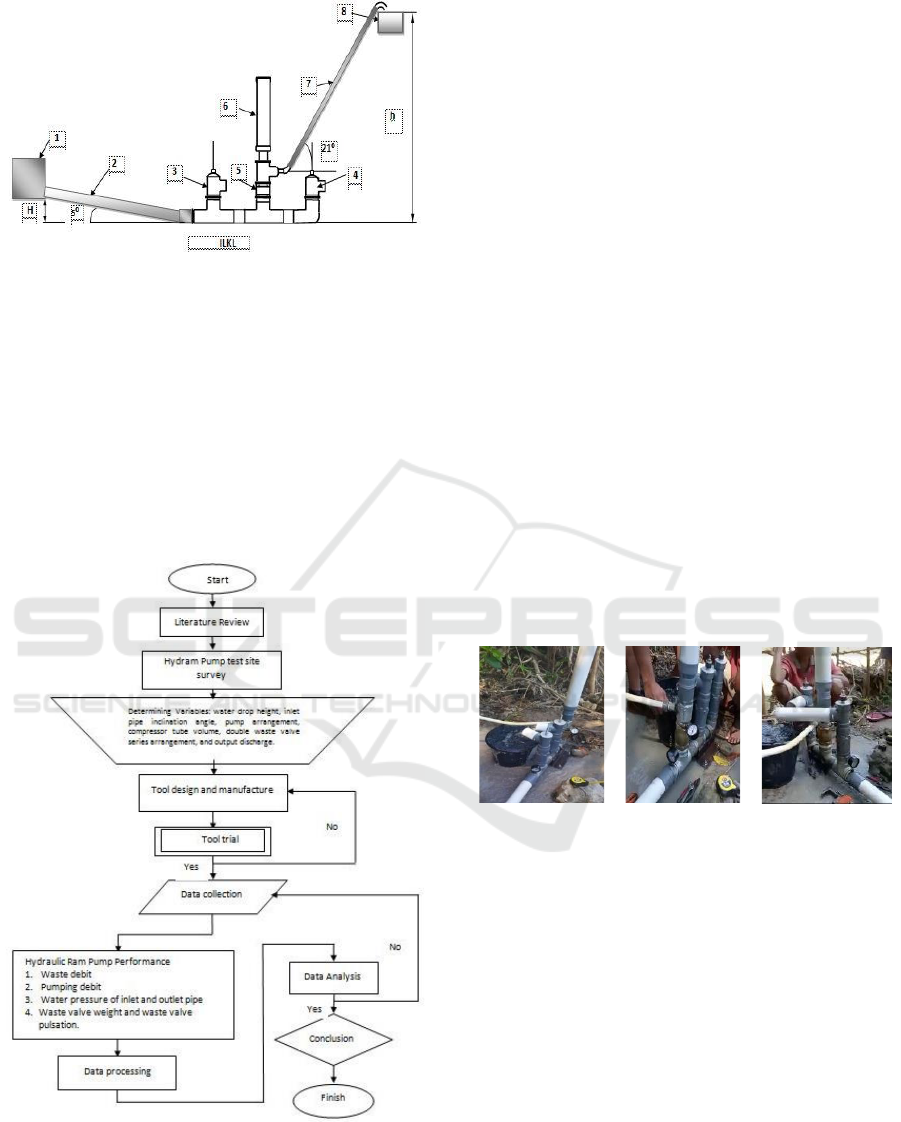

2 RESEARCH METHOD

2.1 Design and Manufacture of 2 Inch

Ram Hydraulic Pump with Double

Drain Valve Series Arrangement

The hydraulic ram pump is designed with an input

pipe diameter of 2” or 5.075 cm, an output pipe

diameter of 1.27 cm, a compressor tube volume of

3000 ml, with variations in the arrangement of

ICWW, IWWC and IWCW. The inclination angle of

the inlet pipe is 5

0

, water drop height is 1.5 meters,

and water lift height is 5 meters. The hydraulic ram

pump is made using iron pipe (T shock) ø 2 inch,

double nipple 2 inch, elbow 2 inch, elbow inch, steel

pipe ø 2½ inch, elbow iron 70x70x6000 mm, solid

stainless ø 10 mm, steel axle ø 40 mm , paralon pipe

ø 2 inch and ½ inch, 5 mm thick rubber, bolts and

nuts. The results of the design of the hydraulic ram

pump as shown in Figures 1, 2 and 3 below:

Figure 1: Installation of Hydraulic Ram Pump in IWWC

Arrangement.

