Experimental Study of Single Action System Compacting Tool in

Sealface Formation with Undercut

Josephine Sambira Pramestari

Design Engineering, Politeknik Manufaktur Bandung, Jalan Kanayakan No.21, Bandung, Indonesia

Keywords: Compacting Tool, Powder Metallurgy, Sealface, Single-Action Tooling System.

Abstract: The sealface is one of the important components in the mechanical seal which functions to prevent leakage

by utilizing two flat surfaces that rub against each other. In general, sealfaces are made through a machining

process (material removal). However, one of the studies conducted a study on the formation of face seals with

powder metallurgy technology seeking to maximize the use of raw materials. This research uses a press

machine and a tool that works with a single action system compacting tool mechanism and produces powder

metallurgical products with a simple sealface ring seal faced is classified into metallurgical products class 1

and 2. Seeing this, the authors try to use existing machines and tools to carry out an experimental study of

single action system compacting tools in the manufacture of powder metallurgical products with class 3 and

4 classifications. This research produces sealface with undercuts (finished product) that have surface hardness

and density values of 541.8 HV and 2.7 gr/mm3, as well as tool design recommendations that can correct the

deficiencies that occur in this research.

1 INTRODUCTION

A mechanical seal is a mechanical device whose

function is to prevent fluid from leaking from a

space/container with a rotating shaft (Kurniawan,

Yudianto, 2014). Mechanical seals have a low

leakage rate when compared to other types of sealing

devices, and have a longer duration of use (Syafi’i,

Priangkoso, 2018). The working principle of the

mechanical seal is to use the sealing surface as the

main point to prevent leakage (primary seal) (Wijaya,

2018). The location of the sealing surface on the

mechanical seal is shown in Figure 1.

Seal faces are generally made through a machining

(material removal) process. However, in one of the

studies at Polman Bandung, a study was conducted on

seal face formation with powder metallurgy

technology (Fachrul Rozy, Kurniawan). The purpose

of this study is to strive for the use of raw materials to

be maximized because, with this technology, raw

material savings can be made up to 97% (Groover,

2010). In addition, sealface for seal face withh this

method is also a component substitution step which

was originallymade with the usual material removal

manufacturing process to become an additive

manufacturing. Figure 2. Is a sealface ring formed by

powder metallurgy technology.

In the research process, powder metallurgy

products classified into classes 1 and 2 were made

with a simple sealface ring shape. The manufacture of

sealfaces utilizes a press machine and compacting

tools that are already available with a single action

tooling system mechanism (one-way compaction).

Seeing this, the author tries to conduct an

experimental study and utilize the available facilities

to make powder metallurgical products with a higher

classification class (class 3 or class 4). This is

intended to see whether existing machines and tools

can be utilized to produce more varied products. The

form that the author takes is a seal face with a simple

undercut.

Figure 1: Seal face components on mechanical seal. Source:

PT Aldea Citta Sejahtera.

870

Pramestari, J.

Experimental Study of Single Action System Compacting Tool in Sealface Formation with Undercut.

DOI: 10.5220/0011904700003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 870-878

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Figure 2: Finished product sealface ring formed by powder

metallurgy technology (Fachrul Rozy, Kurniawan).

2 LITERATURE REVIEW

2.1 Mechanical Seal

A mechanical seal is a mechanical device that

prevents fluid leakage from a space/container with a

rotating shaft. Mechanical seals prevent leakage by

utilizing the contact of two flat surfaces (sealing

faces), namely the stationary unit and the rotary unit.

The two surfaces are in a sealing contact condition,

due to the influence of the spring and the pressure

from the system. Some of the advantages obtained by

using a mechanical seal as a sealing device are that it

can handle all types of fluids, can work even if

misalignment occurs, can work both dynamically and

statically with shaft rotation, and has a long lifetime.

