The Effect of Air Flow Rate on Temperature, Yield and Water

Content in the Production of Active Charcoal from Palm Oil Shells

Using Partial Oxidation Method

Firman

1,3

, Siti Hamidah Mohd-Setapar

2,3

, Muh. Irwan

1

and Sitti Sahraeni

1

1

Department of Chemical Engineering, Politeknik Negeri Samarinda, Jalan Dr. Cipto Mangunkusumo,

Kampus Gunung Lipan Samarinda, 75131, Kalimantan Timur Province, Indonesia

2

Malaysia-Japan International Institute of Technology (MJIIT), Universiti Teknologi Malaysia,

Jalan Sultan Yahya Petra, 54100, UTM Kuala Lumpur, Malaysia

3

Razak Faculty of Technology and Informatics, Universiti Teknologi Malaysia, Jalan Sultan Yahya Petra, 54100,

UTM Kuala Lumpur, Malaysia

Keywords: Air Flow Rate, Active Charcoal, Temperature, Palm Kernel Shell, Partial Oxidation, Yield.

Abstract: Palm kernel shell is one of the palm oil processing waste which is quite large, reaching 6.5% of 1 ton of palm

oil. This shell can be used as an ingredient to make activated charcoal. Activated charcoal is widely used as

adsorbent, gas purification, water purification and so on. The palm shell is the hardest part of the components

found in oil palm. Palm kernel shell contain 26.6% cellulose and 27.7% hemicellulose which are good for

making activated charcoal. This study aims to determine the effect of air flow rate on the average temperature,

yield and moisture content in the manufacture of activated charcoal from oil Palm kernel shell by partial

oxidation method. Carbonization and activation were carried out using pyrolysis with the principle of partial

oxidation. The pyrolysis process was carried out with air flow rates of 20, 25, 30, 35 and 40 L/min for 5 hours.

The best results are shown at an air flow rate of 30 L/min with a product yield of 24,03%, a moisture content

of 5.85% and an average temperature of partial oxidation reaching 517.51

o

C.

1 INTRODUCTION

Oil palm is one of the plantation commodities that has

an important role in economic activity in Indonesia

where the area of oil palm plantations increased by

1.88 percent from 2018 to 14.60 million hectares with

an increase in Crude Palm Oil (CPO) production by

12 , 92 percent to 48.42 million tons (BPS, 2020)

Conversion of Fresh Fruit Bunch (FFB) into CPO is

around 25 to 28 percent and conversion of Palm

Kernel Shell (PKS) production from FFB reaches 6.8

to 7.4 percent. This shows that the potential of PKS

in Indonesia reaches 11.8 million tons per year.

several CPO producing countries such as Indonesia,

Malaysia, Colombia and Brazil, the use of PKS is

widely used as boiler fuel for heating fruit as well as

electricity-producing boilers (Nahrul et al., 2020).

The use of PKS to make activated charcoal which has

more selling value is still lacking in Indonesia, one of

which is the potential for PKS to be converted into

activated charcoal. The potential of PKS as Activated

Charcoal really depends on the composition of the

PKS. The composition of oil palm shell itself consists

of 27.7% cellulose, 21.6% hemicellulose, the lignin

content in this plant is 44%, and the results of

proximate analysis are 11% Moisture, 2.1% Ash, 19.7

Fixed Carbon and 67.2% Volatile Matter. .

The ultimate PKS analysis contains 49.7%

Carbon, 5.32% Hydrogen, 0.08% Nitrogen, 44, 86%

oxygen and 0.16% sulfur (Abnisa et al., 2011).

Activated Charcoal Technology has been carried out

by many researchers from various countries. The

technique used in the manufacture of activated

charcoal generally uses a three-stage process

principle, namely carbonization, chemical activation

and physical activation (Huang et al., 2018).

Based on data from the Central Statistics Agency

processed by the Directorate General of Plantation in

2019, Publication of The 2019 Indonesian Oil Palm

Statistics is an annual publication of BPS-Statistics

Indonesia. This publication presents data of area and

production on palm oil by province and by category

of producers, and the export and import of palm oil

Firman, ., Mohd Setapar, S., Irwan, M. and Sahraeni, S.

The Effect of Air Flow Rate on Temperature, Yield and Water Content in the Production of Active Charcoal from Palm Oil Shells Using Partial Oxidation Method.

DOI: 10.5220/0011811600003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 423-427

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

423

by country of destination and by country of origin.

