Increasing the Efficiency of Bolangi Substation Extension by Using

ACCC Conductor on 150 KV Sungguminasa-Bolangi Overhead

Power Line

Dendhy Widhyantoro

State Polytechnic of Jakarta, University of Indonesia, Jl. Prof. DR. G.A. Siwabessy Kampus, Depok, Indonesia

Keywords: Conductor Reconfiguration, ACCC, ACSR, Efficiency, Overhead Power Line, Substation.

Abstract: Electricity is one of the most important needs for society. Therefore, problems related to electricity will greatly

affect a country. An example of this problem is the electricity crisis. Electrical energy crisis may occur due to

lack of energy efficiency or high operating costs. One of the solutions to overcome these two problems is to

optimize several components that play a part in the distribution of electrical energy such as the conductors

used in the SUTT line. There are various types of conductors, including but not limited to ACSR and ACCC.

Switching to a higher performing conductor can contribute to solving this problem. There are several studies

that support replacing conductors with better ones can affect energy efficiency by increasing the power factor,

reducing power losses, and increasing transmission efficiency so that they can contribute to solving the

electrical energy crisis. The conductor that’s going to be used is ACCC, which is a conductor capable of

operating in high temperatures and has a low sag and is an upgrade and refinement of the ACSR conductor.

By doing this conductor reconfiguration process, the power factor of the substation increased by 6.59%,

transmission efficiency by 2.1% and reduced power loss by 52.82%.

1 INTRODUCTION

Electrical energy is an energy that is used by almost

all people. Therefore, it is one type of energy that is

extremely valuable, especially in the economic side

(Arismunandar & Kuwahara, 2004). Electricity crisis

in Indonesia is mostly related to economic problems,

such as the high operating costs at substations or the

lack of high energy efficiency on substations’ lines

which in turn may cause the aforementioned electrical

energy crisis. Energy efficiency in this case is defined

into more specific variables including but not limited

to; difference in power factor, difference in power

loss, and difference in transmission efficiency.

One of the possible solutions to solve this

electrical energy crisis problem is to optimize the

components that play a role in the distribution of

electrical energy such as the conductor that’s being

used. The conductors used in High Voltage Overhead

Lines (SUTT) play an important part in the

performance and efficiency of the system.

This research is conducted at the High Voltage

Overhead Lines of Sungguminasa – Bolangi where

there is a power loss of 0.2022 MW and a SAIFI index

of 0.57 which is high enough to cause a loss of

economic value. These problems are directly related

to the main component of the SUTT which is the

conductor. They can be of various types, including

but not limited to ACSR (Aluminum Conductor

Steel-Reinforced Cable) and ACCC (Aluminum

Conductor Composite Core).

ACSR is a type of conductor that has a high

capacity, high strain resistance (around 131.9 kN),

and is usually used on High Voltage Overhead Lines.

The outer strand is made of high purity aluminium

which results in good conductivity, light weight, and

low cost. The inner strand is made of steel which has

higher strength and inelastic deformation caused by

mechanical loads such as wind. Steel also has low

coefficient of thermal expansion under current load

(Kenge et al., 2016). These things make ACSR sag

much less than all-aluminium conductors (Lalonde et

al., 2018).

ACCC is a type of high-temperature low-sag

conductor which is capable of operating in high

temperatures and has a low sag. It’s an update or

improvement to ACSR. It replaces the steel core in

ACSR with carbon and glass fibre (Bryant, 2019).

This gives ACCC several advantages over ACSR.

Firstly, ACCC is capable of carrying twice as much

current as ACSR in general (Wareing, 2018).

466

Widhyantoro, D.

Increasing the Efficiency of Bolangi Substation Extension by Using ACCC Conductor on 150 KV Sungguminasa-Bolangi Overhead Power Line.

DOI: 10.5220/0011814100003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 466-472

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Secondly, ACCC is lighter than ACSR, making it

possible for the saved weight to be used for additional

aluminium conductors. Thirdly, ACCC is softer than

ACSR. The latter may use stronger pure aluminium

which contributes to its tensile strength and improved

sag under icy load conditions, but it has less electrical

conductivity and has a limited operating temperature

and more power loss than ACCC (Chen et al., 2012).

