Study on Logistics Warehouse Dynamic Fire Risk Assessment Based

on Gustav Method

Wenhui Ju

1

, Guofeng Su

1

and Lizhi Wu

2

1

Department of Engineering Physics, Tsinghua University, Heqing Road, Haidian District, China

2

China People’s Police University, Xichang Road 220, Anci District, Langfang, Hebei Province, China

Keywords: Logistics Warehouse, Gustav Method, Risk Assessment

Abstract: Modern logistics is a multi-faceted chain link comprised of storage, transfer, sorting, processing, and

distribution. Logistics warehouses, regarded as the most significant infrastructures in the supply chain, have

characteristics such as large building areas, multiple types, storage of miscellaneous goods, and fast goods

flow. In recent years, there has been an increase in the frequency of logistics warehouses fires resulting in

large socio-economic losses. Subsequently, a dynamic fire risk assessment method of logistics warehouses is

needed. Firstly, 52 fire accidents implied that the fire of logistics warehouses generally destroyed large-

destroyed areas, produced poisonous gases, spread rapidly, and led to the collapse of the warehouses.

Secondly, the investigation of logistics warehouses showed that the different ribbons of the logistics chain

had significant fire resources and risks. Thirdly, the fire risk analysis contributed to developing an index

system of fire risk for modernized logistics warehouses with the parameter weights being decided by the AHP

method and Delphi Method. Finally, a fire risk assessment method of modernized logistics warehouses was

developed by using the Gustav method. The users' feedback ascertained that the new method is feasible and

practical even to laymen of very little professional knowledge.

1 INTRODUCTION

Constructing logistics warehouses, which contributed

to the high-speed transportation of goods between

areas, became the most prevalent campaign because

the least time cost of transportation means optimized

social economics. COVIN-19 broke out the most

serious public health crisis, bankrupted countless

industries but boomed the logistics industry. Express

delivery has become one of the necessary parts of our

daily life. However, whether we under-evaluate some

potential social risks?

1.1 Status Quo of Logistics Warehouses

News broadcasted many logistics warehouse fire

accidents in recent years, including the Chinese

Jingdong warehouse fire in 2016, Amazon UK

logistics warehouse (BHX1) fire in 2017, Japanese

transportation logistics warehouse in 2018, and

Amazon American logistics center warehouse

(TEB6) fire in 2020. Logistics warehouse fires

always cause serious economic losses and casualties.