In the mechanical seal there are 3 leakage

containment points, namely:

a. Primary seal, the point of containment of

leakage occurs in the sealing faces, namely the

primary ring and the mating ring

b. Secondary seal, leakage containment point on

the inner diameter of the primary ring

c. Tertiary Seal, leakage containment point on

the outer diameter of the mating ring

The working principle of a mechanical seal in

general is to utilize two very flat and smooth surfaces

(sealface) of two componentseal facey the primary

ring and the mating ring which are in a sealing contact

condition. This condition is achieved so that there is

a minimum but thick enough fluid film between the

two surfaces (Flitney, 2007). Fluid film that acts as a

cushion, serves to lubricate and cool the contact area

2.2 Powder Metallurgy

Powder metallurgy technology is a way of processing

metal where the product is made of metal powder

material. The product is pressed to the desired shape

and then heated to bind the powder particles into a

solid and strong mass (Groover, 2010). There basic

stages in the conventional metallurgical process are

the mixing/blending stage, the compacting/

compacting stage, and the sintering stage Figure 3.

Powder metallurgy technology is a way of

processing metal where the product is made of metal

powder material. The product is pressed to the desired

shape and then heated to bind the powder particles

into a solid and strong mass (Groover, 2010). There

are three basic stages in the con Three basic stages in

the conventional metallurgical process are the ending

stage, the compacting/compacting stage, and the

sintering stage. Figure 3.

Figure 3: Powder metallurgical processes in general

(Kalpakjian, Schmid, 2009).

a. The mixing process is a process of

homogenizing metal powder materials to

become metal alloys that can be used as basic

materials in the solidification stage. At this

stage, the metal powder is mixed with a binder

(binder) and a lubricant (lubricant) based on

both metal and non-metal.

b. The compaction process is the process of

compressing metal alloys into a formation.

c. The sintering process is a process of heating

the solidification (green compact) in a

controlled furnace with a temperature below

the melting point, in order to form a bond

(fusion) of the particles. The goal is to increase

the strength and hardness of the product.

In powder metallurgy technology, the formed

products are classified according to the

complexity of the compaction process (Groover,

2010). The following are the four classes that have

been defined, which can be seen in Figure 4.

Figure 4: Powder metallurgical technology product

classification (Groover, 2010).

• Class I, products with a simple shape and a fairly

Experimental Study of Single Action System Compacting Tool in Sealface Formation with Undercut

871

thin thickness. The compaction process for this

product can be carried out from one side.

• Class II, products with simple shapes but thick

enough. So the compaction process must be

done from two sides.

• Class III, products that have two thickness levels

and the compaction process needs to be carried

out from two sides.

• Class IV, products that have several thickness

levels and the compaction process is carried out

from two sides using separate control settings so

that each density of each level can be achieved

properly.

2.3 Tooling System

In the powder compaction process, there are four tool

systems that can be used (ASM Handbook

Committee, 2015) namely: single-action tooling

system, double-action tooling system, withdrawal

tooling system, and die floating tooling system.

2.4 Specimen Testing

2.4.1 Hardness Test

Vickers hardness (HV) is a quotient obtained by

dividing the applied load F (kgf) by the expanse area

on the indentation surface (mm

2

) of the workpiece

taking into account the pyramidal shape with a square

base and diagonal d and having the same peak angle

as indenter of gem (ASM Handbook Committee,

2015). For the Vickers test, the surface of the test

specimen should be flat and smooth in order to obtain

accurate test results. The test specimen used in the

Vickers hardness test shall not be less than 5 times the

size of the indenter. Vickers hardness number can be

obtained using the following equation:

𝐻𝑉 1.854 P/d

2

(1)

P: given load (N)

d: the average diagonal length of the results

2.4.2 Density Test

Density is a measurement of the mass per unit volume

of an object. The higher the density (density) of an

object, the greater the mass of each volume. In this

test, the Archimedes principle is applied to determine

the density of the sample by weighing the sample in

air and then in a floating liquid (usually distilled

water). Then this density is compared with the

theoretical density (Torosyan, Pak, 2019).