Figure 2: Installation of Hydraulic Ram Pump in ICWW

Arrangement.

Analysis of the Effect of Double Waste Valves in Series Arrangement and Compressor Tube Layout on the Performance Efficiency of 2 Inch

Hydraulic Ram Pump

159

Figure 3: Installation of Hydraulic Ram Pump in IWCW

Arrangement.

Image Captions:

1. Water source 5. Delivery valve

2. Inlet pipe 6. Compressor tube

3. Waste valve (1) 7. Exhaust pipe

4. Waste valve (2) 8. Reservoir

H = Height of fall

h = Lift height

2.2 Research Flowchart

Figure 4: Flowchart of this system.

2.3 Data Collection Method

The method used is experimental method with 10

independent variables. They are the water fall height

(H) 1.5 m, lift height (h) 5 m with a slope of 21,72

0

following the contour of the ground and the length

of the outlet pipe is 13.60 m, the slope angle of the

slide pipe (5

0

) with a slide pipe length of 17.24 m,

water flow entering the pump (180 and 170

liters/min), IWWC position, ICWW position,

IWCW position, compressor tube volume 3000 ml.

While the 7 dependent variables are: sewage

discharge (Q), inlet water pressure, outlet pressure,

pumping discharge (q), waste valve weight, waste

valve pulse and hydraulic ram pump efficiency

(calculated using equation 1).

Prior to testing and data collection, the water

drop height (H) was conditioned at least 1.5 m with

the discharge water being 180 liters/minute and 170

liters/minute. The test will be carried out 18 times in

accordance with 3 variations of the compressor tube

position (IWWC, ICWW, IWCW) and 3 variations

of the weight of the waste valve (367 grams, 567

grams, 695 grams) both at intake discharge of 180

liters/minute and 170 liters/minute. Each test will be

recorded carefully in the data table that has been

prepared.

(a) IWWC

(b) ICWW

(c) IWCW

Figure 5: Schematic of the hydraulic ram pump test

installation.

In testing the researcher used supporting

equipment such as a measuring cup, a bucket, seal

tapes, PVC glue, machete, shovel, roller meter,

pressure gauge, water fitting, nylon ropes, bamboo,

pipe wrench, and a stopwatch. Data retrieval is done

by reading the pressure on the pump inlet pipe,

pressure on the outlet pipe, measuring the pulse of

the waste valve, measuring the discharge of the

waste and the discharge of the pumping.

2.4 Data Processing Method

The data that has been collected in tabular form will

be made in graphical form to obtain the relationship

between variations in the position of the compressor

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

160

tube, variations in the weight of the waste valve, and

the pulse of the waste valve to the pumping

discharge.

The hydraulic ram pump efficiency can be

calculated in two ways:

According to D’Aubuisson (Murni, 2016)

η =

𝑞

(

𝐻+ℎ

)

(𝑄+𝑞)

...................................... (1)

According to Rankine :

η =

𝑞.ℎ

𝑄.𝐻

………………………… (2)

Where: η = hydraulic ram pump

efficiency (%)

q = result (m

3

/det.)

Q = waste (m

3

/det.)

h = head out (m)

H = head in (m)

3 RESULT AND DISCUSSION

The test result data can be seen in Tables 1, 2 and 3

below:

Table 1: Position of IWWC.

Incoming

debit

(L/minute)

Waste

valve

weight

(gram)

Waste

valve

pulsation

(x/minute)

Waste

debit Q

(L/second)

Yield

debit Q

(L/second)

D’Aubuison

Efficiency

ɳ (%)

Pump

inlet

pressure

(bar)

Pump

outlet

pressure

(bar)

180

367

567

695

36

28

26

0,495

0,679

0,800

0,114

0,126

0,120

122

102

85

0,6

0,6

0,6

0,6

0,6

0,6

170

367

567

695

34

26

18

0,537

0,752

0,869

0,095

0,077

0,056

98

60

39

0,6

0,6

0,6

0,6

0,6

0,6

135

Tabel 2: Position of ICWW.

