Safety Integrated Level Analysis and Risk Management in Steam

Drum Based on the Octave Software

Hendrik Elvian Gayuh Prasetya, Muhammad Faldy Ortada and Radina Anggun Nurisma

Powerplant Engineering Department, Politeknik Elektronika Negeri Surabaya, Surabaya, Indonesia

Keywords: Safety Integrated Level, Octave, Steam Drum.

Abstract: As the Level of risk increase, better protection systems are needed to control them. One way to find out the

system's performance is Safety Integrated Level. SIL is a degree of SIF able to implement necessary risk

mitigation successfully. SIF comprises sensors, a Logic Solver, and final control elements. In this study, the

safety levels of the steam drums use the SIL method, with nodes studies on temperature, pressure, and levels.

The logic solver used a DCS solver, and Finale control elements used the main steam valve, valve separator,

and water steam valve. Calculate SIL value using Excel and Octave software. Octave software is used to

determine the level of safety on components automatically. The SIL calculations obtained a PFD value from

a sensor at 0.0242656, PFD from the logic solver at 0.01171875, and PFD from the final control element was

0031280256. Based on the PFD value that has been obtained, PFD would be quantified and average PFD

average by 0.067781661, thereby landing a risk reduction factor (RRF) of 14.75325. Drum steam can be

categorized as having a safety integrated level (SIL) 1. the level of safety on the steam drum component is

classified as safe. By consistently doing regular maintenance.

1 INTRODUCTION

A steam drum is one of the components of the water

pipes that serve as reservoirs of water and water vapor

and separate water vapor from water in forming

superheater steam. In the steam of the drums, water is

pumped by the boiler-circulation pump to the raisins

tube/wall tube to get to the saturation vapor phase

(Eliza Marceliana Zeinda,2017)

In Indonesia, job accidents occur in a plant

environment caused by workers and plant

components. According to the steam laws of 1930 and

law no. 1 in 1970 on job safety that companies using

the boilers were obliged to do an OHS program to

reduce the number of accidents. A company needs

protection and work in its business. So, it needs to

apply risk management (Steam laws Kemnaker,

1930).

Every power plant has a standard for

implementing risk management. It is critical because

it concerns the reliability of an instrumentation

system. As the danger is vital, better protection

systems must control it. One method used to

determine the performance is using the safety system

(SIL) method (Vimalasari,2016).

SIL is a degree of SIF able to implement necessary

risk mitigation successfully. The SIF of SIS is usually

composed of sensors, programmable logic breakers,

and late control elements (FCE). SIL herself refers to

the possibility of SIF failure (PFD). The higher the

SIL value, the PFD of SIS gets lower. The value of

PFD of each determines the SIL level of an SIS - each

SIF of the SIS itself, the sensors, logic solver, and

finale of element control (Fitrani Kamila,2016)

The safety integrated Level (SIL) is separated into

four levels based on IEC 61508, SIL 1, SIL 2, SIL 3,

and SIL 4. The above criteria, which is both

qualitative and quantitative, provides a foundation for

determining SIL in general. The important test

criteria of the products generated determine the

formulation of a category SIL evaluation. Fire,

materials quality, mechanical impact, electronic

operation, and leak tests are just a few examples

(Fitrani Kamila,2016).

This follows the need for a study to identify any

potential dangers to the system and is expected to be

able to recommend proper maintenance so that the

components in the system can function properly, can

identify a systematic operating process, and

determine any deviation in the process that could lead

to unwanted accidents or accidents.

278

Prasetya, H., Ortada, M. and Nurisma, R.

Safety Integrated Level Analysis and Risk Management in Steam Drum Based on the Octave Software.

