Research and Enlightenment on the Design of Food Packaging

Performance Based on New Materials

Jinxiu Wang

1

, Chunhong Zhang

2

, Chen Chen

1

, Xin Chen

3

, Dan Li

2,*

and Kun Sha

1*

1

Naval Health Information Center, Department of Health Service, Naval Medical University, Shanghai 200433, China

2

Naval Specialty Medical Center, Shanghai 200438, China

3

Shandong Institute of Engineering and Technology, Suzhou Institute of Medical Engineering, Chinese Academy of

Sciences, Shandong 250000, China

*

kunie@vip.sina.com

Keywords: Food Packaging Materials, Quality Control, Regulations and Standards.

Abstract: China has witnessed rapid socio-economic development in recent years. As a result of the high-quality

development of modern life, people have increasingly pursued the health and comfort of life and paid

particular attention to food safety. As people require richer and more diverse food, the food packaging industry

is developing rapidly with the birth of various packaging materials. This article reviews the development

status of food and its packaging materials in China and analyzes the main factors affecting the quality of food

packaging products. In accordance with the current domestic and foreign regulations and standards related to

food packaging materials, the article elaborates how food packaging affects food safety and puts forward the

countermeasures to control the quality of food packaging products to safeguard the legitimate rights and

interests of consumers in eating safety.

1 INTRODUCTION

Food packaging is inseparably related to food in

modern life. Food packaging, commonly known as

containers, materials, and auxiliaries, is used to

ensure the food quality in circulation and storage and

serves as the last process of food production. Aside

from being used to promote the food's efficacy, food

packaging is mainly aimed at preventing biological,

chemical, and physical external damage, maintaining

the stable quality of the food and facilitating the

transportation, storage, and sale of food.

2 CLASSIFICATION OF FOOD

PACKAGING MATERIALS

AND THEIR PERFORMANCE

In the past, people tended to pay attention to the

visual, tactile, and taste of food. With the

development of the national economy, policy

adjustment, and the change of consumption concept,

they have turned to focus on internal quality and

nutrition of food and avoid the potential pollution and

hazards. Therefore, they are urgently looking for

environment-friendly packaging materials and

suitable packaging technology.

2.1 Classification of Food Packaging

Materials

China allows the use of various food packaging

materials and containers, which come from five main

categories of raw materials: food-grade paper

packaging materials, synthetic polymer materials

(plastics, rubber, adhesives, coatings, etc.), metal

materials (steel, aluminum, tin, lead, etc.), glass and

ceramic materials, composite materials, fiber

materials (natural fibers, synthetic fibers, textiles,

etc.), wood, other materials, etc. (Huang, Lei, Huang

et al., 2015). According to the packaging function, the

packaging materials have the following categories:

barrier packaging materials, heat-resistant packaging

materials, selective permeability packaging

materials, freshness preservation packaging

materials, conductive packaging materials,

Wang, J., Zhang, C., Chen, C., Chen, X., Li, D. and Sha, K.

Research and Enlightenment on the Design of Food Packaging Performance Based on New Materials.

DOI: 10.5220/0011898000003613

In Proceedings of the 2nd International Conference on New Media Development and Modernized Education (NMDME 2022), pages 57-67

ISBN: 978-989-758-630-9

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

57

decomposable packaging materials, and other

functional packaging materials.

2.2 The Performance of Food

Packaging Materials

Food products, especially high-fat or high-protein

foods, usually require a better and longer shelf life, so

they have certain requirements for their packaging

materials.

2.2.1 Barrier and Physicomechanical

Performance

Packaging materials should have some barrier

performance. For example, greasy food requires high

oxygen and oil barrier packaging; dry food requires

high moisture barrier packaging; aromatic food

requires high odor barrier packaging; fruit,

vegetables, and fresh food require packaging with

certain oxygen, carbon dioxide, and water vapor

permeability.

2.2.2 Chemical Safety

As the medical level has improved in recent years,

food and medicine safety is of great concern. And

plastic packaging materials have a greater impact on

the food and drug in direct contact. For example, the

barrier function of composite film bags coexists with

the mass transfer process of monomers such as

additives. Plastics frequently contacted with

foodstuffs still have monomers after polymerization,

and plastics also have such additives as nucleating

agents, lubricants, antistatic agents, foaming agents,

plasticizers, phenolic antioxidants, dialkyl

hydroxylamines, benzofurans, hindered amine

stabilizers, UV absorbers, heat stabilizers, antacids,

dehydrating agents, anti-fogging agents, dyes,

pigments, and fillers.

2.2.3 Functionality

As packaging materials increasingly demand "fresh-

keeping" and other functionalities, there are limited

options for packaging materials. Therefore, while

ensuring that food products contain fewer

preservatives, new packaging materials, which have

simple processing, portability, light-shielding, easy

storage, and other advantages, are needed to ensure

freshness and a longer storage period.

The composite film material of nano-TiO2, which

has been successfully developed by Japan, the United

States, and Germany, has become popular in recent

years. It is shown that nano-TiO2 has a good

antibacterial effect on bacteria, fungi, and molds.

Moreover, its addition to the packaging materials

allows the packaging materials to be antibacterial,

resulting in better protection of food and inhibition of

food spoilage (Tan,

Hu, Wang, 2020).

2.2.4 Antibacterial Performance

During food storage, packaging materials having

certain antibacterial performance can inhibit or kill

harmful microorganisms inside the packaging and

extend the shelf life of food. With the latest surface

coating technology achieved by special technology, a

layer of antiseptic material is applied to plastic

packaging film based on composite resin and other

substances to replace the preservatives added to the

food, further improving food packaging safety.

2.2.5 Degradability

Photodegradable or photo-biodegradable plastics of

starch-filled polyolefins have been widely used in

mulch, shopping bags, disposable tableware, etc.

However, these plastics are not really "environment-

friendly" and still have poor application performance,

difficult time-controlled degradation, and high cost.

