Life Cycle Assessment of Microalgae Production in a Sanitary

Effluent Medium Supplemented with Glycerol

Eduarda Torres Amaral

a

, Tiele Medianeira Rizzetti

b

, Michele Hoeltz

c

,

Gleison de Souza Celente

d

, Lisianne Brittes Benitez

e

and Rosana de Cassia de Souza Schneider

f

1

Environmental Technology Post-graduate Program, Universidade de Santa Cruz do Sul,

Av. Independência, 2293, Santa Cruz do Sul, Brazil

lisianne@unisc.br, rosana@unisc.br

Keywords: Microalgae, Wastewater Treatment, Glycerol, LCA, Environmental Impact, Chlorella sp.

Abstract: Microalgae are considered renewable and sustainable raw materials. They can be cultivated in wastewater,

enabling its treatment for disposal into water bodies due to the sequestration of residual nutrients such as

nitrogen and phosphorus. The biomass obtained can be used to develop biofuels and biosupplies. Recognizing

the production potential of Chlorella sp. in an alternative culture media, this work aimed to evaluate the major

environmental impacts on biomass production cultivated in three scenarios with NPK solution, effluent, and

effluent with glycerol supplementation. Life Cycle Analysis was performed using data from a 20 L production

scale. The most impacted categories in the process were the production of carcinogenic and non-carcinogenic

pollutants, inorganic respiratory pollutants, ecotoxicity, land acidification, land occupation, global warming,

and non-renewable energy use. Given the best environmental results, cultivation in effluent with glycerol

supplementation led to fewer environmental impacts on Chlorella sp. cultivation since it showed higher

biomass yield than the other two scenarios.

1 INTRODUCTION

Microalgae have been widely studied as a great

potential raw material for the production of biofuels

and biosupplies (Cheng et al. 2019, Do et al. 2022),

e.g., biodiesel, dietary supplements, nutraceuticals,

cosmetics, animal feeds, and pharmaceuticals

(Molazadeh et al. 2019, Fawcett et al. 2022).

Microalgae also can grow in wastewater and

produce low-cost biomass while removing or

consuming organic and inorganic nutrients from

wastewater, making them a sustainable alternative

(Singh et al. 2020).

These organisms offer economic

and environmental advantages, including

photosynthetic efficiency, high growth rate, and CO

2

sequestration (Muhammad et al. 2021, Li et al. 2022).

a

https://orcid.org/ 0000-0002-1140-9173

b

https://orcid.org/0000-0001-6539-1397

c

https://orcid.org/ 0000-0002-6156-2600

d

https://orcid.org/ 0000-0002-9314-2782

e

https://orcid.org/ 0000-0002-0604-1407

f

https://orcid.org/ 0000-0003-1400-8401

In addition, wastewater from various sources such

as agriculture, households, and industries can contain

anthropogenic pollutants that microalgae can

remediate, which otherwise would pose risks to

human health and the environment (Mofijur et al.

2021, Ahmed et al. 2022).

In this sense, microalgae’s benefits to the

environment are unquestionable since they can bring

benefits during growth and biomass use. On the other

hand, biomass production involves inputs and outputs

that potentially impact each life cycle, related to the

need for energy, inputs, equipment sanitization,

separation, and drying. Thus, considering the entire

process, there is an impact on the life cycle of

industrial production of microalgae, whether in a

conventional environment or with effluents. Life

Cycle Assessment (LCA) is a valuable tool to

Amaral, E., Rizzetti, T., Hoeltz, M., Celente, G., Benitez, L. and Schneider, R.

Life Cycle Assessment of Microalgae Production in a Sanitary Effluent Medium Supplemented with Glycerol.

DOI: 10.5220/0011905800003536

In Proceedings of the 3rd International Symposium on Water, Ecology and Environment (ISWEE 2022), pages 77-82

ISBN: 978-989-758-639-2; ISSN: 2975-9439

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

77

determine the environmental impacts associated with

the production of microalgae, evaluating emissions,

energy, and resource consumption (Sun et al. 2019,

Wu et al. 2019), highlighting critical points in the

production process and comparing scenarios (Herrera

et al. 2021).