DOI: 10.5220/0011759700003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 278-283

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

2 ANALYSIS METOD

2.1 Safety Integrated System

A Safety Instrument System is a collection of sensors,

logic solvers, and final parts designed to protect the

system in the event of a defiant operation without

endangering people, the environment, or a valuable

item

2.1.1 Sensor

The sensor is made up of several devices that monitor

the process, such as transmitters and transducers. The

sensor transforms physical data into electrical data

that can be evaluated with an electric circuit

2.1.2 Logic Solver

The logic solver is a processor that takes an electric

signal from one or more sensors and converts it into

electric signals that are supplied to the final element

2.1.3 Finale Control Element

The final control element is part of the SIS, and its

purpose is to act to return to a safe state. The valves

and actuators are the last component.

2.2 Safety Instrument Function

SIF refers to a set of tools designed to lower the risk

of a given danger. SIF is a non-profit organization.

When defined conditions are breached, automatically

bringing an industrial process to a safe state, allowing

a method to move forward safely when stated

conditions allow, and taking measures to reduce the

consequences of an industrial hazard. It consists of

elements that recognize an impending hazard, decide

to act, and then put in the necessary effort to bring the

process to a safe state.

2.3 Safety Integrated Level

SIL is a level of SIF that can successfully perform risk

mitigation. Sensors, programmable logic solvers, and

Finale Control elements are commonly found in the

SIS SIF (FCE). The Safety Integrated Level test is

used to determine whether a system is safe.

SIL ratings correlate to the frequency and severity

of hazards. They determine the performance required

to maintain and achieve safety and the probability of

failure. The higher the SIL, the greater the risk of

failure. And the greater the risk of failure, the stricter

the safety requirements.

The SIL value is calculated using maintenance

data for each piece of BPCS-related equipment. This

data on maintenance aids in determining the MTTF

(Mean Time to Failure).

While the failure rate is calculated using the

equation:

(1)

Then, after the failure rate is known, the PFD

value is calculated using the equation:

PFD=1/2 *λ*Ti (2)

where:

PFD = Probability of Failure on Demand

λ = failure rate (hour)

Ti = test interval (hour)

Table 1: SIL and required safety system performance low

demand mode system.

Safety

Integrated

Level (SIL)

Probability

Failure on

Demand (PFD)

Safety

Availability

(1_PFD)

Risk

Reduction

Factor (RRF)

4

0.0001 – 0.00001

99.99 –

99.999%

10000 –

100000

3 0.001 – 0.0001 99.9 – 99.99% 1000 – 10000

2 0.01 – 0.001 99 – 99.9% 100 – 1000

1 0.1 – 0.01 90 – 99% 10 – 100

Table 1 illustrates that the system's higher PFD

value necessitates a high level of safety. To put it

another way, the more serious the failure, the higher

the level of safety required to verify that the plan is

safe to use. It also demonstrates that the program

requires extra safety procedures to protect it from

failure.

Probability of failure on demand (PFD) is the

probability that a system will fail dangerously and not

be able to perform its safety function when required

Computing the PFD for each SIF made up of the

SIS and then calculating the overall PFD for the SIF

can be used to calculate the SIL. The following

equation is used to calculate the total PFD.

(3)

From the total it can be seen the value of risk

reduction factor, RRF as follows:

(4)

Safety Integrated Level Analysis and Risk Management in Steam Drum Based on the Octave Software

279

2.4 Octave

An octave is a GNU software used for numerical

analysis and is equivalent to MATLAB software

capabilities. This study uses octave software to

automatically perform calculations and determine the

steam drum's level of safety. Thus, choosing the SIL

level on the steam drum component.