Indonesia's charcoal exports reached 188,050 tons

with an export value of 145.09 million US dollars

(BPS, 2020). Due to the increasing demand for

Activated Charcoal., there is a strong need to sort out

the manufacturing technology for Activated Charcoal

preparation which must be cost-effective as well as on

par with commercially available Activated Charcoal.

Although various feedstocks have been explored for

the preparation of Activated Charcoal in previous

studies, scientists are still trying to explore new

materials depending on their availability and

suitability for Activated Charcoal production.

However, the utilization of Plantation waste as a raw

material for making activated charcoal has increased

rapidly in recent years. the use of making activated

charcoal by the partial oxidation method is still poorly

practiced.

Charcoal is a light carbon black residue produced

by heating wood (or other animal and plant materials)

with minimal oxygen to remove all water and other

volatile materials. In most cases, this pyrolysis

process, called charcoal burning, often results in the

formation of a charcoal furnace, where heat is

supplied by burning part of the starting material itself,

with a limited supply of oxygen. Materials can also

be heated in a closed medium. Activated charcoal has

the same initial process of making activated carbon.

Activated carbon (AC) is a non-graphite, non-

graphitizable carbon that has a very irregular

microstructure. It is famous for its high adsorption

capacity due to its high surface area and porosity.

Generally activated carbon can be made from various

raw materials including agricultural and forestry

residues. Generally most of the precursors used for

the manufacture of activated carbon are rich in carbon

(Prahas et al., 2008). AC production is achieved

usually through two methods, physical activation

method and chemical activation method (Bansal et

al., 1988)

Physical activation methods involve

carbonization of the feedstock followed by activation

at high temperatures (between 800 and 1100

o

C) in

the presence of an oxidizing gas such as carbon

dioxide or steam, while the chemical activation

method is mixing chemicals with precursors and then

followed by pyrolysis at moderate temperatures in the

absence of air High activated carbon uptake is closely

related to pore characteristics such as surface area,

pore volume, and pore size distribution. All activated

carbon has a porous structure, containing up to 15%

mineral matter in the form of ash content (Bansal et

al., 1988). The AC structure is formed during the

carbonization process and is continued during

activation, when the space between the forming

crystals is cleared of tar and other carbonated

materials. The structure of the hole and the size of the

hole are very dependent on the nature of the raw

material and the activation process. The activating

process removes the disorganized carbon by exposing

the crystallites to the action of the activating agent

leading to the construction of the diamond structure.

Activated carbon pore systems are of various types

and the individual pores may differ greatly in size and

shape. The drying, pyrolysis, and reduction processes

are heat-absorbing (endothermic), while the oxidation

process is heat-releasing (exothermic). On drying, the

moisture content of the solid fuel is evaporated by

heat absorbed from the oxidation process. In

pyrolysis, the separation of volatile matters (water

vapor, organic liquids, and non-condensed gases)

from charcoal or fuel carbon solids also uses heat

absorbed from the oxidation process. Combustion

oxidizes the carbon and hydrogen content of the fuel

by an exothermic reaction, whereas gasification

reduces the combustion product to gas by an

endothermic reaction. Further explanation regarding

these processes is given in the following description.

One of the important aspects of bioenergy to generate

heat, power and biofuels and products in the form of

activated charcoal for useful applications is biomass

gasification. As technology and materials advanced,

the development of gasification technology has

increased significantly for applications compared to

conventional power sources. This article presents an

overview of technical advances, developments in

biomass gasification technology and obstacles faced

by various stakeholders in the widespread

dissemination of technology for the needs of

individual communities and the business world to

support downstream to upstream activities (Shuit et

al., 2009).

2 METHODOLOGY

Palm oil shells from PT. Kebun Mandiri Sejahahtera

there are still impurities in the form of fibers and palm

seeds. Before carrying out the main process, it is

necessary to clean the shell by separating the

impurities. After it is considered clean, the drying

stage is carried out using sunlight. After that, five

kilograms of each process are weighed and then

stored and ready for use. The method used in this

research is to measure the results of the analysis of

activated charcoal based on SNI 06-3730-1995

standards with the main parameters of Moisture

content (%). The quality of activated charcoal greatly

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

424

affects the water content. The equation used to

calculate the water content is

Moisture content (%) = (((M2-M3))/

((M2-M1)))x100%

(1)

Information:

M1 = Weight of empty petri dish (grams)

M2 = Weight of petri dish containing activated

carbon before oven (grams)

M3 = Weight of petri dish containing activated

carbon after oven (grams)

3 RESULT AND DISCUSSION

The purpose of this study was to determine the effect

of air flow rate on activated charcoal using oil palm

shells with a pyrolysis process using the principle of

partial oxidation on a pilot plant scale with a raw

material capacity of 5 kg/batch, and to determine the

quality of charcoal produced by pyrolysis of oil palm

shells. The pyrolysis process stage is burned for 5

hours. The results of the study obtained the following

data:

Table 1: Research result.

