Design Screw Conveyor Rice Milling Unit (RMU) Capacity 5 Tons for

Parit 1 Api-api Village

Firman Alhaffis and Alfansuri

Mechanical Engineering, Politechnic of Bengkalis State, Bathin Alam Sei Alam Bengkalis, Indonesia

Keywords: Screw Conveyor, Rice Milling, Design, FEA.

Abstract: Bukit Batu District has Parit 1 Api-api Village. Bengkalis Regency is an area that has an area of ± 68 ha of

rice plants. Api-api village is one of the rice production centers that have a potential location for rice

cultivation because it still has vacant land. The rice production process in Parit 1 Api-api Village is often

hampered by the rice milling unit (RMU) process. The process of transporting grain to the factory is carried

out in a very manual way, namely transporting dry grain to RMU by transportation. This of course requires a

lot of manpower. One option to assist these activities is to use a mechanical device in the form of a conveyor.

This study aims to design and analyze the design of conveyor construction. Autodesk Inventor simulation

using linear static analysis. Static analysis is an engineering discipline that determines the stresses in materials

and structures that are subjected to static forces or loads. Static analysis uses finite element analysis (FEA)

and aims to determine the structure or component, that can safely withstand the forces and loads that have

been determined. This condition is reached when the specified stress from the applied force is less than the

yield strength of 275 MPa under load. The results of the design are declared "safe" using 6061 aluminum

material on a screw conveyor with a maximum von Mises stress of 5.25 MPa with a safety factor scale of 15.

1 INTRODUCTION

The need for agricultural tools and machinery in

various fields is currently very much needed, this is

related to improving the quality and quantity of the

work carried out. Industry has proven that the

abundance of natural resources owned is not an

absolute guarantee for the prosperity of a nation. The

availability of skilled and skilled human resources as

well as mastering technology is a dominant factor that

can lead a nation to advance in the agricultural

industry.

Rice is a basic need for the Indonesian population.

As the population increases, causing rice

consumption to increase, therefore, it is necessary to

increase rice production to meet people's

consumption needs by increasing the production

system. The production system can be influenced in

the rice harvesting process, by accelerating the

process of cutting and threshing rice (Ibrahim, 2019).

The rice production process in Parit 1 Api-api

village is often hampered by the Rice Milling Unit

(RMU) process. The process of transporting grain to

the mill is carried out in a very manual way, namely

transporting the dried grain to the RMU by carrying

it. This, of course, requires an excess of human labor

(workload). An option to assist these activities is to

use a mechanical device in the form of a conveyor.

This study aims to design and analyze the design of

conveyor construction.

Conveyor is one part of the combine harvester that

serves to carry the rice stalks that have been cut to the

feeder and thresher holes. To make an optimal simple

harvester conveyor, it is necessary to pay attention to

the dimensions of checking the suitability of the

dimensions of the conveyor with the planned design

with the aim of knowing the conveyor manufacturing

process. The simple rice harvester machine in this

data analysis method accepts workpieces made using

the Solidworks 2016 (Muslimin etc, 2021

application).

The agricultural mechanism in a broad sense aims

to increase labor productivity, increase land

productivity and reduce production costs. The use of

tools and machines in the production process is

intended to increase efficiency, productivity

effectiveness, yield quality and reduce the burden on

farmers.

212

Alhaffis, F. and Alfansuri, .

Design Screw Conveyor Rice Milling Unit (RMU) Capacity 5 Tons for Parit 1 Api-api Village.

DOI: 10.5220/0011740800003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 212-218

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

2 MANUSCRIPT PREPARATION

The working mechanism of the grain packaging

machine in brief is to collect grain from the floor

using a screw conveyor. Research analyzes the effect

of variations in the tilt angle of the screw conveyor

and variations in motor speed on the optimization of

the grain packaging machine. Based on the results of

experimental field tests that have been carried out, the

optimal capacity is obtained at the variation of the tilt

angle of the screw conveyor 100 and the motor speed

on the screw conveyor shaft 100 Rpm, with the result

of a capacity of 1,226 Kg/hour.

2.1 Conveyors

Conveyor is a mechanical system that has the

function of moving goods from one place to another.

Conveyors are widely used in industry for the

transportation of very large and sustainable goods.

