Utilization of Parafin and TiO

2

as Phase Change Materials (PCM) for

Processor Coolers

I Made Arsawan

1a

, I Putu Sastra Negara

1b

and I Gede Oka Pujihadi

2c

1

Politeknik Negeri Bali Badung Bali, Indonesia

2

Department of Mechanical Engineering, Politeknik Negeri Bali, Indonesia

Keywords: Processor Cooler, Heatsink, Phase Change Material.

Abstract: The development of new and renewable energy is an alternative that can be done to avoid an energy crisis.

One of the most prospective energy storage techniques is thermal energy storage. Thermal energy storage

technique is by utilizing the phase change of a material or known as Phase Change Material (PCM). Phase

change materials (PCM) are materials that change their physical characteristics when they absorb or release

heat energy. Many refrigeration technologies currently utilize PCM technology in their cooling process.

(Hikma et al. 2020) AC which was originally used massively and can damage the environment can be replaced

by EGACY on a regular basis. Utilization of PCM in the electronics field has begun to be developed, as

research conducted by(Kandasamy, Wang, and Mujumdar 2008) found that PCM in the heat sink cavity will

improve cooling performance compared to the case of a heat sink without PCM. In this study, we will try to

develop a PCM-based processor cooler, by making a test tool in the form of a PCM-based processor cooling

simulation. After the simulation is complete, the operational system is tested before taking data. Data

collection was carried out with a combination of PCM material in the form of paraffin and TiO

2

with several

variations of the mixture, namely with PCM material in the form of pure paraffin, paraffin + 2% TiO

2

, paraffin

+ 4% TiO

2

, paraffin + 6% TiO

2

, paraffin + 8% TiO

2

, and paraffin + 10 %TiO

2

. The results showed that the

addition of PCM into the heatsink can reduce the processor temperature and the addition of TiO

2

to paraffin

can stabilize the temperature that occurs in the processor. The addition of 4% and 6% TuO

2

provides the best

cooling effect on the processor compared to pure paraffin and TiO

2

concentrations of 2%, 8%, and 10%.

1 INTRODUCTION

The development of new and renewable energy is an

alternative that can be done to avoid an energy crisis.

Many things can be done to develop renewable

energy, such as developing solar energy, developing

micro hydro energy, developing wind energy and

others. One alternative in the effort to utilize

renewable energy is the development of energy

storage devices, which is as important as developing

renewable energy sources. Energy storage not only

reduces the mismatch between supply and demand, it

can also improve the performance and reliability of

energy systems and play an important role in energy

utilization more effectively. One of the most

a

https://orcid.org/0000-0002-2365-9401

b

https://orcid.org/0000-0002-1028-070X

c

https://orcid.org/0000-0003-0417-8538

prospective energy storage techniques is thermal

energy storage. Thermal energy storage technique is

by utilizing the phase change of a material or known

as Phase Change Material (PCM).

Phase change materials (PCM) are materials that

change their physical characteristics when they

absorb or release heat energy. Utilization of phase

changes of a material in the form of liquid and solid

phase changes. When a solid material is heated to a

temperature above its melting point, it absorbs heat

and melts. On the other hand, when a liquid is cooled

below its melting point, the liquid will solidify at a

constant temperature, for example water is put in a

freezer until it changes to a solid phase (Ice).

Furthermore, if you want to melt or condense a

material that can change phase it is necessary to

732

Arsawan, I., Negara, I. and Pujihadi, I.

Utilization of Parafin and TiO2 as Phase Change Materials (PCM) for Processor Coolers.

DOI: 10.5220/0011875800003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 732-740

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

absorb or release a certain amount of energy which is

called "latent heat" or "heat of fusion".

Many refrigeration technologies currently utilize

PCM technology in their cooling process. (Hikma et

al. 2020) Air conditioners that were originally used

massively and can damage the environment can be

replaced by EGACY on a regular basis, so that at

night, cold temperatures can be used as a source of

cooling energy that is stored first by the PCM and

then released during the day. Through pipes

connected to the building, air will flow into the room

and then spread to all parts of the room. When this

is implemented, the benefits of being an

environmentally friendly, economical and of course

energy efficient cooler will be obtained.(Risano, S,

and Pratama 2017) The difference in the efficiency

of using PCM CPO (Crude Palm Oil) in heat transfer

from the inner wall to the Building Intergated

Photovoltaics (BIPV) room can increase the

efficiency by 5.75%. (Putra et al. 2020) A study of

the performance of beeswax (PCM) phase change

materials and heat pipes as a passive battery cooling

system for electric vehicles resulted in the use of

heat pipes to reduce the battery temperature by 26.62

°C under a heat load of 60 W compared to casing

without passive cooling system. Furthermore, the

addition of RT 44 on the heat pipe resulted in a

maximum temperature decrease of 33.42 °C. Thus,

RT 44 HC is more effective than beeswax because

its melting temperature is within the battery's

recommended operating temperature range, and its

latent heat allows more heat to be absorbed than

beeswax.

The use of PCM in the electronics field has

begun to be developed, as research conducted by

(Kandasamy, Wang, and Mujumdar 2008) found

that PCM in the heat sink cavity will improve

cooling performance compared to the case of heat

sinks without PCM when the input power level is

relatively high. The use of liquid metal was

developed as PCM material in Heatsink by (Fan et

al. 2016) liquid metal PCM materials and organic

materials were compared as PCM materials in heat

zinc applications, where molten metal has the ability

to overcome oper heat better than organic materials

(Octadecanol) and The volumetric latent heat of

molten metal smelting is proportional to the latent

heat of organic PCM.