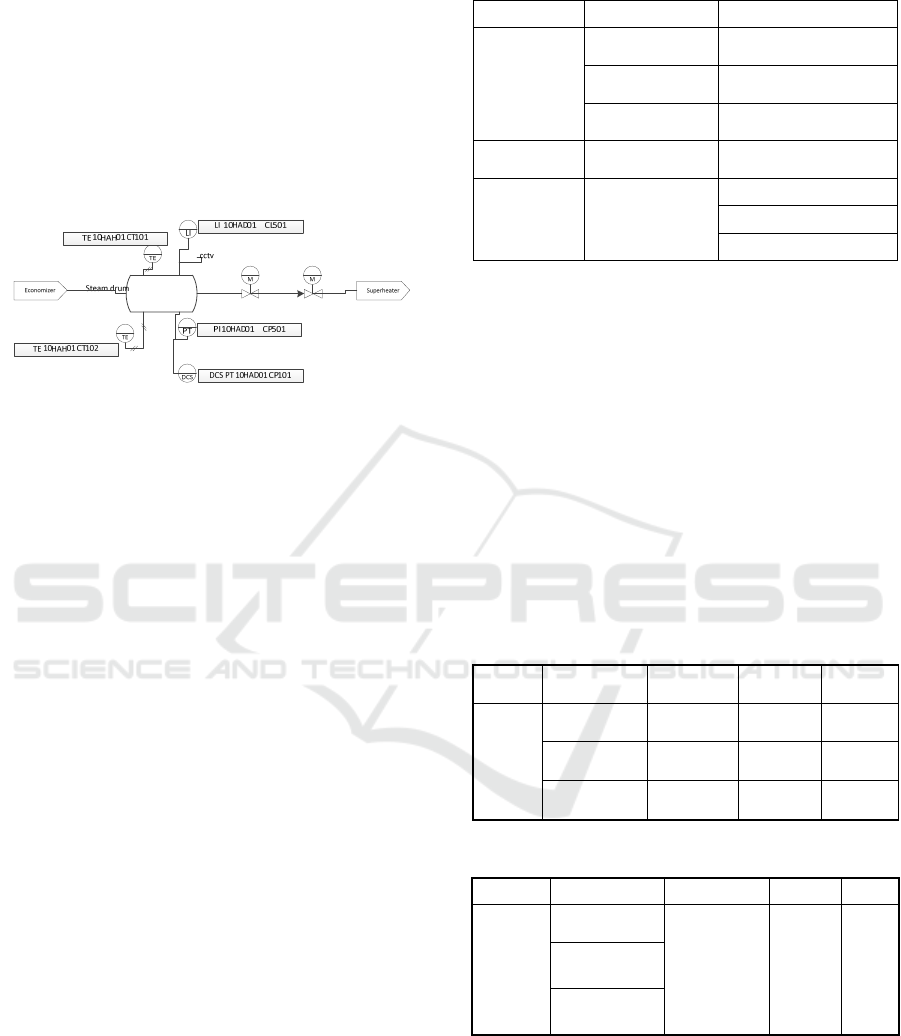

2.5 P&ID Steam Drum

Figure 1: P&ID steam drum.

P&ID (pipe and instrumentation diagram) is a

schematic of a process system's pipeline, equipment,

instrumentation, and control system. The picture

above shows several instrument temperatures,

pressures, and levels, with TE CT101 as the input

temperature sensor on the steam drum, which comes

from the economizer output temperature. The sensor

has CCTV, which functions to determine the value of

the sensor needed by the local operator to see its value

and the condition of the steam drum.

In addition, the steam drum also has a pressure

transmitter sensor at the steam drum's output to

determine the pressure value. And has a Level

indicator to find out how much % the condition of the

water level in the steam drum is. For the logic solver

on the Steam Drum, DCS sends signals to the PLC

and the CCR if there are other problems. After that,

the steam drum has several final control elements in

the form of valves such as the main steam valve,

water valve, and separator valve.

2.6 Study Node

The study node's determination is based on the

frequency of danger on the steam drum in the form of

sensors, logic solver, and Finale control element. The

resolution of the study node is obtained from the

steam drum maintenance data.

Table 2: Study node steam drum.

SIS Component Component

Sensors

TE 10HAH01

CT101

TE 10HAH01 CT101

LI 10HAD01

CL501

LI 10HAD01 CL501

PI 10HAD01

CP501

PI 10HAD01 CP501

logic solver

DCS PT

10HAD01 CP101

DCS PT 10HAD01

CP101

finale control

element

actuator

Main Steam Valve

Valve separator

Water Steam Valve

3 SIL CALCULATION

3.1 Sensor

According to the study node data received from the

steam drum maintenance data, the steam drum

includes three sensors: a temperature sensor, a

pressure sensor, and a level sensor. The sensor has

been repaired, and the Time to Failure has been

calculated (TTF). The value of the Mean Time to

Failure (MTTF) can be calculated using the TTF data,

and then used to calculate the PFD value and failure

data.