Under certain conditions, conveyors are widely used

because they have economic value in the field of

heavy transportation such as trucks and transport cars.

Conveyors can mobilize goods in large quantities and

continuously from one place to another. The

relocation must have a fixed location so that the

conveyor system has economic value (Dianto, 2019).

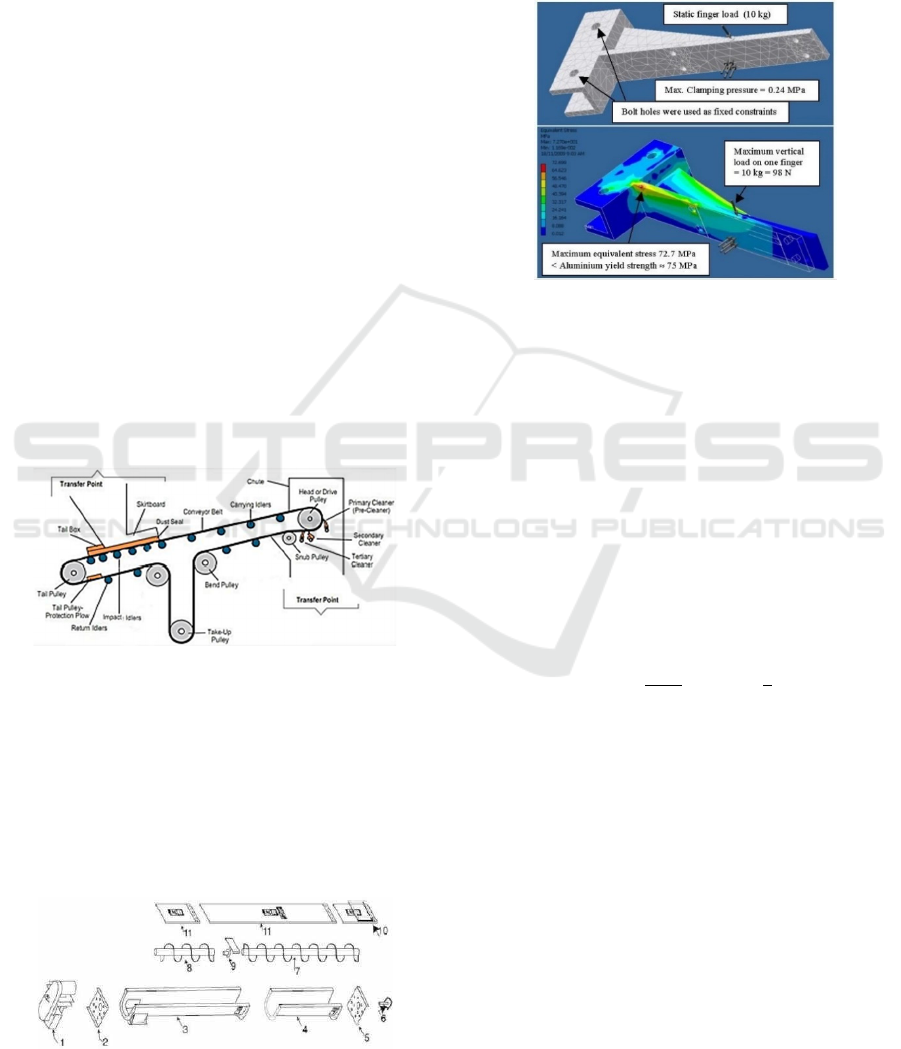

Figure 1: Conveyor. Source: Dianto 2019.

The screw conveyor which is most suitable for

transferring solid or granular raw materials. As the

name suggests, this screw conveyor consists of a

blade that is twisted called a flight. This flight

revolves around an axis so that its shape resembles a

screw. From the two types of conveyors above, the

researcher concludes that the conveyor according to

the title raised is the screw conveyor.

Figure 2: Part of Screw Conveyor.

2.2 Static Stress Analysis

If a component receives the load received slowly,

without shock and is held at a constant value, then the

stress generated in the component is called static

stress. On the load of a structure due to the dead

weight of a building (Mott, 2009).

Figure 3: Static analysis FEA. Source: SN. Cubero, 2018.

2.2.1 Stress

Every material (object) is elastic in its natural state.