Actual Density

𝑚

𝑚𝑠

𝑚𝑠 𝑚𝑔

𝑥

𝐻20

(2)

𝑚 : actual density (gram/cm

3

)

ms : dry sample mass (gram)

mg : mass of sample suspended in water (gram)

𝐻20 : density of water (1 gram/cm

3

)

Theoritical Density

𝑡ℎ

𝑆𝑖𝐶 . 𝑉𝑆𝑖𝐶

(3)

𝑡ℎ: theoretical density

𝑆𝑖𝐶: SiC density

VSiC: SiC mass fraction

3 EXPERIMENTAL METHOD

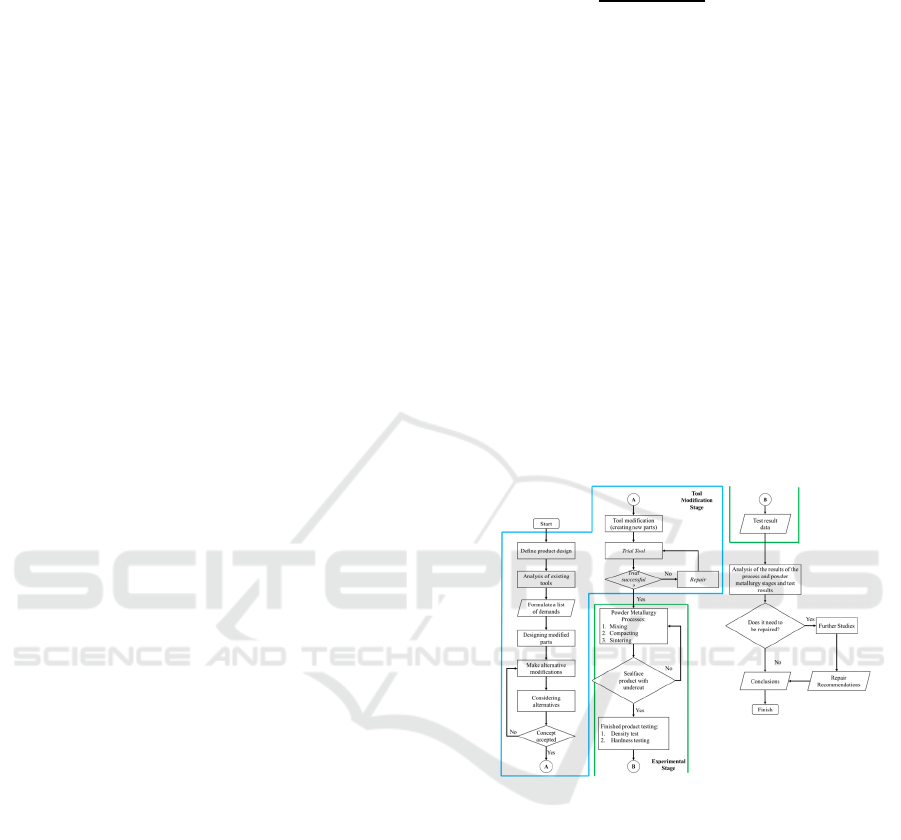

This research is divided into two stages, namely the

tool modification stage and the experimental stage

which can be seen in flowchart below.

Figure 5: Flowchart of this research.

Tool modification is intended to adjust existing

tools in order to form the desired product. The

modification process is carried out to a minimum and

as efficiently as possible. The goal is that there are not

a lot of processing processes and new parts are made,

so that it can save time and work costs. At the

experimental stage, there are two processes that need

to be carried out, namely the implementation of

sealface formation with undercuts using powder

metallurgy technology and testing of the results of

making sealfaces.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

872

3.1 Modification Step

3.1.1 Product Design

The shape of the sealface to be made is a sealface with

an undercut. This shape takes reference from the ISO

3601 O-Ring sizing standard and uses some of the

built-in dimensions of the tool. Working drawings

can be seen in Figure 6.

Figure 6: Product design for sealface with undercut. Where,

D: 56 mm, W: 4mm, H: 1.5mm.

3.1.2 Tool Existing Analysis

After determining the shape of the product, a tool

analysis is carried out to find out the specifications of

the tools and parts that play a direct role in the

formation of the product. The following is a

description of the existing tool specifications which

can be seen in Table 1.

Table 1: Existing Tool Specifications.

No.

Specifica

tion

Information

1.