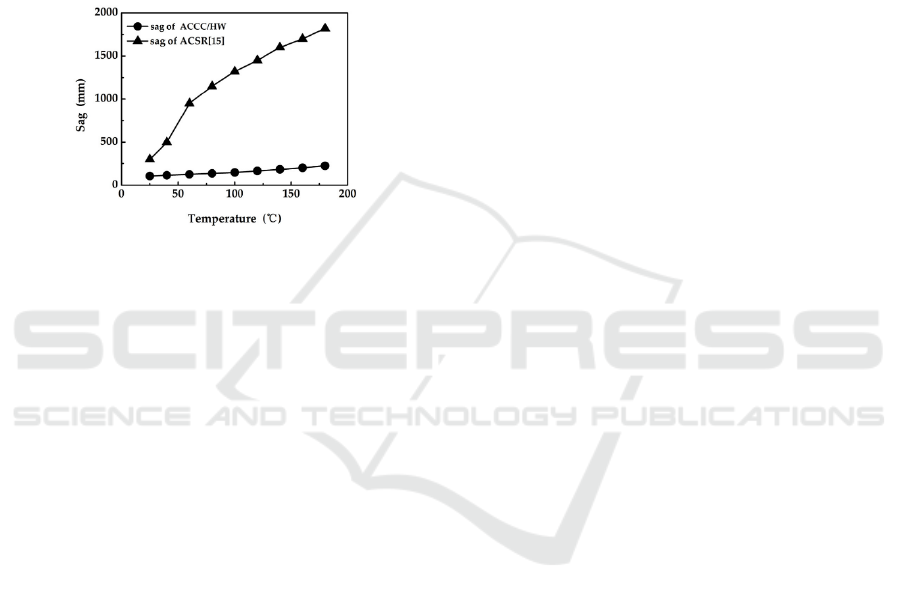

Lastly, ACCC has a much smaller coefficient of

thermal expansion (CTE) of 1.6 ppm/C than ACSR.

This allows ACCC to operate at a much higher

temperature without excessive sag (Slegers, 2011).

Figure 1: Comparison of sag between ACSR and ACCC

conductor (Qiao et al., 2020).

Optimizing the conductor by reconfiguring it into

a higher performing one can help solve the problem

at Sungguminasa – Bolangi powerlines which is the

lack of energy efficiency. Therefore, based on the

advantages of ACCC over ACSR that have been

described above, the former is more suitable for usage

in High Voltage Overhead Lines as it will greatly help

with the energy efficiency issue that is being faced.

This study will calculate and compare the changes in

efficiency after executing the reconfiguration process

from ACSR conductor to ACCC on the High Voltage

Overhead Lines of Sungguminasa – Bolangi wherein

efficiency is again divided into several variables,

including power factor difference, power loss

difference, and transmission efficiency difference.

The purposes of this research will be divided into

three clear, concise points:

1. To calculate and compare the difference in

power factor before and after the conductor

reconfiguration process

2. To calculate and compare the difference in

power loss before and after the conductor

reconfiguration process

3. To calculate and compare the difference in

transmission efficiency before and after the

conductor reconfiguration process

2 THEORITICAL REVIEW

There are studies that discuss the use of several types

of conductors in substation lines. One of these studies

compares two types of conductors with different

specifications, one of them is the ACCC conductor

which has better specifications on a 150 kV

transmission system than the other conductor it’s

compared to. When compared, the ACCC conductor

has smaller resistance per phase and has larger

received power (MW) as well as larger current draw.

The author states that there’s an increase of 1.35% to

the efficiency (Handayani et al., 2019).

Another study discusses the conductor

reconfiguration process in the Mranggen Incomer

High Voltage Overhead Lines. The author states that

reconfiguration occurred because it utilized a single

phi system. Therefore, using this system may cause a

power outage if one of the lines is disturbed. Due to

this concern, they reconfigured the process into a

double phi system, followed by performing a series of

calculations based on the results. It was discovered

that the power loss in the Ungarang-Mranggen Line

before the reconfiguration process was 5.86 kW and

was reduced to 2.75 kW afterwards. Meanwhile, at

the Mranggen Incomer Ungaran-Purwodadi line, the

power loss was reduced from 13.39 kW to 8.9 kW

after reconfiguration (Imam G, 2017).

3 RESEARCH METHODS

This study uses multivariate data analysis technique

which is the method of processing a large number of

variables, where the aim is to find the effect of these

variables on an object simultaneously. The variables

that are analysed include the difference in

transmission efficiency, power factor, and power loss.

