Melon Diameter Estimation for Sorting System Based on

Image Processing

Syamsiar Kautsar

1

, Budi Hariono

2

, Rizza Wijaya

2

, Aulia Brilliantina

2

, Elok Kurnia Novita Sari

2

,

Risse Entikaria Rachmanita

1

and Muhammad Yunus

3

1

Department of Engineering, Politeknik Negeri Jember, Indonesia

2

Department of Agricultural Technology, Politeknik Negeri Jember, Indonesia

3

Department of Health, Politeknik Negeri Jember, Indonesia

budihariono1966@gmail.com

Keywords: Melon, Image Processing, RGB, Diameter.

Abstract: Human visual perception of melon quality is complex because it depends on many internal and external

factors. One critical internal factor is each farmer's visual perception, which usually varies. Sorting is choosing

between good yields and poor yields. While grading is the grouping of harvested crops that have been sorted.

Sorting and grading depend on market demand. The Sorting Equipment was measured w x l x h = 100cm x

60cm x 100 cm and is made of an aluminum frame and covered by a red polycarbonate board. Inside the

sorting box, two cameras are pointing at a melon cup. The melon cup consists of a circular board connected

to a servo motor so that it can rotate the melon position. It aims to obtain several shooting angles for the test

data. 3 LED lights lead to the melon container at an angle of 45 degrees with a distance of +-60 cm. Based on

the research that has been done, the results of the estimated diameter after testing have a deviation of 1.32 cm.

1 INTRODUCTION

Melon is a fruit plant belonging to the Cucurbitaceae

family, melon fruit comes from the Persian Hot

Valley or the Mediterranean area, which is the border

between West Asia and Europe and Africa, so this

plant can be widely spread to the Middle East and

Europe. In the 14th century, melons were brought to

America by Columbus and are commonly grown in

Colorado, California, and Texas. Finally, melons

spread worldwide, especially in tropical and

subtropical areas, including Indonesia. Melon is an

annual plant that grows creeping, similar to the

cucumber plant. But in its cultivation, melon plants

can be propagated on bamboo poles (ajir) (Kim K

Kim K Kim H and Lee K, 2006).

Human visual perception of melon quality is

complex because it depends on many internal and

external factors. One critical internal factor is each

farmer's visual perception, which usually varies

(Tournier J, 2019).

While the external factor is the object's

composition in relation to light reflection,

environmental lighting, illumination distance and

angle, and viewing position. Postharvest handling

involves collecting, sorting, classifying, packaging

and storing fruit based on predetermined sizes and

quality standards. The steps for each post-harvest

activity are as follows (Droby S and Wisniewski M,

2018):

a) Collection

The melons that have been harvested are collected in

one place to be sorted immediately. Transport from

the farm to the collection point must be carried out

carefully.

b) Sorting and Classing (Grading)

Sorting is choosing between good yields and poor

yields. While grading is the grouping of harvested

crops that have been sorted. Sorting and grading

depend on market demand. The elements to be

considered in sorting/selection (Dewi T Risma P and

Oktarina Y, 2020).

After sorting, melons are then grouped and

weighed for grading based on fruit weight and

physical appearance. The classification of melons is

divided into three classes. Meanwhile, young,

overripe, bruised, deformed and other fruits are

classified as off-grade (outside class). Consumer

Kautsar, S., Hariono, B., Wijaya, R., Brilliantina, A., Sari, E., Rachmanita, R. and Yunus, M.

Melon Diameter Estimation for Sorting System Based on Image Processing.

DOI: 10.5220/0011761700003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 295-299

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

295

perception is important to be fulfilled, so the results

of agriculture and plantations must be adjusted to the

standard (Kurnianto M Wibowo M Hariono B Wijaya

R and Brilliantina A, 2020).

2 RELATED WORK

An image is a two-dimensional Value function f (x,y),

where x and y are spatial coordinates and f at a point

(x,y) is the brightness level of an image at a point. An

image is obtained from capturing the strength of the

light reflected by the object. The image as the output

of the recording device can be an analog or a digital

image. Digital image processing is a process that aims

to manipulate and analyze images with the help of

computers. The analysis process in image processing

involves visual perception with input data and output

data obtained in the form of images of the observed

object. Image processing techniques can include

several aspects such as image sharpening,

highlighting specific features of an image, image

compression, and correction of out-of-focus or blurry

images (Chen H, 2021).