Research on PCM materials is growing,

currently, nano-PCM materials have been

developed. This nanotechnology has also been

investigated by (Bayat, Faridzadeh, and Toghraie

2018) regarding the investigation of the

performance of finned heat sinks with nano-level

phase change materials (NePCM) where the

addition of a small portion of nanoparticles (2%),

heat sink performance can be increased up to PCM.

melted completely. Increasing the percentage of

nanoparticles, can cause a decrease in the

performance of heat zinc. With the addition of 2%

aluminum oxide nanoparticles can produce better

heatsink performance compared to the case of

adding copper oxide with the same percentage.

The development of PCM on processor cooling

has not been widely developed, because the

microprocessor is susceptible to liquid fluid which

results in the failure of the processor performance.

Previous research has been done on processor

cooling by using liquid fluid that flows through heat

zinc, where the results of the multi-channel flow

model provide a better cooling effect than the pool-

shaped flow model. In this study, it will be tried to

develop the use of local materials, namely lard as

PCM material combined with faraffin wax in

processor cooling.

2 PHASE CHANGE MATERIAL

(PCM)

PCM can be classified into two, namely organic and

anorganic. This grouping is based on the melting

point and latent heat of fusion. There is no single

material that can fulfill all the desired properties, so

PCM is also developed which is a combination of 2

groups of materials (Sharma et al. 2009).

2.1 Organic PCM

Usually organic PCM has a low temperature range, is

expensive and has a low average latent heat per unit

volume and density. Most organic PCMs are

flammable in nature. Organic PCM can be

distinguished as paraffin and non-paraffin.

2.1.1 Paraffins

Paraffins consist of a mixture of mostly straight chain

n-alkanes CH3-(CH2)-CH3. Crystallization of the

chain (CH3)- releases some latent heat. The melting

point and latent heat of fusion increase with the length

of the chain. The quality of paraffin as a smelting heat

storage material is caused by its wide temperature

range. Some of the melting points and latent heat of

smelting of paraffin can be seen in Table 1.

Utilization of Parafin and TiO2 as Phase Change Materials (PCM) for Processor Coolers

733

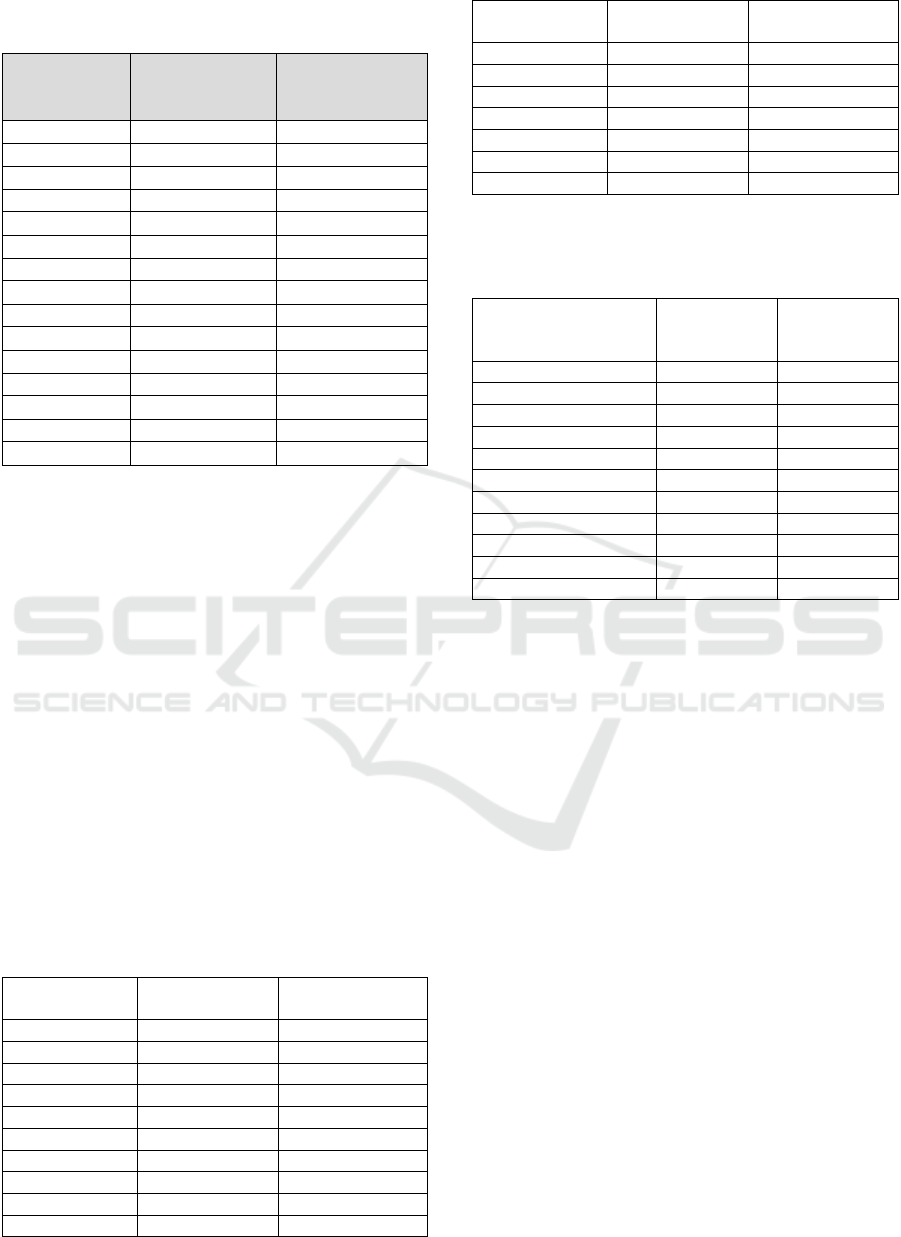

Table 1: Melting Point and Latent Heat of Melting Some

Types of Paraffins.