Air

Flow

Rate

(L/min)

Temperature

Average (

o

C)

Yield

(%)

Moisture

Content

(%)

20

432.69

29.8

6.94

25

474.12

29.01

6.40

30

517.51

24.03

5.85

35

565.34

20.2

5.82

40

585.98

19.01

5.80

SNI06-3730-1995

Max 15

The results of the study in the table1 Shows that

the greater the air flow rate, the higher the average

temperature in the reactor produced. This is due to the

pyrolysis process using limited air, an oxidation

process that is exothermic (releasing heat). In this

oxidation zone, the large amount of air causes the

amount of oxygen present in the air to oxidize the

carbon contained in the material so that the heat

generated is also greater and causes an increase in

temperature. The increase in temperature generally

shifts with increasing air flow rate. The greater the air

flow rate, the maximum temperature (hot spot) will

occur the faster it will occur and then there will be a

decrease in temperature due to reduced carbon

contained in the raw material (Ramos, L.P., 20035).

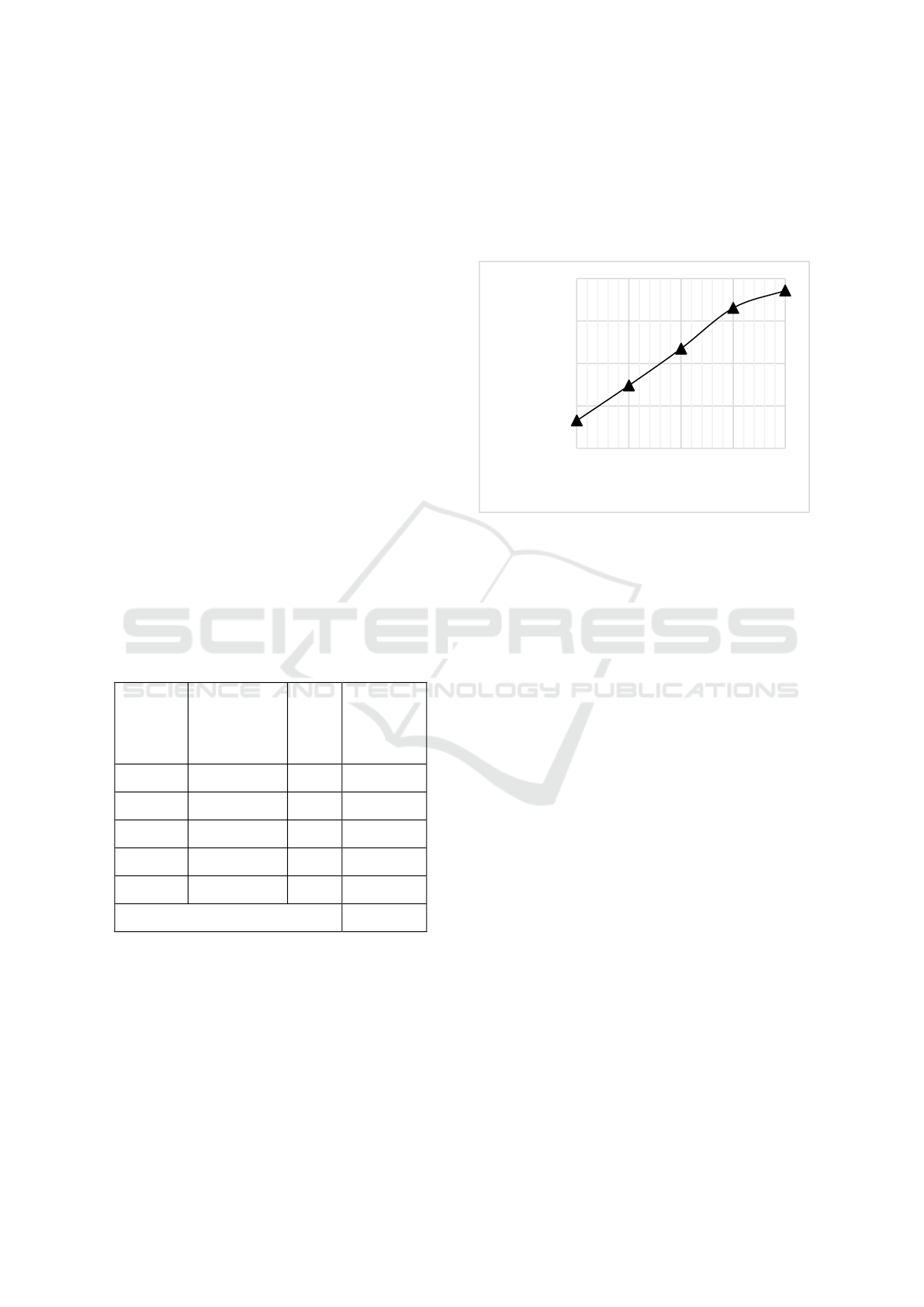

Figure 1: Effect of air flow rate on the average temperature

of pyrolysis.

In Figure 1 it can be seen that at a flow rate of 20

L/min the activated charcoal product produced is at

the maximum yield, which is 29.8%, while at a flow

rate of 40 L/min the minimum yield of activated

charcoal product produced is, which is 19%. It can be

seen that the yield continues to decrease along with

the addition or flow of air into the reactor, namely the

more oxygen and nitrogen gas that is circulated, the

yield of activated charcoal obtained is also relatively

decreased (Hasan et al., 2020). In addition,

temperature is also very influential on the pyrolysis

process. The higher the temperature, the better the

decomposition/decomposition process, but the less

amount of charcoal obtained while the more liquid

and gas results, due to the large number of

decomposed and evaporated substances. The

maximum yield was obtained at an average

temperature of 182.68 °C at 29.8% and the minimum

yield was obtained at a temperature of 448.98 °C at

19%, this is in accordance with the statement of Haji

et al., 2010 that due to the high temperature some

charcoal turns into ash and volatile gases, so the yield

tends to be low. It can be concluded that the oxygen