So if the external force acting on the object will

experience deformation, this resistance which is

united in area is called stress. If an elastic object is

pulled by a force, the object will increase in length up

to a certain size proportional to the force, which

means that there is a certain amount of force acting

on each unit length of the object. The force acting is

proportional to the length of the object and inversely

proportional to its cross-sectional area. The

magnitude of the force acting divided by the cross-

sectional area is defined as stress.

atau

(1)

2.2.2 Strain

Strain is defined as the quotient between the increase

in length and the initial length. If an object is hanging

on a rope, it creates a pulling force on the rope, so the

rope provides resistance in the form of an internal

force that is proportional to the weight of the load it

carries (action force = reaction).

The resistance response of the rope to the load

acting on it will cause the rope to tighten as well as

stretch as an effect of internal displacement at the

atomic level in the particles that make up the rope, so

that the rope experiences an increase in length.

Design Screw Conveyor Rice Milling Unit (RMU) Capacity 5 Tons for Parit 1 Api-api Village

213

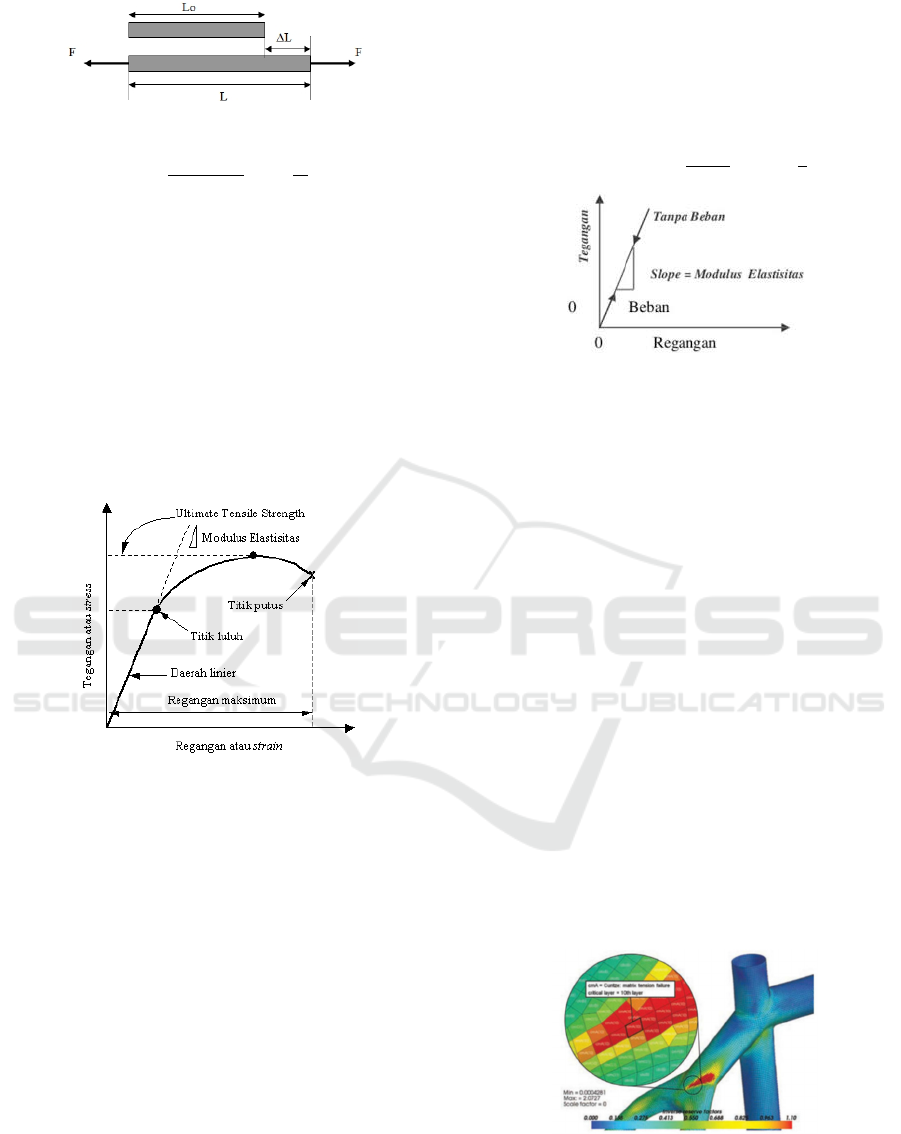

Figure 4: Strain of schematic.

or

∆

(2)

2.2.3 Stress Strain Behavior

The test results usually depend on the test object.

