The Design of DC Motor for Robotic Hand to Install Strain Clamp

Cover on Live Line Voltage 20,000 Volt

I Wayan Jondra, I Gede Suputra Widharma, I Gede Nyoman Suta Waisnawa,

Ni Putu Susri Apriliana Iriani and Ni Made Amustini

Electrical Department, Politeknik Negeri Bali, Jalan Kampus Bukit Jimbaran, Kabupaten Badung, Indonesia

Keywords: Motor, Mechanism, Robot.

Abstract: Economic activities that are: office activities, shops, factories/industries (small and large scale), malls,

households, all of them need electricity. Electricity is the foundation sector for achieving development goals,

such as creating job opportunities, increasing national income, changing the economic structure and

improving people's welfare. The distribution reliability index is calculated by value of SAIDI (System

Average Interruption Duration Index) and SAIFI (System Average Interruption Frequency Index). Thus, the

value of SAIDI and SAIFI must be minimized the outage as small as possible. To minimize planned power

outages or disturbances, robotic hands are needed to install distribution line accessories such as Strain Clamp

Cover on Live Line Condition. The Analysis finding the force to close the hand robot, need 8.23 Newton was

needed with a distance between the load and the hinge that are 0.262 meters. The electric motor is installed at

a distance of 0.088 meters from the hinge, required DC motor with power more than 24.5 watts. After

matching to the specifications of the existing motors, found a DC motor with performance 48 Watt, 12 Volt,

4 amperes. To control the DC motor, it is done with a 5 Amp capacity driver at a voltage of 12 Volts. The test

results found that the maximum current is 6.6 Amperes, without any failure of operation on the motor and

driver. This 48 watt DC motor supported by 5 amperes DC Controller that are available to drive the robotic

hand.

1 INTRODUCTION

Economic activities that are: office activities, shops,

factories/industries (small and large scale), malls,

households, all of them need electricity. The growth

in electrical energy as happened in China is

dominated by consumer growth in the housing sector

(Zhaoguang et al, 2014). Indonesia is also growing in

the use of electrical energy which is quite high.

Electricity is the foundation sector for achieving

development goals, such as creating job

opportunities, increasing national income, changing

the economic structure and improving people's

welfare (Santika, 2020). The distribution reliability

system has a vital need to keep electricity on for 24

hours a day. Thus, the value of SAIDI and SAIFI

must be minimized as small as possible.

The distribution reliability index is calculated by

value of SAIDI (System Average Interupption

Duration Index) and SAIFI (System Average

Interupption Frequency Index) as reliability

indicators. In most areas in Indonesia PLN has not

been able to meet SAIDI and SAIFI standards. To

minimize planned power outages or disturbances,

robotic hands are needed to install distribution line

accessories such as Strain Clamp Cover on Live Line

Condition.

For this robotic hand driver, a driving mechanic is

needed. Thus, this study discusses the driving

mechanics needed for this robotic hand driver. It takes

a mechanical drive with a low speed but has a hard

moment. The use of a speed reducer gearbox with a

speed ratio of 20:1 will result in an increase in force

of 1:20 (Sobhan, 2015). For the robot hand driver, a

DC electric motor will also be used which is equipped

with a gearbox. The problem is how much motor

power is needed and how to control the DC motor.

2 RESEARCH METHODE

2.1 Research Approach and Concept

This quantitative research approach study to find the

design of a electro mechanism to drive the robotic

232

Jondra, I., Widharma, I., Waisnawa, I., Iriani, N. and Amustini, N.

The Design of DC Motor for Robotic Hand to Install Strain Clamp Cover on Live Line Voltage 20,000 Volt.

DOI: 10.5220/0011756100003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 232-238

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

hands. This electro mechanism will move the robot's

hand to open and close then press the cover of the

strain clamp insulator, until it closes perfectly.

The concept of this research is to convert the

required mechanical compressive force at the end of

the pressure point into the required electric motor

power. Based on the power of the electric motor

needed, research on the needs of the motor driver and

microcontroller is needed.

The test of compressive force required the based

load point is carried out by giving the load at the

based load point gradually. The weight of the load at

the based load point in the time of the robot hand

closes the cover strain clamp completely, the weight

of the load is recorded and multiplied by the

acceleration / gravity of the earth as the required

compressive force. The performance test of the DC

motor and control on the robotic hand is done by

observed the voltage and current changes in the DC

motor every 4 seconds until the robotic hand closes

completely.

