Marygold Flower Drying Machine Performance with Cooling

Dehumidification System Using a Refrigeration Machine

I Nyoman Gede Baliarta, Sudirman, Putu Darmawa and Suarta

Politeknik Negeri Bali, Indonesia

Keywords: Cooling Dehumidification, Refrigeration, Drying Machine.

Abstract: The purpose of this research is to make a drying machine for Marygold Flowers (Tagetes ercta L) which

operates below 60 degrees Celsius. Serves so that the color, aroma and components contained in gemitir

flowers are not damaged or greatly reduced due to high drying temperatures. The drying machine is made

using a cooling dehumidification system using a refrigeration machine as the main component. This dryer

operates at a temperature of 30-40 degrees Celsius with a humidity of 40-50%. This machine operates for 24

hours, producing dried flowers with a weight reduction of 90% and the smallest moisture content of 5%.

1 INTRODUCTION

Drying with a dehumidifier basically combines air

conditioning with a dryer/heater. The air conditioner

consists of a compressor, condenser, expansion valve,

evaporator and fan to produce air flow. In a

dehumidifier dryer the air coming out of the

evaporator pumps up to a temperature of 30

o

to 57

o

C

(Minea, 2012) (Acar & Dincer, 2014). An increase in

temperature will increase the rate of heat transfer to

the material being dried and the rate of air diffusion

in the material being dried. The low relative humidity

of the air ultimately aids the movement of air from the

dried material (Zamzami and Muhammad, 2017).

Here are some air dehumidification technologies,

such as refrigeration dehumidification, membrane

dehumidification, absorption dehumidification, and

adsorption dehumidification (G. D. da Silva, at al,

2016) This dehumidification cooling technology is

widely used in industrial and residential

dehumidification fields because of its compactness

and high safety (Caihang Liang, 2014). However,

conventional dehumidification cooling systems are

energy intensive. Energy costs will skyrocket if

ventilation rates are high to control IAQ (Indoor Air

Quality). As a result, a new dehumidification system

was needed (Yu-Cheng Chu, et al, 2017). The

advantage of dehumidifier drying compared to drying

drying is that it is easy to control temperature and air

drying so that it can be used over a wide temperature

range (Chin, et al, 2018).

The process of removing moisture from

agricultural materials is very energy-intensive.

Process energy use is quite large about: 20-25% of the

energy used by the food processing industry or 10-

25% of the energy used in all industries in developed

countries (Ziaforoughi and Esfahani, 2016).

Therefore, energy along with time efficiency is one of

the most significant design and operating parameters

in food processing (Chong, et al, 2014). The low

thermal conductivity and hardening of the material

are the main factors responsible for slowing down the

convective drying

There have been many advances in drying in

recent years, including pretreatments, techniques,

equipment and final product quality. Pretreatments,

for example, are used with the aim of accelerating the

drying process, improving quality and increasing

food safety (G. D. da Silva, at al, 2016).

