Manufacturing Process Planning of Concrete Mixer Driving System

on 3D Concrete Printing Machine for Civil Buildings

Mohamad Fauzi, Tiara Gapuraning Rahayu and Heri Setiawan

Bandung Polytechnic for Manufacturing, Bandung, Indonesia

Keywords: 3D Concrete Printing Machine, Concrete Mixer, Manufacturing Planning.

Abstract: 3D Concrete Printing (3DCP) is a tool that functions to make a building construction automatically. The way

3DP works is to print material layer by layer to form a desired object. A 3D Concrete Printing (3DCP) consists

of Mixer, Nozzle, X-axis Pillar, Y-axis Pillar, and Z-axis Pillar. A concrete mixer on the 3DCP machine is a

tool that functions to mix cement, aggregate, and water homogeneously to form concrete to be distributed and

printed. Generally, the concrete mixer has 4 part-functions, namely the drive function, the container function,

the stirring function and the frame function. The planning of the construction of a concrete mixer driving

system is expected to produce the design and manufacturing stages of the concrete mixer driving system that

can rotate the container system to mix geopolymer cement, aggregate, and water so as to form geopolymer

cement concrete with good homogenization that can meets the needs of geopolymer cement concrete to be

printed.

1 INTRODUCTION

Additive Manufacturing (AM) is one of the methods

where in the process the addition of material is carried

out to make the desired shape. AM is a formal term

for what is called rapid prototyping (RP) and what is

popularly called 3D Printing (3DP) (Gibson, 2015).

The way 3DP works is to print the material layer by

layer until it forms a desired object (Erfiansyah,

2020).

3D Concrete Printing (3DCP), is an innovative

construction method that has recently been

introduced to the construction industry and has

proven to be profitable in terms of optimizing

construction time, cost, design flexibility, and

reducing errors and being environmentally friendly

(Malaeb, 2019). Politeknik Manufaktur Bandung,

which has a vision of becoming a leading institution

in the education, development, and application of

manufacturing technology, plans to design and

manufacture a 3D concrete printing machine for civil

buildings.

The main material in making buildings using 3D

printing techniques is geopolymer cement mixed with

water and aggregate, which will be printed layer by

layer until after setting and hardening will form a

geopolymer cement concrete according to the

working area of 3D Concrete Printing.

Geopolymer cement is obtained from the mixing

process of fly ash and activators in the form of NaOH

(flakes) and Na2SiO3 (granules). Geopolymer

cement must be stirred with water and aggregate to

produce geopolymer cement concrete (Yasin, n.d.).

The process of stirring or mixing geopolymer cement

and water and aggregate cannot be done manually

because manual stirring is not able to meet the needs

of geopolymer cement concrete to be printed. From

these problems, a tool is needed that can stir

geopolymer cement, water and aggregate until it is

mixed into geopolymer cement concrete. The tool

used to agitate concrete is commonly called a

concrete mixer (Wankhede, 2015). In this case, the

author's focus is to make a plan for the manufacture

of a concrete mixer driving system on a 3D concrete

printing machine of civil buildings.

2 METHOD

In the planning process of making a concrete mixer

driving system, there is a design process that adopts

VDI 2221 design method. The VDI 2221 method is a

method with a systematic approach to solving

Fauzi, M., Rahayu, T. and Setiawan, H.

Manufacturing Process Planning of Concrete Mixer Driving System on 3D Concrete Printing Machine for Civil Buildings.

DOI: 10.5220/0011891400003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 813-820