Incoming

debit

(L/minute)

Waste

valve

weight

(gram)

Waste

valve

pulsation

(x /minute)

Waste

debit Q

(L/second)

Yield

Debit Q

(L/second)

D’Aubuison

Efficiency

ɳ (%)

Pump

inlet

pressure

(bar)

Pump

outlet

pressure

(bar)

180

367

567

695

34

28

26

0,494

0,645

0,754

0,115

0,123

0,115

123

104

86

0,6

0,6

0,6

0,6

0,6

0,6

170

367

567

695

33

26

21

0,493

0,768

0,921

0,095

0,077

0,056

115

72

53

0,6

0,6

0,6

0,6

0,6

0,6

135

Tabel 3: Position of IWCW.

Incoming

debit

Waste

valve

Waste

valve

Waste

debit Q

Yield

Debit Q

D’Aubuison

Efficiency

Pump

inlet

Pump

outlet

(L/minute)

weight

(gram)

pulsation

(x /minute)

(L/second)

(L/second)

ɳ (%)

pressure

(bar)

pressure

(bar)

180

367

567

695

34

28

25

0,514

0,639

0,764

0,131

0,131

0,124

132

103

91

0,6

0,6

0,6

0,6

0,6

0,6

170

367

567

695

33

25

17

0,523

0,749

0,088

0,107

0,089

0,066

110

69

37

0,6

0,6

0,6

0,6

0,6

0,6

135

1

The results of the hydraulic ram pump test on the

layout of the compressor tube, Input-Waste-Waste-

Compressor (IWWC), Input-Compressor-Waste-

Waste (ICWW) and Input-Waste-Compressor-Waste

(IWCW) with 2 variations of intake discharge (180

liters) /minute 170 liters/minute) and 3 variations of

the weight of the waste valve, as shown in tables 4.1,

4.2 and 4.3 above. The relationship between the

weight of the waste valve and the output discharge

to the position of the compressor tube is presented in

Figure 5 (incoming flow rate of 180 liters/minute)

and Figure 6 (incoming flow rate of 170

liters/minute). The position of the IWCW

compressor tube shows a higher pumping discharge

compared to the position of the IWWC and ICWW

compressor tubes.

Figure 6: Comparison of the output discharge value with

the weight of the waste valve on the compressor tube

position.

Figure 7: Comparison of the output discharge value with

the weight of the waste valve on the compressor tube

position.

Analysis of the Effect of Double Waste Valves in Series Arrangement and Compressor Tube Layout on the Performance Efficiency of 2 Inch

Hydraulic Ram Pump

161

The most ideal waste valve weight is 567 grams

at the intake discharge of 180 liters/minute for the

three compressor tube positions (IWWC, ICWW and

IWCW), while at the intake discharge 170

liters/minute, the appropriate waste valve weight for

the three compressor tube positions is 367 grams

(see Figure 8), in which the weight of the waste

valve must be adjusted to the intake discharge.

The effect of the weight of the waste valve on the

pulse of the waste valve and the position of the

compressor tube is presented in Figures 7 and 8,

where the heavier the waste valve, the slower the

pulse produced, both at the intake discharge of 180

liters/minute and 170 liters/minute.

Figure 8: Comparison of the value of the weight of the

waste valve with the pulse of the waste valve to the

position of the compressor tube (inlet discharge 180 liters /

minute).

Figure 9: Comparison of the value of the weight of the

waste valve with the pulse of the waste valve to the

position of the compressor tube (at the inlet 170

liters/minute).

The relationship of the waste valve pulse to the

pumping discharge at the hydraulic ram pump with

the arrangement of IWWC, ICWW and IWCW is

shown in Tables 1, 2 and 3, where the higher the

number of pulses, the higher the pumping discharge.

The efficiency of the hydraulic ram pump as a

comparison of the pumping discharge with the inlet

and effluent discharges as well as the ratio of the

weight of the waste valve and the output discharge

in each pump arrangement is presented in Figure 9

below.

Figure 10: Graph of the relationship between compressor

tube position and waste valve weight on D'Aubuisson

efficiency.

In general, the highest efficiency value is

obtained at the position of the IWCW compressor

tube (Input-Waste-Compressor-Waste), both at the

intake discharge of 180 liters/minute and 170

liters/minute with a waste valve weight of 367 grams

which is 132% and 110% (according to the

D'Aubuison efficiency).

The results of previous research using a single

waste valve, the highest efficiency obtained was

only 127% on the IWC hydraulic ram pump

arrangement. This means there is an increase in

efficiency by 5%.