Because it is very unlikely that we use a structure that

is the same size as the size of the test object, we need

to express the test results in a form that can be applied

to structural elements of any size. A simple way to

achieve this goal is to convert the test results to

stresses and strains. The stress-strain diagram is a

characteristic of the material being tested and

provides important information about mechanical

quantities and types of behavior.

Figure 5: Stress strain curve.

2.2.4 Modulus Young

Stress-strain is a characteristic of the material under

test and provides important information about

mechanical quantities and types of behavior.

The modulus of elasticity is often referred to as

Young's modulus which is the ratio between stress

and axial strain in elastic deformation, so that the

modulus of elasticity shows the tendency of a

material to deform and return to its original shape

when given a load.

The modulus of elasticity is a measure of the

stiffness of a material, so the higher the value of the

modulus of elasticity of the material, the less

deformation occurs when a force is applied. So, the

greater the value of this modulus, the smaller the

elastic strain that occurs or the stiffer it is. The amount

of increase in length experienced by each object when

stretched is different from one another depending on

the elasticity of the material.

It is concluded that the strain (ε) that occurs in an

object is directly proportional to the stress (σ) and

inversely proportional to its elasticity. This is

expressed by the formula:

or

(3)

Figure 6: Modulus elasticity (Modulus young).

2.2.5 Finite Element Analysis

Finite Element Analysis (FEA) is a numerical method

that can be used to find accurate solutions to complex

engineering problems. This finite element method is

a method that has been proven to be quite successful

so far to be used to analyze the stresses that occur in

structures. The basic concept of this method is

discretization, which is dividing objects into smaller

forms which still have the same properties as the

constituent objects.

This method is widely used to solve technical

problems and mathematical problems of a physical

phenomenon. The types of physical technical and

mathematical problems that can be solved using the

finite element method are divided into two groups,

namely the structural analysis group and the non-

structural problems group. The types of structural

problems include stress, buckling, and vibration

analysis (modal analysis), while non-structural

problems include heat and mass transfer, fluid

mechanics, and distribution of electric potential and

magnetic potential.

Figure 7: Fail creation komputational FEA.

FEA has become a solution for predicting the

strength of a material that cannot be shown in theory

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

214

and allows designers to see all the theoretical forces

that occur in the model.