Table 3: Safety integrated level sensors.

SIS components MTTF

Failure

Rate

PFD

sensor

TE 10HAH01

CT101

5772 0.000173 0.008316

LI 10HAD01

CL501

5816 0.000172 0.008253

PI 10HAD01

CP101

5844 0.000171 0.008214

Table 4: Safety integrated level sensors.

SIS components PFD average RRF SIL

sensor

TE 10HAH01

CT101

0.024783 40.3508 1

LI 10HAD01

CL501

PI 10HAD01

CP101

The MTTF value for each sensor is different,

according to the equations above. The temperature

sensor measures 5772, the pressure sensor measures

6816, and the level sensor measures 5844. The failure

rate values of each temperature sensor, pressure

sensor, and level sensor are 0.000173, 0.000172, and

0.000171, respectively, based on the computation (1)

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

280

to estimate the failure rate value. After obtaining the

failure rate, we can use the formulas (2) to compute

the PFD and RRF for each sensor (4). The sensors

system can be classified into SIL 1 with a PFD

average value of 0.024783 and RRF 40.3508

3.2 Logic Solver

This steam drum uses a logic solver distributed

control system (DCS). DCS is an integrated system

using controllers, communication, protocols, and

computer that can make it easier for users to control

equipment using analog or digital signals from a

control room.

The programmable logic controller (PLC) and

other controllers are under DCS. So, this SIF is very

crucial. If it is damaged, it can result in a data signal

not being sent to the control room.

Table 5: Safety integrated level logic solver.

SIS component MTTF Failure Rate

PFD

logic

solver

DCS PT

10HAD01 CP101

4096 0.000244

0.011719

Table 6: Safety integrated level logic solver.

SIS component

PFD

average

RRF SIL

logic

solve

r

DCS PT

10HAD01 CP101

0.011719 85.33333 1

After performing calculations based on

maintenance data, the MTTF value in the logic solver

is 4096. Based on the above calculations, the

following PFD and RRF values are obtained

0.011719 and 85.333. So, the logic solver can be

categorized into SIL 1.

3.3 Final Control Element

The final element is part of the SIS, and its purpose is

to act to return to a safe state. The valves and

actuators are the final element. The main steam valve,

water valve, and separator valve are the final control

elements in the steam drum.

Based on the calculation of the MTTF value, the

MTTF of each FC is different. The failure value in

FCE is obtained from the maintenance data, such as

preventive maintenance data and damage in FCE.

After getting the MTTF value, can receive each FCE

component's PFD value to find the PFD average value

and the RRF value on the FCE. Based on these

calculations, it was found that the average PFD value

is 0.03128, and the RRF value is 31.96905 so, so the

FCE can be categorized into SIL 1.

Table 7: Safety integrated level finale control element.

SIS components MTTF

Failure

Rate

PFD

finale

control

element

Main Steam

Valve

5160 0.000194 0.009302

Valve separator 3569 0.00028 0.013449

Water Steam

Valve

5628 0.000178 0.008529

Table 8: Safety integrated level finale control elements.

SIS

components PFD average RRF

SIL

finale

control

element

Main Steam

Valve

0.03128 31.96905

1

Valve

separato

r

Water Steam

Valve

3.4 Safety Integrated Level Steam

Drum

The value of the Safety Integrated Level (SIL) can be

computed based on the failure data that happens in the

instrument on the Steam Drum component to identify

the level of safety on the Steam Drum component and

the PFD (Probability Failure Demand) value.

Table 9: Safety integrated level on the steam drum.

