The Effect of Variation of Catalyst Ratio on Polyester Resin on

Shrinkage and Ability to Absorb Mechanical Load on MiFUS® Case

Riona Ihsan Media

1a

, Roni Kusnowo

2b

, Yogi Muldani Hendrawan

3c

and Hafez Trimukti Ali Musa

3

1

Department of Design Engineering, Politeknik Manufaktur Bandung, Bandung, Indonesia

2

Department of Foundry Engineering, Politeknik Manufaktur Bandung, Bandung, Indonesia

3

Department of Manufacturing Engineering, Politeknik Manufaktur Bandung, Bandung, Indonesia

hafez.trimukti@gmail.com

Keywords: Rapid Tooling, Resin Epoxy, Resin Polyester, 3D Scan, Injection Molding.

Abstract: This study discusses the implementation of rapid tooling in the manufacture of MiFUS casing to find out what

happened and the optimal catalyst. The rapid tooling method is used because standard injection plastic is less

efficient for making low-scale products. Rapid tooling applications are realized by using concrete epoxy resin

as a product and polyester resin as a product. The use of polyester resin in products usually requires booster

because the material is well known and has a high uniqueness of 5-12%. The solution offered is to adjust the

ratio of the polyester resin in order to get the strength to receive optimal and minimum mechanical loads. The

shrinkage that occurs will be used as a design rule or a rule in increasing the size of each catalyst ratio so that

the size obtained is more precise than the function of the product can be achieved. The method begins with

the process of planning, manufacturing, and testing. The result of this research is for the tensile test, the

optimal catalyst ratio is 2.5:100 at 41 MPa while for the flexural test at 3: 100 it is 71 MPa. To distinguish the

minimum is at a catalyst ratio of 1.5: 100.

1 INTRODUCTION

Among the additive manufacturing processes based

on photopolymerization of liquid resins, RP (Rapid

Prototyping) technology using SLA is the oldest and

most popular. The importance of different operation

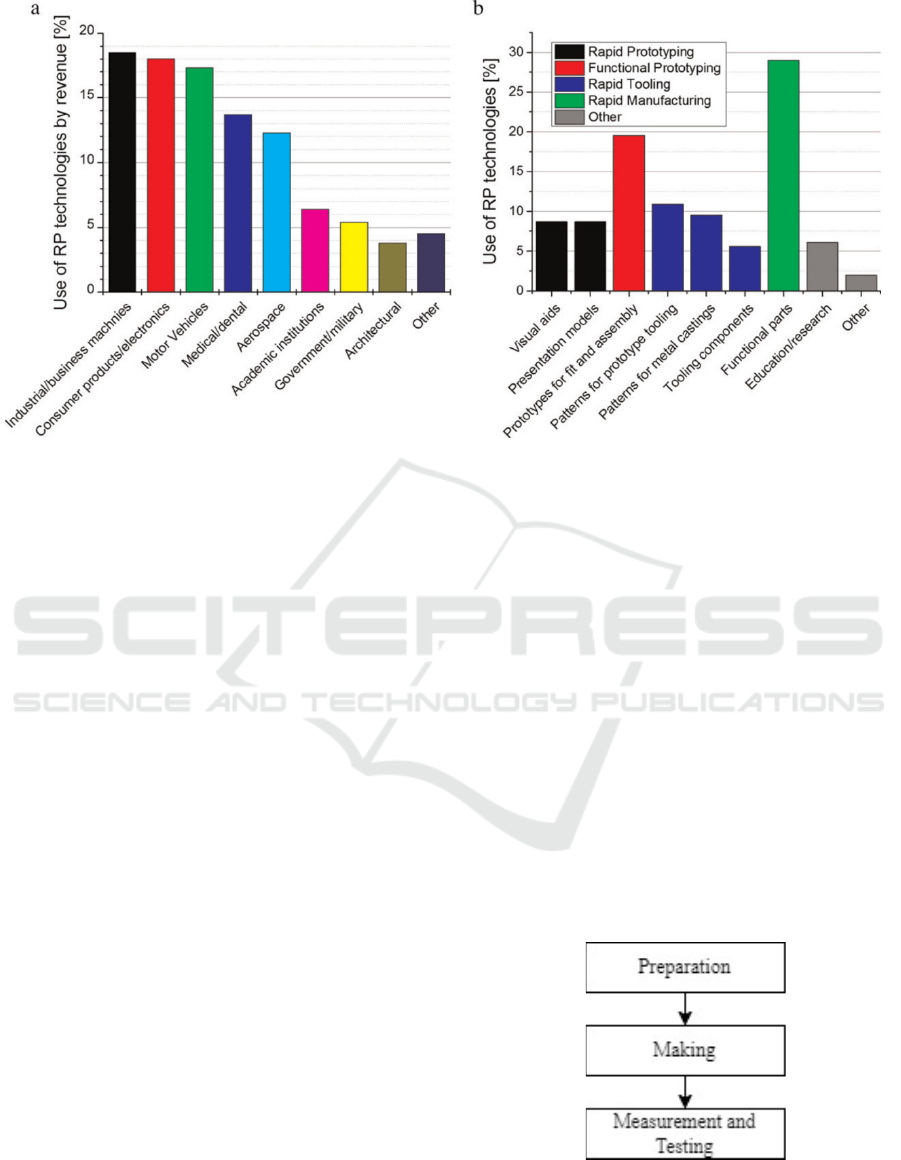

areas and industries can be predicted from Figure 1.