For the sake of sustainable development of the earth's

resources, more renewable resource polymers are

urgently needed to replace the non-renewable

petroleum-based polymer materials, and all-

biodegradable plastics come into being. As of 2010,

the annual production capacity of biodegradable

plastics worldwide has reached one million tons. In

the coming 30-50 years, biodegradable plastics will

eventually occupy 10% of the overall market share of

plastic products, and the proportion of bio-based

biodegradable plastics will account for more than

90% (Li, Ma, Jiang et al., 2021). The performance

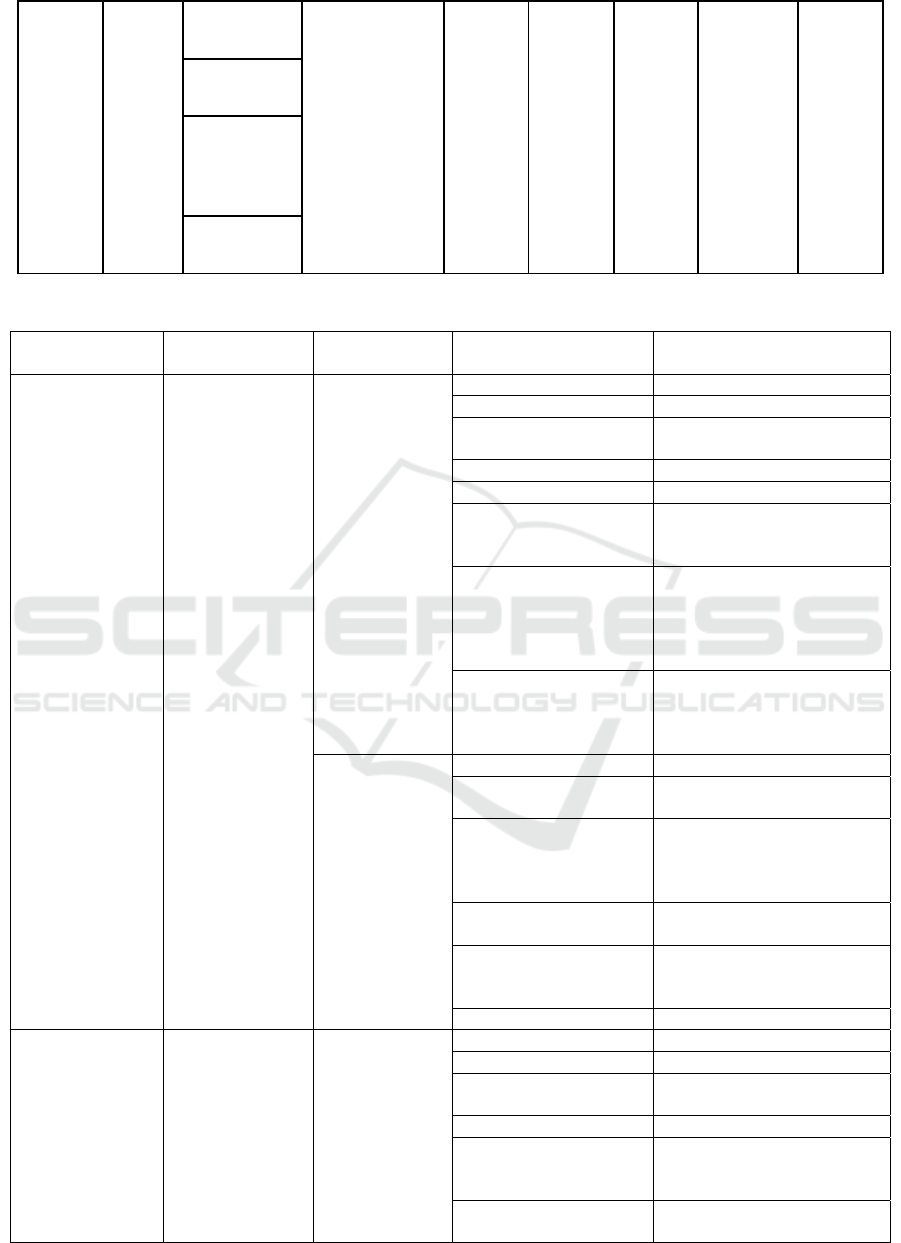

indicators corresponding to each testing item of food

packaging are detailed in Table 1.

NMDME 2022 - The International Conference on New Media Development and Modernized Education

58

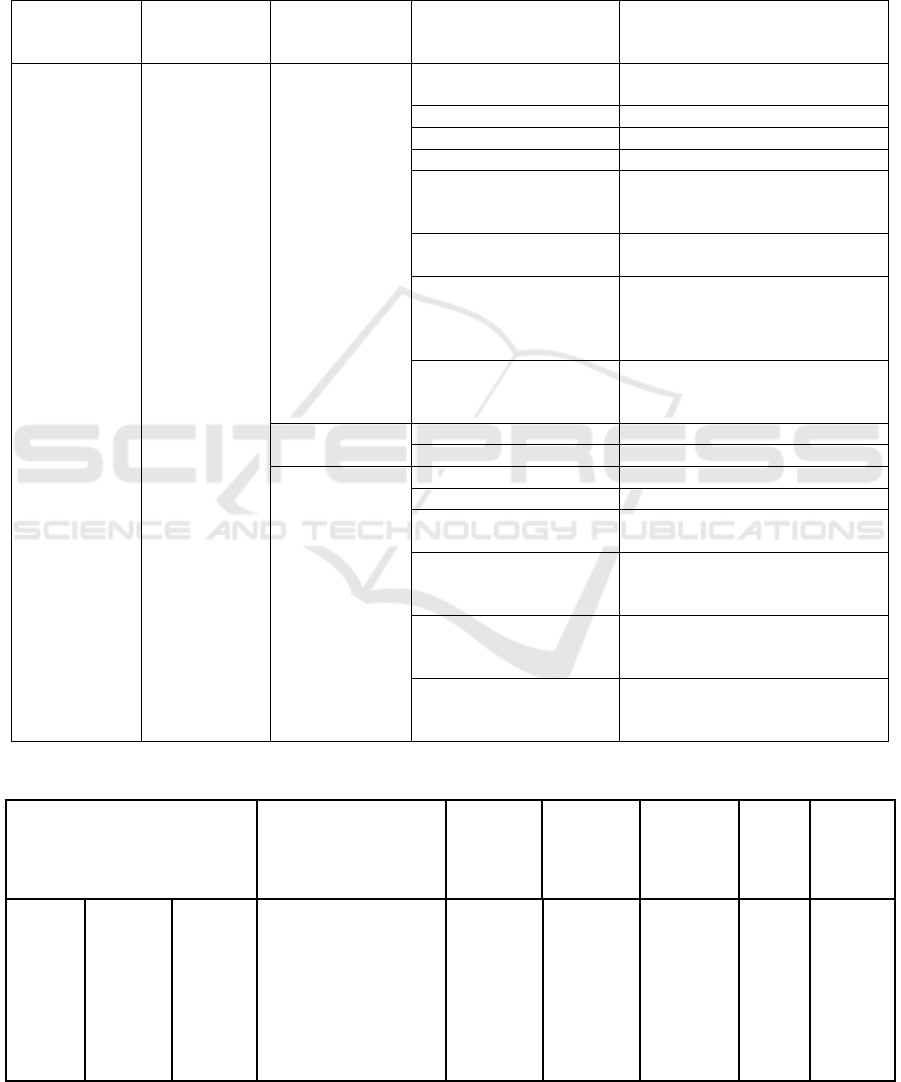

Table 1 The performance indicators corresponding to each testing item of food packaging