N

ame Compactin

g

Tool

2. Material

St.37 and HMD 5

HMD 5: Product-forming

active parts

St.37: Other parts that are not

in contact with the produc

t

3. Dimension 208 X 239 X 248 m

m

4. Weight

± 18 Kg

5. Type

Single-action tooling system

The compaction carried out

during the compaction process

is only carried out from one

direction, namely from the

top.

In Figure 7 it can be seen that the construction of the

active part forming the product on the existing

compacting tool.

Figure 7: Active part layout.

Table 2 describes the function of each active part.

Table 2: Product-forming active parts.

No.

Compon

ent

Name

Function

Other

Information

1. Punch

Plays a role

during the

compaction

process,

pressing

metal powder

from the top.

Dimension: 70

X 70 X 70

Material: HMD

5

Further

process:

Hardening (50-

55 HRC)

2.

Insert

Outer Dies

Product

mold,

forming the

outer

diameter of

the product

Dimesion:

Ø120 X 30

Material: HMD

5

Further

process:

Hardening

(50-55 HRC)

3. Inner Dies

Product

mold,

forming the

inner

diameter of

the product

Dimesion: Ø60

X 100

Material: HMD

5

Further

process:

Hardening

(50-55 HRC)

4. Ejector

Parts for

product

ejection from

molds

Base of

powder

metallurgical

products

Dimension: 15

X 70 X 70

Material: HMD

5

Further

process:

Hardening

(50-55 HRC)

Experimental Study of Single Action System Compacting Tool in Sealface Formation with Undercut

873

3.1.3 Demand List

After looking at the shape of the product and

analyzing existing tools, a list of demands for the

modification process can be issued which can be seen

in Table 3.

Table 3: Demand list.

No.

Demand

Variable

Demand

1.

Product

geometry

Sealface with undercut

Dimension : Ø56 X 8

2.

Product

cate

g

or

y

Class 3-4 powder

metallur

g

ical products.

4.

Modific

ation

parts

Modifications made to a

minimum are only carried

out on the active part

forming the product.

Additional parts are made

in order to produce a

product with the expected

height, namely the ring

settin

g

. Product

g

eometr

y

.

3.1.4 Modification Alternative

There are two alternative modifications that the

author made, namely: the alternative with direct

ejection and indirect ejection. After considering in

terms of manufacture and the working mechanism of

the tool, an indirect ejection alternative was chosen

whose layout can be seen in Figure 8.

Figure 8: Selected alternative layout.

Concept of this alternative:

• The mold is divided into two parts, the left and the

right.

• Green compact (compacting result) is ejected

together with the forming block/mold. Then the

green compact is removed / released from the

mold manually.

3.2 Experimental Stage

There are several machines and tools used in the

process of making sealfaces with powder metallurgy,

including:

1. The mixing process uses a powder mixer

machine.

2. The compaction process uses a hydraulic

press machine.

3. The sintering process uses an annealing

furnace.

4. For molds using compacting the results of the

modifications that have been carried out with

4 ANALYSIS OF

EXPERIMENTAL RESULTS

4.1 Forming Process with Powder

Metallurgy Technology

4.1.1 Mixing

The ingredients that have been provided are then

arranged in composition to get the right mixture. The

following is the percentage of each constituent

material to make a mixture of metal powders which

can be seen in Table 4.

Table 4: Material composition for mixing.

Information Material

Main Material

Green Silicone

carbide Powder (SiC)

Binder

(10% of the total weight

of the main material)

Hydrogenated

casteroil

Oleic Acid

Liquid paraffin

Vasseline petroleum

Lubricant

(0.1% of the total weight

of the main material)

Zinc Stearate

Binder Composisiton Percentage

Hydrogenated casteroil 8%

Oleic Acid 1%

Liquid paraffin 10%

Vasseline petroleum 81%

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

874

The author uses a binder composition with a

percentage of 10%, this refers to the literature study

(Torosyan, Pak, 2019) carried out as well as

considerations when conducting trial and error in the

experimental process.

Before the actual experiment process, the author

conducted a preliminary study. The aim is to know

the characteristics of the alloy with each composition.

In the preliminary study, three types of alloys were

made with a composition of 10% binder, 20% binder

and 30% binder.