and nitrogen that are flowed into the reactor help the

pyrolysis process occur perfectly, the incoming

oxygen reacts with the activated charcoal to become

CO2 which causes the amount of solids to decrease.

The function of oxygen here is to oxidize the material

while nitrogen is a physical activating agent (Gao and

Li, 2008).

400,00

450,00

500,00

550,00

600,00

20 25 30 35 40

Temperature Average (oC)

Air Flow Rate (Liter/Minute)

The Effect of Air Flow Rate on Temperature, Yield and Water Content in the Production of Active Charcoal from Palm Oil Shells Using

Partial Oxidation Method

425

Figure 2: Effect of air flow rate on activated charcoal yield.

Comparison of Figure 1 and Figure 2 From this

data, it can be concluded that the yield of activated

charcoal produced relatively decreased as air was

added or flowed into the reactor during the pyrolysis

process. The calculation of the water content of

activated charcoal aims to determine the hygroscopic

nature (water absorption) of activated charcoal.

Activated charcoal is hygroscopic so it is very easy to

bind moisture from the air. From this very

hygroscopic nature, activated charcoal is used as an

adsorbent (Ikawati & Melati, 2010).

Figure 3: Effect of air flow rate on water content.

The results of the water content are shown in

comparison of Figure 1 and Figure 3 , from the figure

it can be seen that the higher the air flow rate, the

combustion process is close to complete and the

temperature tends to be higher, the less water vapor

trapped in the pores than the low air flow rate. At air

flow rate of 40 L/min the average temperature

obtained is 448.98 °C and the lowest water content is

5.80%, while at air flow rate of 20 L/min the average

temperature obtained is 182.68 ° C and the highest

water content of 6.94%. This increase in water

content is not only caused by an increase in the

hygroscopic nature of activated charcoal to water

vapor, it is also due to the binding of water vapor

molecules (Hasan et al., 2020). The moisture content

of charcoal can be affected by the amount of water

vapor in the air, the length of the cooling, grinding,

and sifting processes. From Figure 4.2 it can be seen

that the water content of all samples of activated

charcoal produced has met the quality standard of

activated charcoal according to SNI 06-3703-1995.

