Nutrient Feeding Automation System in Hydroponic Cultivation

Using NodeMCU Based on PID Controller

Nurmahaludin Nurmahaludin

1

and Gunawan Cahyono

2

1

Politeknik Negeri Banjarmasin, Jl. Brig Jend. Hasan Basri, Banjarmasin, Indonesia

2

Universitas Lambung Mangkurat, Jl. Brigjen Jalan Hasan Basri, Indonesia

Keywords: Hydroponic, NodeMCU, PID Controller.

Abstract: Hydroponic system is the cultivation of plants without soil and using only nutrient solutions in water. The

concentration of these nutrients needs to be adjusted before being given to plants. If the nutrients given are

too concentrated, the plants will die or wilt, on the contrary if the concentration is low, the plants will lack

nutrients. The automation system for regulating nutrient concentrations in this study is based on a PID

controller using nodeMCU. The setpoint is the reference nutrient concentration value which is compared with

the current concentration output measured by the sensor to get an error. If the error is positive, it indicates that

the plant is on the verge of nutrient deficiency so that the nutrient solution valve needs to be opened to increase

the concentration of the solution. On the other hand, if the error is negative it means that the concentration of

the solution exceeds the value it should have, so the water valve needs to be opened to reduce the concentration

that occurs. The test results show that the PID controller with Kp=0.8, Ki=0.5, and Kd=0.5 gives a fairly good

response and a relatively smaller average error of 3.92.

1 INTRODUCTION

There are number of studies have been carried out in

relation with control hydroponic plants, including the

design of a hydroponic plant automation system

through regulating temperature and humidity,

electrical conductivity, pH, and lighting using sensors

and microcontrollers (Pache, Dudhe, & Dharaskar,

2022) as well as temperature and level regulation

(Azhari, Simanjuntak, Hakim, & Sabar, 2022)

(Chaiwongsai, 2019).

Control algorithms are used in the regulation of

hydroponic plants to obtain better performance,

including which uses the PID method to adjust pH of

solution (Hadiatna, Dzulfahmi, & Nataliana, 2020).

Another control method is Fuzzy Logic Controller to

adjust nutrient concentration (Nurmahaludin,

Cahyono, & Riadi, 2020) and to regulate the electrical

conductivity and pH of hydroponic plants (Dela

Vega, Gonzaga, & Gan Lim, 2021).

The next development is the regulation of

providing nutrition to hydroponic plants wirelessly

where Arduino is connected to Wi-Fi (Tembe, Khan,

& Acharekar, 2018) (Sihombing, Karina, Tarigan, &

Syarif, 2018) and an Ethernet module by connecting

to a microcontroller (Haq, Suwardiyanto, & Raya

Jember, 2018). Even though the control has been

done remotely, the settings are still done on-off where

the microcontroller will turn on or turn off the

actuator (pumping machine) when the control

objective has been achieved.

In this study, the PID control algorithm is used

where the resulting error will be processed

proportional, integral, and derivative. The valve

opening process depends on the servo motor

movement based on the PID controller output value

so that the desired density is achieved faster than the

on-off method. The control process is carried out

wirelessly using NodeMCU via an android device.