2.2 Total Sample

This research was conducted with 100% sample that

are 3 set of robotic hands, the collection was carried

out with a total of 30 data. To obtain these 30 data, it

was done by loading the water load repeatedly for 10

time for each sample until the cover strain clamp

closed completely. The total of the water weight plus

the container weight multiplied by the gravitational

force of the earth is recorded as the force required to

close the robotic hand.

Data on the test result of the performance of the

DC motor and control is done by observed voltage

and current in the DC motor every 4 seconds until the

robotic hand closes completely. So that for one

observation, 13 data were obtained for each sample

because the working time was 52 seconds, the total

data became 39 data for the three samples.

2.3 Variable Operational Definition

The focus of this study to observing the magnitude of

the indicators of this research, that are: force, voltage,

current, power and battery capacity. Voltage is

amount in volt of potential test voltage between two

terminal of motor DC. The current is amount in

ampere of electron flow from battery to the motor

DC. Power in watt or newton yang calculated to real

load on the base point of load. Battery capacity was

calculated to the battery insertion in to the robotic

hands.

2.4 Data Analysis

Data obtained from the test results and nameplate are

processed quantitatively. Data processed

mathematically and statistically by finding the data

variation on the step on each water filling. The data

are processed mathematically to obtain the voltage,

current and power at the initial of the test. The output

mathematically data is processed trough statistically

to obtain the average data, data sequence, which is

also displayed graphically.

3 FORCE, DC MOTOR, DRIVER

AND BATTERY

3.1 Force

Newton’s second law of motion points out the

magnitude of force when velocity of body move in

force is proportional to impressed force.

Mathematically, can be describe Force was change in

velocity. That issue is now second law of motion is

based on definition of equation of force is weigh

multiple with velocity for horizontal move, and with

earth gravitation for vertical move, that are as

describe on this formula in below (Sarma, 2017)

𝐹 = 𝑀. 𝑎

(1)

The formula above can be explained that the value

of the force (F) is determined by the mass value (M)

of the object multiplied by the acceleration (a). The

unit of force is measured in Newtons, the unit of mass

of an object is measured in Kg and the unit of

acceleration is measured in m/s

2

(Caldwell et al.,

2020)(Ariadi & Dinata, 2018).

3.2 DC Motor for Robotic

Direct Current Motor Trough electromagnetic

converts the direct current electrical energy to

mechanic energy(Qader, 2017). Electricity in a DC

motor is flowed into the field coil so as to produce

magnetic flux, electricity is also flowed through the

charcoal brush to the rotor coil, so that the rotor coil

produces a rotor field. The size of the mechanical

power produced by the electric motor is greatly

influenced by the size of the field coil and the rotor

coil, so that the larger the coil, the greater the current

that flows and so that the electrical power consumed

is greater, resulting in large mechanical

power(Iswanto et al., 2020).

The Design of DC Motor for Robotic Hand to Install Strain Clamp Cover on Live Line Voltage 20,000 Volt

233

To reverse the rotation of the rotor can be done by

reversing the incoming current to the DC motor

terminal, which was originally positive connected to

a negative voltage source, and vice versa the negative

one was connected to a positive voltage

source(Purnata et al., 2022). This reversal of the

motor terminals will result in the reverse direction of

the current entering the motor, so that the motor

rotation is reversed. This phenomenon occurs in

accordance with the law of the left hand which reads:

the index finger indicates the direction of the current,

the thumb indicates the direction of the pulsation, and

the other three fingers indicate the direction of the

field.

3.3 Driver

There are many ways to control a DC motor. DC

motors can be controlled by switches, contactors,

relay, or electronic switches such as SCR and so on.

The DC motor controller must have a capacity greater

than the nominal current of the DC motor. Starting

current affect to driving torque can overcome the load

torque from the rolling resistance, the motor will

already start rotating(Qader, 2017).

L298 Motor Driver is a module that is often used

to control DC motors or stepper motor(Peerzada et

al., 2021). By using the L298 Motor Driver easily

control both the speed and direction of rotation of 2

motors at once. The L298 Motor Driver is designed

using the L298 Dual H-Bridge IC. The Motor Driver

contains H-Bride logic gates which are already very

popular in the electronics world as controlling the

speed and direction of motor rotation.