Driven by the expanding industrial concern of

LM, a variety of technologies - all summed up under

the term RP - have acquired (Aceto et. al., 2019).

Diverse methods to classifying the diversity of

technologies have been reported in the literature. In

addition to the individual application domains (Figure

1(b)), RP processes can also be classified according

to the initial physical state of the material being

treated and the physical or chemical transformations

underlying integrating each layer (Abdulhameed et.

al., 2019). Nowadays, RP processes are used not only

to visualize design ideas (idea modeling), but also to

a

https://orcid.org/0000-0003-1492-1487

b

https://orcid.org/0000-0002-7632-3434

c

https://orcid.org/0000-0004-4774-4966

manufacture molds and tools in rapid tooling (RT)

applications (Touri et. al., 2019). Furthermore,

additive and freeform layered manufacturing of 3D

models is no longer limited to the visualization of

prototype designs in rapid prototyping (RP), but is

applied to the preparation of prototypes. and Rapid

Tooling (Modi, Y. K., and Sanadhya, S., 2018).

Rapid tooling is a process of prototyping in a short

time. Rapid tooling parts are produced rapidly to test

and validate them prior to tooling production,

especially in the plastic injection molding process

(Bagalkot, 2019).

Rapid tooling parts are a perfect solution for

testing and evaluating prototypes and producing

several hundred parts before actually going into full

production (Ahmed, N., 2019). Fast feed techniques

enable the creation of inserts such as cores, side cores

and part cavities. The whole manufacturing process

depends on the quick tool used; It is also possible to

674

Media, R., Kusnowo, R., Hendrawan, Y. and Musa, H.

The Effect of Variation of Catalyst Ratio on Polyester Resin on Shrinkage and Ability to Absorb Mechanical Load on MiFUS® Case.

DOI: 10.5220/0011862200003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 674-682

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Figure 1: Market share relevance of RP technologies. Revenue earned is related to (a) industry and (b) application sectors.

produce parts through multiple mold cycles.

However, rapid tooling technology need to consider

many factors to get the most out of these benefits, as

they vary in size, consistency, technology, precision,

and materials (Zhou, L. Y., Fu, J., and He, Y., 2020).

Currently, many methods have been developed to

produce a product with the low quantity, the method

is commonly called Rapid Tooling (RT). The term RT

refers to the manufacture of tools that are made

quickly and cheaply, only now the definition of RT is

starting to develop into tools that refer to the age of

the RT itself (Barnhoorn et. al., 2015).

There are several types of Rapid Tooling, namely

RTV (Room-temperature Vulcanizing) Mold, Rapid

Aluminium Tools (RAT), CAFÉ Bridge Tool, and

Direct AIM Rapid Bridge Tool (Wolf et. al., 2018).

Of all the available rapid tooling methods, the RTV

Mold was chosen which was applied by changing the

core and cavity with epoxy resin and polyester resin

materials for the product.

It is just that the problem with the use of polyester

resin in the product is the size deviation caused by

shrinkage. Shrinkage in polyester resins ranges from

5% – 12% (Gao et. al., 2019). The shrinkage that

occurs is expected to be as minimal as possible so that

deviations in the size and function of the product can

be achieved.

In addition to shrinkage, the problem with RTV

molds with resin-based products is the need for

reinforcement in the form of fibers in the resin (Celik,

K., & Belli, S., 2015). With the addition of

reinforcement in the form of fiber, the product will

have better mechanical load-bearing strength. It is

just that the product to be made will not use fiber or

reinforcement so that the strength of the product will

be reduced. So that even without reinforcement, it is

expected that the strength to receive optimal

mechanical loads is obtained.

Although much research addressed obtaining a

good quality product with the optimal solution,

shrinkage has not yet been finished with the optimal

ratio. The solution given to this problem is to try to

adjust the catalyst ratio in the polyester resin to get

the optimal ratio. By adjusting the ratio of the catalyst

to the resin, it is hoped that the shrinkage and strength

to receive the most optimal mechanical load will be

obtained in order to provide a higher quality product

to the user.

2 METHODOLOGY

Figure 2: Research methodology.

The Effect of Variation of Catalyst Ratio on Polyester Resin on Shrinkage and Ability to Absorb Mechanical Load on MiFUS® Case

675

2.1 Preparation

2.1.1 Hypothesis

All scientific thought begins with a hypothesis or

initial guess. In this study, the author made a

hypothesis based on the literature which was further

validated through trials. The following is the

hypothesis in this research:

1. There is an effect of variations in the ratio of

catalysts in polyester resin to shrinkage.

2. The greater the ratio of the catalyst given, the

greater the shrinkage that occurs.

3. The greater the ratio of the catalyst given, the

greater the strength to receive the mechanical

load.

2.1.2 Products Identification

There are 4 products to be made, namely front and

rear MiFUS cases, tensile test samples, and flexural

test samples. For the tensile test the standard size used

is 572-2 while for the flexural test it is ASTM D790-

10.

The front case has several functions, namely as a

battery holder, indicator light holder, and buzzer

holder. In addition, the material of the product must

have heat resistance due to electrical components,

withstand impact loads, and be elastic enough to fulfil

the snap-fit function.