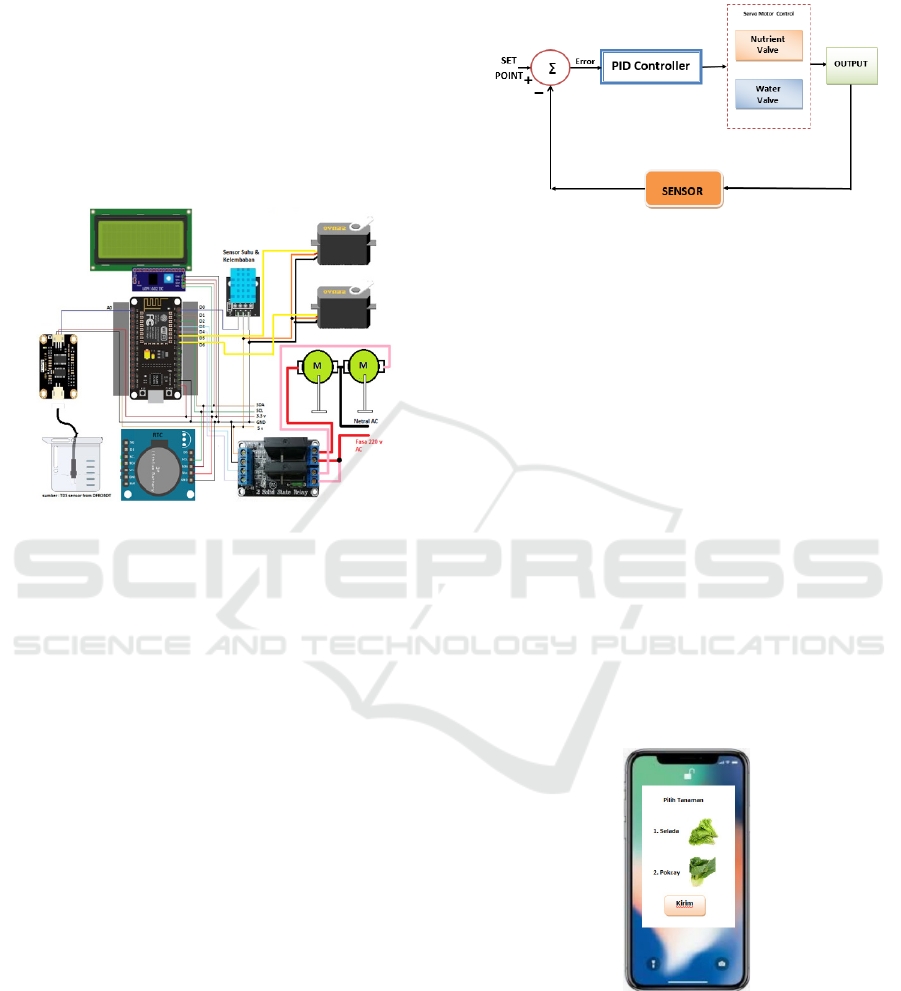

The control process is basically an attempt to keep

output (response) at the desired value of one or more

variables. Control system also aims to obtain good

performance from the controlled variables. Closed

loop control block diagram is shown in Figure 1.

Plant is a controlled system in this case is the

concentration of the hydroponic solution.

Process begins by giving a set point in the form of

the desired nutrient concentration value, then

measure the current output using the TDS sensor. The

results obtained are compared with the set point to

find errors that occur.

Nurmahaludin, N. and Cahyono, G.

Nutrient Feeding Automation System in Hydroponic Cultivation Using NodeMCU Based on PID Controller.

DOI: 10.5220/0011862100003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 669-673

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

669

e(t) = SP

–

PV (1)

where e(t) is error at time t, SP is set point, and PV is

present sensor's measured output.

Figure 1: Block diagram of closed loop control system.

Controller will provide an action based on the

control algorithm used. If using a PID controller, the

resulting error will be processed proportionally (P),

integral (I), and derivative (D) as follows:

a. Proportional Controller (P):

𝑃=𝐾

𝑒(𝑡)

(2)

b. Integral Controller (I):

𝐼= 𝐾

𝑒(𝑡)

(3)

c. Derivative Controller (D):

𝐷= 𝐾

𝜕𝑒

(

𝑡

)

𝜕𝑡

(4)

2 METHODS

The design of the nutrient concentration control

system in order to obtain the nutrient concentration in

accordance with the reference value for each type of

hydroponic plant is shown in Figure 2. To adjust the

solution concentration, a PID control algorithm is

used which will adjust the servo openings in the

nutrient and water valve. After the concentration of

the solution required by the plant is reached, the

hydroponic plants are watered.

Figure 2: System design for nutrient concentration control.

2.1 System Design

Figure 3 shows the hardware design and online

network. The main controller in system is the

NodeMCU microcontroller based on the ESP8266

module.

Figure 3: Hardware and network design.

The process of adjusting the concentration of the

nutrient solution is shown in the flow chart as shown in

Figure 4.

