U-Optimal Accelerated Life Test Scheme Considering Right

Censored Data

Di Cao, Juan Wang and Liangqing Feng

School of Economics and Management, Nanchang Hangkong University, China

Keywords: Accelerated Life Test, Generalized Linear Model, Optimal Criterion, Monte Carlo Technique.

Abstract: The purpose of accelerated life test is to promote more failure units of test products in a shorter time, so as to

predict the reliability of products under normal conditions based on the failure data collected under accelerated

conditions. In view of the right censored data, some statistical optimality is considered. In the framework of

generalized linear model, the semi-parametric Cox proportional hazard model is used to obtain the accelerated

life test scheme under the U- and D-optimal criteria. From the perspective of prediction variance, the fitting

effect is best when the shape parameter 𝛼 is 1.5 in Weibull distribution. The uncertainty of model parameters

is evaluated by Monte Carlo technique to verify the feasibility of the test scheme.

1 INTRODUCTION

A large number of products in the market have a long

expected life. In order to ensure the stable perfor-

mance of product life during the service period, it is

unrealistic to completely observe the product life due

to limiting factors. Therefore, accelerated life test

(ALT) is introduced. ALT ensures that more products

failure data can be obtained in a shorter time, and the

reliability of products can be inferred by establishing

statistical models. However, when faced with irregu-

lar experimental design areas, the regular design loses

some statistical "optimality" and needs to be "tai-

lored" design.

Censored data results from inaccurate observa-

tions of failure times. The definition of right censored

data is that the starting time of the test is known, but

the test fails to fail at the end of the test, thus, the sur-

vival time is longer than the observed time. There is

a huge literature on ALTs. Song Wu et al (Wu, Lu,

Li, 2021) briefly described the relevant theoretical

knowledge of ALT. Under the assumption of lognor-

mal distribution, Xiaopei Li et al (Li, Li, Liang, 2021)

proposed the relationship between single stress varia-

ble and product life. Yi Dai et al (Dai, Liu, 2020) ap-

plied the maximum likelihood theory to design the

optimal test under the condition that the product life

obeys the minimum extreme value distribution. The

literature described above are performed under single

stress conditions. In fact, most product life is affected

by multiple stress variables. Xu et al (Xu, Fei, 2007)

discussed the dual-stress variables with no interaction

between. Park and Yum (Park, Yum, 1996) assumed

the interaction between stress factors and verified it.

The process of obtaining the information matrix is

particularly complex, thus, focusing on the hazard

rate and under the assumption of proportional hazard

model (PH), the ALT scheme is transformed into an

optimization problem under the generalized linear

model (GLM). For different statistical optimality,

Guo and Pan (Guo and Pan, 2007) used GLM method

to obtain the plan under D-criterion. Juan Wang

(Wang, Ma, Wang, 2017) discussed the ALT scheme

with 2 stress factors under the I-optimal criterion for

interval censored data. In addition, due to the uncer-

tainty of model parameters, literature (Dror, Stein-

berg, 2006; Ozol-Godfrey, Anderson-Cook, Robin-

son, 2008) has discussed the wrong designation of rel-

evant parameters.

2 ACCELERATED LIFE TEST

MODEL

The purpose of using D-optimal is to maximize the

determinant of the expected information matrix. The

goal of the U-optimal is to minimize the overall vari-

ance of the model parameter estimator. Specifically,

the D-optimal criterion is expressed as:

530

Cao, D., Wang, J. and Feng, L.

U-Optimal Accelerated Life Test Scheme Considering Right Censored Data.

DOI: 10.5220/0011751400003607

In Proceedings of the 1st International Conference on Public Management, Digital Economy and Internet Technology (ICPDI 2022), pages 530-533

ISBN: 978-989-758-620-0

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

𝜉

∗

≔𝑎𝑟𝑔𝑚𝑎𝑥

|𝑿

𝜉

𝑾𝑿(𝜉)|

U-optimal criterion:

𝜉

∗

:=𝑎𝑟𝑔𝑚𝑖𝑛

𝑥

⋅(𝑿(𝜉)

𝑾𝑿(𝜉))

⋅𝑥

𝑥

represents the stress under the use condition,

𝑿

(

𝜉

)

represents the model matrix of n×p, n and p rep-

resent testing numbers and model parameters, respec-

tively, and W is the weight matrix related to the vari-

ance of the predicted life.