The step in digital image processing begins with

capturing or capturing images (image acquisition)

using sensors in the form of cameras, scanners, etc.

Then proceed with the preparation process

(preprocessing), such as the process of changing the

size (image resizing) or quality improvement (image

enhancement) before finally being used for a specific

purpose. The next step is to divide the image into its

constituent parts (segmentation). This process is done

to separate the desired object apart from other objects.

Because the result of the segmentation process is the

boundaries between the object to be observed further

with other objects, it is necessary to make further

observations (representation and description) to show

that the area within the boundary is the actual object

being observed. The last stage of image processing is

recognition and interpretation and interpretation).

Recognition is the process of assigning a label to an

object based on the information provided by its

descriptor. In contrast, interpretation includes giving

meaning to an object, a set of recognizable objects.

Image classification can use various algorithms,

such as KNN (Z E Fitri A Baskara A Madjid A M N

Imron, 2022), or Neural Network (R Y Adhitya A

Khumaidi S T Sarena S Kautsar B Widiawan and F L

Afriansyah, 2020). An artificial neural network

(ANN) is a network of a group of small processing

units modeled based on a human neural network.

ANN is an adaptive system that can change its

structure to solve problems based on the information

flowing in the network. One part that needs to be

considered in using ANN is the selection of training

methods and ANN architecture. An ANN architecture

that is too small will result in poor problem modeling,

while an ANN that is too large will cause over-fitting

and long computation time (Wijaya R Hariono B

Saputra T W and Rukmi D L, 2020).

3 SYSTEM DESIGN

The Sorting Equipment was measured w x l x h =

100cm x 60cm x 100 cm and is made of an aluminum

frame and covered by a red polycarbonate board.

