Barong Is Bluetooth on Arduino Controlling Robotic Hand to Install

Insulation Cover in Live Line

I Gede Suputra Widharma

1a

, I Wayan Jondra

3b

, I Gede Nyoman Suta Waisnawa

2

,

Ida Bagus Putu Yogi Pramana Putra

1

and I Made Wiryana

1

1

Automation Engineering Program, Electrical Engineering, Bali State Polytechnic, Badung Bali, Indonesia

2

Machine Engineering Program, Machine Engineering, Bali State Polytechnic, Badung Bali, Indonesia

3

Electrical Engineering Program, Electrical Engineering, Bali State Polytechnic, Badung Bali, Indonesia

Keywords: Bluetooth, Arduino, Robotic Hand, Control System, Insulation Cover.

Abstract: The cessation of electricity distribution can cause complaints from consumers. Maintenance of the electricity

network is important to improve service to consumers. This research was motivated by the existence of

problems in the installation of the insulator cover. This is a direct touch job, necessary to turn off the power

because it can be dangerous for workers to touch the live line. The goal is to design a wireless-based robotic

hand controller for the installation of the insulator cover so that workers have a safe distance and without

touching live line during installation. This robot control system uses an application designed with the drag-

drop block programming method on app inventor. This application is installed on smartphone, then connected

to Bluetooth on the Esp32 which has been programmed with the H-Bride logic gate to control the direction

of motor rotation. Controlling the motor direction on the robot's hand can be done with a voltage of 12 Volts.

The output of this design can control the robot's hand to install the insulator cover with the remote work

method using a stick on a live power pole. This is expected to help improve the reliability of the distribution

of electrical energy supply.

1 INTRODUCTION

1.1 System Security: Electrical Power

Distribution Challenge

The more developed industrialization and modern

buildings, the greater the level of dependence on

electrical energy. The cessation of electricity

distribution even for a moment can cause complaints

from consumers. Therefore, maintenance of the

electricity network is important, in order to improve

service to consumers. This research was motivated by

the existence of problems in the installation of the

insulator cover to avoid external threats, especially

the weather. In this era, technology is growing. Many

human jobs that are done manually and require a lot

of energy have been replaced by machines. The

machine used can work automatically, or semi-

automatically by simply pressing a button, so you

a

https://orcid.org/0000-0002-7090-545X

b

https://orcid.org/0000-0001-6800-6415

don't need to exert a lot of energy. This of course

aims to streamline human labor and time to complete

work, especially public works which have limited

time to complete. One of the jobs in question is the

installation of an insulator cover on an electrical

substation with a voltage of 20 kV. Electricity is a

very important component of human activity

(Richard, 2015). Global electricity consumption has

continued to go up faster than energy consumption

(Zhenya, 2016). In this globalization era, electrical

energy has become a primary need in the world.

Electricity consumption occupied by residential to

reach its highest point in China. (Zhaoguang, 2014)

This installation is carried out to protect the wiring

of substations or electricity poles from disturbances

caused by external factors such as trees, animals or

the weather. Especially in the part of the network

construction that is still open, it needs to be protected

to avoid external disturbances. This can be a concern

because this open part may be passed by animals such

764

Widharma, I., Jondra, I., Waisnawa, I., Putra, I. and Wiryana, I.

Barong Is Bluetooth on Arduino Controlling Robotic Hand to Install Insulation Cover in Live Line.

DOI: 10.5220/0011879600003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 764-769

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

as squirrels, resulting in a short circuit that causes the

relay to work and forcibly turn off the electricity. This

of course will cause the distribution of electrical

energy to be hampered to consumers. So, the

installation of this insulator cover is very important in

maintaining the distribution of electrical energy.

Installing this insulator cover is a direct touch job.

This means that type of work is carried out in a non-

voltage condition. However, if there is a blackout, it

will certainly cause complaints from consumers

because community activities that require electricity

will be hampered. The world economy movement is

strongly influenced by the availability of electrical

energy. There will be several problems in human life

without electrical energy. The electrical energy

supply system consists of several parts, such as power

plants, substations, transmission, distribution, and

distribution substations. These parts should be

reliable in handling problems in the electrical system.