4 CONCLUSIONS

The best results in the process of making activated c

From the research that has been carried out on

variations in air flow rates of 20 L/min, 25 L/min, 30

L/min, 35 L/min, and 40 L/min, it can be concluded

that the air flow rate reaches the optimum condition

at a speed of 30 L/min. min. with Optimum results

shown at air flow rate of 30 L/min, with a product

yield of 24%, water content of 5.85%,

ACKNOWLEDGEMENTS

The author would like to thank the Research and

Development Center of the Samarinda State

Polytechnic which has funded this research, and also

to the Chemical Engineering Laboratory of the

Samarinda State Polytechnic as the research site. and

special thanks to Razak Faculty of Technology and

Informatics, Universiti Teknologi Malaysia, UTM

Kuala Lumpur, Malaysia who helped push this article

REFERENCES

Abnisa, F., Daud, W. M. A. W., Husin, W. N. W., & Sahu,

J. N. (2011). Utilization possibilities of palm shell as a

source of biomass energy in Malaysia by producing

bio-oil in pyrolysis process. Biomass and Bioenergy,

35(5), 1863-1872. doi:10.1016/j.biombioe.2011.01.033

Bansal, R.C., Donnet, J.B., Stoeckli, H.F. Active carbon.

Marcel Dekker, (1988), New York.

BPS. (2020). Statistik Kelapa Sawit Indonesia 2019. In N.

P. 05130.2002 (Ed.), (Nomor Publikasi: 05130.2002

ed., pp. 137).

Bansal, R.C., Donnet, J.B., Stoeckli, H.F. Active carbon.

Marcel Dekker, (1988), New York.

Gao, N., Li, A., (2008), “Modeling and Simulation of

combined Pyrolysis and Reduction Zone for a

downdraft Biomass Gasifier”, Energy Conversion and

Management 49, 3483-3490

Huang, Y., Liu, H., Yuan, H., Zhan, H., Zhuang, X., Yuan,

S., Wu, C. (2018). Relevance between chemical

structure and pyrolysis behavior of palm kernel shell

17

19

21

23

25

27

29

31

20 25 30 35 40

Yield (%)

Air Flow Rate (Liter/Minute)

5,70

5,85

6,00

6,15

6,30

6,45

6,60

6,75

6,90

7,05

20 25 30 35 40

Water Content (%)

Air Flow Rate (Liter/Minute)

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

426

lignin. Sci Total Environ, 633, 785-795.

doi:10.1016/j.scitotenv.2018.03.238

Hasan, S., Aladin, A., Syarif, T., & Arman, M. (2020).

Pengaruh Penambahan Gas Nitrogen Terhadap Kualitas

Charcoal Yang Diproduksi Secara Pirolisis Dari

Limbah Biomassa Serbuk Gergaji Kayu Ulin

(Euxideroxylon Zwageri). Journal of Chemical Process

Engineering, 5(1), 61–68. https://doi.org/10.33536/

jcpe.v5i1.472

Ikawati, & Melati. (2010). Pembuatan Karbon Aktif Dari

Kulit Singkong UKM Tapioka Kabupaten Pati. Area,

1–8.

Mohd Salleh MA, Nsamba HK, Yusuf HM, Idris A, Ghani

WAWAK. Effect of equivalence ratio and particle size

on EFB char gasification. Energy Sources, Part A

Recover Util Environ Eff 2015;37:1647e62.

https://doi.org/10.1080

Prahas, D., Kartika, Y., Indraswati, N., Ismadji, S.

(2008),Activated carbon from jackfruit peel waste by

H3PO4 chemical activation: Pore structure and surface

chemistry characterization. Chemical Engineering

Journal., 140, 32-42.

Ramos, L.P., (2003). The chemistry involved in the stram

treatment of lignocellulosic materials. Quim. Nov. 26,

863–871.

Shuit SH, Tan KT, Le KT, Kamaruddin AH, (2009). Oil

palm biomass as a sustainable source: a Malaysian case

study. Energy;34:1225–35.

Yuliusman. (2015). Production of activated carbon from oil

palm shells with KOH and N

2

/CO

2

as activating

ingredients. Seminar on Technology and Engineering

(SENTRA), 978–979.

Nahrul Hayawin, Z., Astimar, A. A., & Idris, J. (2020). Nor

Faizah. J., Ropandi, M., Astimar, AA, Noorshamsiana,

AW, & Abd-Aziz, S.

The Effect of Air Flow Rate on Temperature, Yield and Water Content in the Production of Active Charcoal from Palm Oil Shells Using

Partial Oxidation Method

427