3.4 Battery

Batteries is energy storage for portable electrical

equipment, as well as robotic. Batteries are the critical

component for portable electric robotic live, even if

they are not connected to electric energy source.

Lithium-based batteries have many advantages over

conventional batteries such as Nickel-Cadmium,

Nickel-Metalhydrate or Lead Acid (Knowles,

M.,2013). The advantages of Lithium-based batteries

are high energy density, high power density, low self-

discharge, fast charging, high mass-to-energy ratio,

no memory effect, long lasting if the charging process

is appropriate (Xiaopeng. C. et al.,2012). However,

Lithium-based batteries also have the disadvantage of

being less tolerant, so they require accurate

monitoring and protection procedures to ensure that

one of the battery cells does not overcharge, and

ensure that the battery does not overheat which can

reduce battery life (Ranjbar, A.H., et al.,2012).

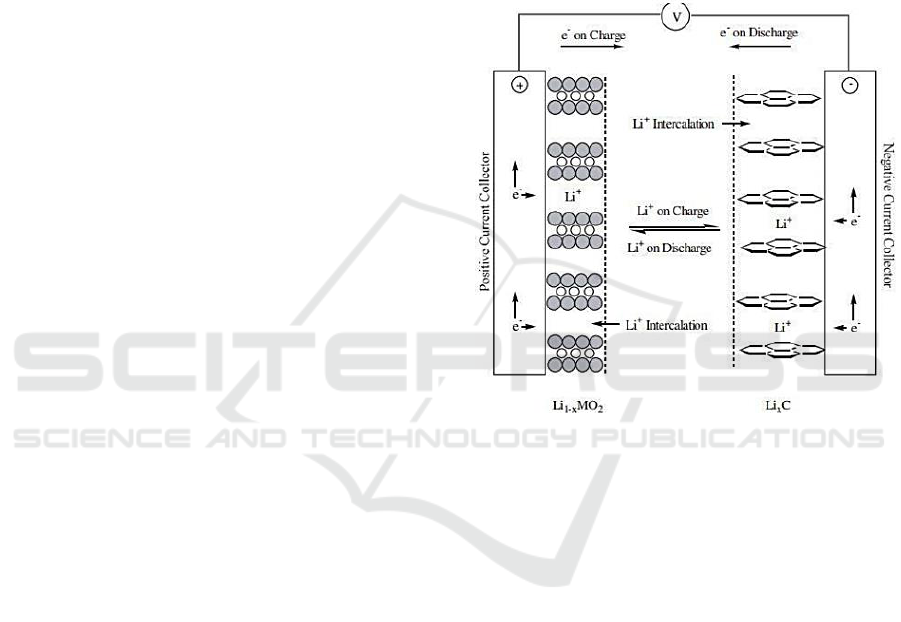

Nowadays Lithium-ion battery that is widely used

in electronic devices. The active electrode in a

Lithium-ion battery is lithium metal oxide for the

positive electrode while carbon is for the negative

electrode. This material contains a metal collector

current with a binder, usually polyvinylidene fluoride

(PVDF) or polyvinylidene fluoride-

hexafluoropropylene (PVDF-HFP) copolymer, and a

conductive diluent.

Figure 1: Electrochemical process in lithium-ion batteries.

The capacity of a battery is greatly influenced by

the quality of the material and the dimensions of the

material, so that in the same type it will appear that

the dimensions are larger for a larger battery capacity.

The capacity of the battery at a certain voltage will be

described by how much current can be stored by the

battery in ampere hours (ampere hours).

4 DC MOTOR AND CONTROL

DESIGN

4.1 DC Motor Design

The amount of DC motor power required to carry out

the robotic hand functions is influenced by the force

as the load of DC motor. The magnitude of the force

load of the DC motor (Newton) in the robotic hand is

influenced by three values, including: (1) the value of

the distance (meters) of the DC motor to the fulcrum,

(2) the value of the distance (meters) from the fulcrum

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

234

to the load point, and (3) the compressive force

(Newton) required by the load.

