The Manufacturing Process of Geopolymer Mortar Nozzle

Construction on Civil Building 3D Printing Machine

Antonius Adi Soetopo

1

, Heri Setiawan

2

and Alvian Andriansyah

1

1

Polman Bandung, Indonesia

2

Politeknik Manufaktur Bandung, Indonesia

Keywords: Nozzle, Geopolymer Mortar, Manufacturing Process.

Abstract: The geopolymer mortar nozzle is one of the components contained in the 3D printing machine of civil

buildings that serves to remove the geopolymer mortar into a certain shape. A civil building 3D printing

machine requires a tool or device designed to control the shape or characteristics of the material flow specially

to regulate the number of geopolymers when exiting a hopper.

The nozzle will store the geopolymer mortar on the hopper, then with the rotation of the stepper motor and

extruder, the geopolymer mortar will come out into a certain shape through the nozzle head. The construction

of the geopolymer mortar nozzle on the 3D printing machine of civil buildings is carried out by cutting plates

using hand grinding and cutting grinding, turning, bending, and welding for the assembly process. After this

geopolymer mortar nozzle is completed and realized at the Manufacturing Engineering Department of the

Bandung Manufacturing Polytechnic, this geopolymer mortar nozzle is expected to be used for the

manufacture of civil buildings and function properly and benefit the polman academic community, the

community, and the State of Indonesia.

1 INTRODUCTION

Civil building 3D printing machine is a machine that

processes geopolymer mortar under computer control

to create three-dimensional objects, with materials

added together (geopolymer concrete, sand, and

water combined). Objects can be either shapes or

geometries and are typically generated using digital

model data from 3D models derived from Additive

Manufacturing Files (AMF). 3D printing builds a

three-dimensional object from a computer-aided

CAD model or AMF file, by adding layers of material

layer by layer in a row.

This civil building 3D printing machine requires a

device or devices designed to control the shape or

characteristics of the material flow (specially to

regulate the number of geopolymers) when exiting (or

entering) a hopper called a nozzle. Oleh therefore, in

this case the author focuses on "Proses Manufacture

of Geopolymer Mortar Nozzle Construction On 3D

Printing Machines of Civil Buildings

2 PURPOSE

The purpose of making this tool is as follows:

1. Knowing the construction of the geopolymer

mortar nozzle on the 3D printing machine of civil

buildings.

2. Knowing the work of the geopolymer mortar

nozzle on the 3D printing machine of civil

buildings.

3. Knowing the manufacturing process of

geopolymer mortar nozzle construction on a civil

building 3D printing machine.

4. Knowing the estimated time required to make the

construction of the geopolymer mortar nozzle on

the civil building 3D printing machine.

5. Knowing the estimated cost needed to make the

construction of a geopolymer mortar nozzle on a

civil building 3D printing machine.

Soetopo, A., Setiawan, H. and Andriansyah, A.

The Manufacturing Process of Geopolymer Mortar Nozzle Construction on Civil Building 3D Printing Machine.

DOI: 10.5220/0011893400003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 843-849