This reliable system is designed to guarantee

continuously standard electrical energy availability.

Security is very important in electrical energy

distribution. The green electrical energy distribution

system securely to the humans, environment, animals,

and plants. There were many electrical blackouts

caused by animal and tree disorders. This will disrupt

the green electrical energy distribution because

animals die after electrical discharge (Melo, 2014).

In this paper, some problems such as the insulator

cover type YSL-70AP insulation resistance,

breakdown voltage of the insulator cover type YSL-

70AP, and the preferable of the insulator cover type

YSL-70AP applied in the 20 kV system, were

investigated. With the use of a wireless control

system, the insulator cover can be installed without

turning off the electricity and without touching the

power cord directly (Jondra, 2019). With the use of a

wireless control system, the insulator cover can be

installed without turning off the electricity and

without touching the power cord directly. Because,

with a wireless control system, workers have a safe

distance in the installation of the insulator cover and

do not touch live power cables directly. This makes

this tool an advantage in optimizing work time which

can be done at any time without the need for a rotating

blackout schedule. Problems in the field need to be

observed for the purpose of obtaining a solution in

solving an existing problem (Turan, 1986).

2 CONTROL SYSTEM FOR THE

SOLUTION

This study uses 2 methodologies namely observation

and experiment. To get the best solution, it is

necessary to carry out various experiments on the

object under investigation the first step taken is to

review the research design and the components

needed. To design a tool, it is necessary to study the

literature so that the tool works in accordance with the

expected goals (IEC, 2209).

2.1 Microcontroller

The function of the microcontroller is as the brain or

controller of an electronic circuit for a specific

purpose. ESP32 is a microcontroller introduced by

the Espressif System which is the successor of the

ESP8266 microcontroller (Sanjay, 2018).

One difference between the ESP32 and the

ESP8266 is the processor. ESP32 is Dual-Core 32-bit

obviously faster than ESP32 in performance. In

addition, this module also has one feature that is not

present in the ESP8266, namely Bluetooth which can

receive data up to 25 meters away without a hitch.

2.2 Power Window Motor

The power window motor is a type of DC motor with

a gearbox that usually functions as a driving force for

the ups and downs of the windshield. This DC motor

requires a voltage of 12 Volt DC (Salman, 2011).

We use this type of motorbike because it is easily

available in the market and in terms of function, this

motorbike has enough torque to see by moving the

windshield. So that this motor is expected to be able

to move the robot's hand insulator cover.

2.3 Motor Driver

The L298 Motor Driver is a module that is often used

to control DC motors. By using the L298 Motor

Driver we can easily control both the speed and

direction of rotation of 2 motors at once. The L298

Motor Driver is designed using the L298 Dual H-

Bridge IC. The Motor Driver contains H-Bride logic

gates which are already very popular in the

electronics world as controlling the speed and

direction of motor rotation [5]. It should be noted that

we use this motor driver because the Drive Current in

this driver is able to supply up to 5A per channel,

which is where the motor we use has been tested for

load and the measurement results are less than 5A. So

Barong Is Bluetooth on Arduino Controlling Robotic Hand to Install Insulation Cover in Live Line

765

this motor driver is able to control the DC motor we

use (Peerzada, 2021).