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

813

problems and optimizing the use of materials and

technology. After the design process is completed,

manufacturing process must be conducted according

to completed design. The following is a complete

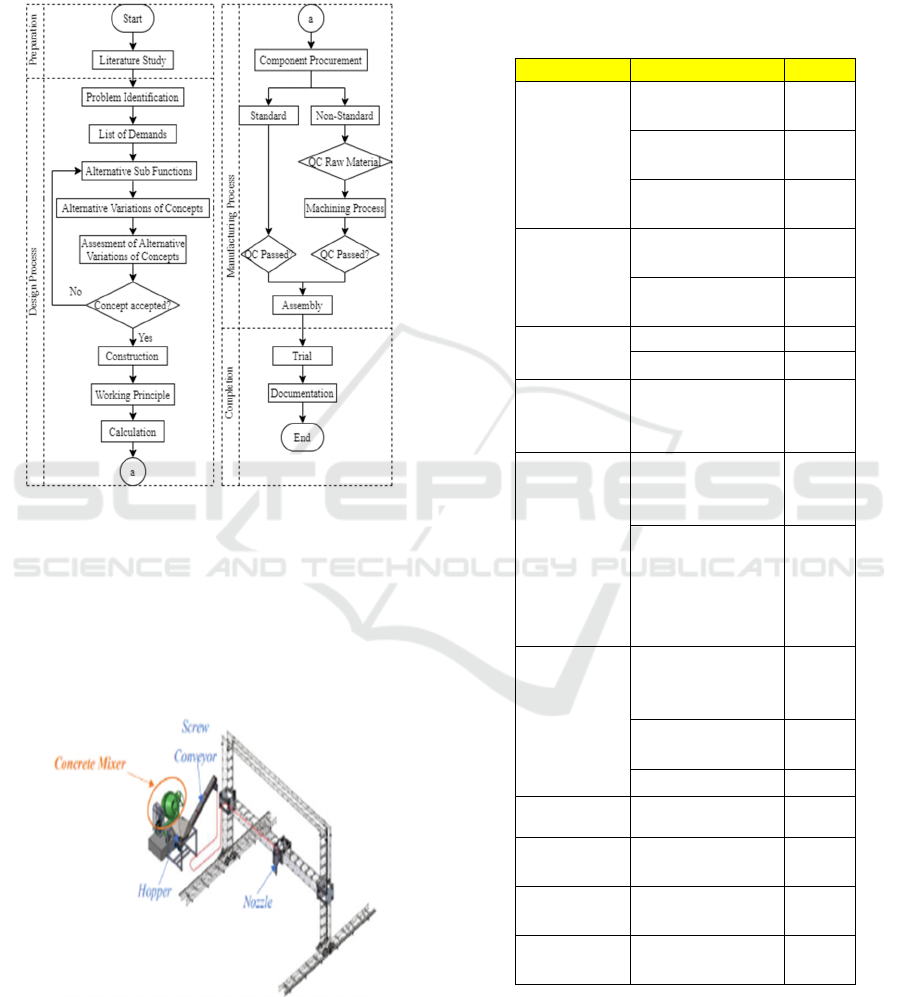

flowchart of the manufacturing process planning.

Diagram 1: Flow Process.

3 RESULT AND DISCUSSION

3.1 Design Process

3.1.1 Problem Identification

Figure 1: Concrete Mixer on 3DCP.

In 3D Concrete Printing technology, a tool is needed

that cn do material stirring (it can also be called a

concrete mixer) for then the material results in the

form of geopolymer cement concrete is ready to be

printed. There are several functions of parts of a

concrete mixer. The author's focus is on the

geopolymer cement stirring drive system.

3.1.2 List of Demands

Table 1: List of Demands.