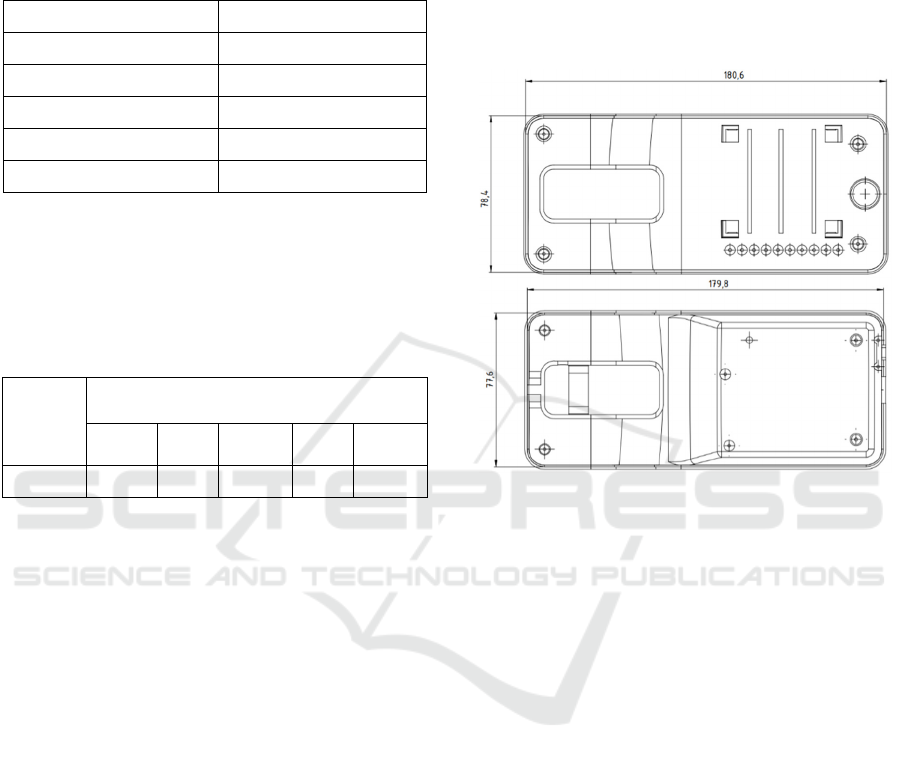

Figure 3: MiFUS front case.

This back-casing product has a function as a

holder for all electrical parts ranging from circuits,

micro-USB, and also sensors. In addition, the

function of this product is as a binder between the

front and back covers.

2.2 Making

Making includes making product masters using 3D

prints, making molds, and making products. The

following is a description of each manufacturing

process.

Figure 4: MiFUS back case.

2.2.1 Products Master Making

The product master is a prototype product that is used

as part of the positive mold. The manufacture of this

product master uses 3D Print technology with ABS

material. For the finishing process on the product to

smooth the surface, the sandpaper process is used for

the MiFUS casing product and vapor smoothing for

the tensile test and flexural test samples.

2.2.2 Mold Making

The molds are divided into 3, namely the molds for

the front MiFUS casing, the front, and the mechanical

load test sample products. It's just that the process is

the same, what makes the difference is the

manufacture of the holder for the MiFUS casing. This

is needed because the formation of the product is less

stable without a stand.

2.2.3 Product Making

Before starting the experiment, it must be determined

in advance the variation of the ratio of the catalyst to

the resin in order to know how many samples to

make. Based on research conducted by Ansari et. al.

(2020) on composites, the variation in the ratio of

catalysts to polyester resins is 0,5:100; 1:100; 2:100;

and 2,5:100 with each ratio made 3 samples. From the

3 samples, the best 1 was taken to be plotted in the

graph. In the end, it was concluded that the most

optimal ratio of all these variations was 2.5:100 and

the less good one was 0.5:100.

Because the mechanical test graph for each

sample shown in previous studies continues to rise,

the authors try to make slightly different variations.

This is intended to obtain a more optimal variation

and to know the limits of the use of a less than optimal

catalyst. Because the more catalyst, the longer the

product will dry and become sticky. Therefore, the

authors make variations in the ratio to 1,5:100; 2:100;

2.5:100; 3:100; 3,5:100.

Furthermore, these variations are presented in

tabular form in order to know the exact volume

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

676

composition between catalyst and resin for each test

product. The volumes in the table are obtained from

the SolidWorks software.

Table 1: Design of total resin volume of each specimen.

Products Volume (mL)

Front Casing 36

Back Casing 45

Tensile Test 10

Flexural Test 6

Total Volume 97 ≈ 100

So, the total resin volume required for 1

experimental batch of sample making is 100 mL.

Next is to calculate the volume of catalyst needed.

The following is a table showing the volume of resin

required for each ratio variation.

Table 2: Resin required for each batch.

Total

Volume

Catalyst required (Catalyst: Resin)

1,5:100 2:100 2,5:100 3:100 3,5:100

100 1,5 2 2,5 3 3.5

2.3 Measurement and Testing

Tests for products are generally divided into 2,

namely measurement of shrinkage with a 3D Scanner

and testing of mechanical loads. Specific shrinkage

measurements for MiFUS casing products so that

later these measurements can be used as a design

reference for materials using polyester resin. For

mechanical load testing, standard samples are made

whose dimensions have been adjusted to existing

standards.

2.3.1 Shrinkage Measurement Using 3D

Scanner

The 3D Scanner machine used for measurement is the

METRASCAN CREAFORM machine. The

advantage of this machine is that it can capture up to

800,000 points every second. Therefore, the

following are the specifications of the 3D Scanner

engine that will be used.