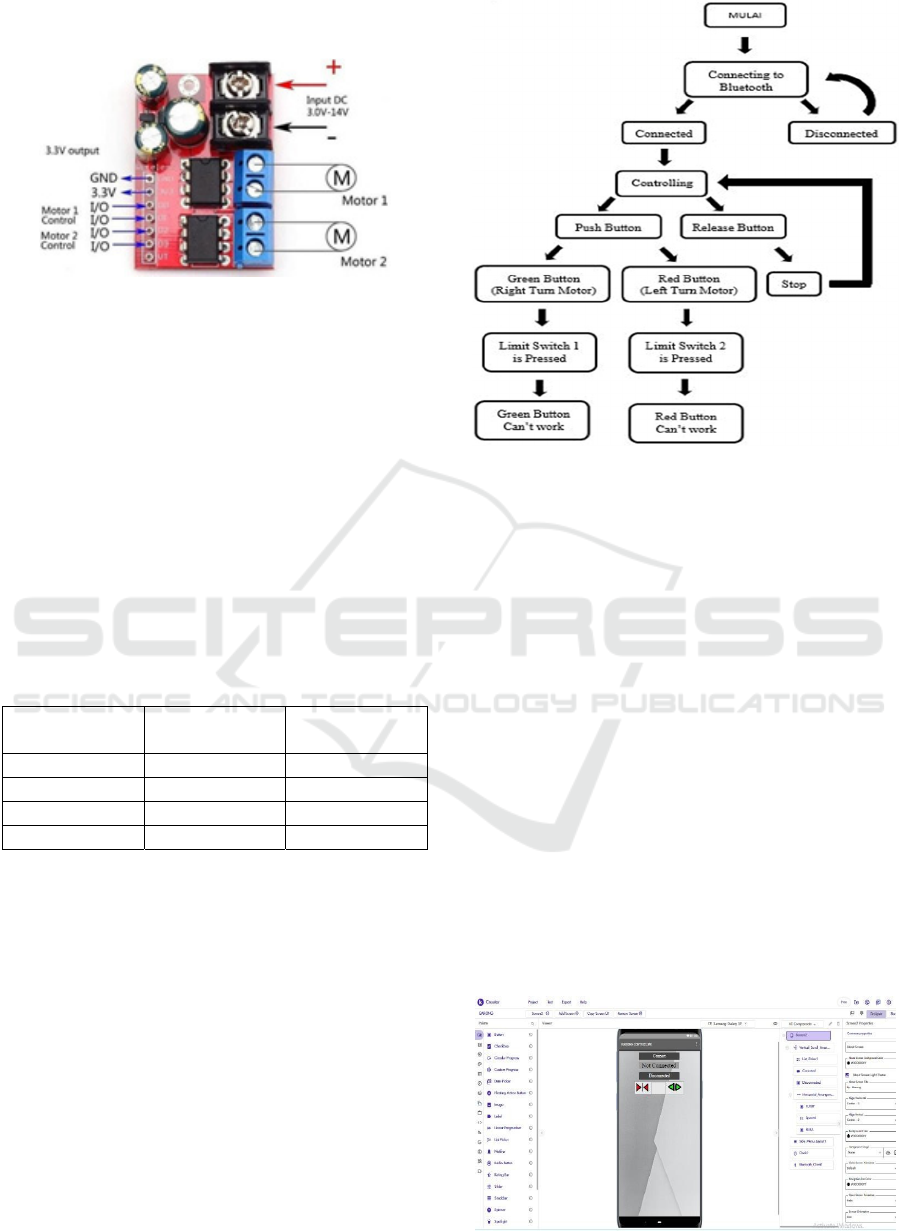

Figure 1: Motor driver L298.

2.4 How to Design of Barong System

The design of this system focuses on the wireless

control system. The first thing that is needed here is

hardware and software to support the wireless control

system. One of the hardware needed is the Esp32

microcontroller. The Esp32 used has been planted

with wifi and Bluetooth features. We use the

Bluetooth feature to make it easier to use. The

software needed is Arduino IDE. Arduino IDE is

software used to program Esp32 microcontroller

boards. Esp32 is the most important hardware part of

this control system. As a controller, Esp32 plays a

role in sending signals to the motor driver.

Table 1: Logics of H-Bridge.

I/O 1 I/O 2

Motor

Condition

Hi

g

h Hi

g

h Off

Low Low Off

Hi

g

h Low Clockwise

Low Hi

g

h Unclockwise

The motor driver that we use is the L298 type, the

DC voltage range is 3-14V as shown below. The

above logic table is our basis for programming the

control system on Esp32. The output pin of the Esp32

will provide a signal that will enter the IN pin of the

motor driver. The rotation of the motor will depend

on the signal given based on the above logic table.