Parameter Specification Priority

Manufacture Standard

components

*

Existing

components

**

Borrowable

components

*

Assembly Easy assembly

system

**

Can be

disassembled

*

Construction Sturdy *

Simple **

Kinematics Mixer tank rotates

at a speed of 40-50

rpm

*

Operation Easy and

ergonomic when

operated

**

Can be used for

stirring geopolymer

cement to form

geopolymer cement

concrete

*

Maintenance Ergonomic during

installation and

maintenance

**

Easy maintenance

and repair

**

Easy to clean **

Safety Safe operation *

Cost Minimum

production cost

**

Resistance Has a long lifetime **

Aesthetic Appealing visual **

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

814

3.1.3 Alternative Sub Functions

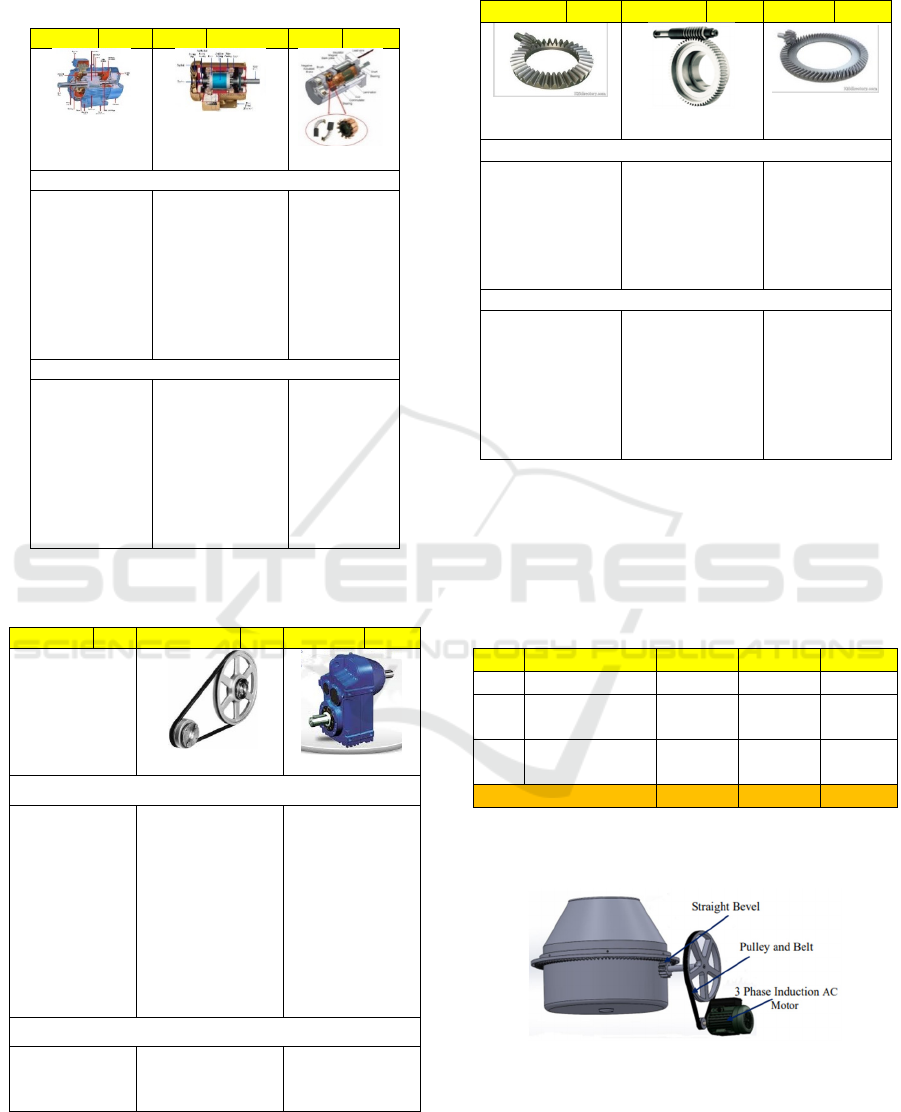

Table 2: Alternative Sub Functions: Drive Source.

Alt 1 A1 Alt 2 A2 Alt 3 A3

3 Phase

Induction AC

Moto

r

1 Phase Induction

AC Motor

Motor DC

Excess

• The use of

electrical

power is

more

efficient.

• Suitable for

use in

industrial

machinery.

• Construction is

simpler.

• Relatively

cheaper.

• Speed and

torque are

easier to

manage.

Deficiency

• Relatively

more

expensive

than 1 phase

induction

motors.

• It is more

suitable for use

in low-power

and medium-

load

applications.

• The relative

price is the

most

expensive.

• Not suitable

for large-

power and

high-speed

applications.

Table 3: Alternative Sub Functions: First Transmission

Element.

Alt 1 B1 Alt 2 B2 Alt 3 B3

Without

transmission

elements

Pulleys and Belts

Gearbox

Excess

• Fewer and

simpler

components

• It can dampen

shock loads,

noise and

vibration.

• Easy design and

flexible, do not

require high

tolerances.

• Relatively

cheaper.

• The

transmission

efficiency is

higher because

no slip occurs.

• Mechanically

stronger.

Deficiency

• Put

operation at

risk.

• Not as

compact as to

gears.

• More

complex

design.