After these variables have been calculated before and

after the reconfiguration process, they will be

compared and analysed whether there is a relation

between variables or a relationship between several

variables with one variable (Wustqa et al., 2018).

3.1 Reconfiguration Method

The reconfiguration method is divided into several

steps, starting from de-energizing to installing the

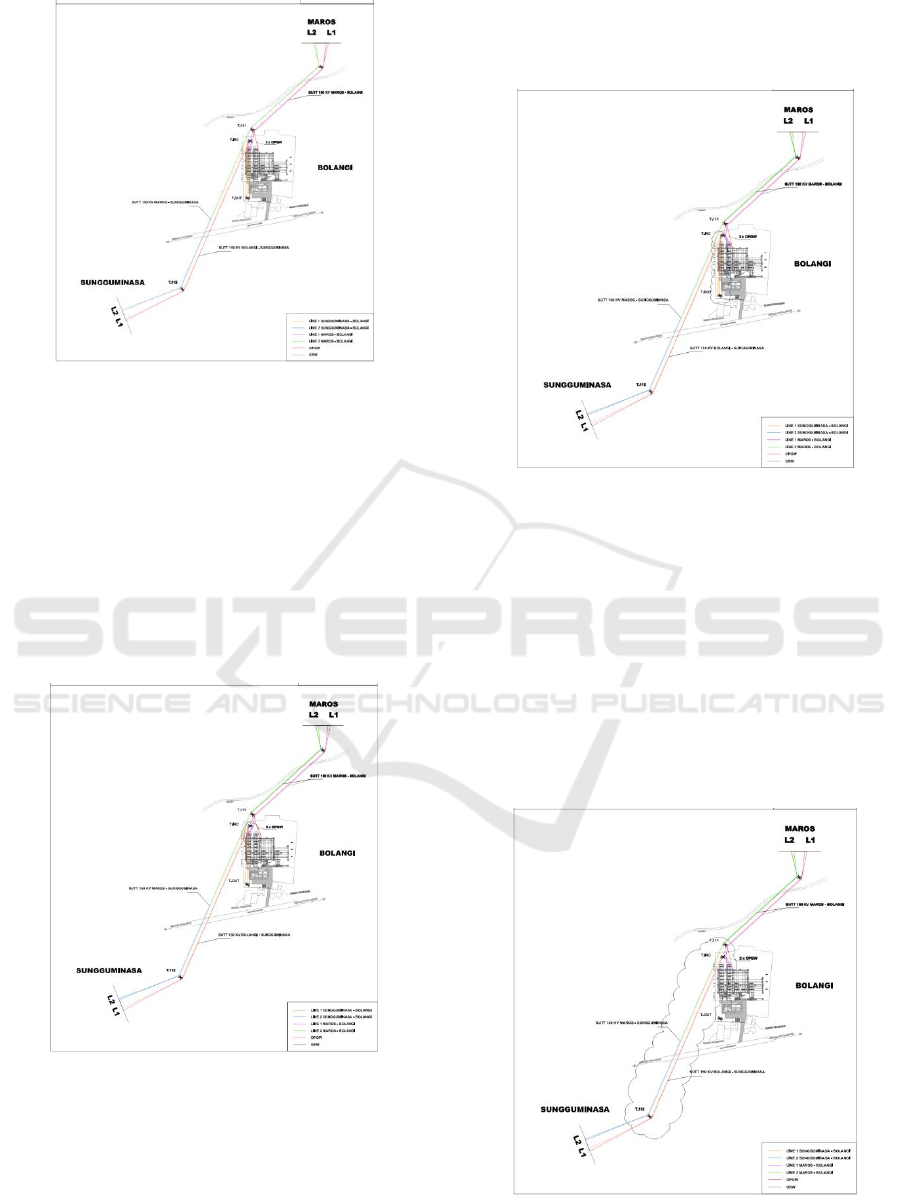

conductor itself. The figure below shows the initial

condition of Bolangi 150 kV substation, without any

reconfiguration process done.

Increasing the Efficiency of Bolangi Substation Extension by Using ACCC Conductor on 150 KV Sungguminasa-Bolangi Overhead Power

Line

467

Figure 2: Substation’s starting condition.

Stage 1 starts with de-energizing Maros-Bolangi

#1 (Existing) line for 3 days to move conductor from

Maros #1 (Existing) bay line to Maros bay line

(New). Next is to re-energize Maros-Bolangi #1 via

the new bay line one day after de-energizing it.