Under the assumption of PH, the failure function

can be expressed as:

𝑓(𝑡)=ℎ(𝑡)𝑅(𝑡)=ℎ

(𝑡)𝑒

𝒙

𝜷

(𝑅

(𝑡))

𝒙

𝜷

ℎ

(𝑡) is underlying hazard function, β is the vec-

tor of regression coefficients, and 𝜂= 𝒙

𝜷 is the lin-

ear prediction of the model. 𝑅

(𝑡) is reliability func-

tion, the relationship with the cumulative hazard

function is 𝑅

(

𝑡

)

= 𝑒𝑥𝑝 (−𝐻(𝑡)). For the right cen-

sored failure time dataset, (𝑡

, 𝑟

),…(𝑡

, 𝑟

),…(𝑡

,

𝑟

),i=1, 2, 3, …n, 𝑡

is the failure or survival time

of the ith data, 𝑟

is indicator variable of censored

time. If the ith test unit fails, 𝑟

takes the value 1; oth-

erwise, it is 0. After simplification, the likelihood

function can be expressed as:

𝐿= (𝑓(𝑡

))

(𝑅(𝑡

))

= (ℎ(𝑡

))

𝑅(𝑡

)

take the logarithm of both sides:

𝑙𝑛𝐿=

𝑟

𝑙𝑛ℎ

(

𝑡

)

+ 𝑙𝑛𝑅

(

𝑡

)

= [𝑟

(𝑙𝑛ℎ

(𝑡

)+𝒙

𝜷)

+ 𝑒

𝒙

𝜷

𝑙𝑛𝑅

(𝑡

)]

let 𝑢

= 𝐻(𝑡

, 𝒙

)=𝑒𝑥𝑝(𝒙

𝜷)(−ln 𝑅

(𝑡

)), this is:

𝑙𝑛𝐿= [𝑟

𝑙𝑛(

1

𝑡

)+(𝑟

𝑙𝑛𝑢

−𝑢

)]

The form 𝑟

𝑙𝑛𝑢

−𝑢

can be regarded as the log-

likelihood function form of Poisson distribution with

mean 𝑢

. So, in the GLM: indicator variable 𝑟

can

be regarded as poisson distribution with mean 𝑢

, the

connection function is the logarithmic function,

𝑙𝑛𝑢

= 𝜂

+ compensation term, the compensation

term is 𝑙𝑛𝐻

(𝑡

).

In the GLM described above, using the elements

𝑢

, 𝑖=1,…𝑛 construct weight matrix, 𝑾=

𝑑𝑖𝑎𝑔{𝑢

, 𝑢

,...,𝑢

}, then the model estimation pa-

rameter 𝜷

is:

𝑉𝑎𝑟(𝜷

)=(𝑿(𝜉)′𝑾𝑿(𝜉))

Among them, (𝑿(𝜉)′𝑾𝑿(𝜉))

is the expected

Fisher information matrix, and the number of ele-

ments in matrix X is n×(p+1):

𝑿=

1 𝑥

,

⋯

1 𝑥

,

⋯

⋮⋮⋱

𝑥

,

𝑥

,

⋮

1 𝑥

,

⋯

𝑥

,

𝑢

in the weight matrix is a function of the failure

time 𝑡

. Therefore, it is more appropriate to express

the weight matrix by the expected value of 𝑢

: 𝑾=

𝑑𝑖𝑎𝑔{𝐸(𝑢)}:

𝐸(𝑢

)=𝐻(𝑡

, 𝒙

)=𝑒𝑥𝑝(𝛽

+ 𝒙

𝜷) ∙𝐸(𝑡

)

= 𝜆

𝑒

𝒙

𝜷

∙𝐸(𝑡

)

𝜆

is the failure rate, 𝛽

= 𝑙𝑛𝜆

, which is the in-

tercept term of linear prediction. Explicitly censoring

time, the expectation function is 𝐸(𝑡

)=[1−

𝑒

(

,𝒙

)

]

𝒙

𝜷

.