Figure 4: Control process flowchart.

2.2 Schematic Circuit

The schematic of electronic circuit is shown in Figure

5. Schematic has the following pin out configuration:

1. The TDS sensor will be connected to the analog pin

A0 of the NodeMCU microcontroller. The sensor

probe is placed in a tub of nutrient solution that

flows into the hydroponic NFT.

2. RTC and LCD use serial I2C, each of which for

SDA data is connected to the D1 pin of the

NodeMCU Microcontroller. Meanwhile, the SCL

leg is connected to the D2 pin of the NodeMCU

Microcontroller.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

670

3. Temperature and humidity sensors are connected

to the D0 pin of the NodeMCU microcontroller

4. Solid State Relay to drive the stirrer motor in the

NFT nutrient circulation basin and the main

nutrient solution reservoir A and B, gets a trigger

from pins D3 and D4 of the NodeMCU

microcontroller.

5. Servo motor is used to rotate the water valve and

the main nutrient valve solution A and B

connected to the D5 and D6 pins of the NodeMCU

microcontroller.

Figure 5: Electronic circuit schematic.

2.3 PID Control Algorithm Design

The nutrient solution concentration control system

with PID control as shown in Figure 6 is as follows:

1. The system input (set point) is the desired reference

value, in this case the concentration value of the

hydroponic plant nutrient solution.

2. The system output is the current value of the

nutrient solution concentration measured using

the TDS (Total Dissolved Solids) sensor.

3. The output value is then compared with the set

point to calculate the error.

4. The output of the PID controller will adjust the

angle of the servo motor to open the nutrient

solution or water valve.

5. If the error value is positive, it indicates that the

plant is approaching the threshold of excess

nutrients. So the controller will drive the servo

motor to open the water valve.

6. On the contrary, if the error value is negative, it

indicates that the plant is starting to approach the

threshold of nutrient deficiency so that the

nutrient solution valve needs to be opened through

servo motor movement.

7. System response data (output) is sent to the

database via the internet by the microcontroller.

These responses can be accessed and displayed

via the web for monitoring and analysis of system

transient responses.

Figure 6: Nutrient concentration control system block

diagram.

3 RESULT AND DISCUSSION

Node-MCU microcontroller will retrieve data from

the database in the form of a reference value for the

concentration of the desired plant nutrient solution.

3.1 Determine Set Point

The data is a set point that can be selected online via

a gadget or computer based on the type of plant.

Display of plant type selection as shown in Figure 7.

In Figure 7 there are two types of plants to be selected.

The selection is based on the type of hydroponic

plants. For example lettuce will be selected then after

the submit button is clicked, the nutrient density value

data from the database will be sent to the NodeMCU

as a set point is an error that will be processed by the

microcontroller using the PID controller.

Figure 7: Web based hydroponic plant selection display.