Inside the sorting box, two cameras are pointing at a

melon cup. The melon cup consists of a circular board

connected to a servo motor so that it can rotate the

melon position. It aims to obtain several shooting

angles for the test data. 3 LED lights lead to the melon

container at an angle of 45 degrees with a distance of

+-60 cm. The lamp power supply uses a variable

power supply to regulate the light intensity in the

sorting box. This aims to get the right light for

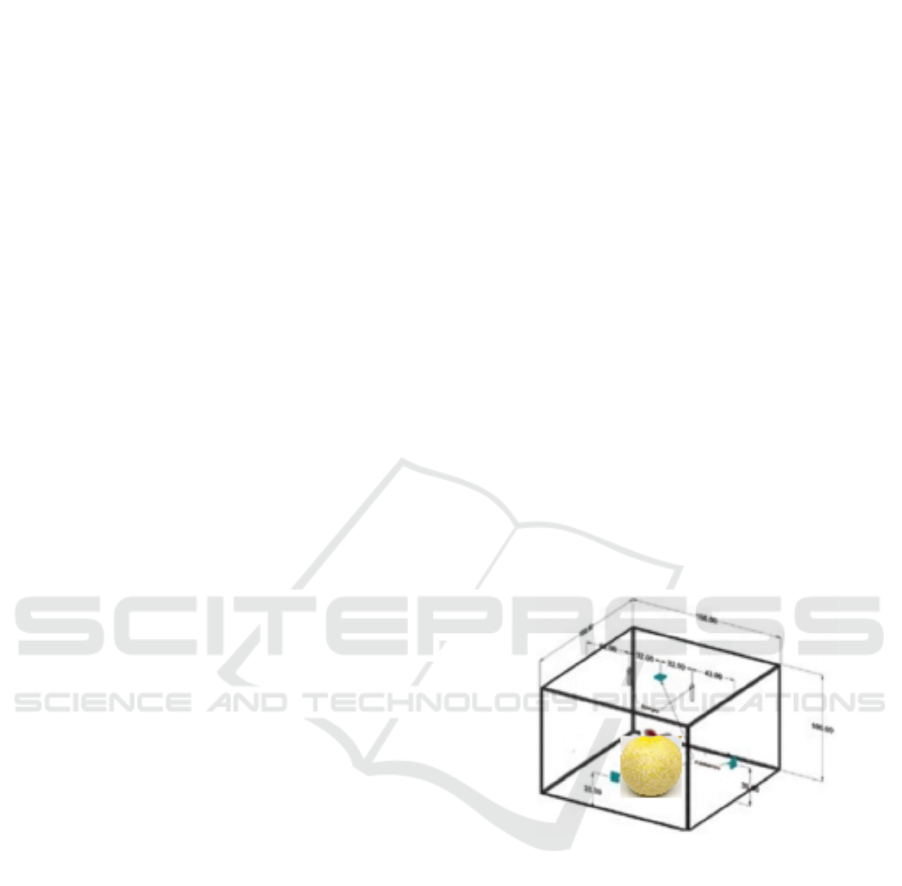

shooting in an enclosed space. Figure 1 is a sorting

box design.

Figure 1: Sortir system design.

Taking pictures using 2 Logitech C922 cameras

with HD 1080P video specifications at 30Fps/720P at

60FPS. 1 camera to take side view pictures, and

another to take top view pictures. An ATMega328

microcontroller is also connected serially to the

computer to adjust the servo working angle on the

melon dish. The computer for image processing has

1GB of Intel Core i5 graphics specifications and 8GB

of RAM. Figure 2 is a system block diagram of the

sorting system used on this paper.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

296

Figure 2: Block Diagram System.

The captured image has a resolution of 640x480.

Image processing for diameter estimation consists of

several stages. The first is capturing & saving images.

After that, the image will be cropped according to the

melon position in the image. The cropped image is

converted to an HSV image. HSV(Hue, Saturation,

Value) is a component that represents the color of

visible light wavelengths (red, orange, yellow, green,

blue, purple). The advantage of HVS is that it consists

of the same colors that are captured by the human

senses. In comparison, the colors formed by other

models such as RGB result from a mixture of primary

colors. The RGB to HSV conversion process uses

equation 1 (Abdulrahman A A Rasheed M and Shihab

S, 2021) (Suryaningsih W Bakri A Kautsar S Hariono

B Brilliantina A and Wijaya R, 2022).

(1)

Gradient separation is performed based on the

min-max HSV value. It aims to obtain the threshold

value for color cropping. After the HSV limit is

determined, the appropriate pixel classification is

carried out to display the circle shape as an estimate

of the diameter in the main image. Figure 3 is a

programming flowchart in this study. The

programming language used is python with additional

OpenCV features for image processing

(Abdulrahman A A Rasheed M and Shihab S, 2021).

Figure 3: Flow Chart Melon Sortation.

4 RESULT AND DISCUSSION

4.1 Hardware Realization

Figure 4 is the result of making a sorting box used to

identify melons. The choice of red color aims to

obtain a contrasting background with the color of the

melon dominated by green to facilitate image

processing. In the early stages of testing the servo

performance based on the input value from the PC.

An image data retrieval program was created based

on angles of 0

o

, 30

o

, 60

o

, 90

o

, 120

o

, 150

o

, and 180

o

simultaneously. Figure 5 shows the image's data

based on the different servo angles. Based on Figure

5, the servo can work according to the given value.

Figure 4: Machine Hardware.

Figure 5: Capture test result.

Melon Diameter Estimation for Sorting System Based on Image Processing

297

4.2 Calibration

Image calibration is performed. It aims to compare

the pixel size to the actual distance. Calibration of the

image using a board equipped with a line 24 cm long.

The board is placed in the center of the melon cup.

Capture images on each camera and then the

calibration process is carried out. Figure 6 is an image

during the calibration process.

Figure 6: Calibration process.

Based on the obtained pixel value, on the top

camera, 24 cm in actual distance is represented by

182 pixels. Using the linear equation according to

equation 2, we get an equation to calculate the actual

distance to the camera as in equation 3.

(2)

𝑑𝑖𝑎𝑚𝑎𝑡𝑒𝑟 0,132 ∗ 2 ∗ 𝑟𝑎𝑑𝑖𝑢𝑠

(3)

The last stage is creating an if then rule for

determining the diameter of the melon. If the diameter

estimate is less than the threshold, the rejected status

will appear on the screen. Figure 7 is the result of

melon image processing to determine the size of the

melon diameter according to the sorting limit (use the

diameter limit of 17cm). 10 melons were used for

testing (figure 8) with accurate sizes as shown in table

1. Based on the test results, the system can work

according to the settings made in the shortener

application. However, there is a difference in the

diameter estimation through image processing and

direct measurement using a ruler. This is due to the

fruit contour not being fully moon, while image

processing takes the diameter from the outermost

radius point of the melon. However, for the sorting

process, the user can set the minimum diameter size

through the application so that the sorting process can

be done flexibly.

a)

b)

Figure 7: a) melon with diameter <17cm, b) melon with

diameter >=17cm.