3 RESEARCH METHODOLOGY

In order to achieve the objectives of the research, it is

necessary to arrange research stages. The following is

a research flow chart for the design of the conveyor

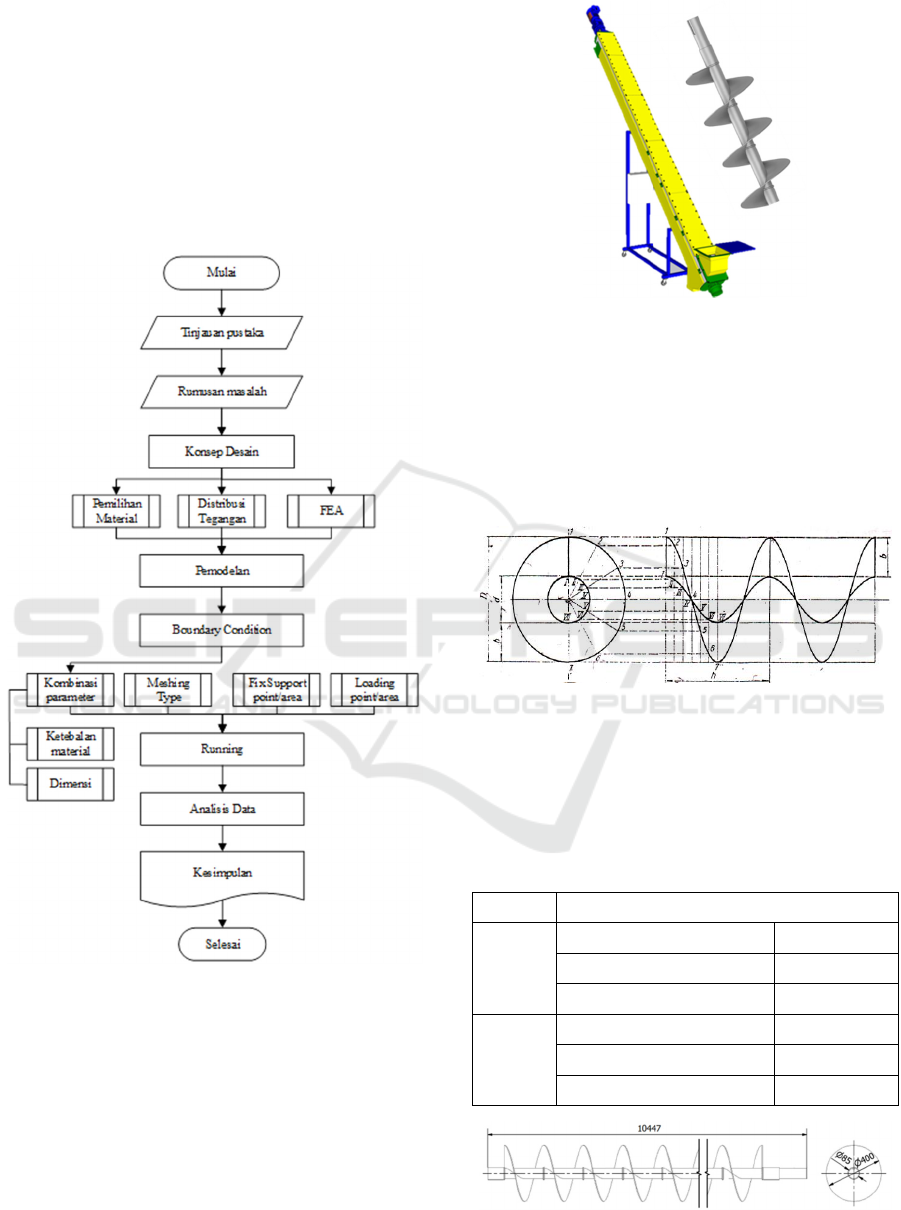

rice milling unit (RMU):

Figure 8: Flowchart of research.

3.1 Research Model

Modeling is the process of forming objects using a

computational system, so that the results of the model

(part) look real according to the original object. The

overall modeling process includes the formation of

parts, the assembly process (part assembly) and a

two-dimensional (2D engineering drawing)

projection model. The output of the modeling is in the

form of volume, mass, and so on.

Figure 9: Modeling as initial reference.

In planning a screw conveyor, the first thing to

consider is the manufacture of threads on the screw.

Initial planning in the manufacture of screw threads

is to determine in advance the screw diameter (D) and

the diameter of the axle or screw shaft (d). The

drawing of the planning for making the screw can be

seen in Figure 10.

Figure 10: Screw manufacturing planning.

3.2 Material

In this study, the material used is Aluminum 6061

with the following characteristics show in Table 1:

Table 1: Materials properties of Aluminum 6061.

Name

Aluminum 6061

General

Mass Density 2.7 gr/cm

3

Yield Strength 275 MPa

Ultimate Tensile Strength 310 MPa

Stress

Young's Modulus 68.9 GPa

Poisson's Ratio 0.33 ul

Shear Modulus 25.9023 GPa

Figure 11: Geometry of screw conveyor (mm).

Design Screw Conveyor Rice Milling Unit (RMU) Capacity 5 Tons for Parit 1 Api-api Village

215

It is shown in Figure 10 that the geometry is 10447

mm in total length and shaft diameter (d) 85 mm and

screw conveyor diameter (D) 400 mm.

Table 2: Number of mesh element and node.

Element

52158

Node

105305

3.3 Boundary Condition

Figure 12 shows the stages of FEA. Numerical

methods that can be used to solve structural problems.

The FEA simulation process is carried out for an

approach to real conditions that occur in materials and

structures. Observing and analyzing the load on the

components.

Figure 12: FEA method simulation stages.

Figure 13 shows the load point that occurs on the

screw conveyor. From the observations, two forces

occur, pure bending load and torsion.

Figure 13: Deflection and moment due at screw conveyor.