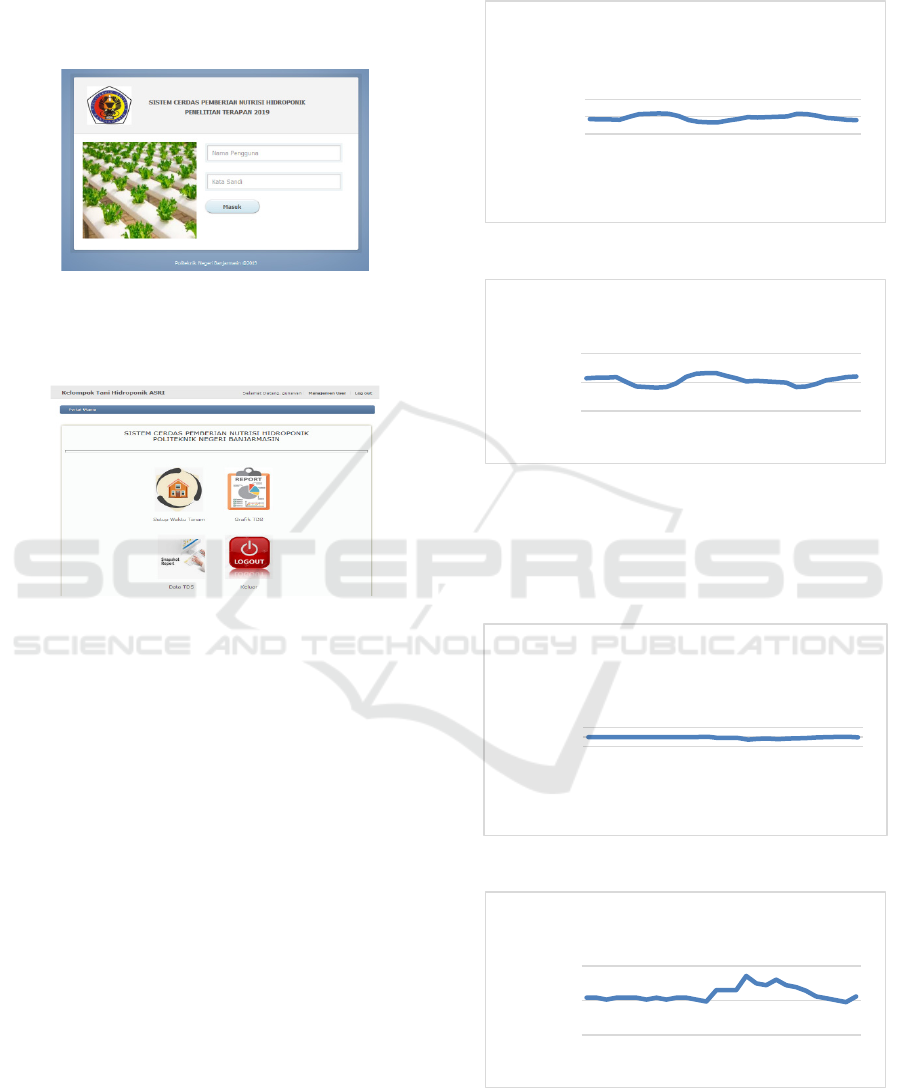

The mechanism for using web based program is

as follows:

1. Activate the WiFi access point that will connect to

NodeMCU microcontroller.

2. Turn on the hardware device for the nutrition

system for hydroponic plants.

Nutrient Feeding Automation System in Hydroponic Cultivation Using NodeMCU Based on PID Controller

671

3. After a few moments, setpoint value, TDS sensor,

temperature, humidity and time display will

appear on the LCD.

4. Open the internet web address and then enter the

username and password as shown in Figure 8.

Figure 8: Menu login.

5. Selecting planting time setup menu as shown in

Figure 9.

Figure 9: Main menu display.

6. Determination of set point starts from the setup

menu for planting date and time on the website.

7. Return to the main menu to enter the TDS Data

menu, to display TDS data, temperature and

humidity. Set point value will be sent to the

NodeMCU microcontroller via the internet as

shown in Figure 7 as before.

8. TDS Graph menu provides system response in

reaching a predetermined set point.

3.2 PID Controller Simulation Results

PID controller testing aims to determine the effect of

the values of Kp, Ki, and Kd on the system response

and the resulting error. Figure 10 provides test results

with values of Kp=0.8, Ki=0.3, and Kd=0.2, where

the value of the concentration of the solution from the

TDS sensor readings are taken for each sampling

time.

Response of the system to the set point is shown

in Figure 5.13, with a set point value of 600 ppm.

While the resulting error which is the difference

between the set point and the output is given in Figure

11. The average error value of the test is 6.95.

Figure 10: System response for Kp=0.8, Ki=0.3, Kd=0.2.

Figure 11: System error for Kp=0.8, Ki=0.3, and Kd=0.2.

Figure 12 is the result of testing using a PID

controller with Kp=0.8, Ki=0.5, Kd=0.5 and a set

point of 600 ppm. Average error value of the test is

3.92 as shown in figure 13.

Figure 12: System response for Kp=0.8, Ki=0.5, Kd=0.5.

Figure 13: System error for Kp=0.8, Ki=0.5, and Kd=0.5.