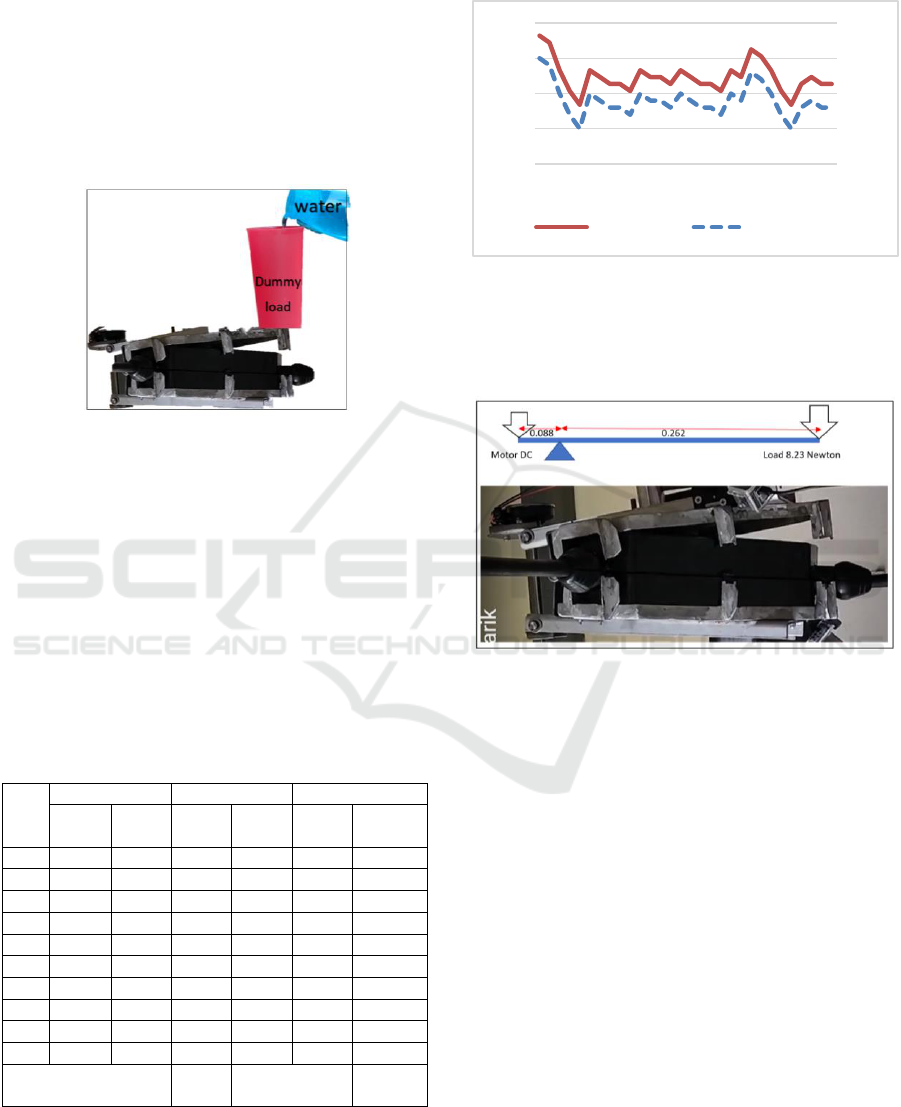

The required of compressive force of the robotic

hand to close the strain clamp cover is carried out by

tested using a dummy load by a water container. The

water container is placed at the end point of load from

the fulcrum. Water is poured into the container slowly

until the robotic hand closes to closes the strain clamp

cover. When the strain clamp cover is completely

closed, the water pouring is stopped.

Figure 2: Loading test.

The water and the container are taken from the

robotic hand to measured its weight. The weight of

the water and the container is multiplied by the earth's

gravity of 9.8 m/s2, then the value of the compressive

force required to closed the strain clamp cover

perfectly. The test results of three samples of robotic

hands, each sample was loaded 10 times, so that the

total data is 30 data were obtained. The data is

processed statistically, so the graph and the average

compressive force will be obtained. The test result

data can be shown in the table below.

Table 1: Force test result.