SIS components MTTF

Failure

Rate

PFD

Sensor

TE 10HAH01 CT101 5772 0.000173 0.008316

LI 10HAD01 CL501 5816 0.000172 0.008253

PI 10HAD01 CP101 5844 0.000171 0.008214

l

ogic solve

r

DCS PT 10HAD01 4096 0.000244 0.011719

finale

control

element

Main Steam Valve 5160 0.000194 0.009302

Valve separator 3569 0.00028 0.013449

Water Steam Valve 5628 0.000178 0.008529

Table 10: Safety integrated level on the steam drum.

SIS component

PFD

average

RRF SIL

Sensor

TE 10HAH01 CT101

0.067782 14.75325 1

LI 10HAD01 CL501

PI 10HAD01 CP101

logic solver DCS PT 10HAD01 CP101

f

inale contro

l

element

Main Steam Valve

Valve separator

Water Steam Valve

Safety Integrated Level Analysis and Risk Management in Steam Drum Based on the Octave Software

281

From the SIL calculation, it is found that the PFD

value of the sensor is 0.024782656, the PFD of the

logic solver is 0.01171875, and the PFD of the final

control element is 0.031280256. Based on the PFD

value that has been obtained, could add up the PFD,

and the average PFD value is 0.067781661 so that the

risk reduction factor (RRF) value is 14,75325. Steam

Drum can be categorized as having a safety integrated

level (SIL) I.

SIL 1 is the best level of security because if the

SIL is high, the risk of failure is high. SIL level power

plant is specific that SIL 1 has a lower risk of failure

compared to other plants such as nuclear. This SIL

calculation can contribute to the powerplant by

knowing the safety level of these components. So that

SIL 1 on the steam drum component needs to be

maintained. The value of SIL on the steam drum

component can be added by adding a system with

safeguards and SIS so that if the system experiences

damage that cannot be handled, the system can still

be repaired.

3.5 Prevention

A step done to avoid failure is prevention. To avoid

failure, there are four types of layers. The following

is a list of preventative categories:

3.5.1 BPCS

Normal Process Control System is a basic process

control system that includes normal processes.

During normal functioning, manual control is the

first line of defense. The BPCS is intended to keep the

process running safely. If it fits the conditions, a

regular operation BPCS control loop can be credited

as an IPL.

3.5.2 Alarm

The alarm is not included in the IPL in terms of

practical functionality. Alarms, on the other hand,

should notify the operator if a failure happens,

therefore the alarm may be significant because the

operator could not respond if the layer is not

triggered.

3.5.3 Operator

The operator is someone who oversees and manages

the process. In this instance, the operator could

assume responsibility for restoring the plant to a safe

operating condition in the event of a failure. When the

BPCS system fails, the operator's function as the IPL

is critical for operators to maintain control.

3.5.4 SIS

When the BPCS and the operator fail to take over and

restore a safe condition, the SIS could be activated.

The SIS system runs on its own, with no intervention

from the operator. In situations where the tolerance is

exceeded, the system could actively safeguard you

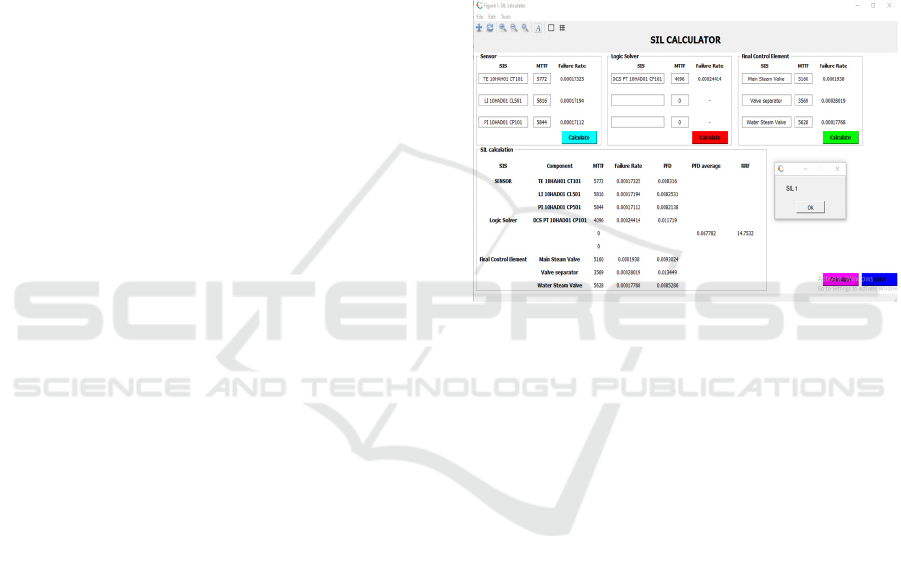

3.6 SIL Calculator Octave

This study uses octave software to perform

calculations automatically and determine the steam

drum's level of safety.