4.1.2 Compacting

During the compaction process, there are two process

parameters that need to be considered, namely

compaction pressure and holding time. For the

compaction pressure, the authors set it at 30 tons

while the holding time is 2 minutes. The amount of

tonnage is determined from the results of the

calculation of the cross-sectional area and

compaction pressure which takes references from the

literature (Upadhyaya, 2002).

4.1.3 Sintering

The sintering process is carried out in stages starting

from a room temperature of 25°C to an optimum

temperature of 1050°C. The purpose of the gradual

process is to increase the temperature slowly with a

stable holding time for each increase in temperature.

This sintering method was chosen based on the results

of the previous preliminary study. Figure 9 is a graph

of the method of increasing temperature in the

sintering process used.

Figure 9: Graph of temperature rise in the sintering process.

4.2 Analysis of Formation Results

4.2.1 Mixing

The author uses a blend with 10% binder.

4.2.2 Compacting

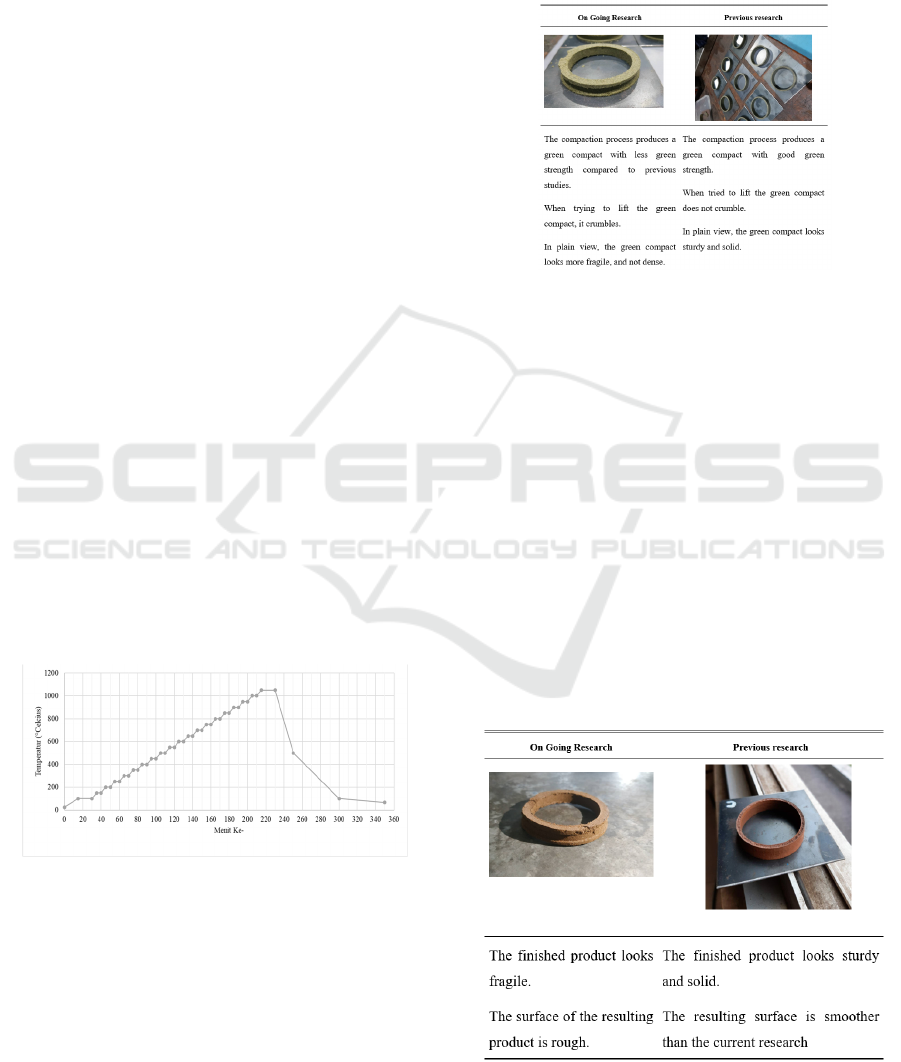

The compaction process is carried out and the results

are compared with previous studies that have been

carried out in Polman, with the comparison results

which can be seen in Figure 10.