Table 4: Alternative Sub Functions: Second Transmission

Element.

Alt 1 C1 Alt 2 C2 Alt 3 C3

Straight Bevel

Gear

Worm Gear

Spiral Bevel

Gea

r

Excess

• High

transmission

efficiency.

• Construction

is simpler.

• Large shock

load capacity.

• It's quieter.

• High

transmission

efficiency.

• The load

capacity is

lar

g

e

r

Deficienc

y

• Produces

greater

vibration and

sound

compared to

spiral bevel

gear.

• Lower

transmission

efficiency.

• At risk during

installation

and use of the

en

g

ine.

• Complex

construction

3.1.4 Alternative Variations of Concepts

Alternative of concept variations will be assessed and

the one with the highest value will be selected for

further detailed designing.

Table 5: Morphology Box.

The following are alternative results of variations in

concepts:

Figure 2: 1

st

Alternative of Concept Variations.

No. Component Var 1 Var 2 Var 3

1. Drive motor A1 A2 A3

2. Transmission

element 1

B1 B2 B3

3. Transmission

element 2

C1 C2 C3

Concept Variations ACV1 ACV2 ACV3

Manufacturing Process Planning of Concrete Mixer Driving System on 3D Concrete Printing Machine for Civil Buildings

815

Figure 3: 2

nd

Alternative of Concept Variations.

Figure 4: 3

rd

Alternative of Concept Variations.

All modeling variations are assessed according to:

Nominal 5: Excellent, very achieved, and very easy.

Nominal 4: Good, achieved, and easy.

Nominal 3: Good enough, quite achieved, and quite easy.

Nominal 2: Not good, less achieved, and less easy

Nominal 1: Not good, not achieved, and not easy.

Table 6: Assessment of Alternative Concept Variations.

