Smart Control Ice Tube Machine Using PLC and HMI with

Superheat Method Based on Compressor Low Pressure Parameters

Basuki Winarno, Budi Triyono, Yuli Prasetyo, Agus Choirul Arifin, Yoga Ahdiat Fakhrudi,

Eva Mirza Syafitri and Muhammad Hanif Nur Kholiq

State Polytechnic of Madiun, Serayu Street No. 84, Madiun City, Indonesia

Keywords: Smart Control, Ice Tube Machine, Superheat, PLC, HMI.

Abstract: Ice tube is a variant of ice cubes in the form of a tube or cylinder that has a hole in the middle with certain

diameters and lengths. Ice tube machine is a cooling machine that has the main function of cooling substances

so that the temperature is lower than the ambient temperature. The main components of the ice tube machine

are the compressor, condenser, and evaporator as the working fluid that circulates on the parts of the ice tube

machine. However, the average ice tube machine in operation is carried out by human operators, this can slow

down the production process of the ice produced. Smart control system is needed so that ice production can

be maximized every day called Smart Control PLC (Programmable Logic Controller) Based Ice Tube

Machine. This control ice tube machine can work automatically and also no longer requires an operator in the

work process of making ice tubes and this control system can be designed according to the needs of the

machine. We can monitor the ice tube machine specifically when the machine process is working on the HMI

(Human Machine Interface). This can make it easier to operate the Ice tube Machine.

1 INTRODUCTION

Ice tube is a variant of ice cubes in the form of a tube

or cylinder with a hole in the middle with certain

dimensions, diameters and lengths. Ice tube is in great

demand by the public, in addition to its easy-to-use

shape to mix various foods and drinks. This ice tube

or ice crystal is more hygienic with a clearer and

neater appearance. With a very wide market share,

this ice making business can be said to be very

potential, still wide open and very promising.

Indonesia has many companies or home industries

that use tube ice as a temporary cooler when shipping

to various places (Triyono et al., 2019). Because it

will not be possible if the freezer is also included

during shipping. Thus, ice tube flakes are one of the

shortcuts needed during the delivery process of frozen

food or beverage products, so that the product will be

maintained at low temperatures, and of course the

freshness of the product will not be disturbed. In

addition to shipping, it can also be used for storage of

products and raw materials that will be used to make

these food products. At this time, the demand for tube

ice is very much in demand by the public. Therefore,

an ice tube maker was made that has a large income

capacity, in order to meet the needs of the community.

The current tube ice machine can produce

approximately up to 1 ton for 24 hours. With an ice

tube machine, the process of making tube ice does not

require a long time and the ice produced is more

hygienic (Eidan et al., 2021; Hervatte, 2021; Salim et

al., 2018). However, there will be not many people

who understand the working principle of this tube ice

machine, there must be an operator to run the ice tube

machine.

Program Logic Controller (PLC) is a tool that is

able to control the control system on a machine that

can be adjusted automatically (Prasetyo, Triyono, et

al., 2021). Human Machine Interface (HMI) is a

communication medium for the processes that occur

in the PLC (Mendoza et al., 2021; Prasetyo,

Hidayatullah, et al., 2021; Triyono et al., 2021). One

of the functions of HMI is as monitoring data that can

be designed according to the needs of the machine

used. PLC and HMI can be combined in the operation

of the tube ice machine. The ice tube machine can

work automatically and also no longer requires an

operator in the process of making tube ice. The

benefit of this PLC and HMI is that all the programs

we want can be set in the PLC, and we can monitor

specifically when the machine process works on the

404

Winarno, B., Triyono, B., Prasetyo, Y., Arifin, A., Fakhrudi, Y., Syafitri, E. and Kholiq, M.

Smart Control Ice Tube Machine Using PLC and HMI with Superheat Method Based on Compressor Low Pressure Parameters.

DOI: 10.5220/0011811200003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 404-408

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

HMI. This can facilitate the operation of the tube Ice

Machine.