The efficiency value obtained according to

D'Aubuisson looks greater than 100%, occurs at

every position of the compressor tube IWWC,

ICWW and IWCW. This is due to the large amount

of water entering the pump, which is 180

liters/minute (measurements before testing). In

addition, the slope angle of the inlet pipe is getting

smaller (50) so that the inlet pipe is getting longer

which affects the suction and thrust forces so that the

efficiency of the hydraulic ram pump is higher.

Research conducted by R. Sutanto (2019), also

shows that the smaller the plunge angle used, the

greater the output discharge generated, the greater

the plunge angle, the smaller the suction and thrust

forces of the hydraulic ram pump.

4 CONCLUSIONS

Based on the results of testing and data processing, it

can be concluded as follows:

a. The largest output/pumping discharge occurred

at the position of the IWCW (Input-Waste-

Compressor-Waste) compressor tube, both at the

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

162

intake discharge of 180 liters/minute and 170

liters/minute with a waste valve weight of 367

grams which were 0.131 liters/second and 0.107

liters. /second.

b. The greatest efficiency also occurs at the position

of the IWCW compressor tube (Input-Waste-

Kompresor-Waste), both at the intake discharge

of 180 liters/minute and 170 liters/minute with a

waste valve weight of 367 grams, which are

132% and 110% (according to the efficiency of

D 'Aubuison).

REFERENCES

Agus Prastyo. Analisa Pengaruh Dimensi Tabung Udara

Terhadap Prestasi Pompa Hidram Prototype, Jurusan

Teknik Mesin Fakultas Teknik Universitas

Muhammadyah Jember.

Aris Eko Setyawan, dkk. (2006). Pengaruh Berat Katub

Limbah dan Ketinggian Discharge Terhadap Kinerja

Pompa Hidram, Pendidikan Teknik Mesin, Fakultas

Teknik Universitas Negeri Surabaya.

Asep Supriyanto, dkk. (2017). Pengaruh Variasi Jarak

Sumbuh Katub Limbah Dengan Sumbuh Tabung

Udara Terhadap Efisiensi Pompa Hidram, Jurnal

Teknik Mesin Univ.Muhammadya Metro, TURBO

Vol. 6 No. 2.

I Gede Bawa Susama dan Rudy Susanto.(2016).

Peningkatan Kinerja Pompa Hidram Berdasarkan

Posisi Tabung Kompresor dengan Saluran Keluar di

bawah Tabung Kompresor, Jurnal Dinamika Teknik

Mesin 6.

Muhamad Fajri, dkk. (2015). Pengaruh Diameter Katub

Limbah dan Jarak antara Katub Limbah dengan Katub

Penghantar Terhadap Efisiensi Pompa Hidram, Jurnal

Teknik Mesin Undana, Vol. 02 No. 01.

Muhamad Jafri, dkk. (2017). Analisis Pompa Hidram 2

inchi dengan Sistim Kompresi Seri, Prosiding Seminar

Nasional Teknik FST-UNDANA .

Murni, dkk. (2016). Kaji Eksperimental Pengaruh

Ketinggian Permukaan Air Pompa Hidram Diameter

Inlet ¾ inch Dengan Sudut Kemiringan 15

0

Terhadap

Kinerja Pompa.

Rafael Mado, dkk. (2021). Pengaruh Tata Letak Rumah

Pompa dan Variasi Volume Tabung Kompresor

Terhadap Efisiensi Unjuk Kerja Pompa Hidram 2

Inch, Laporan Penelitian Terapan, Jurusan Teknik

Mesin Politeknik Negeri Kupang.

R. Sutanto, dkk. (2019). Variasi Sudut Pipa Masukan

Terhadap Unjuk Kerja Pompa Hydram, Jurnal

Keilmuan dan Terapan Teknik Mesin, Dinamika

Teknik Mesin 9 (1).

Teferi Taye. (1998). Hydraulic Ram Pumps, Journal of the

Ethiopian Society of Mechanical Engineers, Vol. II,

No. 1.

Toto Citramurti, dkk. (2015). Pengaruh Beban Katub

Buang di bawah 450 gram Menggunakan Panjang

Input 4 m dan Ketinggian Output 10 m terhadap

Kinerja Pompa Hidram, Jurnal Widya Teknika Vol. 23

No.1.

Widarto dan FX. Sudarto. (1997). Membuat Pompa

Hidram, Teknologi Tepat Guna, Penerbit Kanisius,

Jakarta.

Analysis of the Effect of Double Waste Valves in Series Arrangement and Compressor Tube Layout on the Performance Efficiency of 2 Inch

Hydraulic Ram Pump

163