Number of

Atom C

Melting Poin

(

o

C)

Latent Heat of

Melting (kJ/kg)

14 5.5 228

15 10 205

16 16.7 237.1

17 21.7 213

18 28.0 244

19 32.0 222

20 36.7 246

21 40.2 200

22 44.0 249

23 47.5 232

24 50.6 255

25 49.4 238

26 56.3 256

27 58.8 236

28 61.6 253

Source: Sharma et al.2009

2.1.2 Nonparaffin

PCM from non-paraffin materials is PCM that is

commonly encountered with quite a lot of variation in

properties. Each of these materials has special

characteristics / properties unlike paraffin which has

almost the same properties. This type is the most

common category of PCM. Among the non-paraffinic

materials, the most common types are esters, fatty

acids, alcohols and glycol types (Abhat et al. 1981).

This group is often further subdivided into groups of

fatty acids and other nonparaffinic organics. These

materials are generally flammable and should not be

exposed to high temperatures, near flames and

oxidizing agents. The description of non-paraffin

PCM can be seen in Table 2, while the fatty acid PCM

can be seen in Table 3.

Table 2: Melting Point and Latent Heat of Melting Some

Non Paraffin.

Materials Melting Point

(

o

C)

Latent Heat of

Melting (kJ/kg)

Formic acid 7.8 247

Caprilic acid 16.3 149

Glycerine 17.9 198.7

α-Lactic acid 26 184

Methyl palmitat 29 205

Phenol 41 120

Bee wax 61.8 177

Gyolic acid 63 109

Azobenzene 67.1 121

Acrylic acid 68.0 115

Materials Melting Point

(

o

C)

Latent Heat of

Melting (kJ/kg)

Glutaric acid 97.5 156

Catechol 104.3 207

Quenon 115 171

Benzoic acid 124 167

Benzamide 127.2 169.4

Oxalate 54.3 178

Alpha naphol 96 163

Source: Sharma et al.2009

Table 3: Melting Point Heat of Latent Melting Some Fatty

Acids.

Materials Melting

Point (

o

C)

Latent Heat

of Melting

(kJ/kg)

Acetic acid 16.7 184

Poly ethylene glycol 20.25 146

Capric acid 36 152

Eladic acid 47 218

Lauric acid 49 178

Pentadecanoic acid 52.5 178

Tristearin 56 190

Mirystic acid 58 199

Palmatic acid 55 163

Stearic acid 69.4 199

Acetamide 81 141

Source: Sharma et al.2009

2.2 Anorganic

PCM anorganic PCM is classified as salt hydrate and

metallic. This type of PCM is not very cold and the

heat of fusion will not decrease during rotation.

2.2.1 Hydrates of Salts

Hydrates of salt can be seen as mixtures of inorganic

salts with water to form certain crystalline solids of

the general formula AB.nH2O. The solid-liquid

change of the salt hydrate is a dehydration process of

the salt hydration. Salt hydrates usually melt into a

salt hydrate with very small moles of water.

AB.nH2O → AB.mH2O + (n-m)H2O

or into anhydrous form,

AB.nH2O → AB + nH2O

At their melting point, the hydrate crystals split into

anhydrous salt and water or into a lower hydrate and

water. Salt hydrates are the most important and

widely studied type of PCM in energy storage

systems. The most prominent properties of this type

of PCM are high latent heat of fusion per unit volume,

relatively high thermal conductivity (almost twice

that of paraffin) and small volume change during

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

734

melting. This type of PCM is also less corrosive,

compatible with plastics and only a few types are

toxic. Many types of salt hydrates are inexpensive to

use as heat stores. In Table 4 it can be seen several

types of PCM from salt hydrates.

Table 4: Melting Point and Latent Heat of Melting Some

Salt Hydrates.

Materials Melting

Point (

o

C)

Latent Heat

of Melting

(kJ/kg)

K

2

HPO

4

.6H

2

O 14,0 109

FeBr3.6H

2

O 21,0 105

Mn(NO

3

)

2

.6H

2

O 25,5 148

FeBr

3

.6H

2

O 27,0 105

CaCl

2

.12H

2

O 29,8 174

LiNO

3

.2H

2

O 30,0 296

LiNO

3

.3H

2

O 30 267

Na

2

O

3

.10H

2

O 32,0 241

Na

2

SO

4

.10H

2

O 32,4 173

KFe(SO4)2.12H20 33 138

CaBr

2

.6H

2

O 34 124

LiBr

2

.2H

2

O 34 134

Zn(NO

3

)

2

.6H

2

O 36,1 223

Source: Sharma et al.2009

2.2.2 Metals

This type of metal also includes metals with low

melting points and metal alloys. This type of PCM

has not received much attention because it is very

heavy. If volume is a concern, this type is the choice

because it has a high latent heat of fusion per unit

volume. This metal has a high thermal conductivity

so that no additional heavy filler is needed. A list of

some metallic materials can be seen in Table 5.

Table 5: Melting Point and Latent Melting Heat of Some

Metallics.