In the context of the production of the microalgae

Chlorella sp. in an effluent medium with and without

glycerol (organic carbon source) supplementation,

the effluent treatment was investigated, showing the

benefit for the water treatment by this biological

method and the importance of this biomass as a

source of lipid (Amaral et al. 2022). This research

seeks to recognize, from the experimental research

already conducted, the potential environmental

impacts of the production process in comparison with

the use of NPK solution, an agricultural input widely

used for microalgae biomass production.

2 SCOPE AND DELIMITATION

OF THE SYSTEM

This LCA study aimed to quantify the potential

environmental impacts of microalgae cultivation in

sanitary effluent with and without glycerol

supplementation, promoting the bioremediation of

the effluent and enhancing the production of

microalgal biomass compared to the production in

NPK-rich medium. Thus, three scenarios were

compared in this LCA research for Chlorella sp.

production:

- Scenario 1: Microalgae cultivation in 3 g L

-1

NPK

solution according to Pacheco et al. (2019);

- Scenario 2: Microalgae cultivation in sewage

effluent;

- Scenario 3: Microalgae cultivation in sanitary

effluent with glycerol supplementation;

In all three scenarios, the steps were the same, using

the same equipment for cultivation, harvesting, and

drying. What differs one from the other is the culture

medium and biomass yield for the same production

duration.

The LCA of microalgal biomass production

grown in sanitary effluent with and without glycerol

supplementation was performed at bench-

photobioreactor experiments (Figure 1) with sanitary

effluent from the Wastewater Treatment Plant

(WWTP/UNISC) obtained after anaerobic digestion.

The NPK (Yara, 12:11:18) used was previously

dissolved in water and filtered.

Figure 1. Photobioreactor used in microalgae cultivation.

When the microalgae reached a cell density of 4.75 x

10

5

cel mL

-1

, they were cultivated in a 20 L

photobioreactor with constant aeration and lighting.

The experiment was terminated on day 10 (240 h).

After cultivation, each sample was centrifuged

individually in a benchtop centrifuge for 15 min at

2500 rpm, followed by drying for 24 h at 50 °C. The

input and output data from each step, energy

consumption, yield, inputs, and waste, were used in

SimaPro version 8.5 software to conduct the Life

Cycle Impacts Analysis (LCIA). The equipment used

is shown in Table 1, and the process inputs and

outputs are shown in Table 2.

The potential environmental impacts arising from

the LCA for producing 1 kg of biomass considering

cultivation, separation, and drying were evaluated in

all three scenarios. All inputs and outputs were found

in the Ecoinvent 3.6 database.

Table 1: Equipment used in the cultivation of microalgae in

tubular photobioreactors.

Steps Equipment Specifications

Cultivation

Lamps

LED T8 9W 100-

240V, ~ 50/60HZ

Pumps

Aeration pump

Vigo Ar/ 60Plus.

AC 220V – 60Hz,

2.5 W, 90 L h

-

1

,120 mbar.

Separation Centrifuge

Centrifuge Sigma/

6-16KS, Ano

2015, ~V/Hz 220-

2 40/60, 2300 W.

Drying Greenhouse

Greenhouse

Tecnal/ TE-394,

+7°C-70°C, 1.1

kW.

ISWEE 2022 - International Symposium on Water, Ecology and Environment

78

Table 2: Inputs and outputs of the three scenarios evaluated.