The reason we use this motor driver is that we will

design this system with a power window motor or a

motor that is usually used as a windshield driver on a

car in order to get enough torque to move the robot's

hand. The voltage required to supply this motor is

12V DC. We also designed a power supply with 3

rechargeable batteries to allow charging the battery if

the battery is running low. We have 3 series of 3,7V

batteries in series controlled by the Battery

Management System (BMS) in order to stabilize the

Figure 2: The design of Barong system.

output voltage and maintain battery health, especially

by preventing overcharge and over-discharge.

2.5 Designing the Application for the

Smartphone

The robot hand control is fully controlled by

application users or workers in the field to adjust the

installation conditions of the insulator cover. To

summarize this wireless-based control, an application

is designed as a medium for sending data to the

controller. Kodular is the platform used in building

this Android application. Kodular uses a drag drop

block programming system in building an application

(Knowles, 2013). The drag-drop block programming

system is a programming system that uses function

blocks as the logic for running an application. Even

in designing this system, this system is based on

visual programming, which means programming the

design without writing. The following codular

designs have been made:

Figure 3: Design of visual programming for smartphone.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

766

Control data or commands should be sent via

Bluetooth on the Android device application to the

controller. Therefore, Esp32 on the controller needs

to authenticate the Bluetooth connection of nearby

users to be able to connect to each other to send data

to the controller. (Purnata, 2022). To realize this,

Arduino IDE software is needed to program this

control work system in an Esp32 microcontroller.

This program will of course be integrated with the

program block in the coded. Every data sent from the

application will send a 1 byte number. Where this

number will arrive at the Esp32 microcontroller, then

executed according to the logic that has been made.

Figure 4: Application design of block programming to

control robotic’s hand by bluetooth.

First, it requires a library program or commonly

called a library to summarize the program created.

Defining the variables is also needed in engineering

the work system later. In the void setup, categorize

the output and input pins to be input data or output

data. In void setup also initiates a Bluetooth

connection, so that it is only enough to connect the

android device with the controller once. In the void

loop, logic is given to receive any data from coded.

Receipt of data in the form of a byte number that has

been adjusted to the coded program block. The

delivery of each data is determined from the button

control in the application. If the green button is

pressed then byte number 1 will be sent. If the red

button is pressed, then byte number 2 is sent. If both

buttons are not pressed then byte number 5 will be

sent.

The byte number data sent will be received by

Esp32. If the byte number is 1 then the sublogic that

is executed is void forward or the motor command

will move forward. If the byte number is 2, then the

sublogic that is executed is void backward or the

motor command will move the other way around

(backward). If the byte number is 5, then the motor

will stop spinning. So these systems are integrated

with each other, so that the designed control system

can run as expected.

3 EXPERIMENT TESTED

RESULT AND DISCUSSION

In this study, the experiments tested were divided into

several test subsystems. Each of these subsystems has

an indicator of the success of a designed tool. The first

subsystem tests the success of the Bluetooth

connection between the Android device and the

device. Second, the success of controlling the motor

on the robot's hand through the designed application.

Third, the success of closing or installing the insulator

cover in the field. The information obtained on this

tool is in order to obtain its specifications, such as the

maximum operating distance between the android

device and the designed tool and battery resistance in

carrying out work when installing the insulator cover.