No. Parameter W

ACV 1 ACV 2 ACV 3

P ST P ST P ST

1. Manufacture 4 3 12 3 12 3 12

2. Assembl

y

3 3 9 2 6 3 9

3. Construction 5 3 15 3 15 2 10

4. O

p

eration 5 4 20 4 20 4 20

5. Maintenance 3 4 12 3 9 3 9

6. Safet

y

5 4 20 3 15 2 10

7. Cost 3 4 12 3 9 3 9

8. Aesthetic 2 3 6 4 8 3 6

9. Resistance 4 3 12 4 16 2 8

Total Value 34 31 118 29 110 25

9

3

Percentage 86.7% 80.8% 68.4%

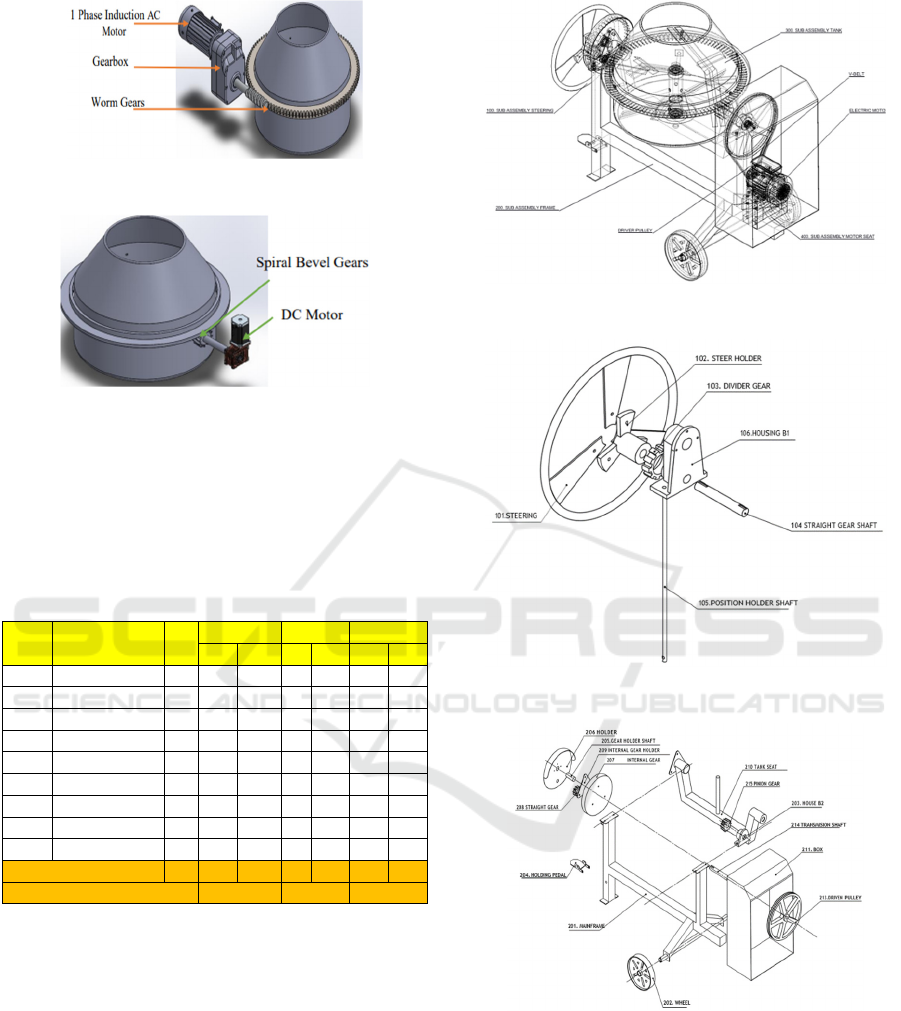

3.1.5 Construction

This stage contains documents that include machine

drawings, machine drawing details, a list of

components, and other documents connected into a

single entity. Here's the overall construction drawing

of the selected 1

st

Alternative of Concept Variations

(ACV1):

Figure 5: Assembly Construction of Concrete Mixer.

Figure 6: Construction of Sub-assy Steering.

Figure 7: Construction of Sub-assy Frame.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

816

Figure 8: Construction of Sub-assy Tank.

Figure 9: Construction of Sub-assy Motor Seat.

3.1.6 Working Principle

Figure 10: Working Principle Illustration.

The working principle of the concrete mixer driving

system is that when the motor as the driving source is

electrified, the motor shaft will rotate, the power and

rotation of the motor shaft are then transmitted to the

transmission system in the form of a pulley and belt,

then passed to the transmission shaft. The rotation of

the transmission shaft is passed to the pinion gear.

The pinion gear rotates its pair, namely the crown

gear that circles the mixer tank so that the mixer tank

can rotate on its axis according to the rotation ratio to

stir the geopolymer cement, water, and aggregate to

form geopolymer cement concrete.

3.1.7 Calculation

Three Phase Induction AC Motor. The motor used

is in accordance with the availability of components

in Polman, with specifications:

• Motor output power = 3.7 kW

• Motor rev = 2890 rpm

• Loading torque = 13,21 Nm

Pulleys and Belts

a. Specifications of pulleys and belts

On the available concrete mixer, there are large pulley

(driven pulley).

Known:

• Large pulley pitch diameters:𝐷

450 𝑚𝑚

• Belt type required = V-Belt type A

• Number of belts required = 2 pieces

Asked:

• Small pulley pitch diameter?

• Shaft distance?

• Belt length?

Answer:

• Small pulley pitch diameter (𝑑

)

→

→𝑑

68 𝑚𝑚 (1)

• Shafts’ Distance Range (C)

The distance between two shafts must meet the

following conditions:

𝐶0,7 𝑑

𝐷

and 𝐶2𝑑

𝐷

(2)

𝐶0,7 68 450 and 𝐶268 450

𝐶362,6 and 𝐶1036

365 mm of shafts’ distance is selected.

• Belt length (L)

𝐿

2. 𝐶

𝑑

𝐷

.

𝐷

𝑑

(3)

𝐿

2.365

𝜋

2

68 450

1

4.365

450 68

𝐿

1643,2 𝑚𝑚

The belt length of the calculation result is adjusted

to the standard on ISO 4184, the belt length is

1655

𝐿

𝐿

mm, which is belt number A46.