Materials Melting

Point (

o

C)

Latent Heat of

Melting

(kJ/kg)

Gallium-gallium

Antimony eutectic

29,8 -

Gallium 30,0 80,3

Cerrolow eutectic 58 90,9

Bi-Cd-In eutectic 61 25

Cerrobend

eutectic

70 32,6

Bi-Pb-In eutectic 70 29

Bi-In eutectic 72 25

Bi-Pb-tin eutectic 96 -

Bi-Pb eutectic 125 -

Source: Sharma et al.2009

2.3 PCM Combination

PCM combination is a composition with the lowest

melting point of two or more components, each of

which melts and solidifies to form a mixture of

crystalline components during the crystallization

process (George 1989). This type of PCM almost

always melts and solidifies without separation

because they solidify into a crystalline mixture,

giving the components little chance to separate. At the

time of melting the two components melt sequentially

with unwanted separation.

Table 6: List of PCM Combinations of Organic-Anorganic.

Materials Melting

Point

(

o

C)

Latent

Heat of

Melting

(kJ/kg)

CaCl

2

.6H

2

O+CaBr

2

.6H

2

O 14,4 140

Triethylethane+water+urea 13,4 160

CaCl

2

+MgCl

2

+6H

2

O 25 95

NH

3

CONH

2

+ NH

3

CONH

2

27 163

Naphtalene+benzoic acid 67 123,4

Freezer salt -50 325

Freezer salt -23 330

Freezer salt -16 330

Source: Sharma et al.2009

2.4 State of the Art

(Hosseinizadeh, Tan, and Moosania 2011) This study

compared heatsinks with different numbers of fins to

cool electronic components, where the results obtained

in heat absorption from a heat zing source with 7 fins

gave an average temperature at low heat zing. Thicker

heat zing results in better heat zing performance and 4

mm and 6 mm thickness have the best effectiveness in

absorbing heat from the source. The higher the fin, the

lower the heat zing temperature. (Markandeyulu,

Krishna Devanuri, and Kiran Kumar 2016) For thermal

management of electronic components, PCM can be a

promising option because it does not need external

assistance and because of its compatibility in size.

PCM can remove heat from electronic components at

a constant temperature where the temperature rise can

be effectively limited. By using PCM, product failures

and assembly failures can be reduced which can further

lead to an increase in productivity. The main problem

with PCM is its low thermal conductivity. This

problem can be overcome by adding high thermal

conductivity materials (eg conductivity enhancers),

nanoparticles, matrix metal foam and metal fins.

(Rehman et al. 2018) The results show that the heat

zing performance with PCM is better than the heat zing

Utilization of Parafin and TiO2 as Phase Change Materials (PCM) for Processor Coolers

735

performance without PCM. The higher volume

fraction of PCM results in more drop in heat zing

temperature at the same input power. Different PCM

materials exhibit different behavior. (Fan et al. 2016)

The results showed that PCM material with molten

metal had a greater impact on temperature reduction on

heat zing than 1-octadecanol organic PCM material.

Judging from the protection time, the liquid metal has

a protection twice as long as 1-octadecanol. (Wang et

al. 2021) Higher alcohol/graphite foam PCM materials

have the ability to lower the heat zing temperature

better than PCM materials using higher alcohol with a

better percentage of 24%. The heat capacity of PCM

higher alcohol/graphite foam material reaches 102.32

J/K with a thermal conductivity of 54.22 W/cm2.