Figure 8: Melon for testing.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

298

Table 1: Diameter Estimation Data.

Data Circumfer

ence (cm)

d = Cir / pi

(cm)

Estimation

Diameter (by

p

icture - cm)

Deviation

(cm)

1 53 16,88 17,96 -1,08

2 52 16,56 17,8 -1,24

3 50 15,92 17,76 -1,84

4 48 15,29 15,6 -0,31

5 45 14,33 15,39 -1,06

6 55 17,52 18,93 -1,41

7 50 15,92 17,88 -1,96

8 48 15,29 17,01 -1,72

9 47 14,97 16,09 -1,12

10 49 15,61 17,11 -1,50

average -1,32

5 CONCLUSIONS

Based on the research, the results of the estimated

diameter after testing have a deviation of 1.32 cm.

The algorithm can detect fruit with gradations of

green to yellow (depending on the level of fruit

maturity). However, the error in the estimation of

diameter measurement is even more significant if the

contour of the melon is not ideally round. In future

research, additional algorithms are needed to process

uneven contours.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the financial

support of this work by grants from PNBP, State

Polytechnic of Jember. The author also thanked the

P3M and Information Technology Department, State

Polytechnic of Jember, which has supported and

assisted in completing this research.

REFERENCES

Kim K Kim K Kim H and Lee K, 2006 Risk Assessment

and Symptoms of Musculoskeletal Disorders in Melon

Farm Workers 4, 4 p. 385–397.

Tournier J et al., 2019 for medical image processing and

visualisation MRtrix3 : A fast , flexible and open

software framework.

Droby S and Wisniewski M, 2018 Postharvest Biology and

Technology The fruit microbiome : A new frontier for

postharvest biocontrol and postharvest biology

Postharvest Biol. Technol. 140, March p. 107–112.

Dewi T Risma P and Oktarina Y, 2020 Fruit sorting robot

based on color and size for an agricultural product

packaging system 9, 4 p. 1438–1445.

Kurnianto M Wibowo M Hariono B Wijaya R and

Brilliantina A, The Analysis of Consumer Perception

on Quality of Soybean Milk Used Importance

Performance Analysis Method The Analysis of

Consumer Perception on Quality of Soybean Milk Used

Importance Performance Analysis Method p. 0–7.

Chen H et al., Pre-Trained Image Processing Transformer

p. 12299–12310.

Wijaya R Hariono B Saputra T W and Rukmi D L, 2020

Development of plant monitoring systems based on

multi-camera image processing techniques on

hydroponic system IOP Conf. Ser. Earth Environ. Sci.

411, 1.

Abdulrahman A A Rasheed M and Shihab S, 2021 The

Analytic of Image Processing Smoothing Spaces Using

Wavelet The Analytic of Image Processing Smoothing

Spaces Using Wavelet.

Suryaningsih W Bakri A Kautsar S Hariono B Brilliantina

A and Wijaya R, 2022 Prototype of Integrated Mini

Exhausting System for Fish Canning Process IOP Conf.

Ser. Earth Environ. Sci. 980, 1.

Z E Fitri A Baskara A Madjid A M N Imron, 2022

Comparison of Classification for Grading Red Dragon

Fruit JURNAL NASIONAL TEKNIK ELEKTRO 11, 1 p.

43-49, doi:10.25077/jnte.v11n1.899.2022

R Y Adhitya A Khumaidi S T Sarena S Kautsar B

Widiawan and F L Afriansyah, 2020 Applied Haar

Cascade and Convolution Neural Network for

Detecting Defects in The PCB Pathway International

Conference on Computer Engineering, Network, and

Intelligent Multimedia (CENIM), p. 408-411, doi:

10.1109/CENIM51130.2020.9297996.

Melon Diameter Estimation for Sorting System Based on Image Processing

299