Scenarios

Item NPK Wastewater Wastewater +

g

l

y

cerol

In

p

ut

N fertilize

r

(

k

g)

1.62 - -

P fertilize

r

(kg) 1.48 - -

K

fertilize

r

(

k

g)

2.43 - -

Wastewate

r

(L) 20 20 20

Gl

y

cerol

(g)

- - 12.5

Wate

r

(L) 20 20 20

Clean Product

(g)

2 2 2

Output

Treated Effluent (L) 20 20 20

Comments: total values are shown in the table

3 LIFE CYCLE IMPACT

ANALYSIS

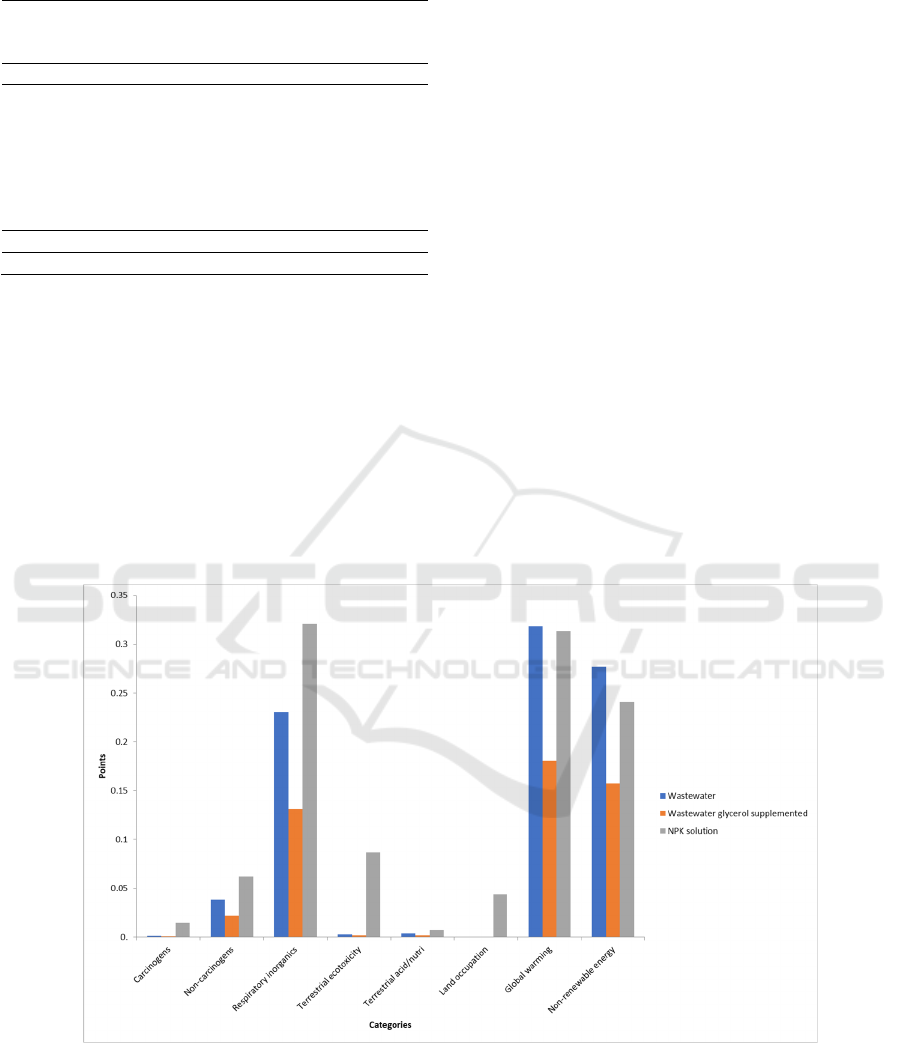

In the study of environmental impacts in the three

scenarios evaluated to produce microalgal biomass, it

was observed that of the 15 categories presented by

the Impact 2002+ method, the categories that are most

significant in the process are related to the production

of carcinogenic and non-carcinogenic pollutants,

inorganic respiratory pollutants, ecotoxicity, and

terrestrial acidification, land occupation, global

warming, and non-renewable energy use. The

impacts are associated with necessary inputs from the

technosphere (water, detergent, glycerol, and NPK)

and energy needs.