• Distance between shafts (C)

The distance between shafts according to the standard

belt length can be calculated by the formula:

𝐶

(4)

𝐶

2.1655 𝜋

450 68

2.1655 𝜋450 68

8

450 68

8

𝐶371,81 𝑚𝑚

Manufacturing Process Planning of Concrete Mixer Driving System on 3D Concrete Printing Machine for Civil Buildings

817

b. Transmission efficiency

Based on calculations, it is known:

• Belt linear speed (V) =10,28

𝑚

𝑠

⁄

• Belt tight side tension 𝑇

=347,28 𝑁

• Belt saggy side tension 𝑇

=95,79 𝑁

Asked:

• Transmission efficiency?

Answer:

Determining torque

𝑇

𝑇

𝑇

𝑟 (5)

𝑇

347,28 95,79

0,034

𝑇8,56 𝑁. 𝑚

Determining the transmitted power

𝑃

𝑇𝜔 (6)

𝑃

𝑇

2𝜋𝑛

60

𝑃

8,56

2𝜋2890

60

𝑃

3009 𝑤𝑎𝑡𝑡 3 𝑘𝑊

Determining transmission efficiency

𝜂

100% (7)

𝜂

3

3,7

100% 81 %

Straight Bevel Gears. On the available concrete

mixer, there are straight bevel gears in the form of

pinion bevel gear and crown bevel gear.

Known:

• The rotation of the tank is desirable (the rotation of

the crown gear): n

45 50 rpm, taken 48 rpm.

• Number of pinion gear: Z

12

• Number of crown gear:Z

108

Asked:

• Pinion bevel rotation to make the crown gear

rotates 48 rpm?

Answer:

→

→𝑛

436 𝑟𝑝𝑚 (8)

Power to Rotates Mixer Tank. The power required

to rotate the tank is the power needed by the pinion

bevel gear to rotate the crown bevel gear.

Figure 11: Illustration of pinion gear rotating crown gear.

Known:

• Power received by pinion gear from the pulley and

belt transmission system = 3009 watts

• Pinion gear rotational speed (n1) = 436 rpm

• Crown bevel gear rotational speed (n2) = 48 rpm

• Mass of mixer tank= 98.58 kg

• Mass of crown gear = 32,40 kg

• Maximum capacity of tank load = 300 kg

• Diameter pitch pinion gear:d

100,9 mm

• Diameter pitch crown gear:d

908,3 mm

Asked:

• Power, force and torque on the pinion gear?

• The force, torque and power required to rotate the

crown gear?

Answer:

• Power, force and torque on the pinion gear

Figure 12: Illustration of the force that occurs in the pinion

gear.

The power received by the pinion gear of the pulley

and belt transmission system is:

𝑃3009 𝑤𝑎𝑡𝑡

Tangential force that occurs in the pinion gear that

can be passed to the crown gear:

P T. ω (9)

𝑃𝐹

. 𝑟.

2𝜋. 𝑛

60

𝐹

𝑃. 60

𝑟 .2𝜋. 𝑛

𝐹

3009. 60

0,05 . 2𝜋. 436

𝐹

1318 𝑁

The torque required to rotate the pinion gear is:

𝑇𝐹

. 𝑟 (10)

𝑇1318 . 0,05

𝑇65,94 𝑁𝑚

• The force, torque and power required to rotate the

crown gear

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

818

Figure 13: Illustration of the force that occurs in the crown

gear.

Looking for tangential force, which is the force that

acts on the crown gear to move in a circle in the

tangential direction of a curved trajectory.

F

m. a

(11)

F

m

m

m

α.r

F

98,58 32,40 3005,02 . 0,45

F

973,58 N

After the tangential force is obtained, the torque,

which is the force required for the crown gear to rotate

on its axis at a distance r, can be calculated by the

formula:

T F

.r (12)

T 973,58 . 0,45

T 438,11 Nm

The power required to rotate the crown gear can be

calculated by:

P T. ω (13)

P 438,11 .

2π.48

60

P 2199 watt 2,2 kW

• Conclusion:

o Tangential force of crown gear < pinion gear

o The power required by crown gear < the power that

the pinion gear receives to be passed on.

o If the calculation of torque with the rotation ratio is

carried out, the torque on the pinion gear and on the

crown gear < the loading torque of the motor which

is 13.21 Nm.

o It can be concluded that the pinion gear can rotate

the crown gear, which means that the tank can

rotate to stir the material that makes up the

geopolymer cement concrete at the maximum

capacity of the tank, which is 300 kg.