NO

Sample 1

Sample 2

Sample 1

Weigh

t (Kg)

Force

(N)

Weigh

t (Kg)

Force

(N)

Weigh

t (Kg)

Force

(N)

1

0.9

8.82

0.85

8.33

0.84

8.23

2

0.89

8.72

0.84

8.23

0.88

8.62

3

0.85

8.33

0.84

8.23

0.87

8.53

4

0.82

8.04

0.83

8.13

0.85

8.33

5

0.8

7.84

0.85

8.33

0.82

8.04

6

0.85

8.33

0.84

8.23

0.8

7.84

7

0.84

8.23

0.83

8.13

0.83

8.13

8

0.83

8.13

0.83

8.13

0.84

8.23

9

0.83

8.13

0.82

8.04

0.83

8.13

10

0.82

8.04

0.85

8.33

0.83

8.13

Average Weight (Kg)

0.84

Average Force

(Newton)

8.23

Based on the data at table 1, the data variation can

be describe by the chart at the figure 2 below. The

variation of the quality strain clamp cover affect to

the variation of weight of dummy load to get the

perfect closes.

Figure 3: Variation of loaded.

The placement of the DC motor and the load

point, carry out the load distributed can be explained

in the figure 3 below.

Figure 4: Robotic hand load distribution.

Like in the figure 3 can be describe (1) the value

of the distance of the DC motor to the fulcrum is

0.088 meters, (2) the value of the distance from the

fulcrum to the load point is 0.262 meters, and (3) the

required of compressive force is 8.23 Newton. Based

on this data, the DC motor power can be analysis

trough balance load principles, as describe at below.

F

1

xl

1

= F

2

x l

2

F

1

x0.008 = 8.23 x 0.262

F

1

= 8.23 x 0.262 / 0.008

F

1

= 24.5 Newton

Base on the calculation, to drive the robotic hand

the DC motor must be produce force more than 24.5

Newton, that are similar more than 24.5 watt, the

assumption is no friction loses.