Based on the simulation results, the PID controller

values with Kp=0.8, Ki=0.5, and Kd=0.5 gave a

550

600

650

1 3 5 7 9 111315171921232527

i

lai Kekentalan

Waktu ke-

Respon Sistem Terhadap Set

Point

-50

0

50

1 3 5 7 9 11 131517 192123 2527

Nilai Error

Data ke-

Grafik Error Respon Sistem

550

600

650

1 3 5 7 9 1113 15 1719 212325 27

a

i Kekentalan

Waktu ke-

Respon Sistem Terhadap Set

Point

-20

0

20

1 3 5 7 9 111315171921232527

Nilai Error

Data ke-

Grafik Error Respon Sistem

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

672

smaller average error and a better response. This is

because integral controller will reduce the steady state

error and the derivative controller is useful for

reducing the overshoot that occurs. So that by

increasing the values of Ki and Kd compared to the

initial value will give better results.

4 CONCLUSIONS

Control the concentration of nutrient solution for

hydroponic plants using a PID controller where the

output of the controller will regulate the opening of

servo motor in the nutrient and water tank valve.

The test results show that the PID controller with

Kp = 0.8, Ki = 0.5, and Kd = 0.5 gives a fairly good

response and a relatively smaller average error of

3.92.

Improvement of system response and mean error

in this test is done by increasing the constant of

integral controller (Ki) and derivative controller (Kd).

ACKNOWLEDGEMENTS

Many thanks to the Politeknik Negeri Banjarmasin

for providing funding so that this research can be

completed.

REFERENCES

Azhari, Simanjuntak, D., Hakim, L., & Sabar. (2022).

Design and control system of temperature and water

level in hydroponic plants. Journal of Physics:

Conference Series, 2193(1). https://doi.org/10.1088/

1742-6596/2193/1/012018

Chaiwongsai, J. (2019). Automatic control and

management system for tropical hydroponic

cultivation. Proceedings - IEEE International

Symposium on Circuits and Systems, 2019-May, 1–4.

https://doi.org/10.1109/ISCAS.2019.8702572

Dela Vega, J. A., Gonzaga, J. A., & Gan Lim, L. A. (2021).

Fuzzy-based automated nutrient solution control for a

hydroponic tower system. IOP Conference Series:

Materials Science and Engineering, 1109(1), 012064.

https://doi.org/10.1088/1757-899x/1109/1/012064

Hadiatna, F., Dzulfahmi, A., & Nataliana, D. (2020).

Analisis Penerapan Kendali Otomatis berbasis PID

terhadap pH Larutan. ELKOMIKA: Jurnal Teknik

Energi Elektrik, Teknik Telekomunikasi, & Teknik

Elektronika, 8(1), 163. https://doi.org/10.26760/

elkomika.v8i1.163

Haq, E. S., Suwardiyanto, D., & Raya Jember, J. (2018).

Online Farm Menggunakan Greenhouse Untuk

Tanaman Hidroponik Berbasis Web. Jurnal Ilmiah

NERO, 3(3), 193–200.

Nurmahaludin, Cahyono, G. R., & Riadi, J. (2020). Nutrient

concentration control system in hydroponic plants

based on fuzzy logic. 3rd International Conference on

Applied Science and Technology, ICAST 2020, 141–

146. https://doi.org/10.1109/

iCAST51016.2020.9557617

Pache, A., Dudhe, A., & Dharaskar, B. (2022). Automated

Hydroponics Systems, A Review and Improvement.

11(5), 19–25. https://doi.org/10.21275/

SR22429121630

Sihombing, P., Karina, N. A., Tarigan, J. T., & Syarif, M.

I. (2018). Automated hydroponics nutrition plants

systems using arduino uno microcontroller based on

android. Journal of Physics: Conference Series, 978(1).

https://doi.org/10.1088/1742-6596/978/1/012014

Tembe, S., Khan, S., & Acharekar, R. (2018). IoT based

Automated Hydroponics System. 67–71.

Nutrient Feeding Automation System in Hydroponic Cultivation Using NodeMCU Based on PID Controller

673