Composer Material of Geopolymer Cement

Concrete. Based on the specifications of pulleys and

belts, straight bevel gears, as well as the power ability

of the motor to rotate the tank, the composition of the

material that can be stirred by the concrete mixer is as

follows:

Table 7: The composition of the stirred material.

No. Identification

1.

T

ank capacit

y

• Tank capacity accommodates load at motor

power 3.7 kW = 300 kg

• It is known that the density of geopolymer

cement is 2400 kg/mm

3

, so the volume of

geopolymer cement that can be accommodated is

=

0,125 𝑚

125 𝑙𝑖𝑡𝑒𝑟

2. The number of each constituent component of

geopolymer cement concrete

With a total capacity of 300 kg, each constituent

component of geopolymer cement concrete is:

1. Geopolymer cement (30%) = 85 kg

2. Water (0,159xgeopolymer cement) = 13,5 kg

3. Coarse aggregate (3/5 x 70%) = 118.8 kg

4. Fine aggregate (2/5 x 70%) = 79.2 kg

3.2 Manufacturing Process

3.2.1 Component Procurement

Table 8: Component of Concrete Mixer Drive System.

No. Component Name Qty

Component Availabilit

y

Yes

No

Standar

d

Non

Electrical Components

1. 3

p

hase AC moto

r

1

√

2. Switch Button 1

√

3. Magnetic contact 1

√

4. Thermal overload rela

y

1

√

5. Pilot lam

p

o

ff

1

√

6. Pilot lam

p

on 1

√

7. NYA cable re

d

1

√

8. NYA cable blac

k

1

√

9. NYA blue cable 1

√

Mechanical Com

p

onents

1. Motor seat 1

√

2

. Driver

p

ulle

y

1

√

3.

B

elt 2

√

4

. Driven pulley 1

√

5. Transmission shaft 1

√

6. T

yp

e A 8×7

p

arallel

p

e

g

2

√

7. Type A 10×8

p

aralle

l

p

egs

1 √

8. Bolt M8 1

√

9. Washe

r

1

√

10. Bearin

g

6205-ZR 1

√

11. Housing bearing 1

√

12. Pinion bevel gea

r

1

√

13. Crown bevel

g

ea

r

1

√

Manufacturing Process Planning of Concrete Mixer Driving System on 3D Concrete Printing Machine for Civil Buildings

819

3.2.2 Machining Process Planning

The stages of the machining process are the sequence

of processes to make raw material into the desired

component. The following are Working process

stages of non-standard components that need to be

made, namely motor seat component.

Table 9: Working process stages of non-standard

components.