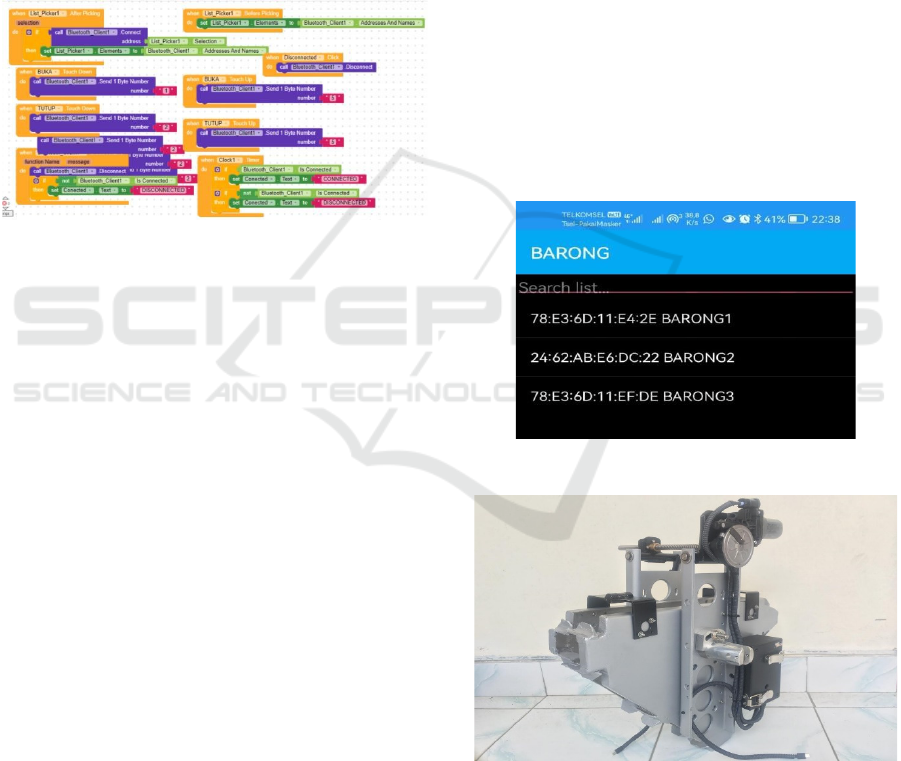

3.1 Testing the Bluetooth Connection

We named each device three samples is

“BARONG1”, “BARONG2” and “BARONG3”.

Figure 5: Bluetooth connectivity detection results.

Figure 6: Barong ready to install insulator cover in the live

line.

The test of the three tools that have been designed

has been successfully detected by the application so

that it can be connected to the Android device. The

maximum operating distance measurement between

Barong Is Bluetooth on Arduino Controlling Robotic Hand to Install Insulation Cover in Live Line

767

the designed tool and the Android device without

obstruction is up to 24 Meters. Above 24 meters the

Bluetooth connection becomes less stable which

causes the connection to be disconnected suddenly.

Table 2: Bluetooth connectivity range measurement results.

No. Distance (m) Connectivity Status

1 4 Connected Stable

2 8 Connected Stable

3 12 Connected Stable

4 16 Connected Stable

5 20 Connected Stable

6 24 Connected Stable

7 28 Connected Unstable

8 32 Not Connected

3.2 Testing the App Control Success

and Battery Lifetime

Motor control uses an app with 2 button that can

rotate the direction of rotation of the motor. The

direction of rotation of this motor will determine the

position of the robot's hand to close or open. Red

button to close and green button to open. From the

experimental results that have been tried, the control

was successfully carried out to open and close the

robot's hand. Battery life in the installation is quite

good. When the battery is fully discharged, this tool

can perform more than 10 times of installation.

Charging the battery takes 2.5 hours.

Figure 7: Performance of Barong with its bluetooth

connectivity results.

There are three results and analyses of this

research, i.e. digitalization process, laboratory web

design process and upload digitalization result to the

web process.

3.3 Final: Testing of Insulator Cover

Installation in the Live Line

The insulator cover installation is tested to determine

the reliability of its installation. The installation

simulation was carried out several times to determine

whether the insulator cover could be installed

properly or not. Ensure that the insulator cover is

securely attached and locks the clamps on the

insulator cover.

Figure 8: Barong install the Insulator Cover on Live Line in

Udiklat PLN Semarang Center Java.