Measurement of depreciation using 3D Scanner

produces a product in the form of a point cloud. This

point cloud cannot be edited using ordinary CAD

software. The software used to help editing and 3D

Compare is Geomagic. The following are the stages

in using software for the 3D Compare process. No dot

should be included after the section title number.

In addition, this measurement also determines the

dimensions that must be measured with a calliper.

This aims to determine the shrinkage in certain parts,

especially in pairs, in order to obtain parameters for

later design. The following are the dimensions that

must be measured with a calliper.

Figure 5: Dimension that will be measured.

2.3.2 Tensile Test and Flexural Test

The purpose of carrying out this flexural test is to

obtain material properties and find out how much

flexural load the product can withstand. It is hoped

that later it will be known whether the product can

fulfil the snap-fit function or not. As for the tensile

test, the goal is to get the tensile strength so that it is

expected to know how brittle the material is.

3 RESULTS AND DISCUSSION

3.1 Shrinkage Data Analysis

To collect depreciation data, two methods are used.

The first method is to measure using a digital calliper

with an accuracy of 0.01 mm and then see the size

deviation that occurs. The second method is to use a

3D Scan tool so that later a standard deviation is

obtained to represent the deviations that occur.

3.1.1 Manual Measurement

Manual measurement is done by determining the

dimensions to be measured first. After that it was

The Effect of Variation of Catalyst Ratio on Polyester Resin on Shrinkage and Ability to Absorb Mechanical Load on MiFUS® Case

677

measured 3 times and the results were averaged. In

addition, the number of samples measured was 15

pairs of product samples (front cover and back cover)

with 3 samples in each ratio variation.

The product that is the measurement reference is

the master product which is made to be negative on

the mold. Before measuring on the product,

measurements are made on the master product which

is compared with 3D CAD. The following are the

measurement results along with the deviations that

occur. So the percentage of deviations that occur is

the result of a comparison between the master product

and the printed product

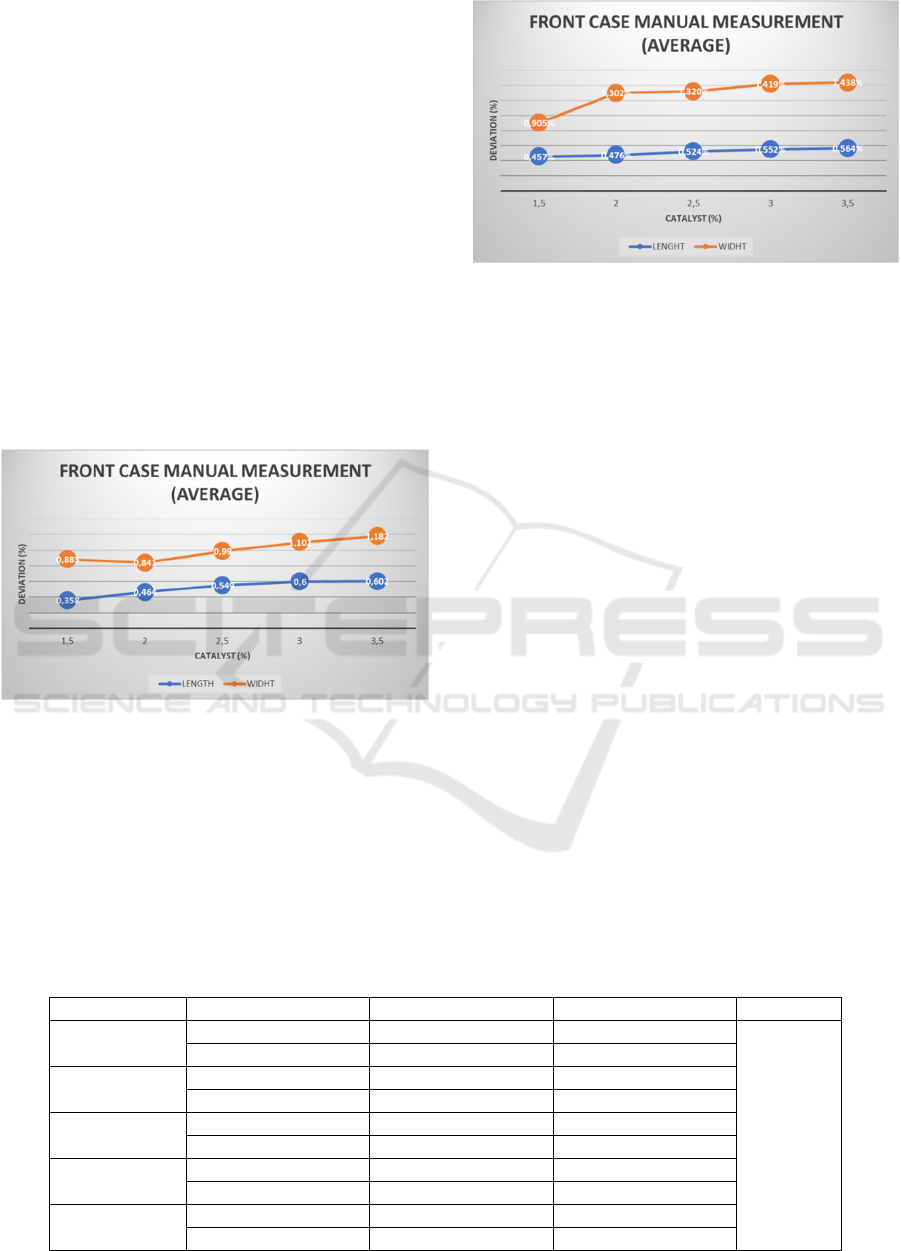

After that the average deviation of the product is

displayed in the form of a graph to see the increase in

the deviation. The following is the deviation data

from manual measurements for the front cover and

back cover which have been averaged for each

catalyst ratio.