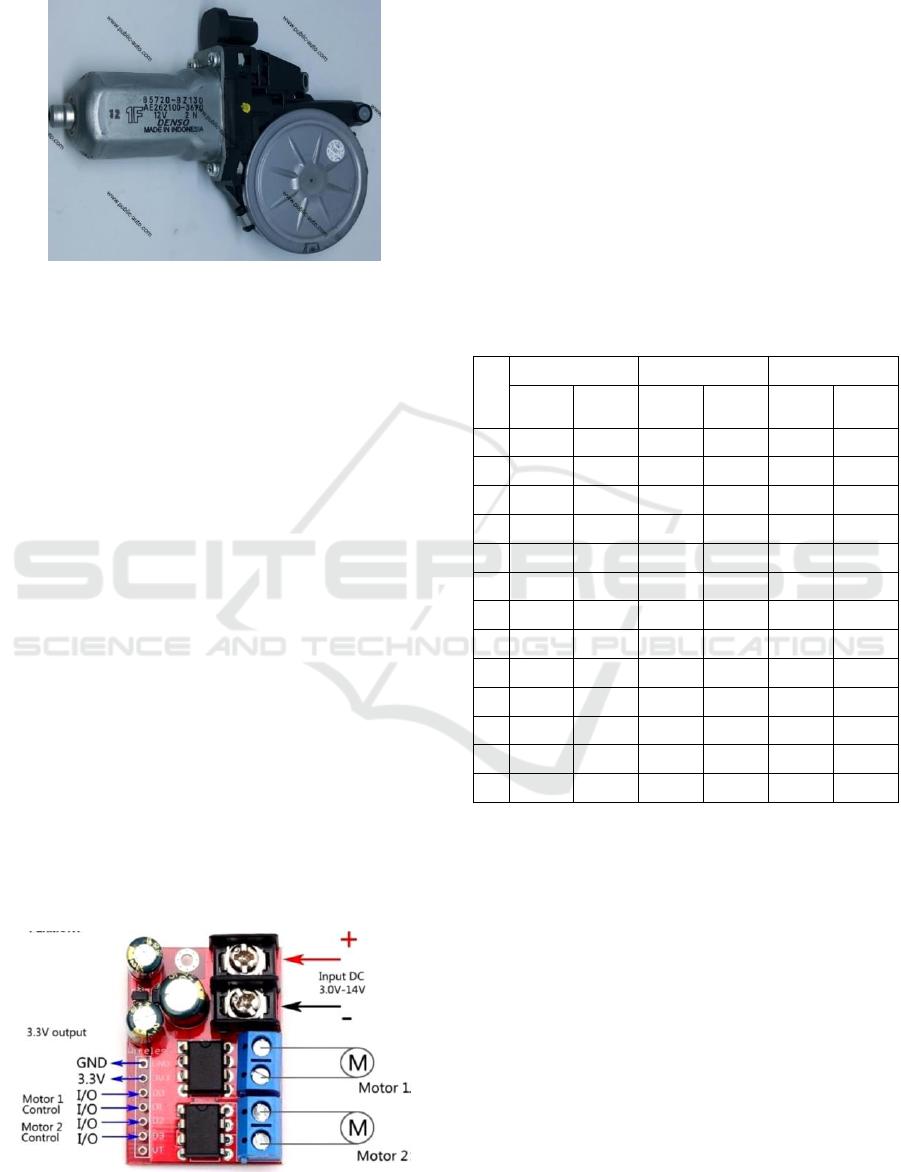

Based on the calculations above, for the robotic

hand driver, a motor above 24.5 watts is needed.

Found on the market a complete DC motor gearbox,

0,75

0,8

0,85

0,9

0,95

7,00

7,50

8,00

8,50

9,00

1 3 5 7 9 111315 17 19 21232527 29

FORCE (N) WEIGTH (Kg)

The Design of DC Motor for Robotic Hand to Install Strain Clamp Cover on Live Line Voltage 20,000 Volt

235

with a capacity of 48 watts, 12 volts, 4 amperes as

shown in the picture below.

Figure 5: DC motor 48 watts.

Based on the data shown in table 3 and graphs in

the figure 5, it appears that the DC motor electric

current shows an increasing trend in the process of

closing the robotic hand. The graph shows the electric

current soaring up at the end, because there is a

process of locking the strain clamp cover. The graph

also shows that the stress drops during the strain

clamp cover locking process.

4.2 Control Design

Based on the choice of the DC motor used to drive the

robotic hand, to determine the driver design, the

maximum DC motor current is calculated. The data

on the DC motor nameplate shows 12 volts of 48

watts (0.064 hp). The calculation of the maximum

motor current is calculated as below.

I = P/V

I = 48/12 = 4 Amperes

Taking the calculation results of the above, that

the nominal DC motor current is 4 amperes, the driver

to control it must have a capacity higher than 4

amperes. Searches in the market show 4 amperes

drivers which are easily available are drivers with a 5

amperes capacity, as shown in the image below.

Figure 6: DC motor controller l298.

5 RESULT AND DISCUSSION

The results of the research are shown in numbers

arranged in a table. The data from the test results are

discussed by mathematically and statistically

analysed, which is finally displayed in the form of a

graph.

5.1 Result

To drive the robotic hand, the gearbox motor is

coupled with a trapezoidal thread to propel the arm.

The performance tested of the DC motor in the

robotic hand, to determine the electric power

consumption.

Table 2: Voltage and current test result.

NO

Sample 1

Sample 2

Sample 1

Voltage

(V)

Current

(A)

Voltage

(V)

Current

(A)

Voltage

(V)

Current

(A)

1

5,3

1,34

5,4

1,35

5,2

1,38

2

9,6

1,34

9,6

1,35

9,7

1,34

3

9,7

1,7

9,8

1,7

9,8

1,7

4

9,6

1

9,7

1,2

9,6

1,23

5

9,8

1,68

9,8

1,68

9,9

1,66

6

9,6

1,9

9,6

1,9

9,6

1,9

7

9,7

1,66

9,8

1,68

9,8

1,68

8

9,5

1,7

9,5

1,7

9,6

1,65

9

9,6

1,8

9,6

1,8

9,7

1,78

10

9,5

1,79

9,4

1,81

9,5

1,78

11

9,1

2,1

9

2,3

9,2

2,26

12

9,5

2,15

9,4

2,17

9,6

2,14

13

6,5

2,69

6,7

2,66

6,6

2,68

5.2 Discussion

Observing the data in table 2, it is necessary to do

statistical processing, to find the average voltage and

current. The DC motor terminal voltage up and down

according to the magnitude of the load current at

every moment of the robotic hand closing process.

Each change in the voltage value of the three samples

is added up and then divided by three, then the

average voltage is obtained so do that for current

flowed to the DC Motors. The results of this

processing will contain 13 voltage data and 13 current

data, respectively. The data explained the

performance of DC motor to drive the robotic hands.