2 MANUSCRIPT PREPARATION

2.1 Schematic Diagram

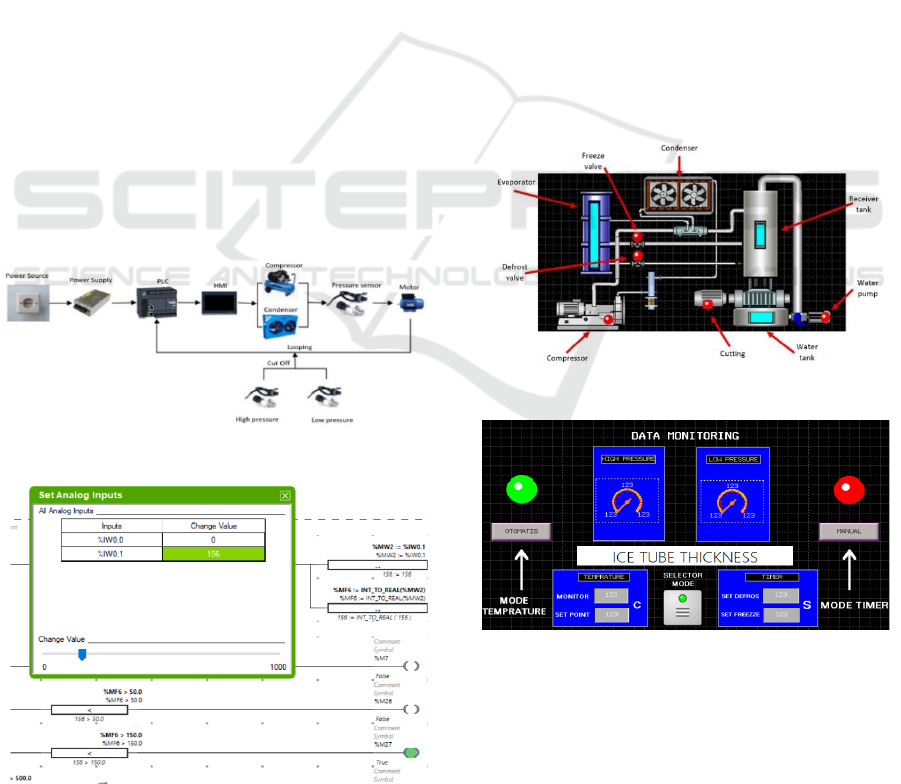

The design model of the PLC program is connected

to a 220V AC source as shown in Figure 1. To start

the circuit work, when the ON button is pressed it will

send a signal to the PLC and start the work process.

The stages of the ice tube machine work process are

starting with filling the water tank, then the tank

enters the freezing tank, namely the evaporator, along

with the compressor and condenser turning on. When

the filling is complete the Freeze process starts, this

process will stop when the temperature in the

evaporator reaches -9

0

C. When the sensor detects it,

the freeze process will stop and change to a defrost

process in which the evaporator will be sprayed with

hot wind to melt the ice cubes so that they are released

from the evaporator and will go down to the ice

storage container. The falling ice will be received by

the cutting motor and cut the ice into small shapes.

After the ice is cut out, the cutting motor will stop

then the working system will loop and start again at

filling the water tank with the compressor running

continuously.

Figure 1: Schematic diagram of ice tube machine.

Figure 2: PLC program reads the data from sensors.

Testing using a PLC Schneider Modicon with a

working step that is in the PLC program with

temperature mode. The temperature mode working

system is when the ON button is pressed, the

compressor, condenser, pump, freeze will work. Then

when the pressure sensor reads the pressure as shown

in Figure 2. Temperature – 9

0

C is configured as

pressure, the process will move to the second stage,

namely the defrost process and ice cutting.

2.2 HMI Design

Making the HMI program using the Schneider type,

namely HMI Magelis as shown in figure 3. The ice

tube machine works in 2 stages, namely stage 1 of the

ice making process and stage 2 of the ice cutting

process starting with the compressor on, followed by

the condenser, pump, and valve defrosting, then after

the sensor or timer works then stage 1 is complete and

turns off. Then stage 2 of the cutting process starts

with Valve defrost flashing (on – off repeatedly) after

a while followed by cutting lit at the specified time

and after the process is complete the machine will

loop back to the stage 1 process.