Figure 10: Comparison of green compacts.

The difference that occurs is caused by the

compaction carried out. In previous studies,

compaction was carried out in stages with the aim that

the print cavity could be completely filled. In the

current study, the same method cannot be used, due

to different geometric shapes. So that to optimize the

formation of a green compact, compaction is only

done once, although with this method there are still

shortcomings that affect the results which can be seen

in the discussion of density testing.

4.2.3 Sintering

After the compaction process is carried out, although

the green compact obtained has poor quality, a

sintering process is carried out in order to see the

characteristics and properties of the finished product.

Figure 11: Comparison of finished products.

Experimental Study of Single Action System Compacting Tool in Sealface Formation with Undercut

875

4.3 Testing Process

After carrying out all stages of the process of forming

powder metallurgy technology, then testing is carried

out. There are two mechanical properties that will be

seen, namely hardness and density. Both of these

properties are quite crucial mechanical properties of

a sealface, both in terms of function and in terms of

manufacturing methods. In terms of function, the

sealface is an important component that has an

important role in sealing leaks with a friction

mechanism so that the wear level needs to be

considered. However, due to the availability of

facilities and cost, the authors take one other

mechanical property that has a relationship with wear

and tear, namely hardness (Mokhtar, 1982).

Meanwhile, in terms of manufacturing methods, the

process of making sealface products is a powder

compaction method. So it is necessary to see the

results of product density. These limits are taken for

the standard sealface used for centrifugal pumps, with

water type fluid (Tolbert et al., 1992).

4.3.1 Density Test

The hardness test standard used refers to ASTM

B311. This method applies the Archimedes principle

to determine the density of a sample by weighing the

test specimen in air (dry measurement) and then in a

floating liquid (usually distilled water) (wet

measurement). Then this density is compared with the

theoretical density (Taylor, McClain, Berrty, 1999).

The test specimen used is a finished product sealface

with an undercut.

4.3.2 Hardness Test

The author chose to use the Vickers hardness test, in

which the testing standard used refers to ASTM E384.

The author decided to use this type of test because the

indentation area of the test specimen is quite narrow,

so a small indenter is required. Similar to density

testing, the test specimens used are finished products

that have been polished to obtain a flat and glossy

surface.