Performance

Indicators

Testing items The performance of the tested sample

Barrier

Performance

Oxygen permeability

Barrier performance of the packaging material to oxygen

in the environment, prevent products from bulging bags,

mildew, rancidity, and other quality problems

Water vapor transmittance

Barrier performance of the packaging material to water

vapor, preventing products from deliquescence, softness,

fragrance, color fade, and other problems

Nitrogen permeability

Preservation performance of the packaging material to

the package internal nitrogen, preventing products from

deflating and oxidation

Carbon dioxide transmittance

Preservation performance of the packaging material for

carbon dioxide inside the bag, preventing products from

color change and shortening shelf life

Peel strength

Characterize the composite fastness of the composite

film, preventing the package from delamination

Heat sealing strength

The heat-sealing effect of the packaging, ensuring no air

leakage, broken bags at the heat seal, and easy unsealing

Heat sealing performance test

Screening the most suitable heat-sealing temperature,

pressure, and time of the packaging material

Thermal viscosity

Whether the uncooled heat-sealed parts are not easy to

leak when the contents or foreign objects impact them

2.3 Testing Indicators

The requirements for the interior packaging of food

refer to the technical requirements to ensure the

quality of food in the corresponding packaging,

including packaging strength, barrier performance,

air permeability, heat resistance, and light protection

requirements. It is the requirement for the exterior

packaging made by the food to maintain its quality.

Food packaging materials usually focus on

barrier performance, physical and mechanical

performance, and chemical hygiene

performance. Among them, the testing items of

barrier performance include oxygen, water

vapor, nitrogen, carbon dioxide permeability and

the permeability of various gases after kneading,

gas permeability in high and low temperatures of

packaging films specific to the application

environment. The testing items of physical and

mechanical properties include mechanical

contact thickness measurement, peel strength,

heat seal strength, heat seal performance test,

heat bond strength, elongation at break, tensile

force, tensile strength, pendulum impact

resistance, oil resistance, falling dart impact

energy, ball drop impact resistance, tear

strength, right-angle tear strength, and chemical

hygiene performance, resistance to pendulum

impact, oil resistance, falling dart impact energy,

resistance to falling ball impact strength, tear

strength, right-angle tearing force, puncture

resistance, friction coefficient, bottle mouth

rotation torque, cap removal force, opening

force, the adhesive force between sealing

material and container mouth, ink layer bonding

fastness, sealing performance (negative pressure

method), bursting pressure, cold resistance test,

cooking resistance test, vacuum residual oxygen

test, headspace analysis, heat shrinkage force,

shrinkage rate, and cold shrinkage force. The

testing items of chemical hygiene performance

mainly include solvent residues, toluenediamine

content, non-volatile migration content, and

heavy metal content.

2.3.1 1Packaging Material Structure and

Key Indicators Control of Common

Food Products

Common food products often refer to dairy products,

meat products, vegetable products, cookies, pastries,

etc. Different food products require different

Research and Enlightenment on the Design of Food Packaging Performance Based on New Materials

59

performance indicators for their packaging materials,

and different food characteristics require different

packaging forms and packaging material structures.

In this article, the packaging forms, material

structures, and their corresponding key indicators

control of the above-mentioned common foods are

summarized (detailed in Tables 2, 3, 4, 5, 6, 7, 8, 9,

10, 11, 12) for the reference of relevant industries of

food packaging R&D, production and food

processing.