Simultaneously, the relay distance at Maros #1 bay

line will also be replaced with a new differential relay

from new substation. After replacing the relay

distance, point to point operation will be carried out

to the RCC master station. After stage 1, the system

will look like what is depicted in the figure below.

Figure 3: Stage 1 of the conductor reconfiguration process.

Stage 2A starts with de-energizing Maros #1

(New) bay line, Sungguminasa #1 (Existing) bay line,

and 60 MVA bay transformer at 150 kV Bolangi

substation for one day to carry out the conductor

removal operation that’s located above the two

Bolangi substation busbars. After that, Maros-

Bolangi #1 will be re-energized via the new bay line

along with the 60 MVA bay transformer. Stage 2A is

shown in the figure below.

Figure 4: Stage 2A of the conductor reconfiguration

process.

Stage 2B first start with de-energizing Bolangi-

Sungguminasa #1 existing line again for 18 days

(continuation of stage 2A) to allow for the conductor

dismantling operation from T.Inc to T.112 and to do

a conductor stringing operation from T.112 to the new

gantry bay line of Sungguminasa #1 (New). After

that, the Sungguminasa-Bolangi #1 line will be

resuming operation via the new bay line. Also at this

stage, OPWG configuration is also carried out for 4

days after stage 2A. This stage is depicted in the

figure below.

Figure 5: Stage 2B of the conductor reconfiguration

process.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

468

Next is stage 3 and 4. First, Sungguminasa-Maros

#2 (Existing) line is to be de-energized for sixteen

days to allow for the conductor dismantling operation

from T.111 to T.112 and conductor stringing

operation for the new conductor from T.111 to T.Out

and T.112 to T.Inc. Simultaneously, the relay distance

at Sungguminasa substation will also be replaced with

a differential relay. After that, Sungguminasa-

Bolangi #2 line will be operational. In stage 4,

transmission line will change to Bolangi-New Power

#2 line. Stage 3 and 4 are depicted together in the

figure below.

Figure 6: Stage 3 and 4 of the reconfiguration process.

Stage 5 is the conductor dismantling operation

and GSW T.76 – T.77 in Maros-Sungguminasa /

Bolangi #2 to T.01 Incomer New Power. OPGW

reconfiguration will also be done. After that, New

Power – Bolangi #2 line will be operational. Stage 6

is the last stage and it’s the installation and operation

of the new conductor in Maros-Sungguminasa. The

T.76 T/L Maros-Sungguminasa and TIP 01 New

Power incomer will be installed. After installation,

the New Power Line – Maros #2 will be operational.

This stage is shown in the figure below. Figure 8 also

shows the before and after of the reconfiguration

process with dotted lines indicating the before and

solid lines indicating the after.

Figure 7: Stage 6 of the conductor reconfiguration process.

Figure 8: Comparison of system before and after the

reconfiguration process.

4 RESULTS AND ANALYSIS

4.1 Results

Measurements of the observed variables for both

ACSR and ACCC conductors were taken and put

together into table 1 and table 2 respectively.

Increasing the Efficiency of Bolangi Substation Extension by Using ACCC Conductor on 150 KV Sungguminasa-Bolangi Overhead Power

Line

469

Table 1: Measurement results for ACSR conductor.

Measurement

Value

R (Resistance) (

0.1155

X

L

(Reactance) (

0.3064

A (Surface area) (mm

2

)

429.1

d (Conductor’s length) (km)

4.1

b (Air pressure) (mmHg)

756.06

T (Average temperature) ()

28

I (Current) (Ampere)

372

Q (Reactive power) (MVAR)

39.1

P (Power) (MW)

85.8105

E (Phase voltage) (Volt)

144

r (Radius) (mm)

28.62

D (Distance between wires) (m)

2.5

Table 2: Measurement results for ACCC conductor.

Measurement

Value

R (Resistance) (

0.0514

X

L

(Reactance) (

0.206

A (Surface area) (mm

2

)

546.5

d (Conductor’s length) (km)

4.1

b (Air pressure) (mmHg)

756.06

T (Average temperature) ()

28

I (Current) (Ampere)

387

Q (Reactive power) (MVAR)

25.2465

P (Power) (MW)

100.7348

E (Phase voltage) (Volt)

144

r (Radius) (mm)

14.315

D (Distance between wires) (m)

2.5

Firstly, resistance and reactance for both

conductors must be multiplied by the respective

conductors’ length.