Logistics has been the tipping point of economic

rise among modern industries and an integral

parameter of financial evaluation. With the increasing

demands of logistics, advanced technologies and

transportation capacity, new automatic modernized

logistics warehouses with a clearance height of over

14m are being developed. As the most substantial link

within the logistics industry, how can we ensure its

safety development? One efficient way is to develop

a fire risk assessment method for modernized

logistics warehouses. The structure of the article is

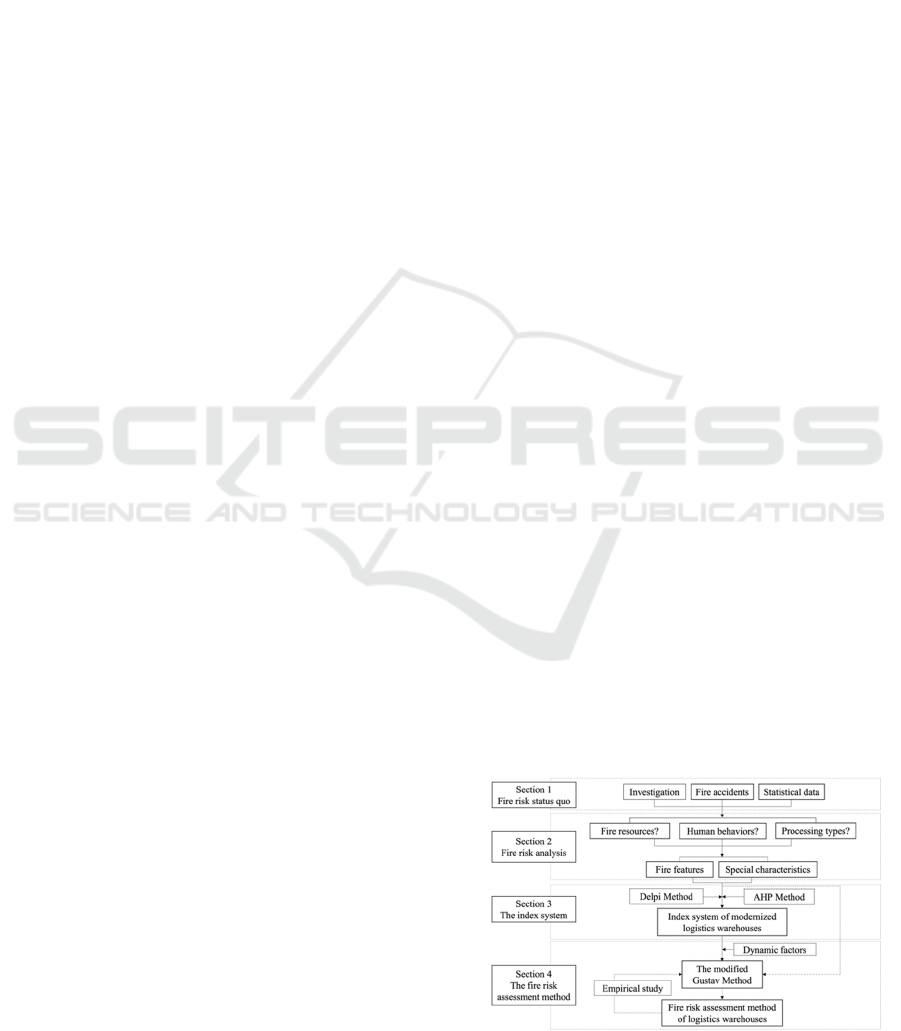

shown in Figure 1.

Figure 1: The structure of the article.

110

Ju, W., Su, G. and Wu, L.

Study on Logistics Warehouse Dynamic Fire Risk Assessment Based on Gustav Method.

DOI: 10.5220/0011905900003612

In Proceedings of the 3rd International Symposium on Automation, Information and Computing (ISAIC 2022), pages 110-114

ISBN: 978-989-758-622-4; ISSN: 2975-9463

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1.2 Research Review

During the early years in the logistics industry,

scholars focused more on how to optimize the layout

of logistics warehouse based on the cost-benefit

model, Melendez 0. et al (2001) and M.Dai.s C.

(2010) suggested different optimization plans. These

optimized plans were not enough to prevent the

warehouse fire from occurring.

Subsequently, countries published their logistics

warehouse regulations for various aspects, including

the NFPA 230 Standard for the Fire Protection of

Storage (2000), National Standard of Canada, The

Building Code of Australia and Classification and

Requirement of Logistics Park of China (2017).

However, the regulations are hysteretic with the

development of warehouses. The new types of

logistics warehouses cannot satisfy the basic

requirement of fire protection in the code. Wenhui J.

(2017) chose nine typical logistics warehouses in

China and studied the contradictions between real

construction and fire department design requirements

to make the fire protection investment more

reasonable and feasible.

How can one value the risk of the logistics

warehouse? This can be done through a risk

evaluation method to ascertain the risk factors. Zang

L.and Zhang J. established an index system for

transportation warehouses using the fuzzy

comprehensive analysis method and the Analytic

Hierarchy Process (AHP). Wenhui J. (2016)

developed the Event and Fault Tree Analysis method

(EFTA) to explore the fire spread mechanism of

various cotton logistics warehouses.

2 FIRE RISK ANALYSIS OF

LOGISTICS WAREHOUSES

Fire risk analysis is an efficient tool to find the fire

risk factors. The general and special characteristics

should be analysed by fire accidents and features of

different functions respectively.

For the common characteristic, 52 fire accidents,

from 2005 to 2020, were collected with their

complete information and investigation reports.

There are four features of fire accidents in logistics

warehouses, larger destroyed areas, abundant toxic

and high-temperature smoke, faster spread speed at

the early fire stage, and collapse.

For the special ones, it depends on the features of

different processes. Warehouse types are defined by

location, application, and automatic degree, which in

effect lead to different fire characteristics. Generally,

storing, sorting, and processing are the essential

components of modernized logistics chains. Special

fire risk analysis can be studied by comparing these

three links.

2.1 Storing Area

Sorting has been the feature of the modernization of

logistics warehouses. Investigations show that

stochastic fluctuation of fire loads, complex

combustion sources, and electrical failure are

significant risk characteristics in the sorting area.

Although it is called ‘zero storage’ in the sorting

center, the storage time is no more than 4 hours, the

storage capacity randomly tips a peak every day as

such making it difficult to predict the fire loads. Duo

to its ‘zero storage’ nature, the sorting center is open

to every person, unsafety behaviours, smoking or

arson. This increases the propensity of a fire accident

more readily. Even though automatic equipment is

popular and advanced, its operation needs electricity.

In the 52 fire accidents analysed, 30% was as a result

of electrical failures, the highest of the loss.

2.2 Manufacturing Area

Manufacturing, including unpacking, thermoplastic,

and repackaging order goods, is the most complex

aspect of logistics warehouses. Lack of efficient fire

separations and high-temperature manufacturing

processes are the unique fire risks in this area.

To shrink the time interval between packing and

transportation, storing area is always close to the

manufacturing area, and the conveyor belts across the

firewall may times. Even some warehouses illegally

dismantle the fire separations. Thermoplastic needs

high-temperature conditions. If the good with the

high-temperature external surfaces, are put near

inflammable things, a fire is likely to occur.