Figure 3: First view of HMI design of ice tube machine.

Figure 4: Second view of HMI design of ice tube machine.

Parts of tube ice machine

1. Compressor: serves to supply air to the engine.

2. Evaporator: air tank from freeze and defrost.

3. Condenser: a fan that serves to help the freeze

process

4. Receiver tank: ice tube formation.

Smart Control Ice Tube Machine Using PLC and HMI with Superheat Method Based on Compressor Low Pressure Parameters

405

5. Water pump: a water pump that delivers water to

the receiver tank

6. Water tank: a water reservoir.

7. Motor cutting: serves to cut the ice that falls from

Receiver tank.

8. Valve freeze: serves as a regulator of the cold

wind pressure opening valve for the

freezing process.

9. Valve defrost: serves as a regulator of the hot air

pressure opening valve for the

defrosting process.

The second display consists of set points for the

timer and temperature as well as monitoring for the

sensors used and then there are manual and automatic

buttons for switching panels/pages as shown in Figure

4.

3 RESULTS

3.1 Specification Data on Pressure

Sensor

The bit value is the configuration value to be entered

on the PLC. Here, the test is carried out when the

sensor is given wind pressure, the maximum bit value

that is read in the PLC is 106bit. Because the bit value

is unstable up and down, the bit value is rounded up

to 100. This value will later be used as the basis for

calculating the PLC configuration.

The sensor voltage value is the value that becomes

the basis for calculating other values. Here the test is

carried out when the sensor is given a maximum wind

pressure, the voltage value that can be read on the

sensor is 3 Volt with a maximum wind pressure of

110 Psi as shown in table 1.

1 psi = 0.06 bar

110 psi x 0,06 bar = 6,6 bar

3 V: 100 bit = 0,03 V

Output voltage in PLC is 110 psi: 100bit = 1.1bit

Table 1: Test Specification Data.

No Test Data Condition value

1 Pressure sensor capacity 110 Psi/6,6 Bar

2

Maximum output voltage

on senso

r

10-13 Volt

3

Maximum output pressure

on senso

r

110 Psi

4 Range bit read by sensor 100

5 Measurable voltage 3 Volt

6 1 bit in PLC 0,03 Volt

7 1.1 bit in PLC 1 Psi

Maximum low pressure on the compressor 110 psi =

11

0

C. Sensor read data on refrigerant R404A Ice tube

freezing temperature -9

0

Celsius = 50 Psi as shown in

table 2.

The working process of the tool is sequential with

stages starting with stage 1 of the freezing process

then after stage 1 is complete proceed to stage 2 of the

defrost process and the program will loop back to the

beginning as in table 3.

Table 2: Calibration sensor on compressor.

No

Pressure

(Psi)

Temperature

(

0

C)

Bit

Voltage

(volt)

1

1 -50 1,1 0,03

2

10 -35 11 0,33

3

20 -27 22 0,66

4

30 -20 33 0,99

5

40 -14 44 1,32

6

50 -9 55 1,65

7

60 -5 66 1,98

8

70 -1 77 2,31

9

80 3 88 2,64

10

90 6 99 2,97

11

100 9 110 3

12

110 11 220 3,3

Table 3: Calibration sensor on compressor.

Step Compressor Condenser Cutting Pump

V.

Freeze

V.