2 MATERIAL AND METHODS

2.1 Equipment

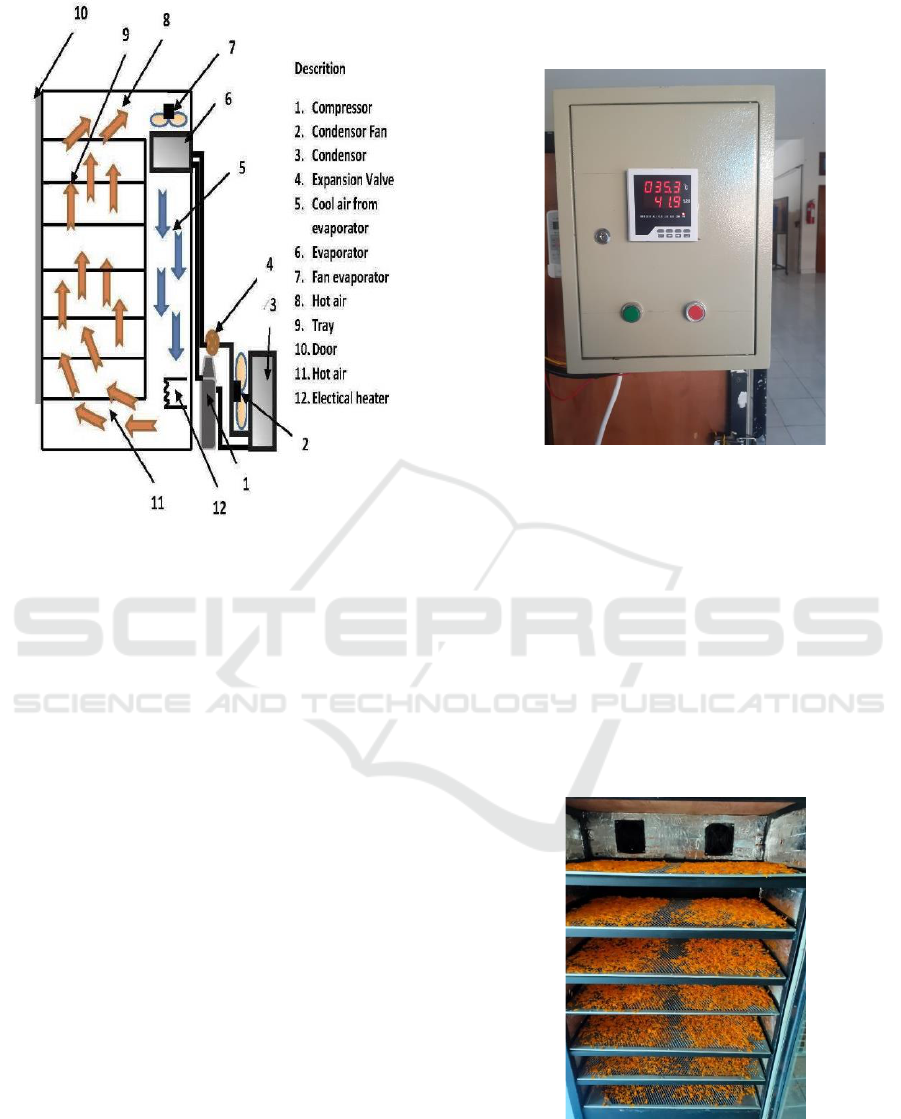

The drying machine is made with a scheme like

Figure 1. Where the main equipment of the machine

made consists of a compressor, condenser, expansion

valve and evaporator. Additional equipment is a

heater element that functions to heat the air coming

out of the evaporator. The working scheme of this

dehumification cooling drying machine at Fig 1.

794

Baliarta, I., Sudirman, ., Darmawa, P. and Suarta, .

Marygold Flower Drying Machine Performance with Cooling Dehumidification System Using a Refrigeration Machine.

DOI: 10.5220/0011884700003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 794-797

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Figure 1: Schematic of the cooling dehumidification dryer.

2.2 Procedure Experiment

The Dryer that will be made uses a Refrigeration

system component with a capacity of 1/2 Pk, with the

evaporator and evaporator fan placed on the inside of

the dryer, while the compressor, condenser and

expansion valve are placed outside the dryer.

The Drying Machine is divided into 2 rooms, the

first room has a shelf as a place for the bitter flowers

to be dried, while the other room functions as a return

air channel to the evaporator which will be cooled

again by the evaporator. The air that is cooled by the

evaporator will decrease in humidity, because in the

evaporator there will be air condensation after passing

through the gemitir flowers to be dried. The cold and

dry air coming out of the evaporator is then heated by

an electric heater. The hot, dry air then flows past the

flowers on the drying racks. Bitter flowers placed on

a drying rack will experience dehumidification, i.e.

the moisture content contained in them will be taken

up by dry and warm air that passes around them. The

air that absorbs moisture from the bitter flower will

be flowed back to the evaporator. And so on until the

bitter flowers that are on the drying rack will become

dry.