Figure 2: Sil Calculator.

To determine the value at the safety level for the

component, first, fill in the MTTF value for each SIS

and then calculate. Then the value from the

calculation will be called back to the SIL calculation.

If all the values are fulfilled, then by pressing the

calculate push button below, it will automatically

determine the safety level on the component via the

message box.

4 CONCLUSIONS

Based on the data obtained and analyzed. The

following are the findings of this research as SIL 1

includes steam drum components with SIF sensors,

DCS, and Finale control features. The approach of

substituting the failure rate of a small component in

SIL calculations, notably by changing the TI value

(time interval) and can also design a re-architecture

of the Steam drum system, is one way to raise the

level of safety. and the use of the SIL calculator

makes it easier to analyze the value of safety on

components

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

282

REFERENCES

Syahnanda, A. W., Permatasari, P. D., & Prasetya, H. E. G.

(2021, September). Design of Steam Power Plant

Condenser Machine Maintenance Using RCM

(Reliability Centered Maintenance) Methods with

RCPS Implementation. In 2021 International

Electronics Symposium (IES) (pp. 458-463). IEEE.

Faqih, M., Arini, N. R., & Prasetya, H. E. G. (2021). The

Development of A Reliability Evaluation Application

for Power Plant Steam Turbine Vibrations to Predict Its

Failure. EMITTER International Journal of

Engineering Technology, 9(2), 268-282.

Muqauwim, M. F., Prasetya, H. E. G., & Nurisma, R. A.

(2020, September). Analysis of Optimal Maintenance

Interval on ID Fan Using Reliability Centered

Maintenance. In 2020 International Electronics

Symposium (IES) (pp. 48-53). IEEE.

Rahmania, W. S., Prasetya, H. E. G., & Sholihah, F. H.

(2020, September). Maintenance Analysis of Boiler

Feed Pump Turbine Using Failure Mode Effect

Analysis (FMEA) Methods. In 2020 International

Electronics Symposium (IES) (pp. 54-59). IEEE.

Eliza Marceliana Zeinda, (2017) Sho’im Hidayat, “risk

assessment kecelakaan kerja pada pengoperasian boiler

di pt. indonesia power unit pembangkitan semarang”,

Vimalasari, T. (2016). Hazard And Operability Study

(HAZOP) Dan Penentuan Safety Integrity Level (SIL)

Pada Boiler SB-02 PT. Smart Tbk Surabaya (Doctoral

dissertation, Institut Teknologi Sepuluh Nopember).

Musyafa’, A., Nuzula, Z. F., & Asy’ari, M. K. (2019,

March). Hazop evaluation and safety integrity level

(SIL) analysis on steam system in ammonia plant

Petrokimia Gresik Ltd. In AIP Conference Proceedings

(Vol. 2088, No. 1, p. 020029). AIP Publishing LLC.

Nur, M. (2019). Usulan Perbaikan Sistem Manajemen

Keselamatan dan Kesehatan Kerja (SMK3) sebagai

Upaya Meminimalisir Angka Kecelakaan Kerja

Menggunakan Metode HAZOP (Studi Kasus: PT.

XYZ). SPECTA Journal of Technology, 3(3), 1-10.

Fitrani Kamila (2016) Penentuan Safety Integrity Level

Dengan Menggunakan Metode Layer of Protection

Analysis Pada Floating Regasification Unit

Safety Integrated Level Analysis and Risk Management in Steam Drum Based on the Octave Software

283