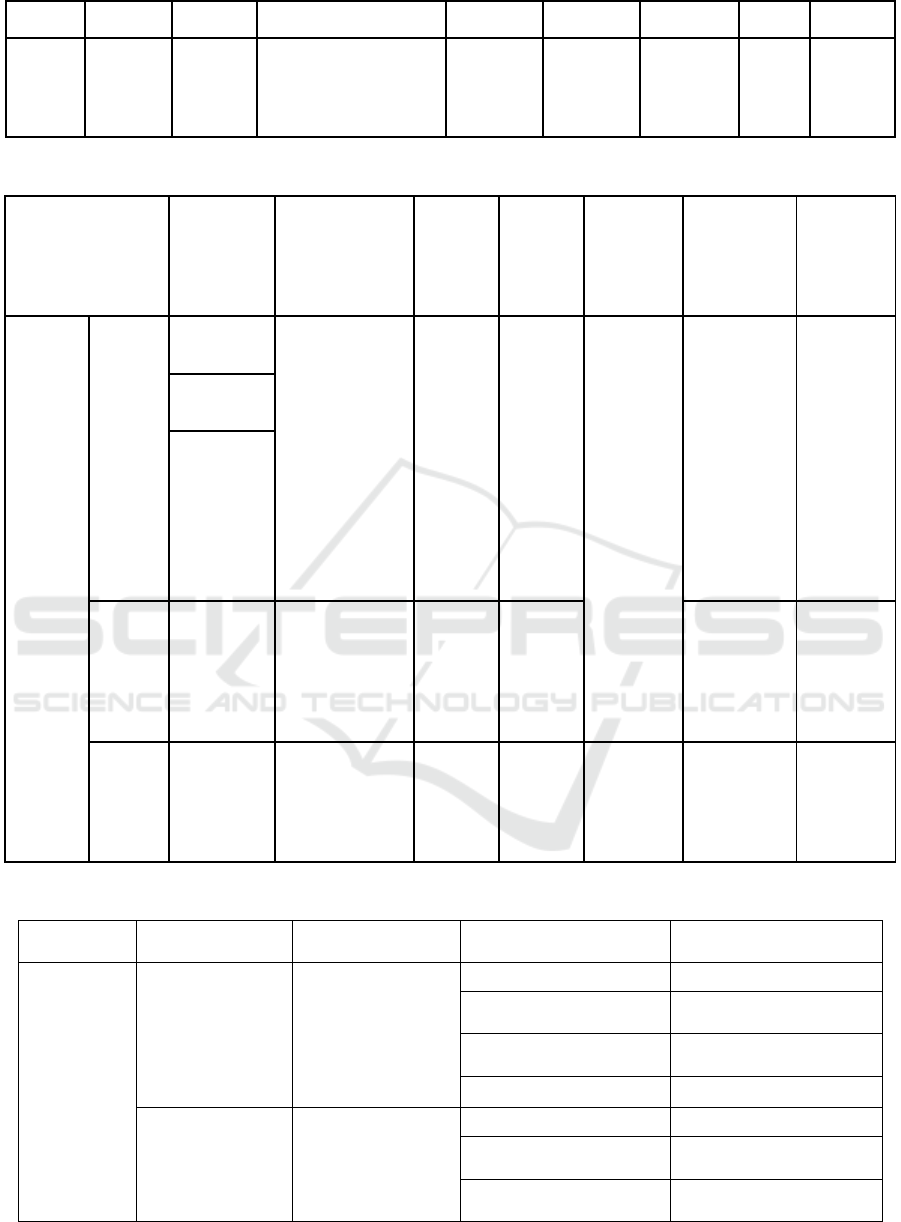

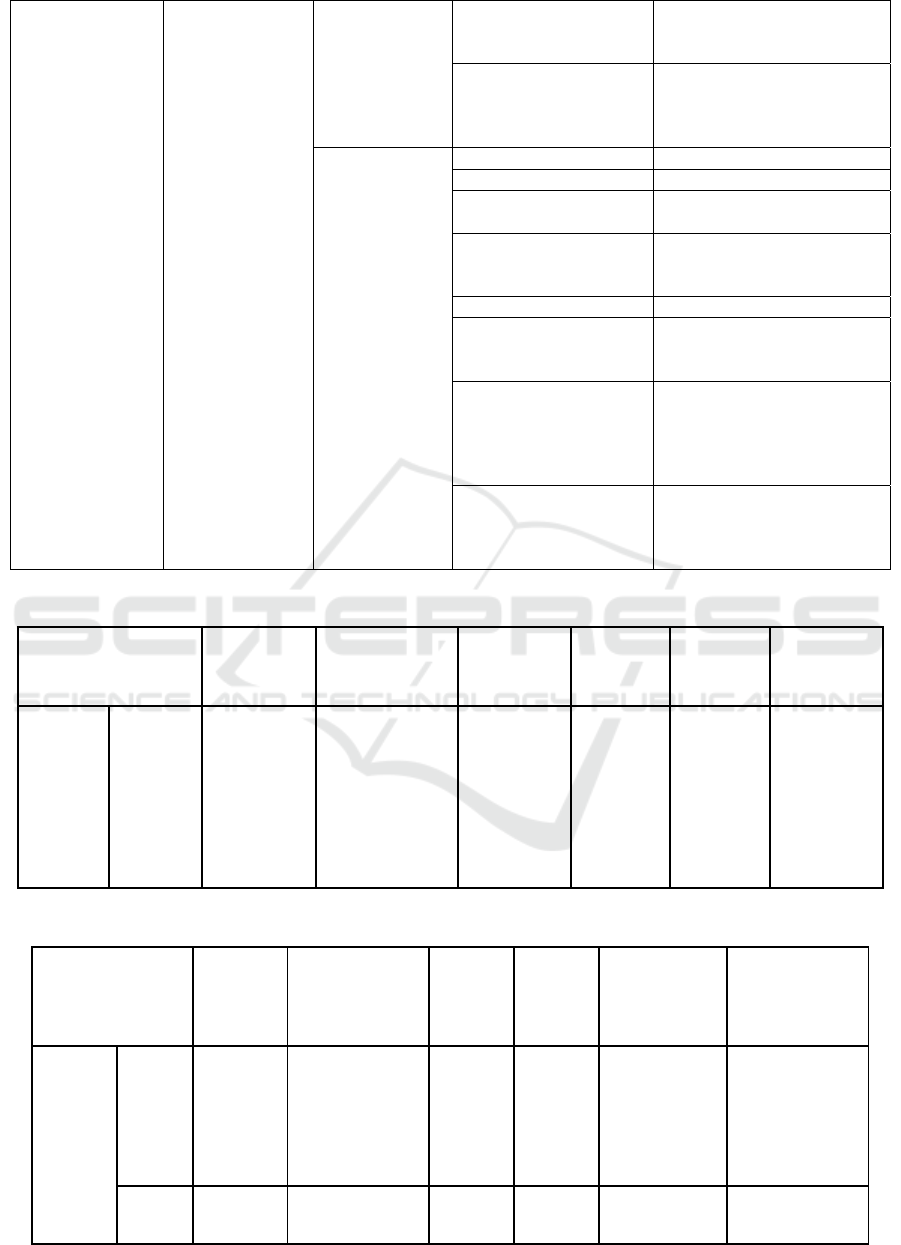

Table 2 Packaging forms of dairy products and their key quality control indicators

Food

Classification

Examples of

products

Packaging

material

Form

Critical quality control

points

Suggested indicators value

Liquid milk

Pure

milk/yogurt

Tetra Pak

Oxygen permeation

Barrier film ≤ 10, non-barrier film

≤ 1800 cm

3

/

(

m

2

·24 h·0.1 MPa

)

Thickness Limit deviation ≤ 10%

Friction coefficient 0.2 ~ 0.3

Heat sealin

g

stren

g

th ≥ 17 N/15 m

m

Sealing performance

(negative pressure

method

)

-89 KPa, airtight

Burst pressure

≥ 40 KPa, without breaking the

b

ag

Solvent residue

Benzene solvents were not

detected, and the total residual

amount of solvents was less than

or equal to 5.0 mg/L

Migration amount of

non-volatile matter

Formulated according to the

hygienic performance standards

followed by-

p

roduct materials

Aseptic pillow

bag

Thickness Deviation ≤ 10%

Ox

yg

en

p

ermeation ≤ 1. 0cm3/

(

m2·24h·0.1 MPa

)

Sterile brick

Thickness Deviation ≤ 10%

Oxygen permeation ≤ 0. 5 cm

3

/

(m

2

·24 h·0.1 MPa)

Oxygen permeation after

kneadin

g

/

Sealing performance

(negative pressure

method)

-89KPa, airtight

Migration amount of

non-volatile matter

Formulated according to the

hygienic performance standards

followed by-

p

roduct materials

Sealing performance

(negative pressure

method)

-89 KPa, airtight

Table 3 Packaging form and material structure characteristics of liquid milk food

Packaging material structure

Material structure

(example)

Shelf life

Storage

requirem

ents

Oxygen

resistanc

e

Impa

ct

resist

ance

Sealabi

lity

Comp

osite

memb

rane

Packa

ging

Coextr

usion

film

(Tetra

Pak)

Black

and

white

film

High barrier film of ≥

3 layers (including

EVOH, LDPE,

LLDPE, black and

white masterbatch);

Non-barrier film

(LDPE, LLDPE, and

b

lack and white

High

barrier

30-90

days

Non-

barrier

7-30

days

Ambient

temperat

ure

Avoid

light

Barrier

film

Higher

Non-

barrier

film

Low

Poor

The

heat

seal is

easy to

leak

NMDME 2022 - The International Conference on New Media Development and Modernized Education

60

masterbatch onl

y)