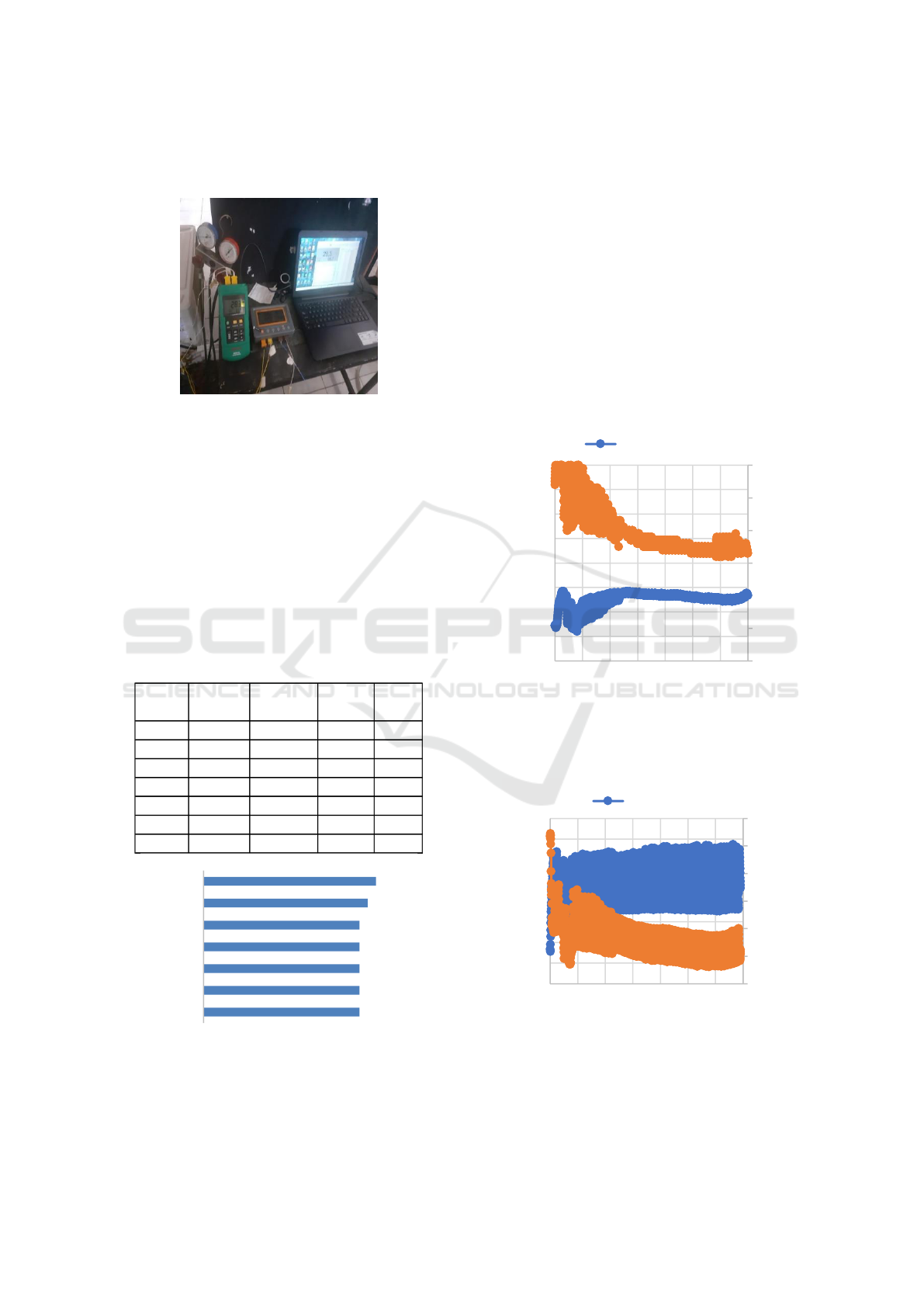

Control This Marygold flower dryer uses a

thermostat to control the heater element at a

temperature of 40 degrees Celsius and uses a

humiditystat to control the compressor which will

turn on at 50% relative humidity and turn off at 40%

relative humidity.

Figure 2: Thermostat and humiditystat installed on the

Smart control panel.

The gemitir flowers are to be dried, the Marygold

flowers are removed from the stems first, then

weighed, each shelf contains 500 grams of flowers.

The drying chamber contains 7 shelves. The flowers

that have been removed from the stems are placed on

a shelf, then put into the drying chamber. The data

logger is installed in the drying chamber and on the

refrigeration system piping. Press the ON push button

so that the dryer starts. Smart control is set at 40

degrees Celsius and humidity at 40%. And leave the

dryer in the dryer for 24 hours.

Figure 3: Marigold flower dried in the drying chamber.

The temperature and humidity conditions of the

dryer are monitored by data loggers and computers.

Fresh flowers and dried flowers were weighed and the

Marygold Flower Drying Machine Performance with Cooling Dehumidification System Using a Refrigeration Machine

795

moisture content was measured using a moisture

meter

Figure 4: Data logger and computer to get test data.

3 RESULTS AND DISCUSSION

The results of the marigold flower research that have

been carried out are shown below.

3.1 Marigold Flower Drying Results

The results of the research that has been done where

there are 7 shelves where dried flowers are made

Table 1.

Table 1: Results of drying research of Marygold flower.

Figure 5: Comparison graph of the weight loss of each shelf.

Flowers on shelf number 7 lost more weight

(90%) than flowers placed on other shelves, because

shelf number 7 was the first shelf to receive dry air

coming out of the evaporator and heated by the

heater. Following rack numbers 6, 5, 4 and so on.

Circulating air conditions in the dryer are depicted

in Figures 6, 7 and 8.

On the condition of the second to 1750 seconds.

Figure 6 shows the air coming out of the evaporator

with a temperature of about 34

o

C and a humidity of

55%, after passing through the heater element the air

temperature will increase to 50

o

C and the humidity is

around 35% (Figure 7). After the drying air passes

through the heater, it then passes through the flowers

on the shelves, taking moisture from the marygold

flowers. The air temperature increased by about 50

o

C

with the humidity also increasing to 43%. (Figure 8).

Figure 6: Graph of the condition of the air in the drying

chamber coming out of the evaporator (point 5).

Figure 7: Graph of the air condition in the drying chamber

after passing through the heater element (point 11).