3 EXPERIMENT SETUP AND

PROCEDURE

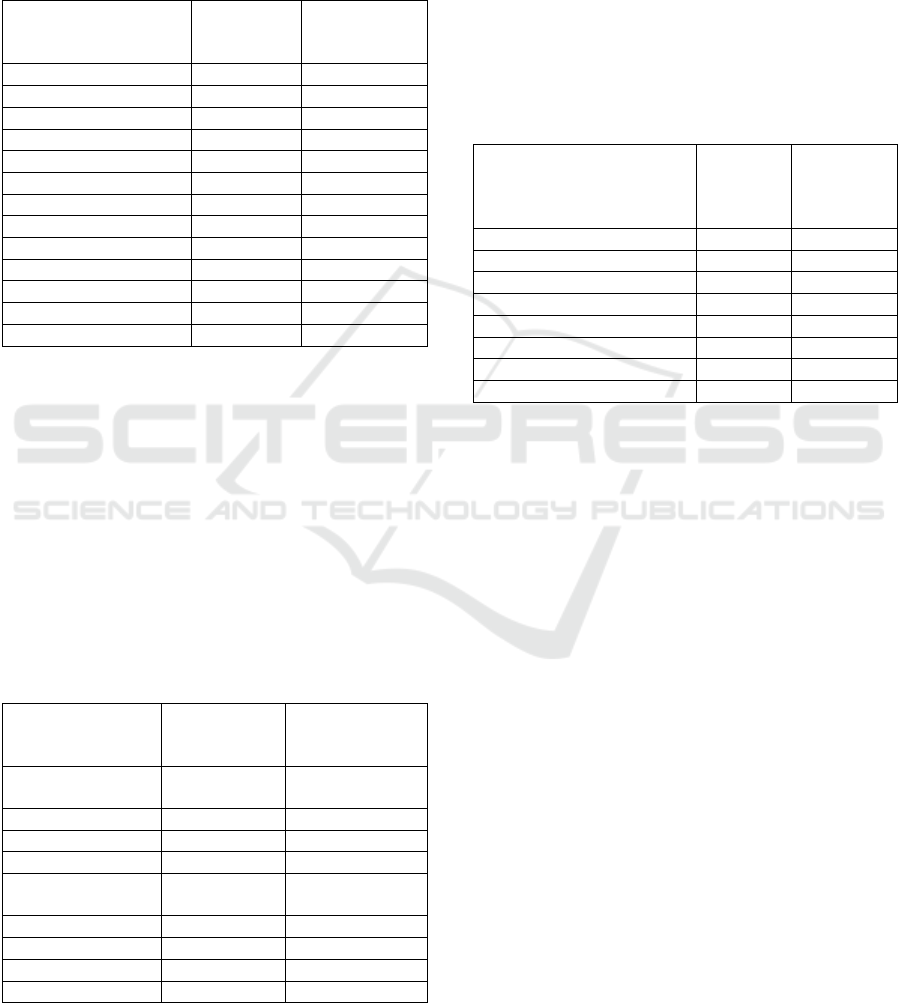

3.1 Research Design

This study was designed using simulation, where the

processor simulated as a source of heat energy, so a

heater with a power of 120 W is made with a heat

capacity of 40 - 70

o

C where this temperature is the

operating temperature of the processor. The heatsink

is made with dimensions of 73 x 73 x 55 mm, as

shown in Figure 1.

PCM material uses paraffin base material with

several variations of TiO

2

concentration and the test

device will be made as shown in Figure 2.

3.2 Determination of Data Sources

The data used in this study is primary data in the form

of temperature data obtained from temperature

measurements placed on the heatsink using a

thermocouple and other primary data in the form of a

mixture of PCM material, namely paraffin and TiO

2

.

In addition to primary data, secondary data is also

obtained from related research data sources in the

form of PCM material characteristics.

3.3 Research Variables

The variables of this study are independent

variables, dependent variables and control variables.

The independent variables in this study are PCM

material and the shape of the heatsink that is made

to vary. The dependent variable is the temperature

generated by the system due to changes in the

variation of the PCM material and the shape of the

Heatsink. As a control variable, namely the input

power given to the system.

Figure 1: Heatsink Model.

(Fan et al. 2016)

Figure 2: Model Design Test Equipment.

3.4 Research Materials

The materials used in this research are PCM materials

in the form of paraffin and TiO2, and the selected

heatsink material is aluminum because it has good

heat conductivity.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

736

3.5 Research Instruments

Several research instruments used in this study are

temperature measuring instruments, namely

thermocouples, AC power meters which are used to

supply power to the system, AC Adapter which

functions to convert alternating current (AC current)

into direct current (DC current), one for the heating

unit that functions as a heat source as a simulation of

the processor heat, Digital PID Temperature

Controller to read the temperature, Solid State Relay

SSR 25A to disconnect and connect current to the

heating system which is controlled via digital PID.

3.6 Research Procedure

This research will begin by making a test instrument

in the form of a PCM-based processor cooling

simulation. After the simulation is complete, the

operational system is tested before taking data. Data

collection was carried out with a combination of

parafin and TiO

2

with a mixture as shown in table 7.

Table 7: Sample Mixture of Paraffin and TiO

2

as PCM.

No

Mixed Percentage (%)

Parafin TiO

2

1 100 0

2 98 2

3 96 4

4 94 6

5 92 8

6 90 10

3.7 Data Analysis Methods

In this study, the data analysis method used is a

descriptive statistical method. Temperature data

obtained from measurements are presented in tabular

form or in graphical form as a basis for making

decisions. The data will be further processed so that it

is known the effect of using PCM and the shape of the

Heatsink on the cooling effectiveness of the

processor. In addition to temperature data, photo data

obtained from digital cameras that are used to observe

phenomena that occur in PCM materials during

testing will be analyzed qualitatively.