Single

film

packa

ging

Monola

yer film

Ecolea

n bag

70%CaCO3+30%PP,

PE

7-21

days

Low

temperat

ure

Higher Good Good

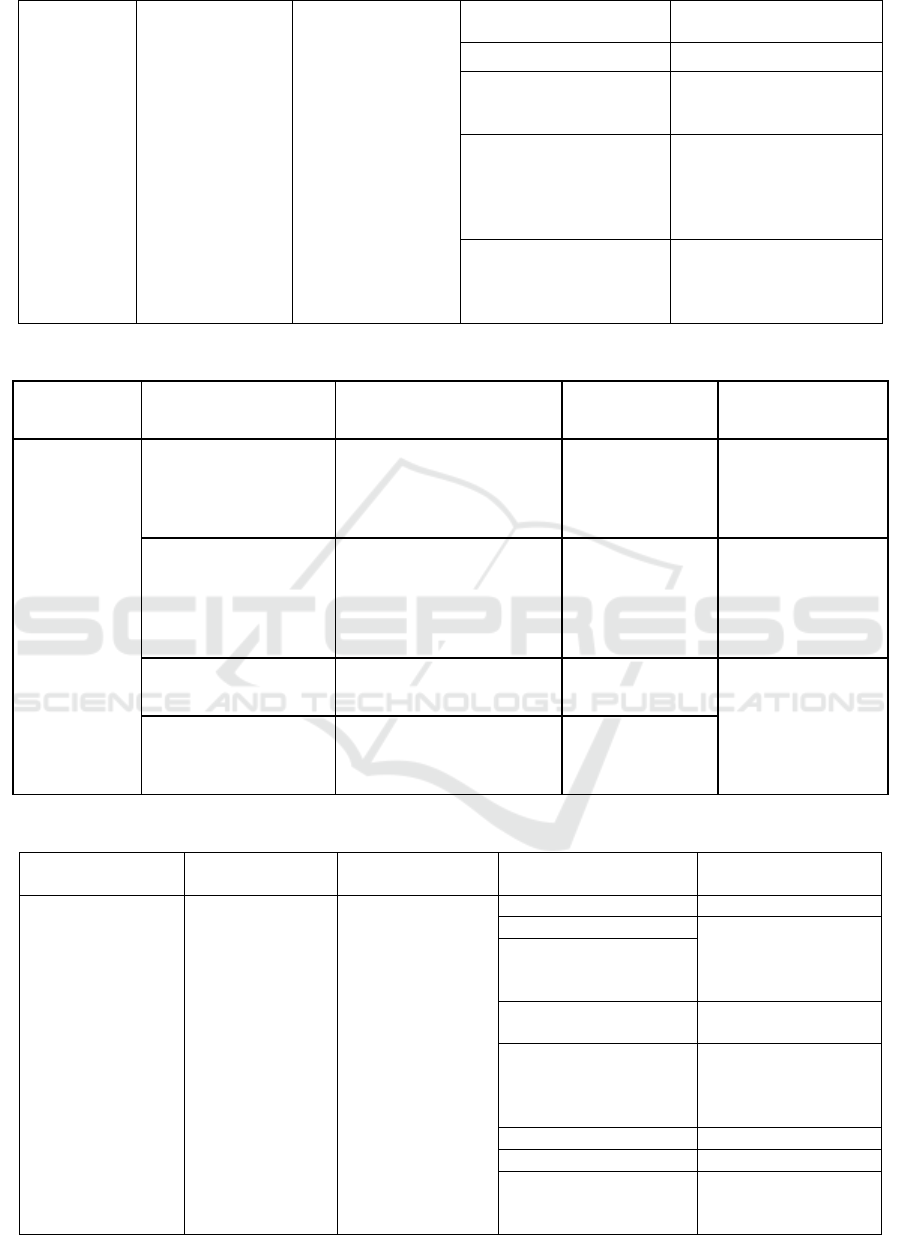

Table 4 Packaging form and material structure characteristics of milk powder

Packaging

material structure

Packaging

form

Material

structure

(example)

Shelf

life

Oxyge

n

resistan

ce

Whether

it is a

modified

atmosphe

re

Anti-

rubbing or

puncture

Sealabilit

y

Compo

site

film

packag

ing

Alumi

num-

plastic

compo

site

film

or

Alumi

nized

compo

site

film

Four sides

Seal bag

PET/Al/LDPE

PET/Al/PET/L

LDPE

PET/Al/PA/PE

BOPP/Al/PE

BOPA/Al/PA/

PE

PET/VMPET/

PE

BOPP/VMPE

T/LLDPE

PET/VMCPP

6-12

months

High

Need

Nitrogen

filling

Or

CO

2

charging

2

Modified

atmosphe

re

Aluminum

foil, thin or

too thick,

aluminized

Composite

membrane

Not

resistant to

rubbing or

puncture

Easy to

leak in

heat seal

or folded

edges on

both

sides;

Occasion

ally,

there are

holes in

the bag

b

od

y

Stereosco

p

ic ba

g

Back seal

Folding

bag

etc.

Paper-

plastic

compo

site

film

Multiple

Bag-

shaped

PVDC/Paper/

Al/PE

Paper/PVDC/P

E

Paper/PVDC/

VMPET/PE

3-12

months

Depend

ing on

the

materia

l

Not

resistant to

rubbing

Easy to

leak in

the heat

seal

Plastic

compo

site

film

Internal

Small

package

PET/CPP,

KPET/PE,

PET/PA/PE,

KOPP/PE, etc.