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

843

3 MANUFACTURING PROCESS

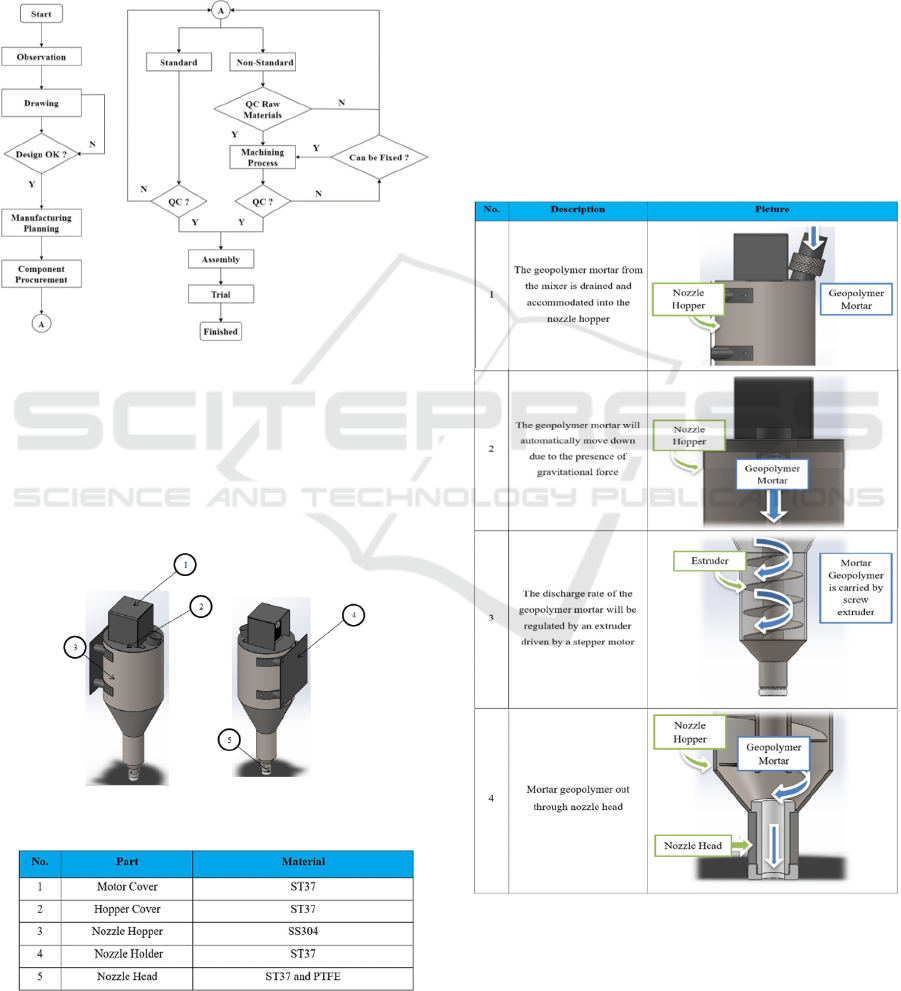

3.1 Manufacturing Process Flow

The process of making the construction of a

geopolymer mortar nozzle consists of several stages,

these stages can be described in general on the

following flow chart:

Diagram 1: Flow Chart of The Construction Process of

Geopolymer Mortar Nozzle Construction.

3.2 Construction Nozzle Mortar

Geopolymers

Below is a picture of the construction of the

geopolymer mortar nozzle:

Figure 1: Construction of the Geopolymer Mortar Nozzle.

Figure 2: List of Parts Names and Materials for

Construction of Geopolymer Mortar Nozzles.

Material is the raw material for the manufacturing

process both directly from natural and artificial which

will be processed into a product. The main materials

used in the manufacturing process of geopolymer

mortar nozzle construction in civil crane 3D printing

machines are ST37, SS304 and PTFE.

3.3 Working Principle

The working principle of this tool is mortar

geopolymers accommodated inside hopper nozzle

will move down due to the force of gravity and the

large amount of expenditure mortar geopolymers are

governed by Extruder driven by the motor Stepper.

Here is an explanatory table of the working principles

of construction mortar nozzle geopolymer on the

machine 3D printing civil buildings.

Figure 3: Table of Working Principle of Geopolymer

Mortar Nozzle.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

844

3.4 Mass Nozzle Mortar Geopolymer

The nozzle mass of the geopolymer mortar is the

summation of the construction mass of the nozzle,

extruder, stepper motor, standard components, and

mass of the geopolymer mortar.

3.4.1 Calculation of the Mass of Geopolymer

Mortar on the Hopper Nozzle

The calculation of the mass of the geopolymer mortar

on the nozzle hopper is carried out by calculating the

volume of tube 1, tube 2, reducer 1, reducer 2 and

connecting nozzle head. The sizes of the hopper

nozzle are as follows:

Figure 4: Nozzle Hopper.

a) Geoolimer Mass on Tube 1

• Volume at T1 =

π x r

2

x t

(1)