Figure 6: Manual measurement graphic for Front Case.

From the two graphs, it can be concluded that the

more catalysts are included, the larger the deviation

or in this case the shrinkage of the measured part. In

addition, the graph shows that the largest shrinkage

for the front cover and back cover occurs at a catalyst

ratio of 3.5: 100. Meanwhile, the smallest shrinkage

at a catalyst ratio of 1.5: 100. The depreciation that

occurs

is

lower

than

the

depreciation

in

the

given

Figure 7: Manual measurement graphic for Back Case.

theory, which is 5%-12%. This is caused because the

product is made too thin so that the shrinkage that

occurs is getting smaller.

In both graphs there are similarities, namely the

average deviation of the largest deviation in the

width. This is because the contact area in the width

dimension is longer than the long dimension. In

addition, because the process of taking the product is

carried out when the product is half dry to make it

easier to take, this can cause the product to be

deformed.

From the measurement data obtained, it is then

used as the basis for determining the recommended

dimensions for the length and width of the pre-

determined product. The following are the suggested

dimensions for each variation of the catalyst ratio in

the length and width dimensions.

Table 3: Dimension recommendation for length and width for front case.

Catalyst Ratio Length and Width Ref. Dim. Rec. Dim. Tol

1,5

L 179,86 179,04

± 0,3

W 77,59 76,89

2

L 179,86 179,01

W 77,59 76,58

2,5

L 179,86 178,92

W 77,59 76,57

3

L 179,86 178,87

W 77,59 76,49

3,5

L 179,86 178,85

W 77,59 76,48

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

678

Table 4: Dimension recommendation for length and width for front case.

Catalyst Ratio Length and Width Ref. Dim. Rec. Dim. Tol

1,5

L 179,86 179,22

± 0,3

W 77,59 76,91

2

L 179,86 179,03

W 77,59 76,94

2,5

L 179,86 178,88

W 77,59 76,83

3

L 179,86 178,78

W 77,59 76,74

3,5

L 179,86 178,78

W 77,59 78.71

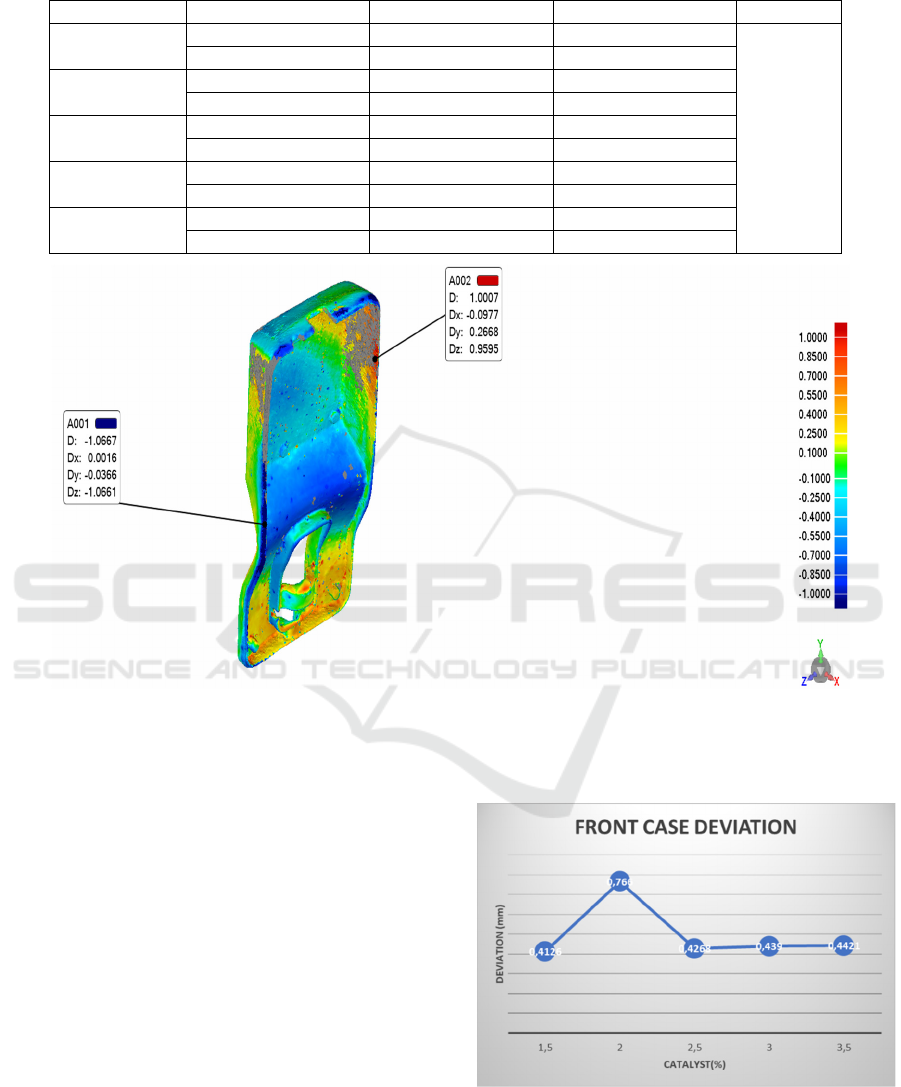

Figure 8: Example of 3D compare product.