3-12

months

Depend

ing on

the

materia

l

None

Rubbing

resistance

Not

resistant to

p

uncture

Easy to

leak in

the heat

seal

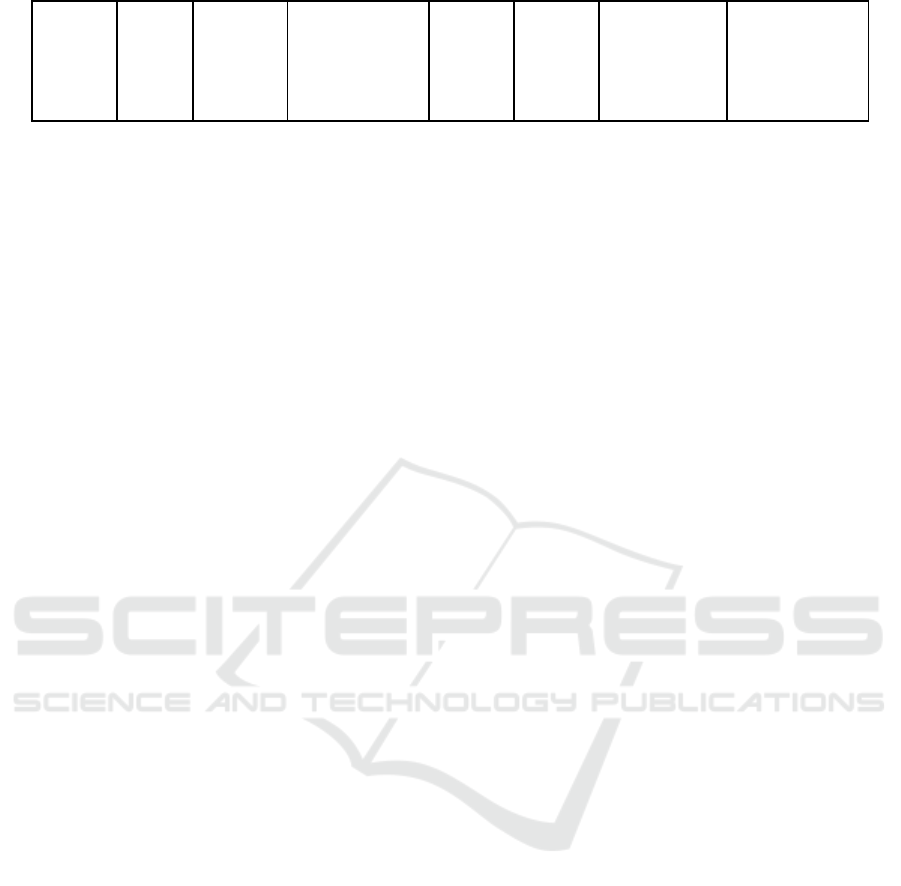

Table 5 Packaging forms and key quality control indicators of meat products

Food

classification

Examples of

p

roducts

Packaging material

form

Critical quality control

p

oints

Suggested indicators

value

Intestines

Ham sausage

Shrinkage casing

membrane

Thickness Deviation ≤ 10%

Shrinkage rate and

shrinkage force

Oxygen permeation

≤ 50 cm

3

/(m

2

·24 h·0.1

MPa)

Water vapor permeability ≤ 5 g/(m

2

·24 h)

Crispy

sausage/sausage

Plastic composite

film

Thickness Deviation ≤ 10%

Oxygen permeation

≤ 50 cm

3

/(m

2

·24 h·0.1

MPa

)

Tension, elongation, and

elastic modulus

/

Research and Enlightenment on the Design of Food Packaging Performance Based on New Materials

61

Anti-pendulum impact

ener

gy

/

Heat sealing strength ≥ 20 N/15 mm

Sealing performance

(negative pressure

method

)

-89 KPa, airtight

Residual solvent

Benzene solvents were

not detected, and the total

residual amount of

solvents was less than or

e

q

ual to 5.0 m

g

/L

Migration amount of non-

volatile matter

Formulated according to

the hygienic performance

standards followed by-

p

roduct materials

Table 6 Packaging forms and material structure characteristics of meat products

Packaging

Form

Material structure Advantages Disadvantages Application

Degassing

shrink

packaging

Polyvinylidene

chloride (PVDC)

casing

Good high-temperature

resistance, good barrier

performance, and good

heat shrinka

g

e

Sensitive to

temperature

High temperature

steamed ham

sausage

Nylon (PA or NY)

casings

Good high-temperature

resistance, good oil

resistance, high oxygen

resistance, good toughness,

and stren

g

th

Limited

shrinkage and

poor moisture

resistance

High temperature

boiled ham

sausage, low-

temperature

sausa

g

e

Cellulose series

casin

g

s

Good air permeability, can

b

e fumi

g

ate

d

Not edible

Low-temperature

intestines

Collagen casing

Good air permeability,

edible, suitable for high

automatic enema machine

Not suitable for

smoking

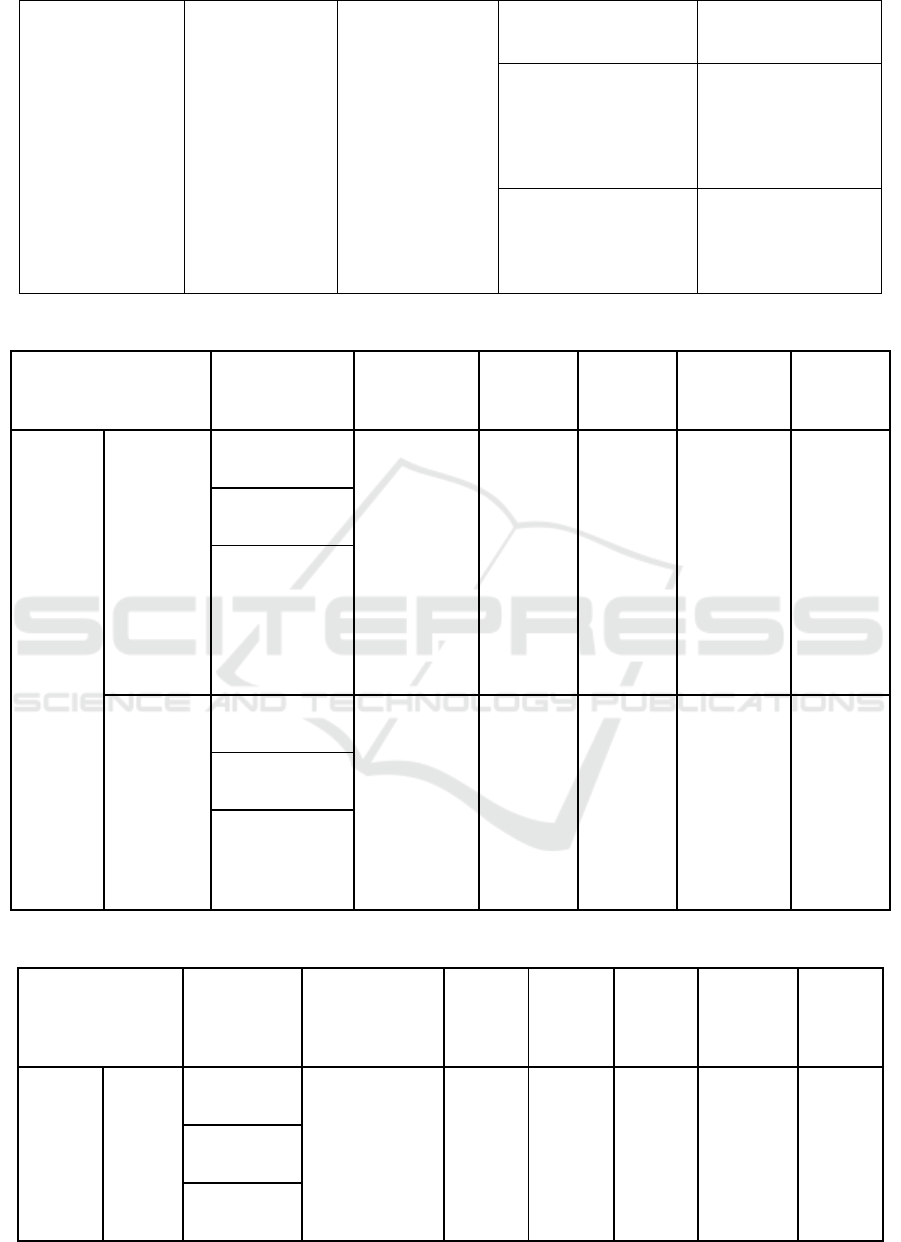

Table 7 Packaging forms and key quality control indicators of cakes and biscuits

Food classification

Examples of

p

roducts

Packaging material

Form

Critical quality control

p

oints

Suggested indicators

value

Crispy cakes or

cakes with more oil

content

Heong

Peng/sliced

bread/cake

Aluminized

composite film

Thickness Deviation ≤ 10%

Ox

yg

en

p

ermeation

≤ 20 cm

3

/( m

2

·24

h·0.1 MPa)