4 RESULTS AND DISCUSSION

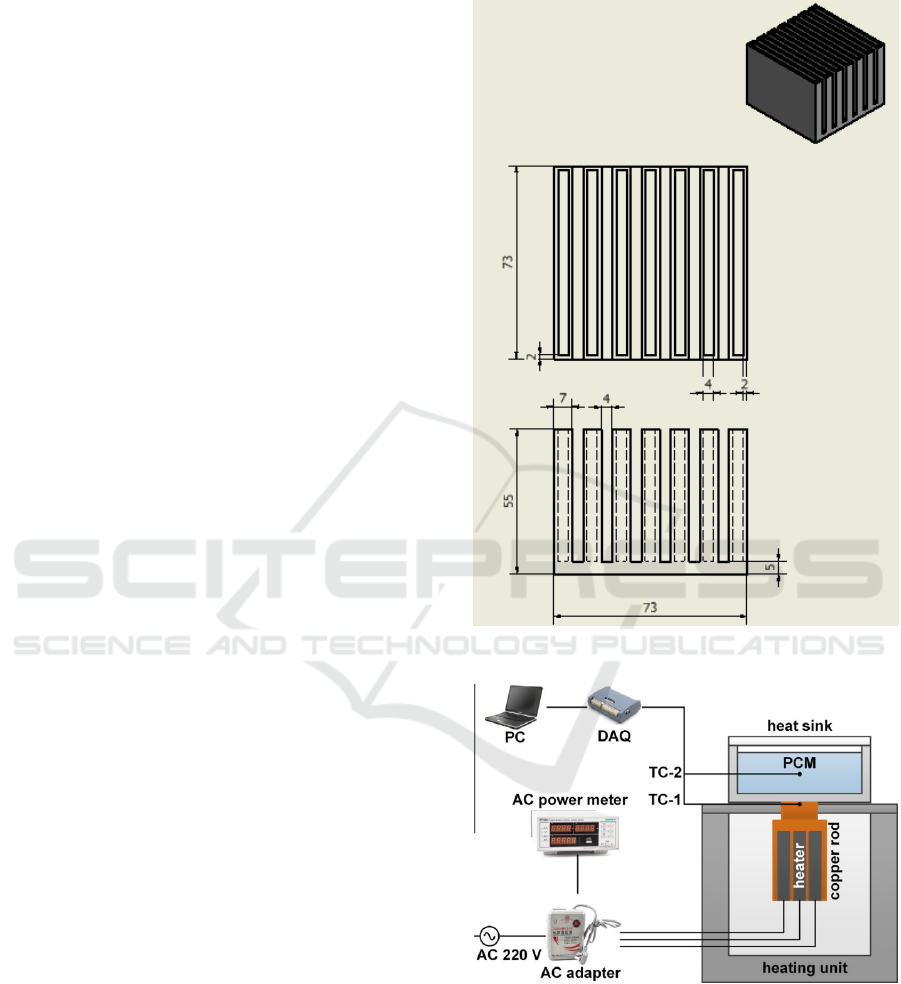

Simulated processor temperature by heating with

heatsink cooling without PCM, heatsink with PCM

using pure paraffin and heatsink with PCM material

with some mixture of paraffin and TiO2 can be seen

in Figure 3.

Figure 3: Chart of the effect of adding PCM to the heatsink

on the cooling effect of the processor.

From Figure 3, it can be seen that the cooling of the

processor with a heatsink without a PCM shows that

the temperature continues to increase from 0 seconds

to 150 seconds, and the processor temperature

reaches 93

o

C in 150 seconds. Processor temperature

that continues to increase due to cooling by

conduction method from the processor to the heatsink

and free convection alone is not able to eliminate the

presence of heat in the processor. The addition of

paraffin to the heatsink is able to stabilize the

temperature on the processor below 50

o

C. The use of

TiO2 mixed with paraffin as PCM material is able to

increase the thermal conductivity of PCM as

evidenced by the faster cooling effect that occurs in

the processor, where the greater the TiO2 content

given to paraffin, the faster the cooling effect.

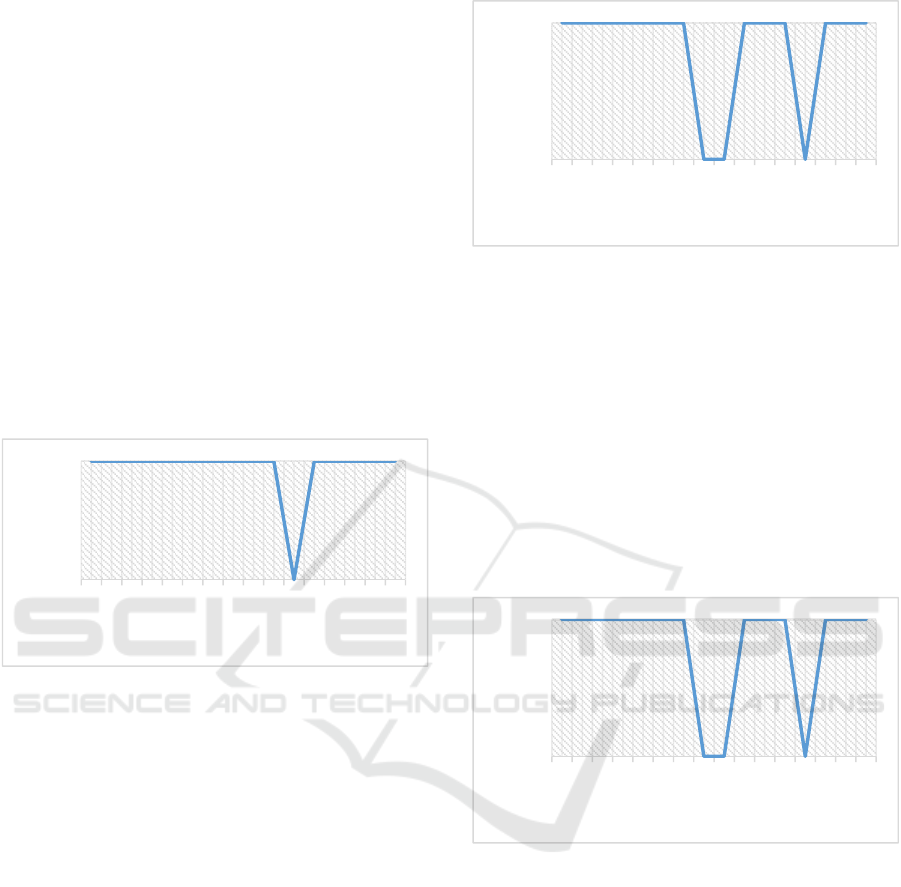

4.1 Effect of Using Heatsink without

PCM on Processor Cooling

Cooling with heatsink without PCM shows a

significant increase in processor temperature starting

from 0 minutes to 15 minutes continues to increase.

The processor temperature at 47

o

C only lasted until

the first 3 minutes, then the processor temperature

continued to increase, meaning that cooling the

processor only by relying on the heatsink was not

enough, maybe because the area of conduction heat

transfer from the processor to the heatsink was not

enough. Figure 4 shows the power input On at minute

1 to minute 3 then at minute 4 the power input is Off

and the 5th minute is On again and so on. The input

power is set at a temperature of 47

o

C if the processor

temperature reaches 47

o

C then the input power is Off

and if the processor temperature is below 46

o

C then

the input power is On.