Finally get the expected value:

𝐸(𝑢

)=[1−𝑒

(

,𝒙

)

]

3 THE EXAMPLE ANALYSIS

3.1 The Scheme Affected by

Temperature and Humidity

Consider tests related to metal oxide semiconductors

(Zhu, Elsayed, 2011). Assuming that the lifetime of

the semiconductor is affected by two stress variables,

temperature and humidity. 100 samples is planned to

be tested, and the test is set to be censored at 50 hours.

It is assumed that lifetime obeys the Weibull distribu-

tion, and the cumulative hazard function is 𝐻(𝑡, 𝒙)=

𝜆

𝑡

𝑒

𝒙

𝜷

, 𝛼 is the shape parameter. Various factors

are considered in this paper, and 𝛼=1.5 is taken as

the value. In the test, under normal conditions, the

temperature and humidity range is (25℃, 25%)-

(45℃, 40%). In the ALT, set temperature range of

(60℃-110℃), humidity range is (60%-90%), the

temperature of natural stress level is expressed as

𝑆

= 11605/𝑇, T is an unit with Kelvin, natural

stress level of relative humidity is expressed as 𝑆

=

ln ℎ, h is relative humidity. To normalize the pro-

cessing, the following linear transformation of tem-

perature and humidity is used: 𝑥

=

, 𝑥

=

, 𝑆

(0, 0) said the highest stress level, 𝑆

(1, 1)

U-Optimal Accelerated Life Test Scheme Considering Right Censored Data

531

minimum levels of stress, 𝑥

and 𝑥

are the coding

stress variables corresponding to 𝑆

and 𝑆

. In this

paper, the interaction effect of temperature and hu-

midity is considered and the previous empirical for-

mula is followed: 𝜂= −4.086𝑥

−1.476𝑥

+

0.01𝑥

𝑥

.