(1)

(2)

After finding both resistance and reactance

values, we can find the impedance using Pythagoras

theorem and finding the phase by finding the arctan

of reactance over resistance.

(3)

(4)

Put the two values together, we get the total

impedance (Z):

(5)

First is to calculate the first variable which is the

power factor. From the two tables of ACSR and

ACCC measurements, we take the P (power) and the

Q (reactive power) of each conductor and find the S

(apparent power) and from there we can find the

power factor.

(6)

Plugging the apparent power into the power factor

formula, we get:

(7)

(8)

Second is to calculate the power loss which is

divided into two parts: transmission power loss and

corona power loss. Calculating transmission power

loss for 3 phase system is to multiply the current

squared with resistance and three.

(9)

Before we can find the corona losses, we need to

find the relative air density and the voltage

gradient (E

g

). We can find the relative air density

using the following formula:

(10)

To find the voltage gradient for a 3-phase

transmission line, we can use the formula from (W. S.

Peterson, 1933).

(11)

Finally, after calculating both relative air density

and voltage gradient, we can find the corona loss for

both conductors with the following formula which is

Peek’s formula and is based on an equation from (F.

W. Peek, 1929) to find the power loss due to the

corona effect (ionization surrounding the conductor).

Corona losses included losses caused by frequency,

conductor’s size, air pressure, temperature, and

atmospheric conditions.

(12)

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

470

Where

is the voltage gradient of the surface

of the wire and m is the irregularity factor. Plugging

in all of the values into the equation and we will get:

(13)

To find the corona loss for the conductor, we need

to multiply it with the conductor’s length.

(14)

After calculating both power losses, we can find

the total power loss by adding the two together.

(15)

(16)

Transmission efficiency can be found by dividing

the power with the total transmitted power, the latter

of which includes the power and the total power

losses, and then multiplying it by 100. The total

transmitted power (

is as follows:

(17)

(18)

Plugging these into the respective conductor’s

transmission efficiency formula, we will get both

conductors’ transmission efficiency.

(19)

(20)

4.2 Analysis

In this section, the results from the calculations that

have been done in the previous section will be talked

about and compared between the two conductors.

First, the summary of all the important calculations

have been put neatly into the table below.

Table 3: Summary of calculations.

ACSR

ACCC

Power Factor

0.91

0.97

85.8105

100.7348

0.1966

0.0947

0.00558

0.00287

0.20218

0.0976

87

100.8323

87.845

99.9

Starting first with the power factor, the

calculations for the power factor of ACSR resulted in

0.91. Power factor has a range of 0 to 1 with 0 being

very inefficient and 1 being very efficient and

therefore less power being wasted (Dani &

Hasanuddin, 2018). 0.91 or 91% for power factor is

already a good indication of efficiency, but it can still

be improved since the upper limit is 1 or 100%. After

the reconfiguration process into ACCC conductor, the

power factor increased to 0.97 or 97% which is a

6.59% improvement.

Figure 9: Comparison of power factor.

That number may sound insignificant, but if seen

in the long term, such as in a few months or years,

6.59% will save electricity costs significantly. 6.59%

in substation value can also be used to power several

houses.

Moving on to the next variable which is power

loss. The total power losses are shown as

and

for both ACSR and

ACCC conductor respectively. Before the

reconfiguration process, the total power loss is 0.2022

MW which is significantly more than after the

reconfiguration process which is only 0.0976 MW.

This equates to around 51.75% decrease of power loss

which is very significant and in the long run will save

even more power and benefit everyone economically.

The figure below shows the comparison between both

power losses.

Figure 10: Comparison of total power loss.

Increasing the Efficiency of Bolangi Substation Extension by Using ACCC Conductor on 150 KV Sungguminasa-Bolangi Overhead Power

Line

471

By dividing the corona losses by the total power

losses, we can see that corona losses only contribute

about 2.76 – 2.94% of the total power losses.

The last variable that’s compared is the

transmission efficiency which is defined as the ratio

between the power and the total power, the latter of

which includes the total power losses and the power

combined. Before the reconfiguration process, ACSR

conductor has a transmission efficiency of 97.845%.