No. Component Qty Work Process

1. Motor seat part 1 2 CG-HG-DR

2. Motor seat part 2 2 CG-DR-MI-EW-HG

3. Motor seat

p

art 3 2 CG-DR

CG= Cutting grinding, DR=Drill, HG=Hand

grinding, MI=Milling, EW=Electric welding

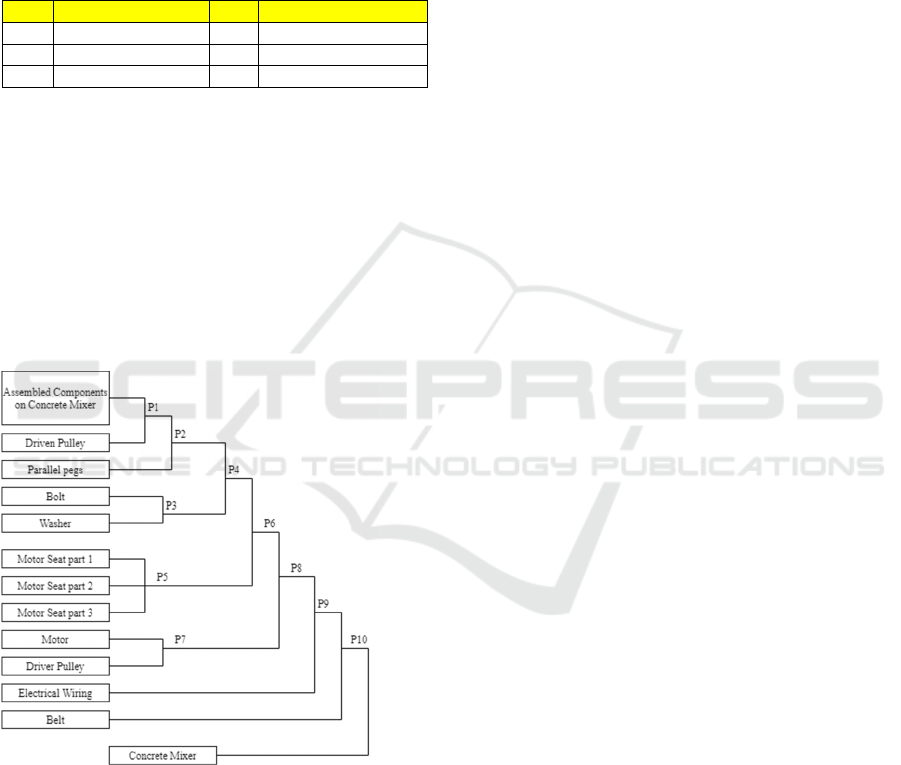

3.2.3 Assembly Planning

Assembly is a process of compiling and unifying

several component parts into a tool or machine that

has a certain function. These assembly activities

include drafting, placing, fastening, and measuring.

The following are the assembly stages of the drive

system on the concrete mixer:

Diagram 2: Component Assembly Diagram of Concrete

Mixer Driving System.

3.2.4 Trial

The trial stage is carried out to ensure that the

concrete mixer can be used according to its function.

This aims to determine the tank's ability to stir

geopolymer material, so it is expected that after the

trial stage, what can be obtained is the data on the

ideal capacity of geopolymer material that can be

stirred by concrete mixer and the time required to

achieve homogenization of materials.

4 CONCLUSIONS

The working principle of the concrete mixer driving

system is that when the motor as the driving source is

electrified, the motor shaft will rotate, the power and

rotation of the motor shaft are then transmitted to the

transmission system in the form of a pulley and belt,

then passed to the transmission shaft. The rotation of

the transmission shaft is passed to the pinion gear.

The pinion gear rotates its pair, namely the crown

gear that circles the mixer tank so that the mixer tank

can rotate on its axis according to the rotation ratio to

stir the geopolymer cement, water, and aggregate to

form geopolymer cement concrete.

In planning the manufacture of this concrete mixer,

the process begins with the design method of VDI

2221, then continues with the planning process, then

continues with the process of procurement of

components. After that, the process of machining,

assembly, trial and document collection should be

carried out.

REFERENCES

Gibson, Ian. Stucker, Brent. Rosen, David. (2015). Additive

Manufacturing Technologies. New York: Springer

Erfiansyah. Erfin. (2020). DESIGN OF CARTESIAN

TYPE 3D PRINTING MACHINE CONSTRUCTION

BASED ON FUSED DEPOSITION MODELING.

Bandung: Politeknik Manufaktur Negeri Bandung.

Malaeb, Zevia. AlSakka, Fatima. Hamzeh, Farook. (2019).

3D Printing. Lebanon: Elsevier Inc.

Yasin. Abdul Karim. (2019) ASH-BASED

GEOPOLYMER CONCRETE ENGINEERING.

Surabaya: Ten November Institute of Technology.

Wankhede. Amruta K, Sahu. A. R. (2015). Design,

Modification and Analysis of Concrete Mixer Machine.

G. Pahl, W. Beitz, J. Feldhusen, dan K. H. Grote. (2007).

Engineering design: A systematic approach.

Sularso and K. Suga. (2004). Basic Planning and Selection

of Machine Elements. Jakarta: PT. Pradnya Paramita.

Jelaska. Damir. (2012). Gears and Gear Drives. Croatia: A

John Wiley & Sons, Ltd., Publication.

Ichniarsyah, Nur Annissa. A, Azhar. (2019). MOTOR

DRIVE. Jakarta: Agricultural Education Center.

Waloeyo, Gamawan A. (2009). PPC Basic Cost. Bandung:

Politeknik Manufaktur Negeri Bandung.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

820