= 3.14 x 150

2

x 340

= 2.4033 x 10

7

mm

3

= 24,033dm

3

• Mass at T1 = 24,033 x 2.4

= 57.68 Kg

b) Geolymer Mass on Tube 2

• Volume at T2 = 3.14 x 50

2

x 165

= 1.2952 x 10

6

mm

3

= 1.2952 dm

3

• Mass at T2 = 1.2952 x 2.4

= 3.1 Kg

c) Geolymer Mass on The Join

• Volume at Join = 3.14 x 22.5

2

x 25

= 3.9740 x 10

4

mm

3

= 0.0397 dm

3

• Mass at Join = 0.0397 x 2.4

= 0.1 Kg

d) Gepolimer mass on Reducer 1

• Volume on Reducer 1

=

1/3 x π x t x (R

2

+ R x r + r

2

)

(2)

= 1/3 x 3.14 x 205 x (150

2

+ 150 x 50 + 50

2

)

= 6.9734 x 10

6

mm

3

= 6.9734 dm

3

Figure 5: Reducer 1.

• Mass on Reducer 1

= 6.9734 dm

3

x 2.4 Kg/ dm

3

= 16.74 Kg

Figure 6 Reducer 2.

a) Mass Reducer 2

• Volume Reducer 2

= 1/3 x 3.14 x 40 x (50

2

+ 50 x 22.5 + 22.5

2

)

= 1.7296 x 10

5

mm

3

= 0.1729 dm

3

• Mass Reducer 2

= 0.1729 dm

3

x 2.4 Kg/ dm

3

= 0.41 Kg

So the total mass of the geopolymer mortar is the

summation of the mass of tube 1, tube 2, reducer 1,

reducer 2 and connecting nozzle head which is 78.03

Kg.

3.4.2 Mass Calculation Nozzle Mortar

Geopolymers

Figure 7: Table of Mass of Geopolymer Mortar Nozzle

Parts.

The mass of the nozzle of the geopolymer mortar

= 30,318 Kg + 78.03 Kg

= 108,348 Kg

The Manufacturing Process of Geopolymer Mortar Nozzle Construction on Civil Building 3D Printing Machine

845

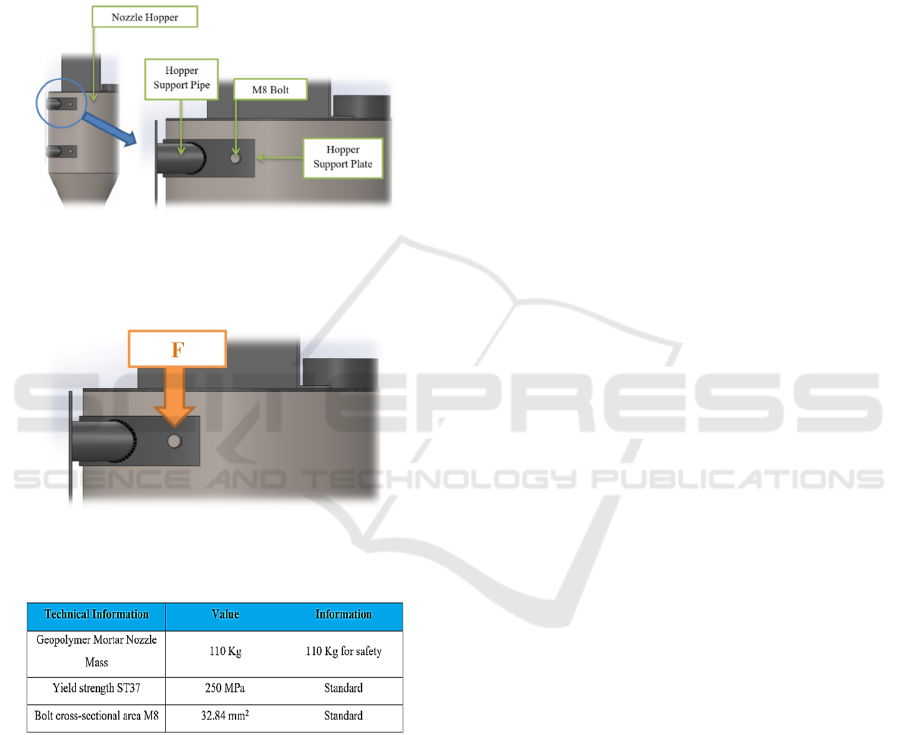

3.5 Calculation of Voltage Occurring in

BoltEd Joints

In the manufacturing process of the geopolymer

mortar nozzle construction, the connection on the

hopper support plate must be considered, because this

plate will hold the nozzle of the geopolymer mortar.