Through statistical processing, can be obtained the

data contained in table 3.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

236

Table 3: Current and voltage analysed.

NO

Average

Voltage

(V)

Current

(A)

1

5,30

1,36

2

9,63

1,34

3

9,77

1,70

4

9,63

1,14

5

9,83

1,67

6

9,60

1,90

7

9,77

1,67

8

9,53

1,68

9

9,63

1,79

10

9,47

1,79

11

9,10

2,22

12

9,50

2,15

13

6,60

2,68

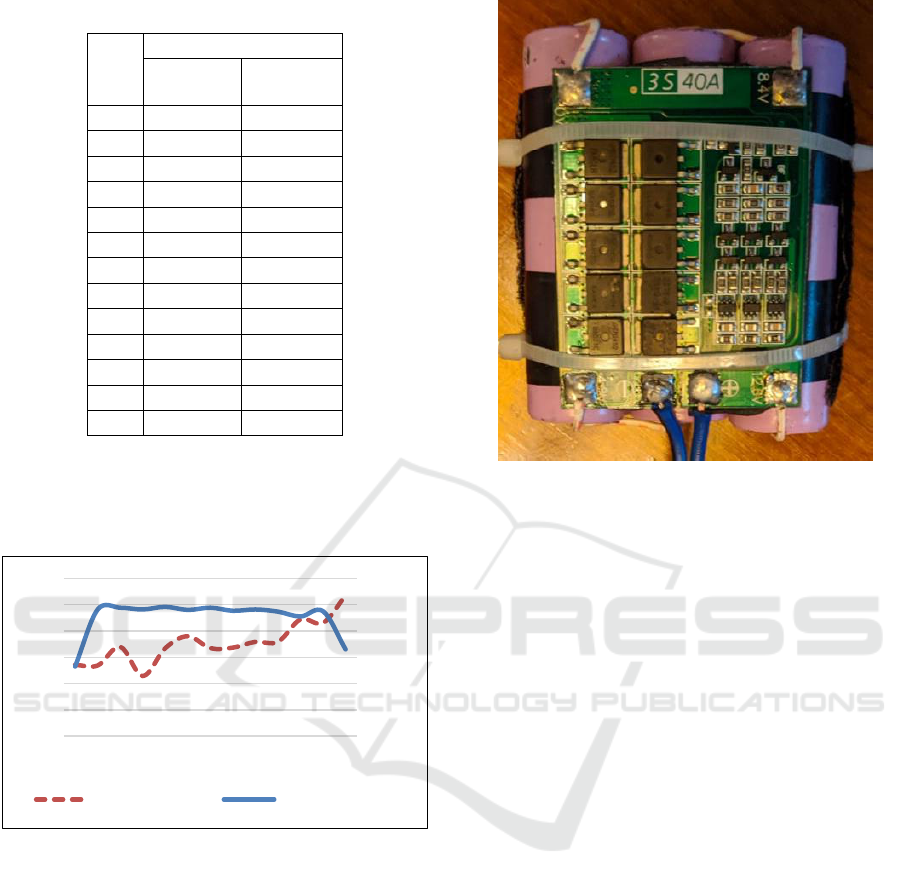

Based on the data at table 3, the data variation can

be describe by the chart at the figure 5 below. The

variation of the current affect to the voltage of battery

for every step of closing process.

Figure 7: Current trend.

The drivers l298 was installed to control DC

Motor, with a 5 amperes capacity, rated voltage 3

Volt up to 12 Volt. The choice of the l298 driver is

the right and safe choice. With a nominal current

capacity of 5 amperes, this driver will easily control a

DC motor that works with an average maximum

current of 2.8 Amperes.

To support the performance of this robotic hand,

3 pieces 4.5 Volt 3ah batteries are used, connected in

series. This battery was chosen because the DC motor

current is close to 3 amperes. With this battery, the

robotic hand will be able to operate for 45 minute

non-stop. This battery is also equipped with a battery

management system, with a nominal current

capability of 30 Amperes as shown in the image

below. Battery must be

Figure 8: Battery.

6 CONCLUSIONS

Based on the results of testing and analysis can be

concluded as follows:

1. To drive for robotic hand with 8.23 Newton

workload, are sufficient a DC motor 48 watts 12

volt.