0

10

20

30

40

50

60

70

80

90

100

0123456789101112131415

Temperature (oC)

Time (menit)

Haeatsink

Without PCM

Heatsink with

pure paraffin

PCM

Heatsink with

PCM Parafin +

2%TiO2

Heatsink with

PCM Parafin +

4%TiO2

Heatsink with

PCM Parafin +

6%TiO2

Heatsink with

PCM Parafin +

8%TiO2

Utilization of Parafin and TiO2 as Phase Change Materials (PCM) for Processor Coolers

737

Figure 4: Input Power On/Off On Processor Cooling with

Heatsink without PCM.

4.2 Effect of Using Heatsink with PCM

Made of Pure Paraffin

The addition of pure paraffin to the heatsink affects

the cooling effect on the processor, where the

processor reaches the 7th minute the temperature is

still below 47

o

C which is indicated by the supply the

power is in the On position and at the 8th minute the

power supply is Off, meaning that the processor

temperature has reached 47oC or more and at the 9th

minute the power supply is On, it means that the

processor temperature is below 47

o

C, this is because

at a temperature of 47

o

C the paraffin has started to

melt so it absorbs heat that occurs in the processor so

that the processor temperature drops again. In the

13th to 15th minute the power supply is turned off

again because the temperature that has occurred has

reached 47

o

C or more and at the 15th minute the

power supply is back on. An overview of On/Off

Supply power based on heating time can be seen in

Figure 5.

Figure 5: Input Power On/Off On Processor Cooling with

Heatsink Using Pure Paraffin As PCM.

4.3 Effect of Using Heatsink with PCM

Made of Paraffin + 2% TiO

2

The addition of a mixture of paraffin + 2% TiO2 on

the heatsink has an impact on the temperature that

occurs in the processor. With the addition of 2% TiO

2

to paraffin, it provides a fairly stable cooling effect,

as evidenced by the persistence of the processor

temperature below 47

o

C until the 8th minute and at

the 9th - 11th minute the temperature is still in the

range of 47

o

C - 48

o

C, then at the 12th minute up to

15 minutes the processor temperature is below 47

o

C

Again, due to the PCM material on the heatsink has

melted and the process of absorbing heat from the

processor to the heatsing occurs. An overview of

On/Off Supply of power based on heating time can be

seen in Figure 6.

Figure 6: Input Power On/Off in Processor Cooling with

Heatsink Using Paraffin + 2% TiO

2

as PCM.

4.4 Effect of Using Heatsink with PCM

Made of Paraffin + 4% TiO

2

Addition of a mixture of paraffin + 4% TiO

2

to the

heatsink has an impact on the temperature that occurs

on the processor. With the addition of 4% TiO

2

in

paraffin, it provides a fairly stable cooling effect

where the processor temperature is only at 10 minutes

which exceeds 47

o

C, as evidenced by the power

supply being On at all times except Off at 10 minutes.

This shows that the addition of 4% TiO

2

to paraffin

has a significant impact on the cooling process of the

processor. An overview of On/Off Supply of power

based on heating time can be seen in Figure 7.

Figure 7: Input Power On/Off In Processor Cooling with

Heatsink Using Paraffin + 4% TiO

2

As PCM.

1111

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0123456789101112131415

Power Supply

On/Off

Time (minute)

1111111

0

1111

000

1

0

1

12345678910111213141516

Power Supply On/Off

Time (minute)

11111111

000

11111

0

1

12345678910111213141516

Power Supply On/Off

Time (minute)

1111111111

0

11111

0

1

0123456789101112131415

Power Supply On/Off

Time (minute)

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

738

4.5 Effect of Heatsink Utilization with

PCM Made of Paraffin +6% TiO

2

The addition of a mixture of paraffin + 6% TiO

2

on

the heatsink has an impact on the temperature that

occurs on the processor. With the addition of 6% TiO

2

to paraffin, it provides a fairly stable cooling effect

where the processor temperature is only at 10 minutes

which exceeds 47

o

C, as evidenced by the power

supply being On at all times except Off at 10 minutes.

This shows that the addition of 6% TiO

2

to paraffin

has a significant impact on the cooling process of the

processor. The difference with 4% TiO

2

content is in

the temperature difference at each time, which is the

overall processor temperature at each time is lower

than PCM with 4% TiO

2

content. An overview of

On/Off Supply of power based on heating time can be

seen in Figure 8.

Figure 8: Input Power On/Off on Processor Cooling with

Heatsink Using Paraffin + 6% TiO

2

As PCM.

4.6 Effect of Using Heatsink with PCM

Made of Paraffin +8% TiO

2

The addition of a mixture of paraffin + 8% TiO

2

on

the heatsink has an impact on the temperature that

occurs on the processor. With the addition of 8% TiO

2

to paraffin, the temperature effect in the early minutes

is lower than the percentage of TiO

2

below 8%, but

the achievement of temperatures above 47

o

C is also

faster. In this mixture of paraffin + 8% TiO

2

, the

processor temperature is also less stable, as shown in

Figure 9. On/Off fluctuations occur in the power

supply due to temperature fluctuations that occur in

the processor due to an increase in the conductivity of

the PCM material which causes the PCM material to

melt earlier.

Figure 9: Input Power On/Off on Processor Cooling with

Heatsink Using Paraffin + 8% TiO

2

As PCM.

4.7 Effect of Using Heatsink with PCM

Made of Paraffin + 10% TiO

2

The addition of a mixture of paraffin + 10% TiO

2

on

the heatsink has an impact on the unstable

temperature that occurs in the processor. Processor

temperature characteristics that occur in a mixture of

paraffin + 10% TiO

2

are almost similar to a mixture

of paraffin + PCM 8% TiO

2

. An overview of On/Off

Supply of power based on heating time can be seen in

Figure 10.