In the cultivation stage, there is a great influence

of the use of electricity to operate the pumps to

transfer CO

2

to the medium and to produce light

energy, essential for photosynthesis and the

conversion of inorganic carbon into biomass. In

separating biomass by centrifugation and in oven

drying, there was a greater contribution of impacts

associated with electricity use.

By adding glycerol, the effect of electricity

consumption was minimized due to the increased

production of microalgal biomass, enabling

production in a mixotrophic metabolic mode.

Producing more biomass at the same energy

consumption is a premise for achieving a lower

environmental impact. Using inputs more efficiently

leads to a higher biomass yield can reduce

production’s environmental impacts. Residual inputs

can determine better yield without adding more

economic and environmental impacts (Kabir et al.

2022).

Figure 2. Impact categories obtained in the biomass production with different mediums (wastewater, wastewater

supplemented with glycerol, and NPK solution) using Simapro 8.5 with Impact 2002+ method and Ecoinvent database.

It was observed that the glycerol supplementation

scenario generated the least environmental impacts

(Figure 2), even though purified glycerol was used as

an input, which added environmental impacts to the

system but led to a greater gain in biomass. Residual

glycerol, obtained after methanol recovery, should

have its pH analyzed and adjusted and, therefore, may

be responsible for an even better environmental

Life Cycle Assessment of Microalgae Production in a Sanitary Effluent Medium Supplemented with Glycerol

79

performance of microalgal biomass production.

Crude glycerol is already recognized as a suitable

carbon source in mixotrophic microalgae production

(Xu et al. 2019, Gougoulias et al. 2022). In previous

research conducted by this group, it was observed that

adding glycerol may be a factor in improving the C/N

ratio and using microalgae to reduce residual nitrogen

after conventional urban wastewater treatment (not

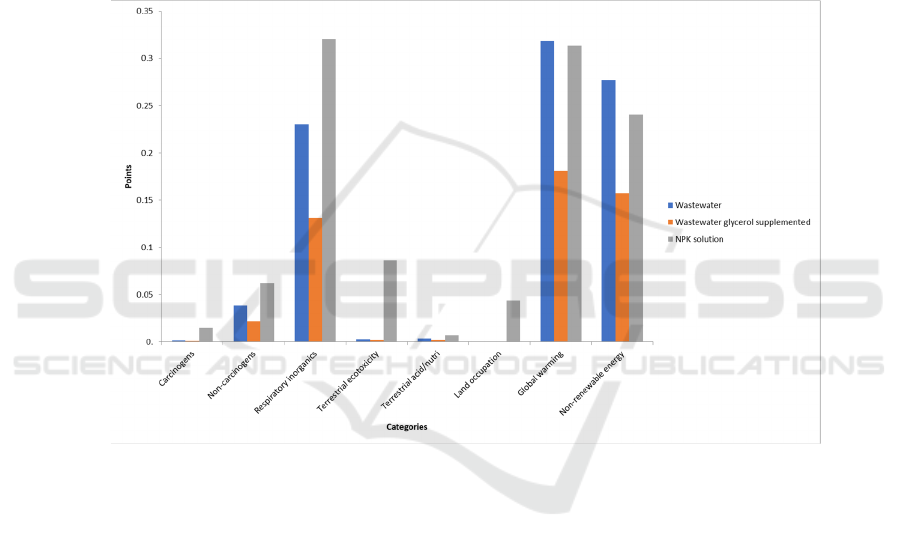

published). Figure 3 shows the main normalized

environmental damages associated with microalgal

biomass production from the scenarios under study.

The use of NPK in microalgae production adds the

most impact in all categories, being the greatest for

human health. Li et al. (2022), when studying the life

cycle of microalgae production in wastewater using

the ReCiPe method, which presents the impacts on

mid and endpoints, also observed the benefits of using

wastewater in microalgae production, showing a

reduction in long-term impacts to human health and

the ecosystem. They also noted the energy input

requirement and no nutrient recovery effect as factors

responsible for lower environmental performance.

In the uncertainty analysis for the three scenarios

concerning the main impact categories, the data in

Table 3 were obtained. The greatest uncertainties in

the impact categories in both methods are related to

the scenario in which microalgae was cultivated in a

medium with NPK.