2. Drivers at a capacity of 5 Amperes are sufficient

to controlled DC motor for a robotic hand with

a maximum working current of 2.98 Amperes.

3. The battery 12 volt, with a capacity of 3 ah, is

enough to supply 75% of its capacity to a DC

motor with a maximum operating time of 45

minutes non-stop.

ACKNOWLEDGEMENTS

This research was funded by Lembaga Pengelola

Dana Pendidikan dan Direktorat Jenderal Pendidikan

Vokasi Kementerian Pendidikan, Kebudayaan, Riset,

dan Teknologi Year 2021. We thank Project

Management Office of Domestic Vocational

Higher Education Program Implementation of the

Applied Scientific Research in 2021 for his support to

this research..

0,00

2,00

4,00

6,00

8,00

10,00

12,00

0,00

0,50

1,00

1,50

2,00

2,50

3,00

1 2 3 4 5 6 7 8 9 10 11 12 13

CURRENT (AMP) VOLTAGE (VOLT)

The Design of DC Motor for Robotic Hand to Install Strain Clamp Cover on Live Line Voltage 20,000 Volt

237

REFERENCES

Ariadi, P., & Dinata, C. (2018). Students’ Mental Model

About Newton’ S Third Law in Indonesia: Analysis and

Suggestion To Overcome It. Unnes Science Education

Journal (USEJ), 7(2), 146–155.

Caldwell, G. E., Robertson, D. G. E., & Whittlesey, S. N.

(2020). Forces and Their Measurement. In Research

Methods in Biomechanics (Issue March).

https://doi.org/10.5040/9781492595809.ch-004

Knowles, M. (2013). Through-life management of electric

vehicles. International through-life engineering

services conference, Procedia CIRP 11 (2013) 260 –

265 2nd.

Iswanto, Ma’arif, A., Puriyanto, R. D., Raharja, N. M., &

Rahmadhia, S. N. (2020). Arduino Embedded Control

System of DC Motor Using Proportional Integral

Derivative. International Journal of Control and

Automation, 13(4), 658–667.

Peerzada, P., Larika, W. H., & Mahar, A. A. (2021). DC

Motor Speed Control Through Arduino andL298N

Motor Driver Using PID Controller. International

Journal of Electrical Engineering & Emerging

Technology, 04(2), 21–24.

Purnata, H., Ramadan, S., Hidayat, M. A., & Maulana, I.

(2022). PID Control Schematic Design for Omni-

directional Wheel Mobile Robot Cilacap State of

Polytechnic. 12(2), 89–94.

Qader, M. R. (2017). Identifying the Optimal Controller

Strategy for DC Motors. IAES International Journal of

Robotics and Automation (IJRA), 6(4), 252.

https://doi.org/10.11591/ijra.v6i4.pp252-268

Ranjbar, A.H., Anahita Banei, Amir Khoobroo, and Babak

Fahimi. (2012) Online estimation of state of charge in

Li-Ion batteries using implse respone concept. IEEE

Transactions on Smart Grid, Vol. 3, No. 1. March 2012.

Santika Wayan G. TaniaUrme, elizSimseka, Parisa

A.Bahri, and M.Anisuzzaman. (2020) An assessment of

energy policy impacts on achieving Sustainable

Development Goal 7 in Indonesia. International Energy

Initiative. Volume 59, December 2020, Pages 33-48.

Published by Elsevier Inc. All rights reserved.

https://www.sciencedirect.com/science/article/pii/S097

3082620302921.

Sarma, A. (2017). TECHNOLOGY. International Journal

of Engineering Sciences & Research Technology,

6(12), 57–79

Sobhan, P. (2015). Design and Assembly of Worm Gear

Reducer. Global Journal For Research Analysis,

Volume-4, Issue-4, April-2015 • ISSN No 2277 - 8160

Xiaopeng. C., Weixiang Shen, Thanks Tu VO, Zhenwei

Caoi, and Ajay Kapoor. (2012). An overview of

lithium-ion batteries for electric vehicles. International

power & energy conference, December 2012.

Zhaoguang Hu, Xiandong Tan and Zhaoyuan Xu. (2014).

A Review of china’s economic development and

electricity consumption, An Exploration into China's

Economic Development and Electricity Demand by the

Year 2050. Cambridge: Elsevier Inc.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

238