3.1.2 3D Scan Measurement

Measurements using 3D Scan were carried out using

5 pairs of product samples (front cover and back

cover) with 1 sample for each variation of the catalyst

ratio. This is because there are some products with too

many voids or trapped air so that they are considered

unfit for the 3D Scanning process. The product used

is the product with the least trapped air holes or voids

on the product display in order to obtain a topology

that is closest to the product master. Measurements

are made by comparing the master product that is

made into a mold with the printed product. After that,

it is compared using the Geomagic software using the

3D Compare feature to get the deviation that occurs

in each product.The tolerance entered in the software

is ±0.1 mm. This is based on a maximum product

thickness of 2 mm and follows standard general

tolerances. The following is graphics of 3D Scan

results along with the maximum and minimum

deviations that occur in the product.

Figure 9: Front case deviation.

The Effect of Variation of Catalyst Ratio on Polyester Resin on Shrinkage and Ability to Absorb Mechanical Load on MiFUS® Case

679

Figure 10: Back case deviation.

In the standard deviation chart on the front cover,

the smallest deviation occurs at a ratio of 1.5: 100 and

the largest is 2:100 with each deviation of 0.4126 mm

and 0.766 mm.

The non-linear increase in the ratio of 2: 100 is

most likely due to different treatments during the

manufacturing process such as clamping that is not

hard enough, room temperature is too low, or uneven

stirring. However, after a ratio of 2: 100 the data

obtained is quite linear.

In contrast to the back cover, the largest deviation

occurred at the catalyst ratio of 2.5: 100. However,

the smallest deviation remained at the catalyst ratio of

1.5: 100. This data obtained quite linear data.

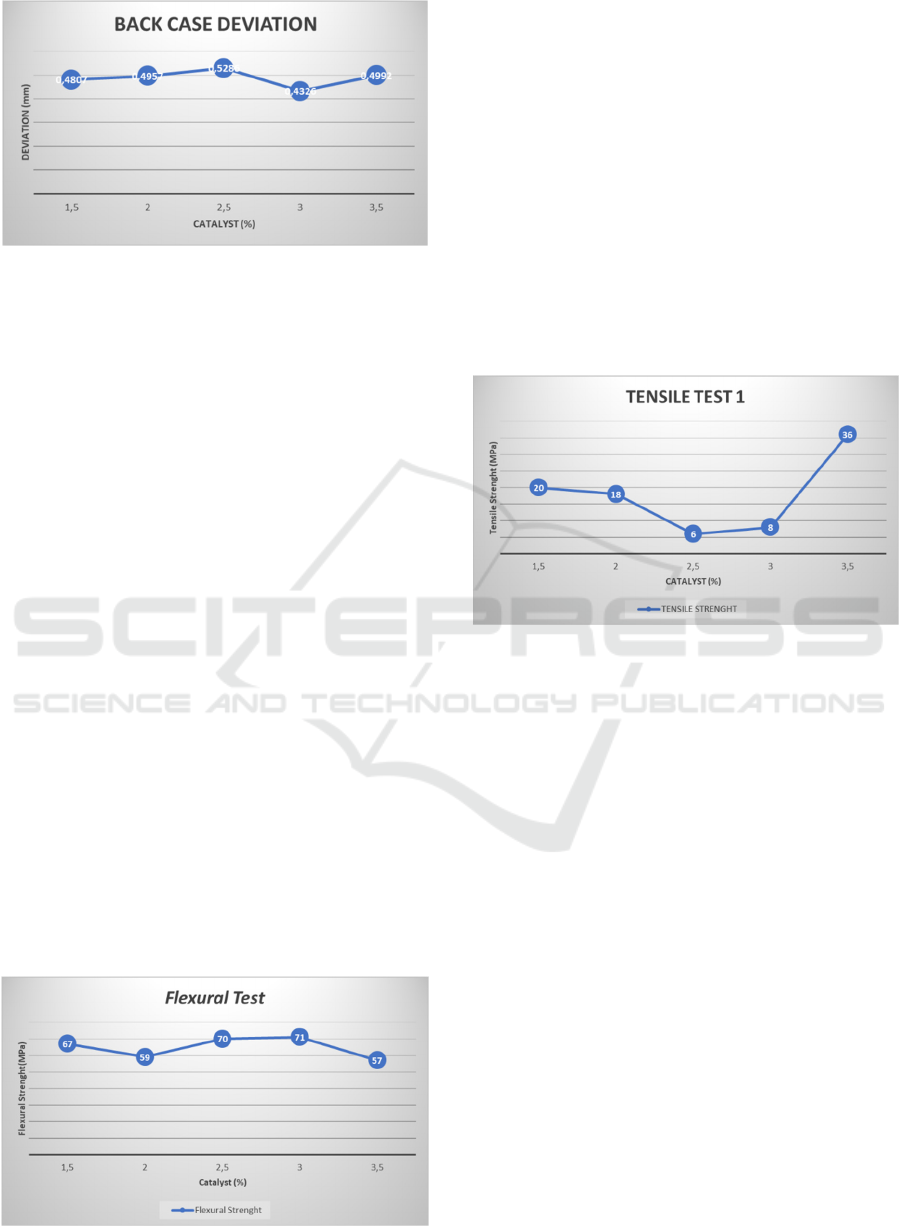

3.2 Mechanical Test

Mechanical properties testing carried out is 2 tests,

namely flexural test and tensile test. All mechanical

load testing is carried out in the material testing

laboratory in the metal casting department. The

following are the results of the mechanical load

testing.