4.4 Analysis of Test Results

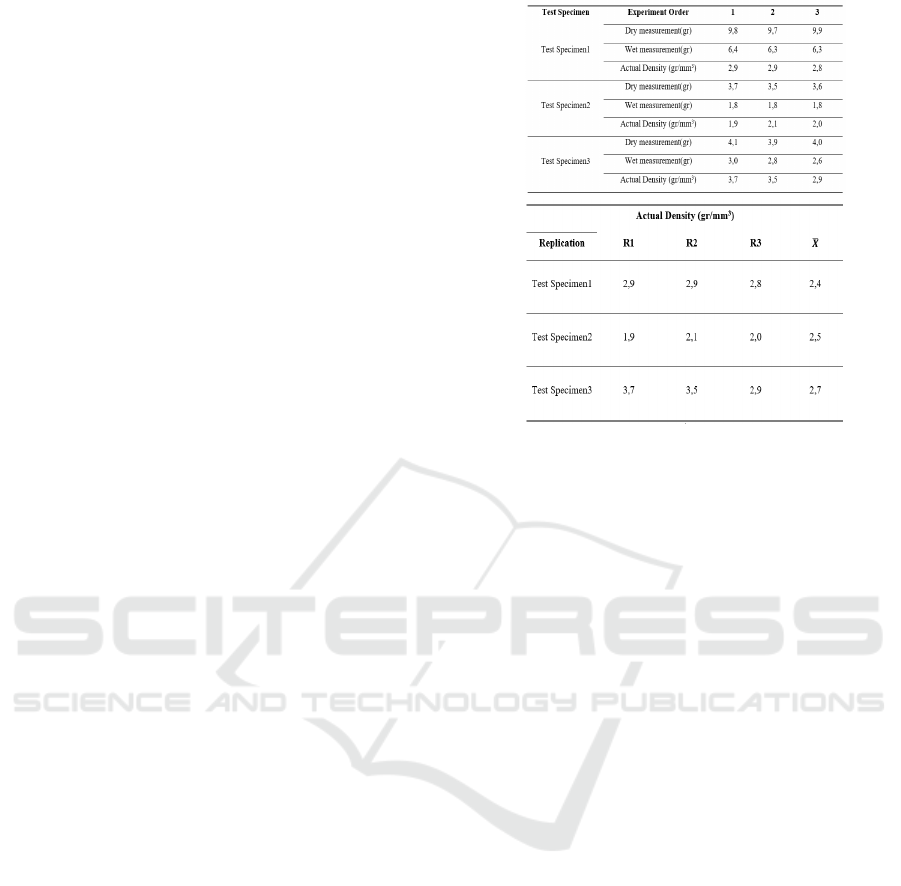

4.4.1 Density Test

In Figure 12, it can be seen that the density value

obtained after carrying out density testing on the test

specimen.

Figure 12: Density test data.

Based on the data that has been taken, it is known

that this value is far from the nominal limit used as a

reference. This could be because the formation

method used is not the same, from the existing

references it is not explained about the method used.

Therefore, this study compared with research

related to the formation of sealface rings with powder

metallurgy technology (Fachrul Rozy, Kurniawan),

where the results showed that the highest density

obtained was 3.00 gr/mm

3

. This value has a

difference of 0.3 gr/mm

3

from the highest density

value (2.7 gr/mm

3

) in this study. The difference in the

results is not that far, it proves that the process stages

and the same process parameters that have been

adjusted can produce characteristics that are not much

different. Indeed, the resulting density value has a less

value, this can be caused by differences that occur in

the compaction process.

Differences in density can occur due to the lack of

metal powder present in the mold cavity, as well as

the unevenness of the compaction force applied.

There are variations in thickness (on the undercut) on

the product and the use of ring settings that are the

cause.

The pressure applied to the powder product is

aimed at reducing the porosity by increasing the

contact points between the powder particles.

However, because during compaction a ring setting is

used and there is an undercut shape, the compaction

load does not directly affect the mixture and the

compaction is restrained and only compacts the top

part of the green compact. So if you look at the

results, the green compact is a little dense at the top

of the green product.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

876

4.4.2 Hardness Test

In Figure 13, it can be seen that the hardness value

obtained after carrying out the hardness test on the

test specimen.

Figure 13: Hardness test data.

The maximum hardness is 57 Rockwell-45. If the

maximum value is compared with the table for the

material properties of the sealface, it is known that the

hardness obtained has not reached the standard

nominal value (86-88 Rockwell-45). The hardness

results obtained can be increased again, by increasing

the sintering temperature. When the results of this

study are compared with previous studies, the results

are not so far off. In this study, the sintering process

was carried out at a temperature of 1050°C and the

maximum hardness was obtained, namely 514.17 HV

510 HV 54.7 Rockwell-45 N.

4.5 Further Studies

Based on the discussion of the results of the formation

and test data, it ca be said that the sealface product

with undercut in this study was not good and was

classified into a reject product. This is based on the

following results:

• Judging from the final result of the powder

metallurgy process. The finished product has the

characteristics of being brittle and having a

rough surface. A rough surface indicates

imperfect compaction, so that the SiC grains are

still in their original shape and are not deformed.

Meanwhile, brittle characteristics can occur

because the product has poor interparticle bonds

due to incomplete compaction.

• Judging from the results of the stages of the

compaction process. At the stage of the

compaction process, a green compact was

obtained with brittle characteristics and poor

green strength. This can be seen from the green

compact's ability to maintain its shape. When

subjected to slight shocks (held manually by

hand) the green compact tends to crumble.

From these results, the authors decided that further

studies were needed. Further studies are aimed at

providing recommendations for improvements that

need to be made based on the author's observations

during the process of forming sealface products with

undercuts. The recommendations for improvement

that the authors propose are expected to improve

existing deficiencies.

The following are failure points that are the focus

of improvements that need to be made, the results of

the author's observations:

• The resulting green compact has poor green

strength, so it is easy to crush. This can be

caused by the compacting process that does not

reach the proper density.

• The molding mechanism that causes cracks in

the green compact.