This plate relates to the hopper nozzle using the

method of splicing nuts and bolts M8.

Figures 8: Bolt joints on the Hopper support plate.

3.5.1 Load/Voltage on M8 Bolts

Figures 9: The direction of force occurring on the M8 bolts.

Known:

Figure 10: M8 bolt information table.

find:

a) Permissible voltage

b) Maximum load of bolts

c) Voltage on the bolts

Answer:

1) Determining the Clearance Voltage

σ permissions = Re/Sf (3)

= 250 / 1.5

= 167 N/mm

2

τ permissions = 0.7 x σ permissions

= 0.7 x 167 N/mm

2

= 117 N/mm

2

Information:

σizin= Tensile voltage/normal clearance ( N/mm

2

)

τizin= Clearance shear stress ( N/mm

2

)

Re= Resistant extension ( N/mm

2

)

Sf= Safety factor

Safety Factor for static loading = 1.2 – 2

2) Maximum load bolts M8

τ= F / A (4)

F= τ x A (5)

= 117 x 32.84

= 3842 N

Description:

τ= Shear stress ( N/mm

2

)

A= Cross-sectional area ( mm

2

)

The force of the geopolymer mortar nozzle is 1100 N,

it can be determined that 1 bolt M8 is able to

withstand the load of the geopolymer mortar nozzle.

However, due to several considerations, namely

extreme weather factors and natural disasters such as

earthquakes, 4 M8 bolts were used.

3) Determining the shear stress that the bolt

receives

F = 1 100 N

F = 1 nz100 N / 4 = 275 N (Loading divided on 4

bolts)

τ= F / A (6)

= 275 N / 32.84 mm

2

= 8.4 N/mm

2

3.6 Material Use

The procurement of materials for the construction of

geopolymer mortar nozzles is divided into 2, namely

standard parts and raw materials.

3.6.1 Standart Parts

This Standard Part is obtained by buying standard

parts/components without the need to do the

machining process again, for example standard

components, namely baut and nuts. For the next

process these standard components go directly into

the assembly process.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

846

3.6.2 Non-Standart Parts/Raw Material

This Raw Material is obtained by purchasing raw

materials, then the machining process is carried out to

get the desired shape and function according to the

working drawing.