4 RESULT AND ANALYSIS

Autodesk Inventor simulation results using linear

static analysis. Static analysis is an engineering

discipline that determines stresses in materials and

structures that experience static or dynamic forces or

loads (W. Younis, 2011). The static analysis uses the

finite element method and aims to determine the

structure or component, can safely withstand the

forces and loads that have been determined. The

condition is reached when the specified stress from

the applied force is less than the yield strength in

resisting the load. This voltage relationship is often

referred to as a safety factor and is used in many

analyzes as an indicator of success or failure in an

analysis (Wibawa, 2018).

The characteristics of the material will be known

if it is given a load. The purpose of this study was to

observe the effect of the load on the Aluminum 6061

material applied to the screw conveyor. The

maximum allowable stress limit in this design refers

to the yield strength value of CFRP, which is 275

MPa.

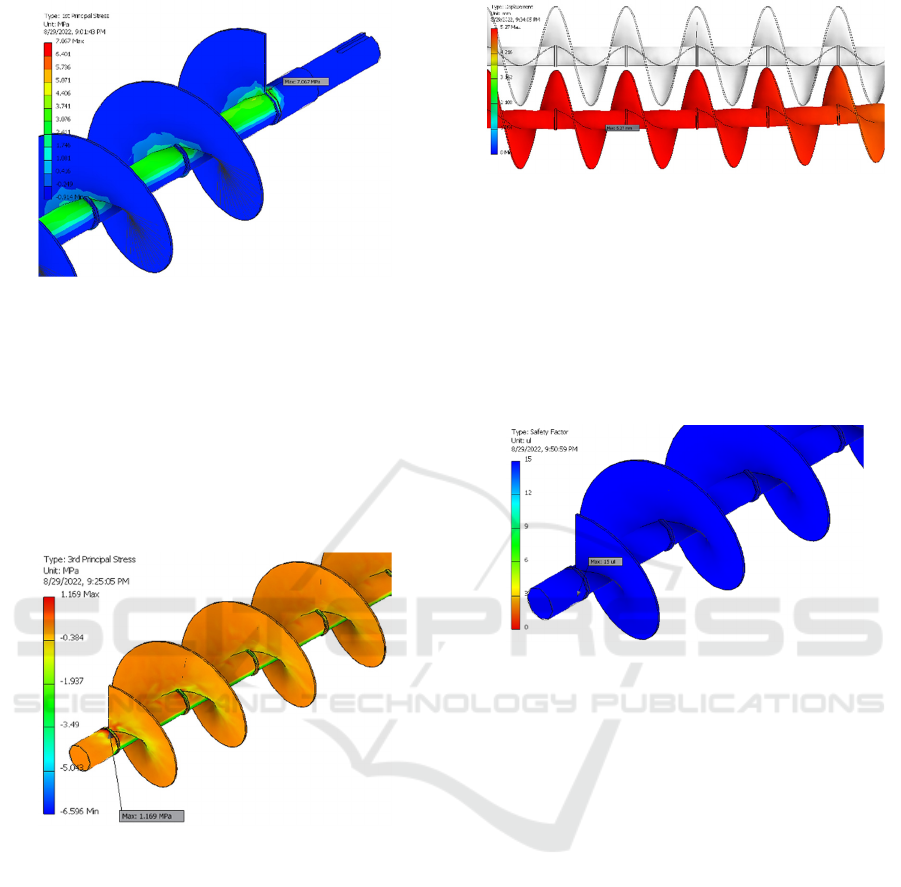

4.1 Von Mises Stress

The Von Mises stress results use color contours to

indicate the calculated maximum and minimum

stresses. Aluminum 6061 on the screw conveyor is

declared to begin to yield when the von Mises stress

reaches the yield strength value.

Figure 14: Maximum von Mises stress zone.

It is observed from Figure 14 that the overall

construction of Aluminum 6061 can support the load

very well, which is 5,623 MPa which is still far below

the yield value.

4.2 1

st

Principal Stress

The value of the 1

st

principal stress is the normal

tensile stress of a plane where the shear stress is zero.

1st principal stress to determine the zone of maximum

tensile stress that occurs on the screw conveyor due

to the interaction of loading and support as shown in

Figure 15. From the computational results, the 1st

principal stress value is only 7.067 MPa.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

216

Figure 15: The maximum tensile stress that occurs on the

conveyor.

4.3 3

rd

Principal Stress

Figure 16 shows the maximum yield of the 3

rd

Principal Stress is 1.169 MPa. The 3

rd

Principal Stress

functions to determine the normal compressive stress

that occurs in the frame where the shear stress is zero.