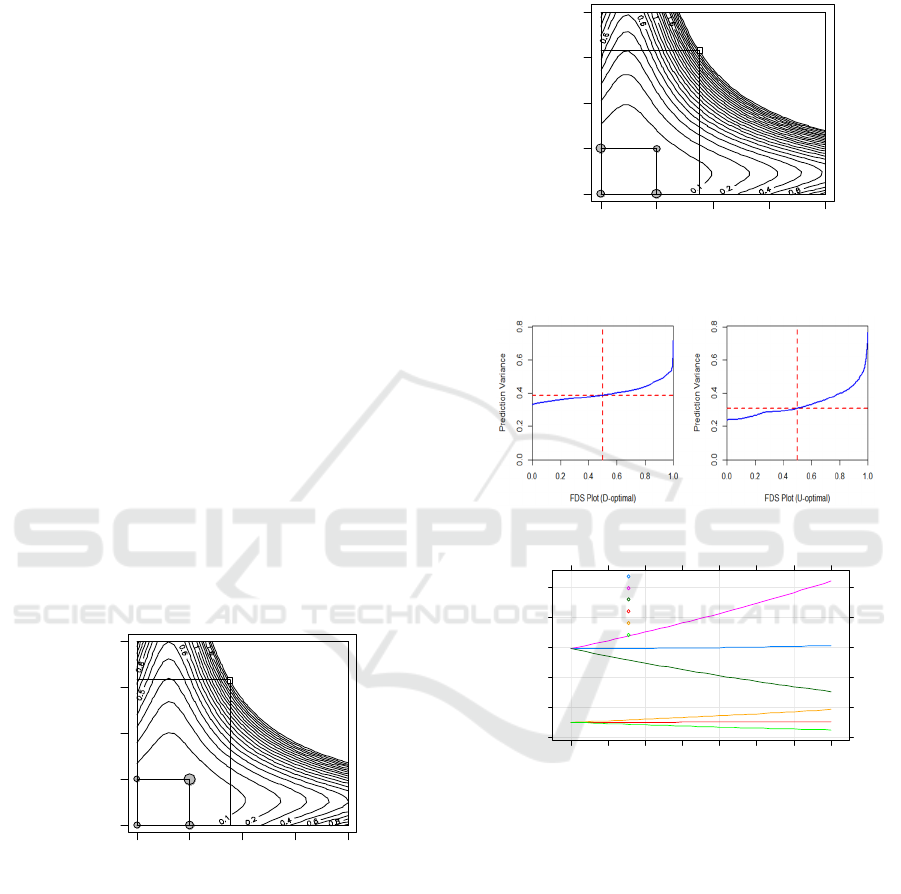

Figure 1 and Figure 2 show the test protocol under

U- and D-criterion and the contour plots of predicted

variance in the use area. The process of calculating

100 test points is more complicated, using a clustering

algorithm to aggregate the points into four different

stress level combinations. Small square area of a

graphic after the corresponding standardized test area,

the origin (0, 0) corresponding to (110℃, 90%), point

(1, 0)-(60 ℃, 90%), (0, 1)-(110 ℃, 60%), (1, 1)-(60

℃, 60%). The circle diameter corresponds to the as-

signed sample size under the test conditions, and the

contour lines outline the positions where the predicted

variance are equal. Comparing the two figures, it can

be seen that the predicted variance under the U-crite-

rion scheme is smaller than that under the D-criterion;

It can be seen from Figure 1 that under the U-crite-

rion, the number of test samples assigned to point (1,

1) is the largest. The reason may be that the low stress

level is closer to the normal operating conditions, and

more test samples have been censored when they do

not reach the high stress level. According to Figure 2,

the number of samples distributed around each stress

point under the D-criterion is roughly balanced.

Figure 1: U-optimal criterion design plot.

The graphical evaluation tool further compares

the test protocols under the U- and the D-criterion. In

the FUS (Fraction of Design Space) plot, the pre-

dicted variance of the ordinate increases with the in-

crease of the ratio of test areas, and the vertical red

line represents the mean. The results show that the

predicted variance of D-criterion is larger than that of

U-criterion. In the VDUS (Variance Dispersion of

Use Space) diagram, ave, min and max respectively

represent the mean, minimum and maximum value. It

can be clearly seen that the predicted variance value

under the D-criterion test scheme is larger.

Figure 2: D-optimal criterion design plot.

Figure 3: FDS design plot.

Figure 4: VDUS design plot.

The prediction results are expected to be accurate

from the perspective of predicted variance, and the

shape parameter 𝛼 in Weibull distribution is an inde-

terminate variable. The above results are obtained un-

der the assumption that 𝛼=1.5. In order to show the

rationality of the method, the case of 𝛼 taking other

values is further discussed. When 𝛼=1, the pre-

dicted variance under D- and U-criteria are 4.33 and

3.58, respectively, and when 𝛼=2, the predicted

variance are 2.14 and 1.92. The experimental results

show that the predicted variance of the U-criterion is

always smaller than that of the D-criterion for differ-

ent values of 𝛼. In addition, in terms of sample num,

when the value of 𝛼 changes, the sample num under

01234

01234

x1

x2

21 2

6

19 34

PV = 1.91

01234

01234

x1

x2

24 2

8

27 21

PV = 2.34

Variance Dispersion of Use Space

Prediction Variance

5

10

15

20

25

0 5 10 15 20 25 30 35

VDUS.D avg

VDUS.D max

VDUS.D min

VDUS.U avg

VDUS.U max

VDUS.U min

ICPDI 2022 - International Conference on Public Management, Digital Economy and Internet Technology

532

D-criterion does not change significantly, on the con-

trary, the sample num under U-criterion changes sig-

nificantly, especially the num of point (1, 1) decreases

with the increase of the value of 𝛼. The results show

that U-criterion has a more obvious influence on the

value change.