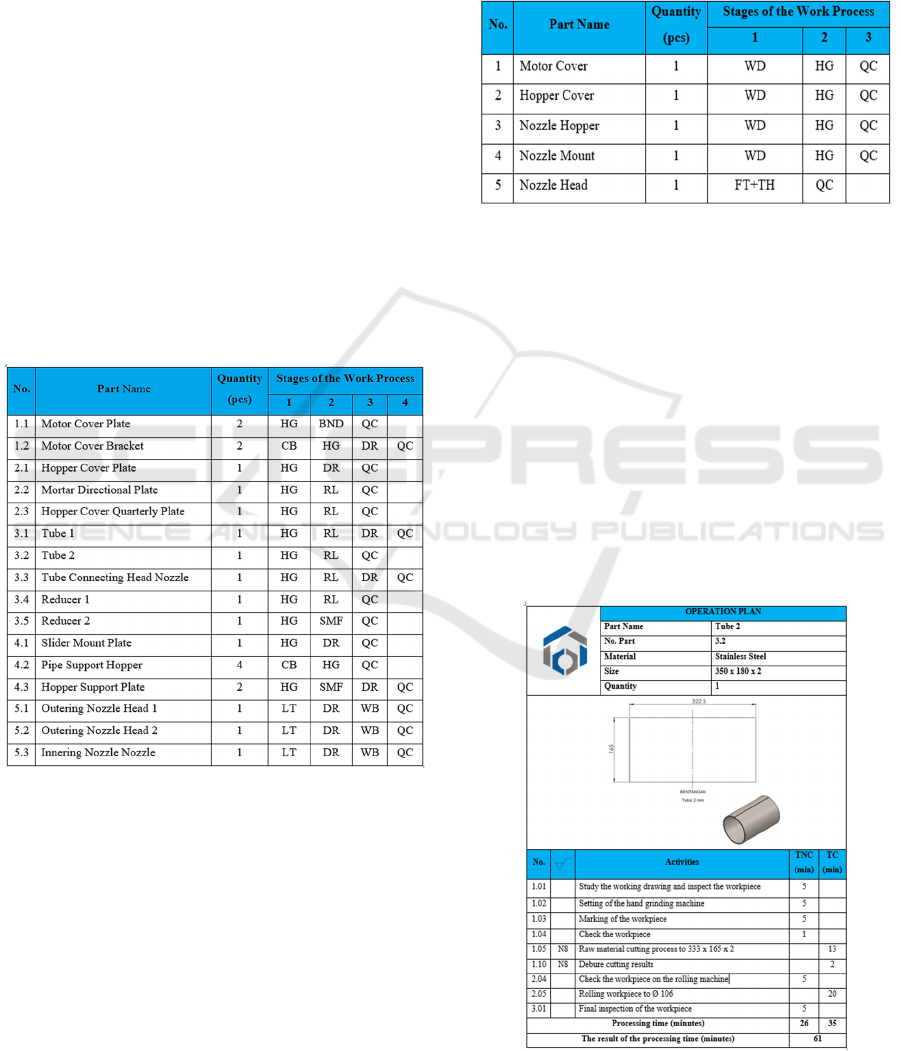

3.7 Machining Process

The machining process discusses the work of raw

materials and sub assembly parts, this machining

process includes the stages of the work process,

operation plan and quality control process. The

following is an explanation of each stage of the

machining process.

3.7.1 Stages of Raw Material Work Process

The stages of the work process are the sequence of

processes for making raw material components. The

following are the stages of work on the raw material

components of the construction of the geopolymer

mortar nozzle.

Figure 11: Stages of the raw material work process.

Information:

HG: Hand Grinding

CB: Cut Burrs

DR: Drill

LT: Lathe

QC: Quality Control

RL: Rolling

BND: Bending

SMF: Sheet Metal Forming

WD: Welding

KB: Work Bench

3.7.2 Stages of the Process of Working on

sub Assembly Parts

The following are the stages of the process of working

on the components of the sub assembly part sub

assembly construction of the geopolymer mortar

nozzle.

Figure 12: Stages of the process of working on sub

assembly parts.

Information:

HG: Hand Grinding

WD: Welding

FT+TH: Fit+Thread

QC: Quality Control

3.8 Operation Plan

Work planning is made to regulate the workprocess

to avoid mistakes and as a source of information to

calculate the estimated processing time. The

following is one of the operation plans for the

construction of the geopolymer mortar nozzle.

Figure 13: Operation Plan (OP).

The Manufacturing Process of Geopolymer Mortar Nozzle Construction on Civil Building 3D Printing Machine