Figure 10: Input Power On/Off on Processor Cooling with

Heatsink Using Paraffin + 8% TiO

2

As PCM.

5 CONCLUSION

From the research that has been done, it can be

concluded as follows:

1. The addition of PCM to the heatsink has a

significant effect on the temperature that occurs

in the processor, where the addition of PCM to

heatzing can reduce the temperature that occurs

in the processor compared to using a heatsink

without PCM.

1111111111

0

11111

0

1

0123456789101112131415

Power Supply On/Off

Time (minute)

1111111

00

111

0

111

0

1

12345678910111213141516

Power Supply On/Off

Time (minute)

1111111

00

111

0

111

0

1

12345678910111213141516

Power Supply On/Off

Time (minute)

Utilization of Parafin and TiO2 as Phase Change Materials (PCM) for Processor Coolers

739

2. The addition of TiO2 concentration in paraffin

as PCM material can stabilize the temperature

that occurs in the processor.

3. The addition of 4% and 6% TiO2 concentrations

in paraffin gave the best impact on processor

cooling.

ACKNOWLEDGMENT

Thank you to the Bali State Polytechnic for the

financial assistance that has been given so that this

research can be carried out. Researchers really hope

that this research can be continued with several

heatsink models and other PCM composite material

models, so that an effective and efficient processor

cooling system is found.

REFERENCES

Abhat, A, D Heine, M Heinisch, N A Malatidis, and G

Neuer. 1981. “Development of a Modular Heat

Exchanger with an Integrated Latent Heat Storage.”

Report No. BMFT FBT.

Bayat, Milad, Mohammad Reza Faridzadeh, and Davood

Toghraie. 2018. “Investigation Of Finned Heat Sink

Performance With Nano Enhanced Phase Change

Material (NePCM).” Thermal Science and Engineering

Progress. https://doi.org/10.1016/j.tsep.2017.10.021.

Fan, Li Wu, Yu Yue Wu, Yu Qi Xiao, Yi Zeng, Yi Ling

Zhang, and Zi Tao Yu. 2016. “Transient Performance

of a Thermal Energy Storage-Based Heat Sink Using a

Liquid Metal as the Phase Change Material.” Applied

Thermal Engineering 109. https://doi.org/10.1016/

j.applthermaleng.2016.08.137.

Hikma, Nurfi, Saktioto Jurusan, Fisika Fakultas,

Matematika Dan Ilmu, Pengetahuan Alam, and

Universitas Riau. 2020. Air Conditioning Di Kota

Pekanbaru.

Hosseinizadeh, S. F., F. L. Tan, and S. M. Moosania. 2011.

“Experimental and Numerical Studies on Performance

of PCM-Based Heat Sink with Different Configurations

of Internal Fins.” In Applied Thermal Engineering. Vol.

31. https://doi.org/10.1016/j.applthermaleng.2011.07.0

31.

Kandasamy, Ravi, Xiang Qi Wang, and Arun S. Mujumdar.

2008. “Transient Cooling of Electronics Using Phase

Change Material (PCM)-Based Heat Sinks.” Applied

Thermal Engineering 28 (8–9): 1047–57.

https://doi.org/10.1016/j.applthermaleng.2007.06.010.

Markandeyulu, Thota, Jaya Krishna Devanuri, and K. Kiran

Kumar. 2016. “On the Suitability of Phase Change

Material (PCM) for Thermal Management of Electronic

Components.” Indian Journal of Science and

Technology 9 (S1). https://doi.org/10.17485/ijst/2016/

v9is1/107939.

Rehman, Tauseef ur, Hafiz Muhammad Ali, Ahmed Saieed,

William Pao, and Muzaffar Ali. 2018. “Copper

Foam/PCMs Based Heat Sinks: An Experimental Study

for Electronic Cooling Systems.” International Journal

of Heat and Mass Transfer 127. https://doi.org/

10.1016/j.ijheatmasstransfer.2018.07.120.

Risano, A Yudi Eka, M Dyan Susila E S, and Yoga

Pratama. 2017. “Aplikasi Minyak Kelapa Sawit Pada

Photovoltaic Yang Terintegrasi Pada Dinding

Bangunan Sebagai Pendingin Pasif Untuk

Meningkatkan Efisiensi Dan Menurunkan Beban

Pendingin Ruangan.” Turbo : Jurnal Program Studi

Teknik Mesin 6 (1). https://doi.org/10.24127/trb.v6i1.4

60.

Sharma, Atul, V. V. Tyagi, C. R. Chen, and D. Buddhi.

2009. “Review on Thermal Energy Storage with Phase

Change Materials and Applications.” Renewable and

Sustainable Energy Reviews. https://doi.org/10.1016/

j.rser.2007.10.005.

Wang, Shisong, Yuming Xing, Zhaolong Hao, Jianbao Yin,

Xu Hou, and Zixian Wang. 2021. “Experimental Study

on the Thermal Performance of PCMs Based Heat Sink

Using Higher Alcohol/Graphite Foam.” Applied

Thermal Engineering 198. https://doi.org/10.1016/

j.applthermaleng.2021.117452.

Putra, P., Liriwati, F. Y., Tahrim, T., Syafrudin, S., &

Aslan, A. (2020). The students learning from home

experience during covid-19 school closures policy in

indonesia. Jurnal Iqra, 5(2).

George, J. M. (1989). Mood and absence. Journal of

applied psychology, 74(2), 317.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

740