• The process of releasing the mold that still uses

conventional methods

5 CONCLUSION

Based on the results of research on an experimental

study of single-action system compacting tools in

sealface formation with undercuts, the following

conclusions can be drawn:

Machines and tools with single-action system

compacting tools are not suitable for use in making

class 3 and class 4 powder metallurgy products.

The assessment of the feasibility of this single-

action compacting tool machine is based on the

following results: Observation of phenomena that

occur in each powder metallurgical process, which

discusses the compaction process a lot both in terms

of compaction work, compaction results, and the

effect of compaction results on the finished product

in terms of quality and characteristics. the final

product The compaction process is the main focus in

this discussion because the machine used plays an

important role in the stages of the compaction

process.

REFERENCES

Kurniawan, O., & Yudianto. (2014). “Kajian Kegagalan

Kinerja Sil Mekanik Produksi Dalam Negeri,”. Seminar

Nasional - XIII-Rekayasa Dan Aplikasi Teknik Mesin.

No., Hal.

Experimental Study of Single Action System Compacting Tool in Sealface Formation with Undercut

877

Syafi’i, M., & Priangkoso, T. (2018). “Penggantian Gland

Packing Ke Mechanical Seal Pada Pompa Oli TCU Di

PT. Polidayaguna Perkasa Ungaran,”. Semarang.

Wijaya, R. (2018). “Landasan Teori - Mechanical Seal,”.

Jakarta.

Fachrul Rozy, O, P., & Kurniawan, “Analisis Pembentukan

Sealface Dengan Teknologi Metalurgi Serbuk

Menggunakan Metode Taguchi Dan Teknik Grey

Relational Analysis,” J. Teknol. Dan Rekayasa

Manufaktur (JTRM) POLMAN BANDUNG.

Groover, M, P. (2010). “Powder Metallurgy,” in

Fundamental of Manufacturing Materials, Processes,

Andsystem, 4th Ed., Danvers: John Wiley & Sons, Inc,.

Flitney, R. (2007). Seals and Sealing Handbook, 5th Ed.

Oxford.

Kalpakjian, S., & Schmid, S, R. (2009). “Powder

Metallurgy Processing and Equipment,” in

Manufacturing Engineering and Technology, 6th ed.,

New York: Pearson.

Samal, P., & Newkirk, J. (2015). Materials Standards and

Test Method Standards for Powder Metallurgy. ASM

Handb, 7, 45-51.

Torosyan, K. S., & Pak, V. G. (2019, June). Influence of the

binder composition on the properties of the silicon

carbide green compacts and sintered parts prepared

from the powders produced by SHS. In IOP Conference

Series: Materials Science and Engineering (Vol. 558,

No. 1, p. 012052). IOP Publishing.

Upadhyaya, G. S. (1997). Powder metallurgy technology.

Cambridge Int Science Publishing.

Mokhtar, M. O. A. (1982). The effect of hardness on the

frictional behaviour of metals. Wear, 78(3), 297-304.

Tolbert, L. M., Nesselroth, S. M., Netzel, T. L., Raya, N.,

& Stapleton, M. (1992). Substituent effects on

carbanion photophysics: 9-arylfluorenyl anions. The

Journal of Physical Chemistry, 96(11), 4492-4496.

Lobanoff Val, S., & Ross, R. (1992). Centrifugal pumps:

Design and Application.

Kafkas, F., Karataş, Ç., Sozen, A., Arcaklioğlu, E., &

Saritaş, S. (2007). Determination of residual stresses

based on heat treatment conditions and densities on a

hybrid (FLN2-4405) powder metallurgy steel usi

ng

artificial neural network. Materials & design, 28(9), 2431-

2442.

R., P., Taylor, S., T., McClain, J., T., Berrty. (1999). “Uncertainty

Analysis of Metal-Casting Porosity Measurements Using

Archimedes’s Principle,” Int. J. Cast Met. Res. Vol., 11. No.,

4. Hal., 247–257.

Hardness, A. B. (1999). Standard Test Method for

Microindentation Hardness of Materials. ASTM Committee:

West Conshohocken, PA, USA, 384, 399.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

878