847

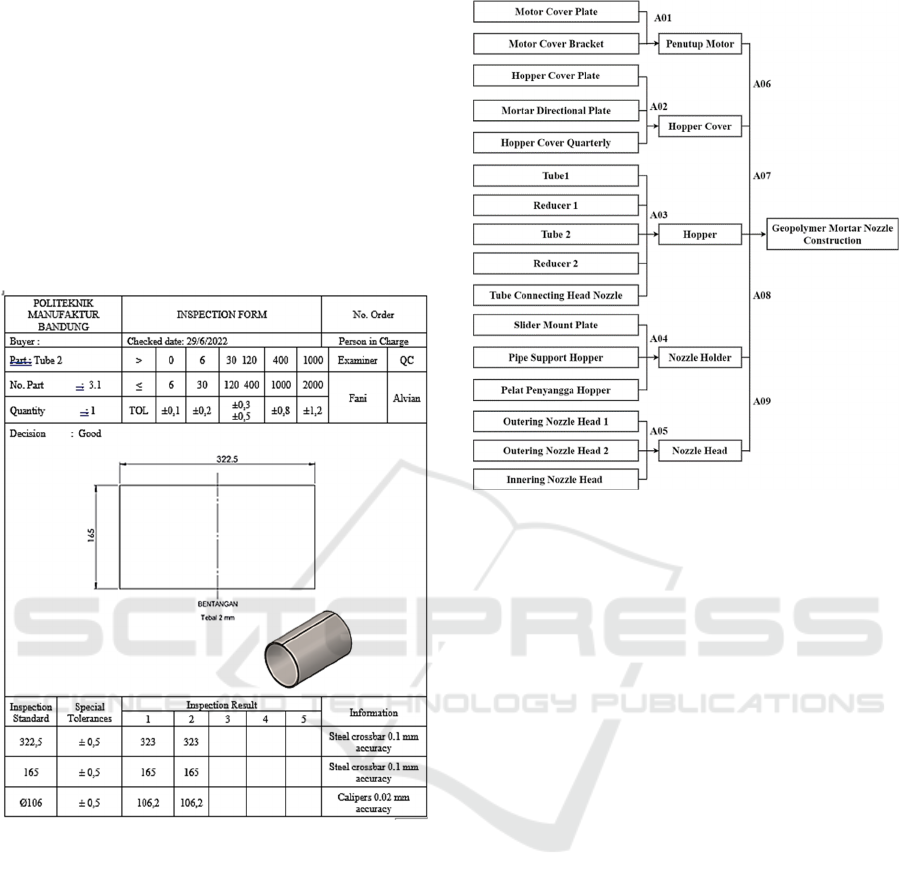

3.9 Quality Control (QC)

After carrying out the planning of the process and the

machining process. Thework that has been completed

in the process will pass the Quality Control (QC)

stage.

Quality Control aims to check that the parts that

have been made are in accordance with their

respective work drawings, if the compensatoryis not

suitable and exceeds the existing tolerances, then the

components must bere-worked or re-procured and

cannot be continued to the next process.

Figure 14: Quality control (QC).

3.10 Assembly

Assembly is the activity of combining components or

parts that have been made into a unit that has a certain

function. The components of machining, cutting and

fabrication are assembled in a manner in accordance

with the existing working drawings until all these

components become unitary and can be used

according to their functions.

The following are the stages of assembly of each

part of the construction of the geopolymer mortar

nozzle:

Diagram 2: Geopolymer mortar nozzle construction

assembly process.

3.11 Trial

After the construction of the geopolymer mortar

nozzle is completed, the next step is a trial. The trial

stage is carried out to ensure that the construction of

the geopolymer mortar nozzle can be used in

accordance with its function. At this stage, what must

be done is a trial of the production of geopolymer

material, starting with inserting a geopolymer mortar

into the nozzle hopper as much as 30 liters, then

turning the extruder by adjusting the strepper motor

at different speeds each time the test is carried out.

This aims to determine the construction ability of

the geopolymer mortar nozzle in removing

geopolymer material.

Itis hoped that after the trial

stage, data on the speed of the motror stepper and the

ideal fluid discharge will be obtained so as to produce

the best production of geopolymer material.