Nitrogen permeation

(nitrogen-filled

p

acka

g

e

)

Water vapor

p

ermeabilit

y

≤ 1 g/( m

2

·24 h)

Oxygen permeation

after kneading

No more than ten

times of oxygen

permeation before

kneading

Peel strength

/

Heat sealin

g

stren

g

th

/

Sealing performance

(negative pressure

method

)

≥-70 KPa, no air

leakage

NMDME 2022 - The International Conference on New Media Development and Modernized Education

62

Headspace air body

analysis (nitrogen-filled

p

ackaging)

It is similar to the gas

composition ratio

during filling

Residual solvent

Benzene solvents

were not detected, and

the total residual

amount of solvents

was less than or equal

to 5.0 m

g

/L

Migration amount of

non-volatile matter

Formulated according

to the hygienic

performance

standards followed

b

y-

p

roduct materials

Table 8 Packaging form and material structure characteristics of biscuits

Packaging material

structure

Packaging

Form

Material

structure

(example)

Oxygen

resistanc

e

Moisture

resistanc

e

Anti-

rubbing or

p

uncture

Sealabilit

y

Compos

ite film

packagi

ng

Aluminize

d

composite

film

Ordinary

p

acking

BOPP/VMC

PP

BOPP/VMP

ET/CPP (PE)

PET/VMPE

T/PE

VMBOPP

(Cold

Sealed)

VMPET

(Cold

Sealed

)

High High

The

aluminized

layer is

thin and

not

resistant to

rubbing

It is easy

to leak in

the heat

seal or

the

folded

edges on

both

sides

Inflatable

p

ackin

g

Inner lining

tray, outer

wrapping

package

Plastic

composite

film

Ordinary

p

ackin

g

BOPP/CPP

PET/PE

OPP/PE

KOPP/PE

BOPP/KOPP

/PE etc.

Dependin

g on the

material

Higher

Rubbing

resistance

Poor

puncture

resistance

It is easy

to leak or

break the

bag in

the heat

seal

Inflatable

p

acking

Inner lining

tray, outer

wrapping

p

acka

g

e

Table 9 Packaging form and material structure characteristics of cakes

Packaging

material structure

Packaging

form

Material

structure

(example)

Oxyge

n

resistan

ce

Moistu

re

resistan

ce

Nitroge

n

resistan

ce

Anti-

rubbing

or

p

uncture

Sealabi

lity

Compo

site

film

packagi

ng

Alumi

nized

compo

site

film

Ordinary

p

acking

BOPP/VMCPP

BOPP/VMPET

/CPP (PE)

PA/VMPET/P

E

BOPET/VMCP

P

High High High

The

aluminiz

ed layer

is thin

and not

resistant

to

It is

easy to

leak in

the

heat

seal or

the

Inflatable

p

ackin

g

Inner lining

tray, outer

Research and Enlightenment on the Design of Food Packaging Performance Based on New Materials

63

wrapping

p

ackage

BOPP/VMPET

(heat seal with

coating on

BOPP)

BOPP/VMOPP

rubbing folded

edges

on both

sides

Inflatable

p

ackin

g

Inner lining

tray, outer

wrapping

p

acka

g

e

Vacuum

p

ackaging

Table 10 Packaging forms and key quality control indicators of convenience food

Food

classification

Products

Exam

p

le

Packaging

material for

m

Critical quality control

p

oints

Suggested indicators value

Instant noodles,

instant rice

noodles, instant

vermicelli, etc.

Fried instant

noodles

Plastic

composite film

Thickness Deviation ≤ 10%

Oxygen permeation ≤150 cm

3

/

(m

2

∙24 h∙0.1 MPa)

Water vapor

p

ermeabilit

y

≤4.0 g/(m

2

∙24 h)

Intensity of puncture

/

Heat sealing strength

/

Sealing performance

(negative pressure

method)

≥-70KPa, no air leakage

Solvent residue

Benzene solvents were not

detected, and the total

residual amount of solvents

was less than or equal to 5.0

m

g

/L

Migration amount of

non-volatile matter

Formulated according to the

hygienic performance

standards followed by-

p

roduct materials

Barreled

Ox

yg

en

p

ermeation

/

Water vapor

p

ermeabilit

y

/

Migration amount of

non-volatile matter

Formulated according to the

hygienic performance

standards followed by-

p

roduct materials

Opening force of cover

membrane

/

Sealing performance

(negative pressure

method

)

/

Compressive strength

/

Other

convenience

foods

Instant powder

drinks such as

black sesame

paste

Plastic

composite film

Thickness Deviation ≤ 10%

Oxygen permeation ≤120 cm

3

/

(m

2

∙24 h∙0.1 MPa)

Water vapor

p

ermeabilit

y

≤3.0g/(m

2

∙24 h)

Heat sealing strength

/

Sealing performance

(negative pressure

method

)

-89 KPa, airtight

Solvent residue

Benzene solvents were not

detected, and the total

NMDME 2022 - The International Conference on New Media Development and Modernized Education

64

residual amount of solvents

was less than or equal to 5.0

mg/L

Migration amount of

non-volatile matter

Formulated according to the

hygienic performance

standards followed by-

p

roduct materials

Aluminized

composite film

Thickness Deviation ≤ 10%

Oxygen

p

ermeation ≤40 cm

3

/

(m

2

∙24 h∙0.1 MPa)

Water vapor

p

ermeabilit

y

≤1.5 g/(m

2

∙24 h)

Oxygen permeation

after kneading

No more than four times of

oxygen permeation before

kneading

Heat sealing strength

/

Sealing performance

(negative pressure

method)

-89 KPa, airtight

Solvent residue

Benzene solvents were not

detected, and the total

residual amount of solvents

was less than or equal to 5.0

m

g

/L

Migration amount of

non-volatile matter

Formulated according to the

hygienic performance

standards followed by-

p

roduct materials

Table 11 Packaging forms and material structure characteristics of instant Powder Drink

Packaging material

structure

Packaging

Form

Material

structure

(example)

Oxygen

resistance

Water

resistanc

e

Rubbing

resistanc

e

Sealability

Plastics

Film

packagi

ng

Aluminu

m-

plastic

composi

te film

Ordinary

packing

PET/Al/LDPE

PET/Al/PA/CP

P

High High Poor

It is easy to

leak at the

heat seal or

the crease

on both

sides of the

packaging

b

a

g

Table 12 Packaging Forms and Material Structure Characteristics of Instant Noodles and Other Instant Foods