From the situation experiment, there are obstacles

in limiting excessive control when pressing the button

for too long when the condition of the robotic hand

has opened or closed the maximum. This can cause

the motor to overheat due to excessive performance

and cause the tool or insulator cap to be damaged due

to pressure on the construction. Based on the results

of this description are many suggestions as described:

PLN must utilize Insulator cover type: YSL-70 AP

optimally because the results of this study indicate the

performance is over than standardization. This

insulator cover can protect again tree and animal

disturbance. Tree disturbance is the problem of

equipment outage. If it is deemed to increase the

isolation resistance of this insulator cover it needs

some modification, to improve the safety to install an

insulator cover. The installation of the insulator cover

by utilizing this Barong robotic hand will keep the

line still live and workers safe from possibility of

being exposed to high voltage electricity.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

768

4 CONCLUSIONS – POTENTIAL

AND PROSPECTS FOR THE

INSTALLATION IN THE LIVE

LINE SAFELY

The design system for the robotic hand control that

installs the insulator cover has been realized and

tested. From the experimental results obtained some

information that needs to be considered.

First, this robotic hand can operate effectively

with a range of up to 24 meters from the smartphone

device used.

Second, the installation of the insulator cover is

carried out perfectly without any locking clamps that

have not been locked. So, the installation of this

insulator cover can be said to be successful.

Third, the battery life is capable of installing up to

more than 10 times of installation. So enough to

support the work of the day. On the other hand, this

tool needs to be improved, especially in limiting

excessive control when pressing the button for too

long when the robot's hand condition has opened or

closed to the maximum.

As a suggestion, additional components such as a

limit switch as a barrier to motor movement in order

to prevent overheating of the motor due to excessive

performance and prevent the tool or insulator cover

from being damaged due to pressure on the

construction.

ACKNOWLEDGEMENTS

This research was funded by BRIN. We thank to

BRIN, The Centre of Education and Training of PLN

Semarang, Student Tasks Channel, Electrical and

Machine Engineering Department, and the Centre for

Research and Community Service (P3M PNB) for

providing the kind support.

REFERENCES

Richard F, Jonathan H and Koomey G (2015). The

Electricity Journal 28 72-84

Zhenya L (2016). Global Energy Interconnection

(Cambridge: Elsevier)

Zhaoguang Hu, Xiandong Tan and Zhaoyuan Xu. (2014).

A Review of china’s economic development and

electricity consumption, An Exploration into China's

Economic Development and Electricity Demand by the

Year 2050. Cambridge: Elsevier Inc.

Jondra, IW, Widharma, IGS, I N Sunaya, (2019). Insulation

resistance and breakdown voltage analysis for insulator

cover type YSL-70AP. Journal of Physics: Conference

Series

Sanjay G, Kaustubh D and Priyanka M., (2018). Journal of

Engineering and Technology (IRJET) 05

Salman, A and Muhammad, A. (2011). Semantic Scholar,

15

Melo A, M Martinez and De Queiroz A A., (2014). Journal

of Materials Engineering and Performance

Purnata, H., Ramadan, S., Hidayat, M. A., & Maulana, I.

(2022). PID Control Schematic Design for Omni-

directional Wheel Mobile Robot Cilacap State of

Polytechnic. 12(2), 89–94.

Peerzada, P., Larika, W. H., & Mahar, A. A. (2021). DC

Motor Speed Control Through Arduino andL298N

Motor Driver Using PID Controller. International

Journal of Electrical Engineering & Emerging

Technology, 04(2), 21–24.

Knowles, M. (2013). Through-life management of electric

vehicles. International through-life engineering

services conference, Procedia CIRP 11 (2013) 260 –

265 2nd.

Suputra Widharma, IG, Sunaya, IN, Arka, IGP, and

Sajayasa, IM. (2017). Effect of Using Ground Wire to

Lightning Surge Interference at 20 KV Medium

Voltage Distribution System Based on Genetics

Algorithm. International Research Journal of

Engineering, IT & Scientific Research (IRJEIS), 3 (3),

65-76.

Turan, G, et all. (1986). Electric Power Distribution System

Engineering (Singapore: McGraw-Hill Book Co.)

IEC 60038 2009 IEC Standard Voltage (Geneva: IEC and

SEK)

Barong Is Bluetooth on Arduino Controlling Robotic Hand to Install Insulation Cover in Live Line

769