4 ESTIMATED TIME AND COST

4.1 Estimated Time

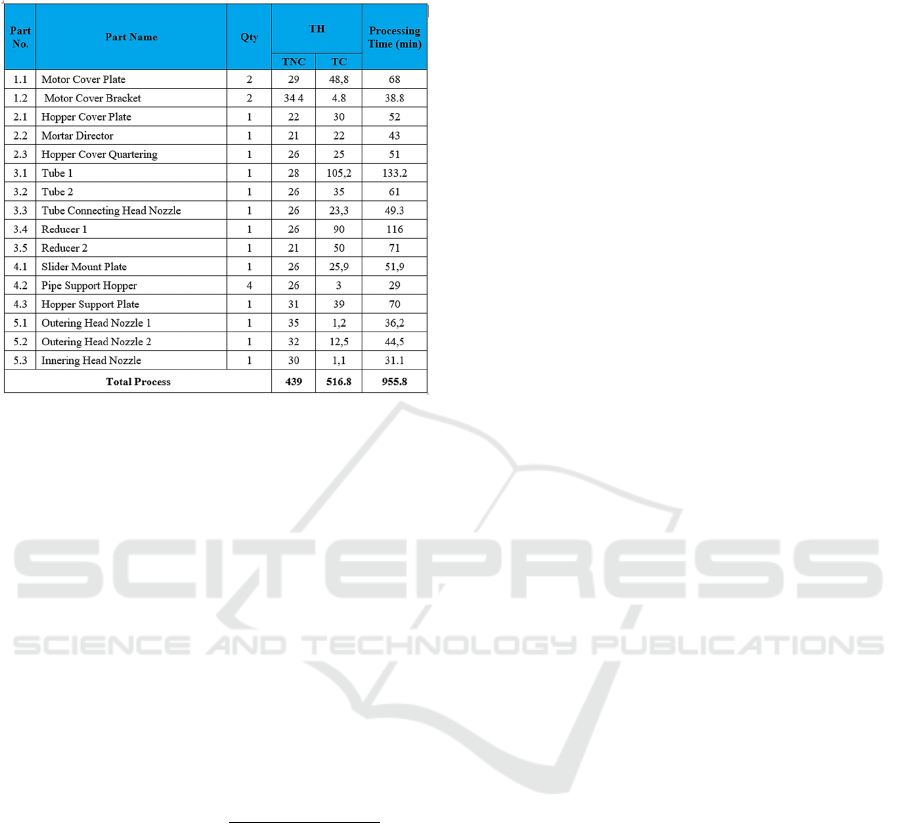

Etime estimation is obtained from the summation of

TNC (Time non cutting) and TC (Time Cutting) on

the operation plan. Here is the calculation of the total

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

848

estimated time of the construction process of the

geopolymer

mortar nozzle construction:

Figure 15: Total Estimated Time.

Total machining process time:

= 955.8 minutes : 60 minutes

= 15.93 hours

7 hours = 1 working day

15.93 hours = 2.3 days ≈ 3 working days

4.2 Estimated Cost

Here is the overall cost of the manufacturing process

of geopolymer mortar nozzle construction on civil

building 3D Printing machine:

• Total Biata Raw Material Rp. 664.500,00,-

• Total Standard Part

Cost Rp. 4,500.00,-

• Total Machining Cost Rp. 497.100,00,-

• Total Operator

Fee Rp. 257.400,00,- +

• Total Cost Rp. 1.423.500,00,-

• Overhead Costs (20% x Process Costs)

Rp. 284.700,00,-

So, the total cost of the basic cost of the geopolymer

mortar nozzle

construction process on the civil

building 3D printing

machine is Rp. 1,708,200.00,-

≈ Rp. 1,708,500.00,-.

5 CONCLUSION

Overall, the results of the manufacturing process of

the geopolymer mortar nozzle construction on the

civil building 3D printing machine can be concluded

as follows:

1. The process of making geopolymer mortar

nozzle construction produces designs, work

drawings and manufacturing process planning

which are used to reference the manufacturing

process of Geopolymer Mortar Nozzle

Construction on Civil Building 3D Printing

Machines.

2. The working principle of this tool is that the

geopolymer mortar accommodated in the hopper

nozzle will move down due to the force of gravity

and the large expenditure of the geopolymer

mortar is regulated by the extruder driven by the

stepper motor.

3. In the process of making Geopolymer Mortar

Nozzle Construction on the Civil Building 3D

Printing Machine, this includes observation,

manufacturing planning, machining and

fabrication ice pros, assembly planning and trial

planning. The machining process includes a lathe

and a drill. The fabrication process includes

cutting grinding, hand grinding, drilling, Sheet

Metal forming, bending, rolling, and welding.

4. The total estimated time required in the

construction process of the geopolymer mortar

nozzle is 15.93 hours and the total estimated cost

of the geopolymer mortar nozzle construction

process is Rp. 1,700,500.00,-.

REFERENCES

Elemen Mesin 3 Perhitungan Elemen Mesin:

Politeknik Manufaktur Negeri Bandung.

Goeritno Wahjoe; Wikanda Uli; dan S. Ecep. 2000. Standar

Polman Seri 0. Bandung: Politeknik Manufaktur Negeri

Bandung.

Waloeyo, Gamawan A. 2021. Biaya Dasar PPC,

Bandung: Politeknik Manufaktur Negeri Bandung.

Anonim, Elemen Mesin 1

Anonim, Elemen Mesin 2

The Manufacturing Process of Geopolymer Mortar Nozzle Construction on Civil Building 3D Printing Machine

849