Packaging

material structure

Packagi

ng

Form

Material

structure

(Example)

Oxyge

n

resistan

ce

Water

resistan

ce

Rubbing or

puncture

resistance

Sealability

Plastics

Film

packagi

ng

Alumi

num-

plastic

comp

osite

fil

m

Ordinary

packing

PET/Al/PA/CP

P

PET/Al/PE

High High

Not resistant

to rubbing

High

puncture

resistance

It is easy to

leak at the heat

seal or the

crease on both

sides of the

p

acka

g

in

g

ba

g

Alumi

nized

Ordinary

p

acka

g

in

BOPP/VMCPP

PA/VMPET/P

Higher Higher

Less resistant

to rubbin

g

Easy to leak in

the heat seal

Research and Enlightenment on the Design of Food Packaging Performance Based on New Materials

65

comp

osite

film

g or

covering

film

E

BOPP/VMPET

/PE

PET/VMPET/

PE

High

puncture

resistance

3 REGULATIONS AND

STANDARDS FOR FOOD

PACKAGING MATERIALS

Food containers and packaging materials have a dual

significance for food safety. Suitable packaging

methods and packaging materials can protect food

from external environmental pollution and keep the

moisture, quality, and other characteristics of the food

unchanged; however, the chemical components

contained in the packaging materials may migrate

into the food. Food safety will be affected if the

migrated amount exceeds a certain value.

In this regard, countries worldwide attach great

importance to the quality and safety of food contact

materials. To ensure food safety, it is necessary to

guarantee the quality and safety of food contact

materials. To this end, many countries have

established and improved corresponding regulations,

formulated relevant quality and safety standards, and

developed testing technologies and other measures.

3.1 China

On February 3, 2019, the State Administration for

Market Supervision of China announced the notice of

the 2019 Legislative Work Plan of the State

Administration for Market Supervision. In particular,

to strengthen the supervision of food packaging

quality and safety, the Measures for Supervision and

Administration of Food-related Product Quality and

Safety was formulated, which indicates that the State

Administration for Market Supervision will tighten

the supervision on food-related products.

3.2 Europe and the United States

US FDA

(Anonymous, 2020) has the following

regulations on associated packaging: food must be

packaged under hygienic conditions; the production

of food packaging materials must be based on Good

Manufacturing Practice (GMP); packaging materials

and their components in contact with food must meet

the requirements of regulations and standards.

The Safety Regulations on Migration of Food

Contact Packaging Materials and Appliances

formulated by the US Food and Drug Administration

(FDA) and the European Union have constituted a

green trade barrier to various importing countries. As

a result of this regulation, China's exports of food

packaging materials and food products have suffered

from a series of obstacles abroad due to contact

material (Xu, Li, Wei, 2009). The EU's trade barriers

to packaging have increased from a few to dozens in

recent years. The EU issues as many as 40 warnings

on food packaging materials to China each year,

revealing that China has a difficult situation for food

packaging materials.

4 ENLIGHTENMENT

As consumers focus on the function, health,

convenience, and nutrition of food today, the food

industry is continuously putting forward new

demands on food packaging. According to this

article, the development trend of food packaging is

analyzed as follows: food packaging is more

convenient, lightweight, and green, which greatly

promotes the development of low temperature

resistant, microwaveable or special packaging

materials. Complex packaging materials are

replacing the single type, and environmental-friendly

biodegradable materials are preferred for food

packaging. Such development of food packaging is

more in line with the needs of modern consumption.

In the overall assessment of food packaging

materials, biodegradable materials have high

transportation and storage costs, and edible

packaging has many problems to be solved (such as

packaging performance, production costs, processing

technology, varieties, application targets, safety

assessment).

Owing to various factors, China lags in the

administration of food packaging materials. The

standard of some food containers, packaging

materials, and processing aids is too old, and the

testing items are relatively few. There are no

corresponding standards and testing methods for

many components and new products, resulting in

NMDME 2022 - The International Conference on New Media Development and Modernized Education

66

ineffective control of harmful components in

packaging materials. In the production of complex

packaging materials, there are no sanitary standards

and nationally unified product standards for the

widely used inks and adhesives. Following the

emergence of some new food packaging materials,

there is an urgent need to develop, revise and update

the standards, and improve the safety evaluation

procedures and evaluation mechanisms for new

materials.

The market access system for food packaging

materials and appliances includes a production

licensing system, mandatory inspection system,

market access mark system, and supervision and

inspection system. We can learn from the successful

experience of Europe and the United States and other

developed countries to build a traceable food and

packaging safety database, establish and improve the

food packaging access system and regulatory

measures, such as food and packaging quality and

safety certification system, food and packaging recall

system.

In designing and selecting packaging materials,

the following methods can be used to select materials

according to needs: referring to existing or already

used packaging materials for the same or similar

characteristics of food; comparing the advantages and

disadvantages of similar food packaging materials on

the market; determining the type and specifications of

packaging materials through trial and test packaging.

Before choosing, the parameters testing of packaging

materials can also be carried out. Users should fully

understand the parameters of packaging materials

such as oxygen permeability, water permeability,

pressure resistance, tensile resistance, tear resistance,

folding resistance, heat resistance, peeling, mold

resistance. They also need to understand the

parameters of the packaging parts such as drop,

pressure resistance, vibration resistance, impact

resistance, and rotation test for the storage and

transportation process. Therefore, it requires the user

to be aware of packaging regulations and standards to

ensure the smooth operation of packaging materials,

operations, and circulation.

5 CONCLUSION

China will continue developing food packaging

materials and related regulations and standards to

achieve high standards and quality. As China

becomes a major food production and consumption

country, there is an increasing urgency to study the

safety of food packaging materials. Therefore, it is

suggested that China's food safety-related

departments and research institutes are committed to

the study of high-quality and safe food packaging

materials while promoting the development of

corresponding regulations and standards to ensure the

healthy and rapid development of China's food

packaging industry.

REFERENCES

Anonymous. Food and Drugs Administration, (2020)

Food and Drugs Administration [S]

Huang Y Q, Lei X P, Huang J M et al. (2015) Safety status

and development trend of food packaging materials in

my country [J]. Food Safety Guide. (12): 37.

Li H, Ma L, Jiang Y et al. (2021) Research progress of

nanocarriers containing antibacterial agents in active

plastic packaging [J]. Plastics Industry. 49(07): 1-5.

Tan L, Hu C Y, Wang Z W. (2020) Research progress of

nano-titanium dioxide antibacterial food packaging

composite film [J]. Journal of Food Safety and Quality

Inspection. 11(22): 8341-8350.

Xu W C, Li D L, Wei H. (2009) Research progress of food

packaging safety at home and abroad [J]. Packaging

Engineering. 30(08): 86-90.

Research and Enlightenment on the Design of Food Packaging Performance Based on New Materials

67