Figure 3. Environmental damage categories obtained in the biomass production with different mediums (wastewater,

wastewater supplemented with glycerol, and NPK solution) using Simapro 8.5 with Impact 2002+ method and Ecoinvent

database.

The uncertainties of these data for the main

categories of impacts analyzed correspond to the

division of the standard deviation by the mean in each

category. The largest uncertainties in the impact

categories in both methods are in the categories of

land cover in the wastewater cultivation scenario and

carcinogenic and non-carcinogenic pollutants for

cultivation in NPK solution; however, all

uncertainties were considered low since they are less

than 0.3 (Pearson and Casarim 2018).

4 FUTURE PERSPECTIVES

For the production of Chlorella sp., besides the

benefits associated with the fact that microalgae are

photosynthesizers, responsible for carbon capture

from the atmosphere, and are suitable for capturing

nutrients from the water, it is observed by the Life

Cycle Inventory (LCI) that they can also be promising

as a cleaner production process if we use effluent for

cultivation. Supplementing glycerol, especially crude

glycerol, also adds a better environmental

performance associated with a higher biomass yield.

To improve the process, it is still possible to

reduce impacts associated with biomass drying by

using a solar dryer with heated air through the

biomass, as presented by Silva et al. (2021) for

Spirulina platensis, which reached 11% of biomass

moisture in less than 3.5 h.

Notably, the reduction of the impacts of the

process by cultivating in an effluent medium with

ISWEE 2022 - International Symposium on Water, Ecology and Environment

80

residual glycerol can lead to the loss of some

properties and the risk of contamination, which

reduces the possibilities of biomass use. This process

can be environmentally cleaner, with several benefits.

However, the use of the biomass obtained should be

considered. Nevertheless, the biomass can be used as

biofertilizer (Vishwakarma et al. 2022), and biofuels

(de Souza Celente et al. 2019, de Souza et al. 2021)

are more likely products to be developed with the

biomass.

Another aspect of microalgae production's

environmental viability is the cultivation location (de

Souza et al. 2022). In this LCA, the need for effluent

and glycerol transportation was not considered, and if

there is transportation, the impacts increase due to

fuel consumption. For many microalgae, the use of

effluent in cultivation can be promising; however, if

there are large distances between the generation of

effluent and the production of microalgae, the

alternative is no longer viable.

Table 3: Uncertainty analysis by Monte Carlo simulation (1000 interactions and 95% confidence) of the impact results of the

categories highlighted in the LCIA with the Impact 2002+ method.

Categories Unit

NPK Wastewater Wastewater + glycerol

Average CV Average CV Average CV

Carcino

g

ens k

g

C

2

H

3

Cl e

q

3.73E+01 0.183 3.70E+00 0.004 2.14 7.15E-03

Global warmin

g

k

g

CO

2

e

q

3.11E+03 0.036 3.15E+03 0.000 1791.28 1.67E-04

Land occupation m

2

or

g

.arable 5.48E+02 0.033 5.22E-02 0.132 5.04 9.15E-02

N

on-carcino

g

ens k

g

C

2

H

3

Cl e

q

1.57E+02 0.120 9.72E+01 0.000 55.35 8.40E-04

N

on-renewable ener

gy

MJ primar

y

3.65E+04 0.036 4.21E+04 0.000 23906.24 1.46E-04

Respirator

y

inor

g

anics k

g

PM

2.5

e

q

3.25E+00 0.047 2.33E+00 0.000 1.33 2.75E-04

Terrestrial acid/nutri k

g

SO

2

e

q

9.33E+01 0.042 4.80E+01 0.000 27.35 3.81E-04

Terrestrial ecotoxicit

y

k

g

TEG soil 1.50E+05 0.046 4.86E+03 0.002 3132.06 2.21E-02

5 CONCLUSIONS

The environmental performance of microalgal

biomass production was obtained by LCA comparing

three cultivation scenarios (NPK solution, effluent,

and effluent with glycerol supplementation). When

comparing the scenarios, it was observed that using

sanitary effluent with glycerol supplementation led to

less environmental impacts in the cultivation process

of Chlorella sp. Thus, glycerol can reduce microalgal

biomass production impacts when supplemented with

effluent. However, this will depend on the biomass’s

applicability, production logistics, and transport

impacts.