3.2.1 Flexural Test

The number of samples tested in the flexural test

amounted to 5 samples. From the test results obtained

the following results.

Figure 11: Flexural Test.

Based on the test results, it is found that the

greater the catalyst that is inserted into the polyester

resin, the higher the load-taking ability. In addition,

the most optimal alloy is the 3: 100 alloy with the

ability to accept mechanical loads of 71 MPa. This is

approximately 38% higher than the theoretical basis

that has been given, which is about 40.6 MPa.

While the lowest bending strength is at a ratio of

3.5:100 with a strength of 57 MPa. This is because

too much catalyst makes the material more brittle or

brittle and unable to withstand bending loads.

3.2.2 Tensile Test

The tensile test uses 5 samples. The following is the

tensile test result data presented in the form graphs.

Figure 12: Tensile Test 1.

Based on the test results, it was found that the

most optimal yield was 3.5: 100. This was due to the

increasing number of catalyst alloys and the harder

and more brittle material. In samples 2, 3 and 4 there

was a decrease in strength this was due to the poor

drying process so that the material was not strong

enough to withstand tensile loads. In addition, it is

suspected that the stirring process is not good so that

the catalyst is not mixed evenly. Therefore, after

discussing with the supervisor, it was decided to carry

out a tensile test for the second time. The following is

the data from the second tensile test which is

presented in the form of tables and graphs.

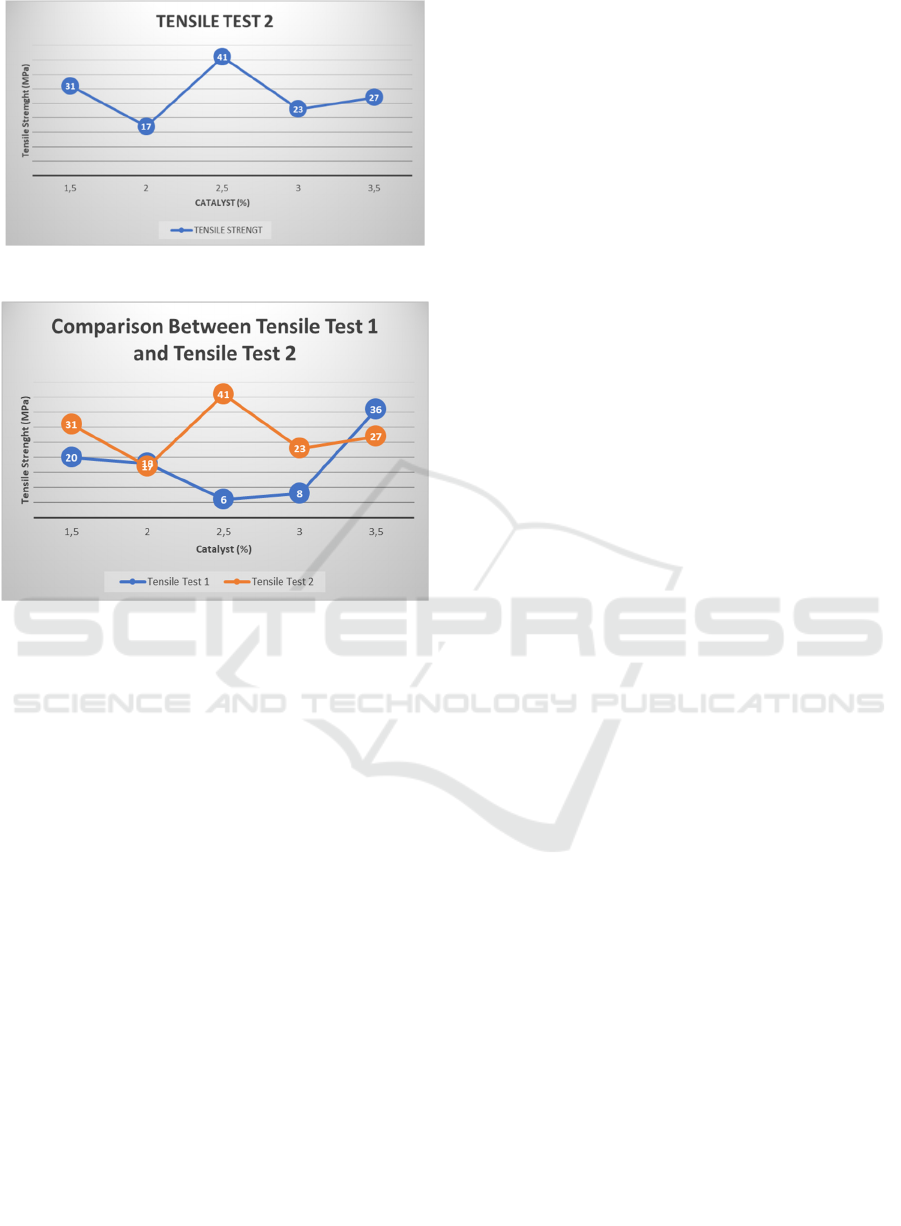

Based on the graph of the test results, it was found

that the most optimal alloy was at a ratio of 2.5:100

of 41 MPa and this was 19.5% greater than the given

theory, which was 33 MPa. However, the gradient is

still not linear even though the time and method of

stirring have been the same.