Defrost

1 1 1 0 1 1 0

2 1 0 1 0 0 1

3.2 PLC Program Testing in

Temperature Mode

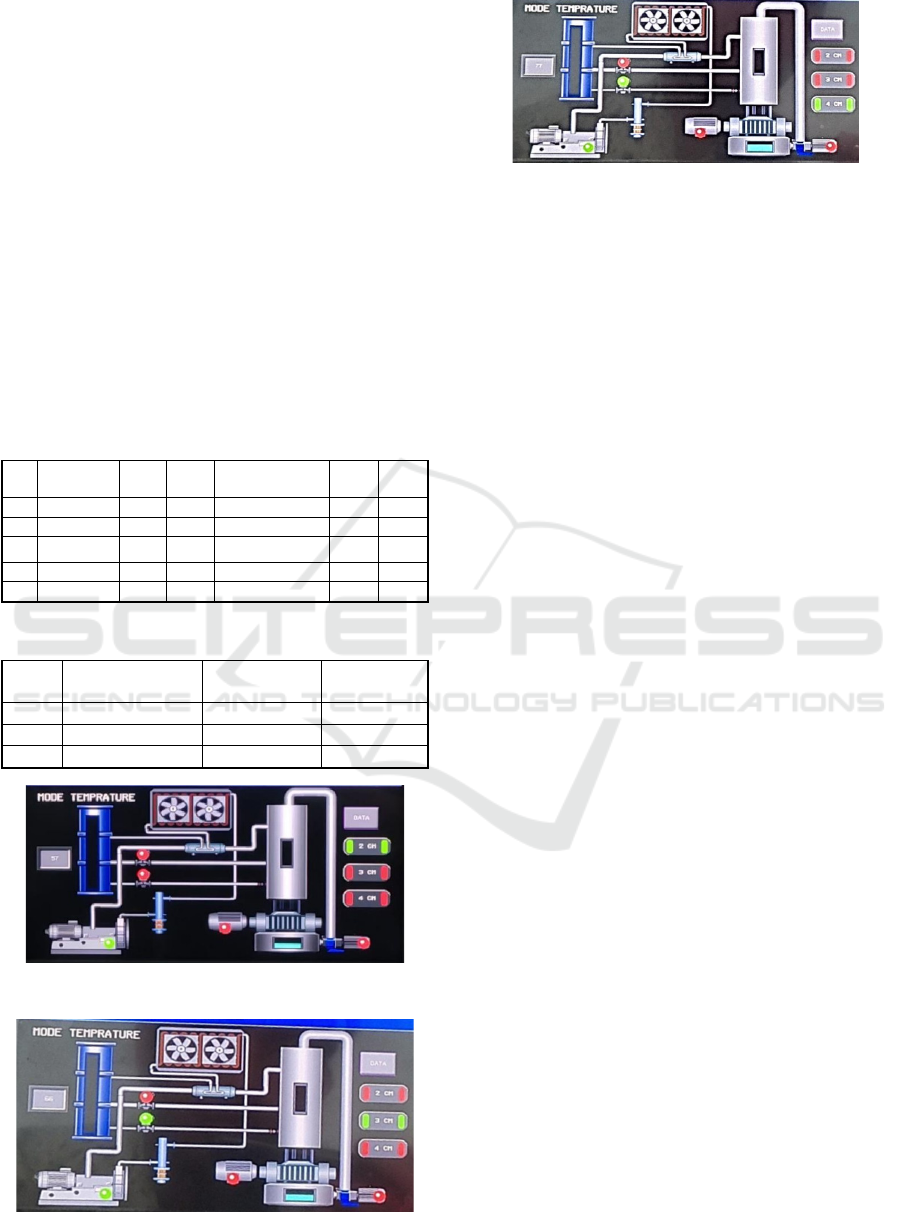

System testing using PLC Modicon and HMI

Magelis. The test runs according to the working

stages of the tool. When the temperature mode must

wait until the adjusted temperature is reached. The

results of parameter testing on the PLC in temperature

mode are as in table 4.

Temperature Mode Stages:

a. Display the monitoring data page on the HMI by

pressing the DATA button.

b. Select in the selector to temperature mode.

c. Select the thickness of the ice tube on the

selection buttons provided on the HMI monitor,

namely 2cm, 3cm, 4cm, before running the

program.

d. When the selection is correct and the ON button

is pressed then the program can run. The effect

of temperature on the ice machine is that it can

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

406

adjust the thickness of the ice using the bit value

setting point on the PLC control in the HMI as

shown in table 5.

Set points are entered on the HMI monitor when you

want to make changes to the thickness of the ice tube.

The following is a display of the thickness of the ice

tube on the HMI monitor. When the ice thickness is

set to a thickness of 2 cm with a temperature of -1

0

C,

the sensor will read the bit value at 55bit and display

it on the HMI monitor as shown in Figure 5.