Shelf

Number

Weigh Fresh

Flower

Weight Dry

Flower

Weiht Loss

(Gram)

Weiht

Loss (%)

1 150 25 125 83,33

2 150 25 125 83,33

3 150 25 125 83,33

4 150 25 125 83,33

5 150 25 125 83,33

6 150 20 130 86,67

7 150 15 135 90,00

83,33

83,33

83,33

83,33

83,33

86,67

90,00

1

2

3

4

5

6

7

Shelf Number

20

30

40

50

60

70

80

20

25

30

35

40

45

50

55

60

0 250 500 750 1000125015001750

RH (%)

Temperature (⁰C)

Time (minute)

Temperature°C

20

30

40

50

60

70

80

20

25

30

35

40

45

50

55

60

0 250 500 750 1000125015001750

RH (%)

Temperatur (⁰C)

Time (minute)

Temperature°C

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

796

Figure 8: Graph of the air condition in the drying chamber

after passing through rack number 1. (point 8).

Figure 9: Moisture content of dried marigold flowers on

each shelf.

The smallest moisture content is on the 7th shelf,

because the flowers on that shelf are the first to

receive the air heated by the heater element. Because

in addition to the hot air that hits it causes the water

vapor contained in the flowers to be easily released

and also floats up towards the shelves above.

4 CONCLUSIONS

The results of drying marygold flowers are quite

satisfactory, because the water content of dried

flowers produced on average is below 10%, but not

all of them show good results. Also the time it takes

is still too long about 24 hours. It is necessary to make

improvements to the machine, so that the results of

the dried flowers are evenly distributed and the time

required is under 24 hours.

ACKNOWLEDGEMENTS

This research can be carried out well, because of the

generosity of the Director of the Bali State

Polytechnic through the Center for Research and

Community Service (P3M PNB) providing sufficient

funds.

REFERENCES

Minea, V. (2012). Part I drying heat pumps system

integration.International Journal of Refrigeration 36:

643-658.

Acar, C., & Dincer, I. (2014). Performance Assessment of

a Two–stage Heat Pump–Drying System. Progress in

Sustainable Energy Technologies: Generating

Renewable Energy, 149–164. doi:10.1007/978-3-319-

07896-0_7

Zamzami, Muhammad Abror,(2017), Pengaruh Kecepatan

Udara Terhadap Laju Pengeringan Rimpang Jahe

(Zingiber Officinale Roscoe) pada Pengeringan

Kombinasi Surya-Tapis Molekuler, Downloaded from

Repositori Institusi USU, Univsersitas Sumatera Utara

Caihang Liang (2014) Research on a Refrigeration

Dehumidification System with Membrane-Based Total

Heat Recovery, Heat Transfer Engineering, 35:11-12,

1043-1049,

https://DOI:10.1080/01457632.2013.863072

Yu-Cheng Chu, Ling-Chia Weng, Pen-Chang Tseng, Yu-

Hao Kang & Chi-Chuan Wang (2017): On Effective

Design and Operating Conditions of Desiccant

Dehumidification System, Heat Transfer Engineering,

DOI: 10.1080/01457632.2017.1325657

Chin, S. K., Lee, Y. H., & Chung, B. K. (2018). Drying

characteristics and quality of lemon slices dried

undergone Coulomb force assisted heat pump drying.

Proceedings of 21th International Drying Symposium.

Presented at the 21st International Drying Symposium.

doi: https://doi.org/10.4995/IDS2018.2018.7294

Chong, C. H., Figiel, A., Law, C. L., & Wojdyło, A. (2014).

Combined drying of apple cubes by using of heat pump,

vacuum-microwave, and intermittent techniques. Food

and Bioprocess Technology, 7(4), 975–989.

https://doi.org/10.1007/s11947-013-1123-7

G. D. da Silva, Z. M. P. Barros, R. A. B. de Medeiros, C. B.

O. de Carvalho, S. C. Rupert Brandão, and P. M.

Azoubel, 2016 “Pretreatments for melon drying

implementing ultrasound and vacuum,” LWT - Food

Science and Technology, vol. 74, pp. 114–119, Dec.

2016.

Ziaforoughi and J. A. Esfahani, 2016 “A salient reduction

of energy consumption and drying time in a novel PV-

solar collectorassisted intermittent infrared dryer,”

Solar Energy, vol. 136, pp. 428–436, Oct. 2016.

20

30

40

50

60

70

80

20

25

30

35

40

45

50

55

60

0 250 500 7501000125015001750

RH (%)

Tmperatur (⁰C)

Time (Minute)

Temperature°C Humidity%

10

9,3

8,80

8,5

8,3

7,5

5

0

1

2

3

4

5

6

7

8

9

10

1 2 3 4 5 6 7

Moisture conten

(%)

Shelft Number

Marygold Flower Drying Machine Performance with Cooling Dehumidification System Using a Refrigeration Machine

797