After that the author tries to compare the data

from the tensile test results one and two in one graph

and see how the difference is. The following is a

comparison chart between tensile tests 1 and 2.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

680

Figure 13: Tensile Test 2.

Figure 14: Comparison between tensile test 1 and tensile

test 2.

From the graph, it can be seen that there was an

increase in the average tensile strength from 17.8

MPa to 27.8 MPa. This shows that the time and

method of stirring have an effect on the resin product

made

Based on the test results obtained data that is less

linear, this has several factors causing the data to be

less linear. The following are factors that affect the

data to be less linear:

1. Unstable room temperature

The product production process is carried out

outdoors because it will be quite dangerous if the

production process is carried out indoors due to toxic

substances in polyester resin. Due to the outdoor

production process, the temperature of the

manufacturing environment during the day will be

different from the manufacturing temperature in the

morning. The higher the temperature, the faster the

reaction will occur.

2. Poor Molding

The main problem with the mold is that the ejection

process is difficult and lacks rigidity. So that when the

product is ejected, the mold is damaged and parts of

the mold sometimes stick to the product. In addition,

the surface of the resulting product is uneven so that

when the test results are gripped by the tensile testing

machine there are cracks in the product before the test

is carried out.

3. Drying time

In the products made there are several test samples

which after being made a few hours later the test is

immediately carried out. So that the sample is not

completely dry at the time of testing. The optimal

drying time for the resin is 1 to 2 days after the

product is made for the product to dry completely.

4 CONCLUSIONS

There is an effect of changes in catalyst ratio

variations in polyester resins on shrinkage. The

hypothesis that the greater the catalyst is inserted, the

greater the shrinkage that occurs is true based on the

results of manual measurements and 3D Scans. While

the results of manual measurements and 3D Scanning

obtained the smallest deviation or deviation due to

shrinkage is at a ratio of 1.5: 100. In addition,

shrinkage parameters are produced for the length and

width of the product for each variation of the ratio of

catalyst to resin.

There is an effect of changes in catalyst ratio

variations in polyester resin on the ability to accept

mechanical loads. The hypothesis given is not

entirely correct, because the data obtained do not

show that the larger the catalyst, the greater the

mechanical ability. In the bending test the most

optimal alloy is 3:100, which is 71 MPa, while for the

tensile test it is 2.5:100 at 41 MPa.

REFERENCES

Aceto, G., Persico, V., & Pescapé, A. (2019). A survey on

information and communication technologies for

industry 4.0: State-of-the-art, taxonomies, perspectives,

and challenges. IEEE Communications Surveys &

Tutorials, 21(4), 3467-3501.

Abdulhameed, O., Al-Ahmari, A., Ameen, W., & Mian, S.

H. (2019). Additive manufacturing: Challenges, trends,

and applications. Advances in Mechanical Engineering,

11(2), 1687814018822880.

Touri, M., Kabirian, F., Saadati, M., Ramakrishna, S., &

Mozafari, M. (2019). Additive manufacturing of

biomaterials− the evolution of rapid prototyping.

Advanced Engineering Materials, 21(2), 1800511.

Modi, Y. K., & Sanadhya, S. (2018). Design and additive

manufacturing of patient-specific cranial and pelvic

bone implants from computed tomography data.

The Effect of Variation of Catalyst Ratio on Polyester Resin on Shrinkage and Ability to Absorb Mechanical Load on MiFUS® Case

681

Journal of the Brazilian Society of Mechanical Sciences

and Engineering, 40(10), 1-11.

Bagalkot, A., Pons, D., Clucas, D., & Symons, D. (2019).

A methodology for setting the injection moulding

process parameters for polymer rapid tooling inserts.

Rapid Prototyping Journal.

Ahmed, N. (2019). Direct metal fabrication in rapid

prototyping: A review. Journal of Manufacturing

Processes, 42, 167-191.

Zhou, L. Y., Fu, J., & He, Y. (2020). A review of 3D

printing technologies for soft polymer materials.

Advanced Functional Materials, 30(28), 2000187.

Barnhoorn, J. S., Haasnoot, E., Bocanegra, B. R., & van

Steenbergen, H. (2015). QRTEngine: An easy solution

for running online reaction time experiments using

Qualtrics. Behavior research methods, 47(4), 918-929.

Wolf, M. P., Salieb-Beugelaar, G. B., & Hunziker, P.

(2018). PDMS with designer functionalities—

Properties, modifications strategies, and applications.

Progress in Polymer Science, 83, 97-134.

Gao, Y., Zhang, H., Huang, M., & Lai, F. (2019).

Unsaturated polyester resin concrete: A review.

Construction and Building Materials, 228, 116709.

Celik, K., & Belli, S. (2015). The effect of different

restoration techniques on fracture strength of teeth with

flared roots. Journal of Adhesion Science and

Technology, 29(1), 12-23.

Ansari, A. A., Dhakad, S. K., & Agarwal, P. (2020).

Investigation of mechanical properties of sisal fibre and

human hair reinforced with epoxy resin hybrid polymer

composite. Materials Today: Proceedings, 26, 2400-

2404.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

682