The distribution of compressive stress occurs in

almost all areas of the screw conveyor.

Figure 16: Zone 3

rd

Principal Stress.

4.4 Displacement

Displacement provides information on changes in the

shape of the screw conveyor from its original shape.

The computational results found the whole deformed

part. Maximum deformation 5.27 mm. Deflection is

quite large influenced by the load and the length of

the shaft which reaches 10 meters supported by each

end. Changes in the shape of the skeleton are not

permanent or are still in the elastic zone. Illustration

shown Figure 16 is shown in color for easy

identification.

Figure 17: The maximum deformation that occurs in the

conveyor is influenced by the length and pure bending.

4.5 Safety Factor

The safety factor of the 6061 aluminum screw

conveyor can be measured, calculated, and predicted.

If the safety factor equation is the ratio of yield

strength to maximum stress (actual stress), the value

must be greater than 1.0.

Figure 18: Safety factor material conveyor aluminum 6061.

Figure 18 illustrates that from 18 points and 1

moment applied, the results of a safety factor scale of

15 show that the Aluminum 6061 material conveyor

is very "safe".

5 CONCLUSIONS

Based on the analysis of the aluminum 6061 material

applied to the screw conveyor, it can be concluded

that:

1. When using 6061 aluminum material with a

density of 2.7 gr/cm3, the total weight of the

screw conveyor becomes 187 kg.

2. The maximum von Mises stress that occurs in one

of the zones is 5.623 MPa but overall it is still very

safe below the yield strength limit of 275 MPa.

3. The deflection that occurs is quite large in the

center of the screw conveyor. The maximum

deflection is 5.27 mm, this condition is influenced

by the applied load and the length of the shaft is

10 meters supported at each end so that there is a

deflection.

Design Screw Conveyor Rice Milling Unit (RMU) Capacity 5 Tons for Parit 1 Api-api Village

217

4. Further development needs to be combined with

several types of materials so that the ability of the

frame is under the applied load but lighter weight.

So it is more efficient in the production process.

REFERENCES

Van Vlack, L. H. (1959). Elements Of Materials Science:

An Introductory Text For Engineering Students.

Younis, W. (2010). Up and running with Autodesk Inventor

Simulation 2011: a step-by-step guide to engineering

design solutions. Elsevier.

Wibawa, L. A. N. (2018). Merancang Komponen Roket 3D

dengan Autodesk Inventor Professional 2017. Buku

Katta.

Rantawi, A. B. (2013). Perancangan Unit Transfer (Screw

Conveyor) pada Mesin Pengisi Polibag untuk

Meningkatkan Efektvitas Kinerja di Bidang

Pembibitan. Jurnal Citra Widya Edukasi, 5(1), 60-67.

Sabardiyanto, S., & Iskandar, N. (2016). Analisis Mekanik

Screw Conveyor Tubular Diameter 200 Mm Dengan

Autodesk Inventor. Jurnal Teknik Mesin, 4(2), 178-

186.

Rofeg, A., Kabib, M., & Winarso, R. (2018). Pembuatan

Mesin Screw Conveyor Untuk Pencampuran Garam

Dan Iodium Sesuai SNI 3556. Jurnal Crankshaft, 1(1),

21-28.

Alhaffis, F. (2017). Implementasi Serat Karbon/Epoksi

Untuk Drive Shaft Pada Kendaraan Penggerak Roda

Belakang (Doctoral dissertation, Institut Teknologi

Sepuluh Nopember).

Dianto, B. B. W. (2019). Perancangan Portable Belt

Conveyor Untuk Pengangkutan Hasil Pertanian Ke

Dalam Alat Angkut Dengan Kapasitas 15

Ton/Jam (Doctoral Dissertation, University Of

Muhammadiyah Malang).

Ibrahim, I. M., Abdelmalek, D. H., & Elfiky, A. A. (2019).

GRP78: A cell's response to stress. Life sciences, 226,

156-163.

Muslimin, Z. I. (2021). Berpikir positif dan resiliensi pada

mahasiswa yang sedang menyelesaikan skripsi. Jurnal

Psikologi Integratif, 9(1), 115-131.

Mott, J., & Wiley, D. (2009). Open for learning: The CMS

and the open learning network.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

218