When the ice thickness is set at a thickness of

3 cm with a temperature of -5

0

C, the sensor will read

the bit value at 66bit and display it on the HMI

monitor as shown in Figure 6. When the ice thickness

is set at a thickness of 4 cm with a temperature of -

9

0

C, the sensor will read bit value in the 77bit number

and displayed on the HMI monitor figure 7.

Table 4: Test parameters on PLC in temperature mode.

No.

Pressure

(Psi)

High Low Temperature Step 1 Step 2

1 > 350 1 0 0 0 0

2 < 20 0 0 0 0 0

Temp. (

0

C) High Low Temperature Step 1 Step 2

1 < -9 0 0 0 1 0

2 > -9 0 0 1 0 1

Table 5: Result in mode temperature.

No

Thickness of

ice tube (cm)

Temperature

Bit value

in PLC

1 2 -1 55

2 3 -5 66

3 4 -9 77

Figure 5: HMI display when the ice tube thickness is 2 cm.

Figure 6: HMI display when the ice tube thickness is 3 cm.

Figure 7: HMI display when the ice tube thickness is 4 cm.

4 CONCLUSIONS

The ladder diagram program in the PLC and the tool

design display in the HMI work smoothly according

to the working stages of the ice tube machine. The

effect of temperature on the ice tube machine is as a

regulator of the thickness parameter on the ice tube in

temperature mode. The effect of wind pressure on the

ice tube machine is that it functions as a helper for the

freezing process and the melting process of tube ice

formation and is also one of the main components of

the tube ice machine.

ACKNOWLEDGEMENTS

Financial support for this paper is supported by the

Ministry of Education, Culture, Research and

Technology as well as the Collaboration of Dudi

Partners with the Education Fund Management

Institute (LPDP) through the 2021 Applied Scientific

Research Program Funding Program, for this

gratefully acknowledged.

REFERENCES

Eidan, A. A., Alshukri, M. J., Al-fahham, M., AlSahlani,

A., & Abdulridha, D. M. (2021). Optimizing the

performance of the air conditioning system using an

innovative heat pipe heat exchanger. Case Studies in

Thermal Engineering, 26, 101075. https://doi.org/

10.1016/j.csite.2021.101075

Hervatte, A. M. (2021). CFD Simulation of a Fin-Tube

evaporator under icing. 64.

Mendoza, E., Andramuño, J., Núñez, J., & Córdova, L.

(2021). Human machine interface (HMI) based on a

multi-agent system in a water purification plant. Journal

of Physics: Conference Series, 2090(1), 012122.

https://doi.org/10.1088/1742-6596/2090/1/012122

Prasetyo, Y., Hidayatullah, N. A., Artono, B., & Danu S, B.

(2021). Power Factor Correction Using Programmable

Logic Control Based Rotary Method. Journal of

Smart Control Ice Tube Machine Using PLC and HMI with Superheat Method Based on Compressor Low Pressure Parameters

407

Physics: Conference Series, 1845(1), 012045.

https://doi.org/10.1088/1742-6596/1845/1/012045

Prasetyo, Y., Triyono, B., & Kusbandono, H. (2021). Dual

Axis Solar Tracker Using Astronomic Method Based

Smart Relay. JAREE (Journal on Advanced Research

in Electrical Engineering), 5(1). https://doi.org/

10.12962/jaree.v5i1.156

Salim, A. T. A., Prasetyo, Y., & Fakhrudin, Y. A. (2018).

Study of Effect Comparison Thermoelectric

Characteristics of TEC and TEG by Considering the

Difference in Temperature and Variable Resistant. 3(4),

4.

Triyono, B., Prasetyo, Y., Subkhan, M. F., & Haryo, J. K.

(2019). Air Conditioning Modification into Crystal Ice

Machine with Fast Cooling Based on Smart Relay. 4(4),

3.

Triyono, B., Prasetyo, Y., Winarno, B., & Wicaksono, H.

H. (2021). Electrical Motor Interference Monitoring

Based On Current Characteristics. Journal of Physics:

Conference Series, 1845(1), 012044. https://doi.org/

10.1088/1742-6596/1845/1/012044

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

408