ACKNOWLEDGEMENTS

This work was supported by Coordenação de

Aperfeiçoamento de Pessoal de Nível Superior –

Brasil (CAPES) – Finance Code 001 and Conselho

Nacional de Desenvolvimento Científico e

Tecnológico - CNPq – protocol 310228/2019-0 and

400862/2019-0.

REFERENCES

Ahmed, S. F., Mofijur, M., Parisa, T. A., Islam, N.,

Kusumo, F., Inayat, A., Le, V. G., Badruddin, I. A.,

Khan, T. M. Y. and Ong, H. C. 2022. Progress and

challenges of contaminate removal from wastewater

using microalgae biomass. Chemosphere 286: 131656.

Amaral, E. T., Alves, G., Julich, J., da Silva, M. B., Celente,

G. d. S., Hoeltz, M., Schneider, R. d. C. d. S. and

Benitez, L. B. 2022. Sanitary wastewater supplemented

with glycerol to obtain lipid-rich microalgal biomass.

Submited.

Cheng, D. L., Ngo, H. H., Guo, W. S., Chang, S. W.,

Nguyen, D. D. and Kumar, S. M. 2019. Microalgae

biomass from swine wastewater and its conversion to

bioenergy. Bioresour. Technol. 275: 109-122.

de Souza Celente, G., Colares, G. S., Machado, Ê. L. and

Lobo, E. A. 2019. Algae turf scrubber and vertical

constructed wetlands combined system for

decentralized secondary wastewater treatment.

Environ. Sci. Pollut. Res. 26(10): 9931-9937.

de Souza, D. S., Valadão, R. C., de Souza, E. R. P., Barbosa,

M. I. M. J. and de Mendonça, H. V. 2022. Enhanced

Arthrospira platensis Biomass Production Combined

with Anaerobic Cattle Wastewater Bioremediation.

BioEnergy Res. 15(1): 412-425.

de Souza, L., Lima, A. S., Matos, Â. P., Wheeler, R. M.,

Bork, J. A., Vieira Cubas, A. L. and Moecke, E. H. S.

Life Cycle Assessment of Microalgae Production in a Sanitary Effluent Medium Supplemented with Glycerol

81

2021. Biopolishing sanitary landfill leachate via

cultivation of lipid-rich Scenedesmus microalgae. J.

Cleaner Prod. 303: 127094.

Do, C. V. T., Pham, M. H. T., Pham, T. Y. T., Dinh, C. T.,

Bui, T. U. T., Tran, T. D. and Nguyen, V. T. 2022.

Microalgae and bioremediation of domestic

wastewater. Curr. Opin. Green Sustainable Chem. 34:

100595.

Fawcett, C. A., Senhorinho, G. N. A., Laamanen, C. A. and

Scott, J. A. 2022. Microalgae as an alternative to oil

crops for edible oils and animal feed. Algal Res. 64:

102663.

Gougoulias, N., Papapolymerou, G., Mpesios, A.,

Kasiteropoulou, D., Metsoviti, M. N. and Gregoriou,

M. E. 2022. Effect of macronutrients and of anaerobic

digestate on the heterotrophic cultivation of Chlorella

vulgaris grown with glycerol. Environ. Sci. Pollut. Res.

29(20): 29638-29650.

Herrera, A., D’Imporzano, G., Acién Fernandez, F. G. and

Adani, F. 2021. Sustainable production of microalgae

in raceways: Nutrients and water management as key

factors influencing environmental impacts. J. Cleaner

Prod. 287: 125005.