3.2 Model to Evaluate

The coefficients specified are taken from previous ex-

perimental results; therefore, ALT protocol with as-

sumed model coefficients needs to be evaluated. The

previous scheme assumes that the real value of stress

coefficient is not more than ±20% away from the set

value. In this paper, Monte Carlo technology is used

to analyze the uncertainty of the model coefficient,

calculate the fluctuation range of the error, and verify

the robustness in reverse.

The Monte Carlo technique uses repeated random

sampling method to obtain numerical results, which

is beneficial to the processing of complex tests. First,

specify the right censored data type, input the sample

size, expectation matrix, linear predictor coefficient

and other relevant variables; Secondly, the GLM was

fitted to obtain the values in the model matrix. Fi-

nally, Monte Carlo simulation is used to evaluate the

intercept term, temperature coefficient 𝑥

, humidity

coefficient 𝑥

, and interaction coefficient 𝑥

𝑥

in

the linear predictor given the values of the running

matrix and the statistical model fitted to the data. The

expected test result is (0, 0, 0, 0). The actual test re-

sults are as follows: the intercept term change rate is

19.65%, 𝑥

is 19.27%, 𝑥

is 19.95%, 𝑥

𝑥

is

19.17%. The test results show that the change rate of

each coefficient is less than 20%, thus, the error rate

of the test scheme is acceptable. The coefficients in

the linear predictor vary within the range, which will

not affect the operation of the test scheme, and the

scheme is still robust.

4 CONCLUSION

In this paper, we discuss the ALT scheme based on

optimal criteria in the framework of GLM with right

censored data. However, the method of parameter es-

timation is based on determining the failure data dis-

tribution, and the parameters are fixed. In fact, in

many cases, the failure data are limited or non-exist-

ent, which makes it difficult to determine the data dis-

tribution. In this case, the Bayesian method is an op-

tion. In the following research, when the failure data

are interval censored, Bayesian method is used to ob-

tain the posterior distribution according to the prior

estimation of parameters, so as to reduce the depend-

ence of model parameters.

REFERENCES

Dror H A, Steinberg D M. Robust experimental design for

multivariate generalized linear models[J]. Technomet-

rics, 2006, 48(4), 520-529.

Guo H, Pan R. D-optimal reliability test design for two-

stress accelerated life tests[C]. International Confer-

ence on Industrial Engineering and Engineering Man-

agement. IEEE, 2007: 1236-1240.

Juan Wang, Yizhong Ma, Jianjun Wang. I-optimal acceler-

ated life test scheme considering interval-censored

data[J]. Practice and Understanding of Mathematics,

2017, 47(17): 184-193.

Ozol-Godfrey A, Anderson-Cook C, Robinson T J. Fraction

of design space plots for generalized linear models[J].

Journal of Statistical Planning and Inference, 2008,

138(1): 203-219.

Park J W, Yum B J. Optimal design of accelerated life tests

with two stresses[J]. Naval Research Logistics(NRL),

1996, 43(4): 863-884.

Song Wu, Jingjing Lu, Xiaokang Li. Review of Reliability

Accelerated Life Test[J]. Reliability and Environmental

Testing of Electronic Products, 2021, 39(01): 94-100.

Xiaopei Li, Fanchang Li, Helan Liang. A Tensor Decom-

position Imputation Algorithm for Bayesian Log-Nor-

mal Distribution[J]. Computer Applications and Soft-

ware, 2021, 38(07): 214-221.

Xu H Y, Fei H L. Planning step-stress accelerated life tests

with two experimental variables[J]. IEEE transactions

on reliability, 2007, 56(3): 569-579.

Yi Dai, Qin Liu. Reliability Evaluation Based on Survival

Analysis and Maximum Likelihood Method[J]. Com-

puter Integrated Manufacturing Systems, 2020, 26(11):

2976-2981.

Zhu Y, Elsayed E A. Design of equivalent accelerated life

testing plans under different stress applications[J].

Quality Technology & Quantitative Management,

2011, 8(4): 463-478.

U-Optimal Accelerated Life Test Scheme Considering Right Censored Data

533