After reconfiguring into ACCC, we have a

transmission efficiency of 99.9%. Comparing these

two values, there’s an increase of around 2.1% in

transmission efficiency. Similar to power factor, the

effect of this will be more significant as time goes on.

Figure 11: Comparison of transmission efficiency.

5 CONCLUSIONS

Based on this research which carries out the process

of reconfiguring the conductor on High Voltage

Overhead Lines from ACSR to ACCC conductor,

there are several conclusions that can be drawn.

1. The reconfiguration process from ACSR to

ACCC resulted in the increase of power

factor by 6.59% from 0.91 to 0.97.

2. The reconfiguration process from ACSR to

ACCC resulted in the decrease of power loss

by 51.75% from 0.2022 MW to 0.09756

MW.

3. The reconfiguration process from ACSR to

ACCC resulted in the increase of

transmission efficiency by 2.1% from

97.845% to 99.9%.

4. Other factors such as air density,

temperature, and atmospheric conditions

only contribute around 2.76 – 2.94% to the

total power loss of the system.

REFERENCES

Arismunandar, A., & Kuwahara, S. (2004). Buku Pegangan

Teknik Tenaga Listrik Jilid II Saluran Transmisi (2nd

ed.). PT. Pradnya Paramita.

Bryant, D. (2019). Engineering Transmission Lines with

High Capacity Low Sag ACCC® Conductors. Capacity

| CTC ACCC Conductor.

Chen, G., Wang, X., Wang, J., Liu, J., Zhang, T., & Tang,

W. (2012). Damage investigation of the aged

aluminium cable steel reinforced (ACSR) conductors in

a high-voltage transmission line. Engineering Failure

Analysis, 19, 13–21.

https://doi.org/10.1016/j.engfailanal.2011.09.002

Dani, A., & Hasanuddin, M. (2018). Perbaikan Faktor Daya

Menggunakan Kapasitor Sebagai Kompensator Daya

Reaktif (Studi Kasus STT Sinar Husni). STMIK Royal

– AMIK Royal, 1(1), 673–678.

F. W. Peek. (1929). Dielectric phenomena in high-voltage

engineering (3rd ed.). New York McGraw-Hill Book

Company, Inc.

Handayani, O., Darmana, T., & Widyastuti, C. (2019).

Analisis Perbandingan Efisiensi Penyaluran Listrik

Antara Penghantar ACSR dan ACCC pada Sistem

Transmisi 150kV. Energi & Kelistrikan, 11(1), 37–45.

https://doi.org/10.33322/energi.v11i1.480

Imam G. (2017). Analisa Rugi Penghantar Rekonduktoring

Acsr – Accc Saluran Udara Tegangan Tinggi 150 Kv

Mranggen Incomer. TJ Mechanical Engineering and

Machinery.

Kenge, A. v., Dusane, S. v., & Sarkar, J. (2016). Statistical

analysis & comparison of HTLS conductor with

conventional ACSR conductor. 2016 International

Conference on Electrical, Electronics, and

Optimization Techniques (ICEEOT), 2955–2959.

https://doi.org/10.1109/ICEEOT.2016.7755241

Lalonde, S., Guilbault, R., & Langlois, S. (2018).

Numerical Analysis of ACSR Conductor–Clamp

Systems Undergoing Wind-Induced Cyclic Loads.

IEEE Transactions on Power Delivery, 33(4), 1518–

1526. https://doi.org/10.1109/TPWRD.2017.2704934

Qiao, K., Zhu, A., Wang, B., Di, C., Yu, J., & Zhu, B.

(2020). Characteristics of Heat Resistant Aluminum

Alloy Composite Core Conductor Used in overhead

Power Transmission Lines. Materials, 13(7), 1592.

https://doi.org/10.3390/ma13071592

Slegers, J. (2011). Transmission Line Loading: Sag

Calculations and High-Temperature Conductor

Technologies.

W. S. Peterson. (1933). Development of a Corona Loss

Formula.

Wareing, B. (2018). Types and Uses of High Temperature

Conductors.

Wustqa, D. U., Listyani, E., Subekti, R., Kusumawati, R.,

Susanti, M., & Kismiantini, K. (2018). Analisis Data

Multivariat Dengan Program R. Jurnal Pengabdian

Masyarakat MIPA Dan Pendidikan MIPA, 2(2), 83–86.

https://doi.org/10.21831/jpmmp.v2i2.21913.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

472