Kabir, S. B., Khalekuzzaman, M., Hossain, N., Jamal, M.,

Alam, M. A. and Abomohra, A. E.-F. 2022. Progress in

biohythane production from microalgae-wastewater

sludge co-digestion: An integrated biorefinery

approach. Biotechnol. Adv. 57: 107933.

Li, P., Luo, Y. and Yuan, X. 2022. Life cycle and techno-

economic assessment of source-separated wastewater-

integrated microalgae biofuel production plant: A

nutrient organization approach. Bioresour. Technol.

344: 126230.

Li, S., Li, X. and Ho, S.-H. 2022. Microalgae as a solution

of third world energy crisis for biofuels production

from wastewater toward carbon neutrality: An updated

review. Chemosphere 291: 132863.

Mofijur, M., Fattah, I. M. R., Kumar, P. S., Siddiki, S. Y.

A., Rahman, S. M. A., Ahmed, S. F., Ong, H. C., Lam,

S. S., Badruddin, I. A., Khan, T. M. Y. and Mahlia, T.

M. I. 2021. Bioenergy recovery potential through the

treatment of the meat processing industry waste in

Australia. J. Environ. Chem. Eng. 9(4): 105657.

Molazadeh, M., Ahmadzadeh, H., Pourianfar, H., Lyon, S.

and Rampelotto, P. 2019. The Use of Microalgae for

Coupling Wastewater Treatment With CO2

Biofixation. Front. Bioeng. Biotechnol. 7: 42.

Muhammad, G., Alam, M. A., Mofijur, M., Jahirul, M. I.,

Lv, Y., Xiong, W., Ong, H. C. and Xu, J. 2021. Modern

developmental aspects in the field of economical

harvesting and biodiesel production from microalgae

biomass. Renewable Sustainable Energy Rev. 135:

110209.

Pacheco, M., Hoeltz, M., Bjerk, T., Souza, M., da Silva, L.,

Gressler, P., Moraes, M., Alcayaga, E. and Schneider,

R. 2019. Evaluation of microalgae growth in a mixed-

type photobioreactor system for the phycoremediation

of wastewater: Wastewater phycoremediation with

mixed-type photobioreactor. J. Chem. Technol.

Biotechnol. 94.

Pearson, T. R. H. and Casarim, F. (2018). Guidance on

applying the Monte Carlo approach to uncertainty

analyses in forestry and greenhouse gas accounting.

Silva, J. P. S., Veloso, C. R. R., de Souza Barrozo, M. A.

and Vieira, L. G. M. 2021. Indirect solar drying of

Spirulina platensis and the effect of operating

conditions on product quality. Algal Res. 60: 102521.

Singh, A., Ummalyma, S. B. and Sahoo, D. 2020.

Bioremediation and biomass production of microalgae

cultivation in river water contaminated with

pharmaceutical effluent. Bioresour. Technol. 307:

123233.

Sun, C.-H., Fu, Q., Liao, Q., Xia, A., Huang, Y., Zhu, X.,

Reungsang, A. and Chang, H.-X. 2019. Life-cycle

assessment of biofuel production from microalgae via

various bioenergy conversion systems. Energy 171:

1033-1045.

Vishwakarma, R., Dhaka, V., Ariyadasa, T. U. and Malik,

A. 2022. Exploring algal technologies for a circular bio-

based economy in rural sector. J. Cleaner Prod. 354:

131653.

Wu, W., Lei, Y.-C. and Chang, J.-S. 2019. Life cycle

assessment of upgraded microalgae-to-biofuel chains.

Bioresour. Technol. 288: 121492.

Xu, S., Elsayed, M., Ismail, G. A., Li, C., Wang, S. and

Abomohra, A. E.-F. 2019. Evaluation of bioethanol and

biodiesel production from Scenedesmus obliquus

grown in biodiesel waste glycerol: A sequential

integrated route for enhanced energy recovery. Energy

Convers. Manage. 197: 111907.

ISWEE 2022 - International Symposium on Water, Ecology and Environment

82