3 INDEX SYSTEM OF FIRE RISK

ASSESSMENT FOR

MODERNIZED LOGISTICS

WAREHOUSES

Index system is a general method to evaluate logistics

warehouses’ fire risk. There exits quite a lot of index

systems that is different in either warehouse

categories or risk parameters. However, they cannot

satisfy the modernized classification with high-tech

and multi-function. Compared to the traditional

Study on Logistics Warehouse Dynamic Fire Risk Assessment Based on Gustav Method

111

warehouses, the modern ones have new fire risk

sources and the context-specific fire characteristics

ignored by any of the existed index systems.

Therefore, a need to construct an updated version of

the modernized logistics warehouse index system.

3.1 Construction Principle of Index

System

The science and efficacy of the risk evaluation index

system is dependent on whether the evaluation

parameters are chosen reasonably. The effect between

risk parameters of warehouses is complex enough as

hinted by several principles always reminded us

through the construction process.

Firstly, what is the main purpose of establishing

an index system? It’s to find out fire risk sources,

distinguish risk factors, make sure fragile spots are

eliminated or control the risks. Secondly, over-

comprehensive should be avoided. Too many risk

indexes may lead to an overlap of similar risk factors,

and it may cause an over-evaluated risk level leading

to a waste in fire protection investment.

Unfortunately, it is not feasible for users to check out

at first glance which fire risk should be eliminated

without personalized characteristics being included.

It is imperative therefore to consider special risk

characteristics for developing warehouses.

Fortunately, the research provides the basis for it.

3.2 The Parameters of the Index

System

According to the theory of two types of hazards and

the fire risk analysis, an optimized and multiple index

system of modernized logistics warehouses is

composed of four parameters in the first level, ten in

the second level, and thirty-two in the third level, as

shown in Figure 2.

There are four noteworthy points in the new index

system. The first takes into account the risk of

different process characteristics (B

2

) into account.

The second one is that it considers the risk of fire

shutter in different parts, fire curtain at the firewall

(C

27

), and fire curtain near the conveyor belt (C

28

).

The third, safety management (B

5

) considers whether

the garbage materials cleaning is in time (C

32

). The

fourth, evacuation factors are omitted because the

investigation showed that the workers in modernized

logistics warehouses are few and familiar with the

evacuation plans.

Figure 2: The index system of fire risk assessment of

modernized logistics warehouses.

3.3 Weighted Parameters

Due to the lack of a database for logistics warehouses,

it is scientific to calculate the weight of parameters in

the index system was calculated using the AHP

method and the Delphi method based on the fire risk

analysis above. We invited more than ten renowned

first safety Chinese experts.

Two methods were used to determine the weight

of the judgment interval matrix, the relevant weight

between indicators. We used MATLAB to calculate

the weighted value of parameters and assess the

consistency. The result of the consistency test of the

judgment matrix is well, as is shown in Table 1.

Table 1: Consistency test of judgment matrix.

Judgment matrix CR Consistency test

𝑅

←

0.0440 Yes

𝑅

0.0191 Yes

𝑅

0.0415 Yes

𝑅

0.0257 Yes

𝑅

0.0428 Yes

𝑅

0.0191 Yes

𝑅

0.0036 Yes

𝑅

0.0036 Yes

ISAIC 2022 - International Symposium on Automation, Information and Computing

112

4 THE MODIFIED GUSTAV

METHOD FOR FIRE RISK

ASSESSMENT OF LOGISTICS

WAREHOUSES

When it is uncertain on which method to select

amongst the many evaluation methods, the status quo

and analysis of reasons should be considered. The

status quo shows that the lack of historical data of

logistics warehouse fire accidents excludes the

quantitative methods, and the research goal of

workers’ evaluation method decides that the new

method should be simple to learn and easy to operate.

4.1 Modified Gustav Method

Gustav method is a semi-quantitative risk analysis

method. It separates fire risks into two aspects, the

structure destroys of construction outside (GR) and

property loss and casualties of construction inside

(IR). The method constructs a rectangular coordinate

system, x-axis defined as GR against the y-axis as IR.

Two figures decide one point defined as risk level in

the rectangular coordinate system. In this way,

Gustav method could provide simple and feasible fire

protection plan to companies, even those who don't

have enough knowledge of fire prevention. However,

the traditional Gustav method can only determine a

fixable fire risk level. Considering the fire protection

status quo and fire risks analysis in modernized

logistics warehouses, it is necessary to modify the

traditional version to consist with fire risk

characteristics. So, we added dynamic factors into GR

and IR to account for the dynamic assessment.

For GR, we added mobile fire loads and their

inflammable degrees. We also considered the

different links, similar to categorizing the special fire

risks into storing, sorting and manufacturing areas.

𝐺𝑅 =

(𝑄

∙𝛼+𝑄

)∙𝑆∙𝐵∙𝑇

𝑊∙𝑅

(1)

𝑄

and 𝑄

, the mobile fire risk loads and fixable

fire risk loads respectively; 𝛼 , the inflammable

degree of 𝑄

; S, the building area; B, the risk

parameter of location; T, the function district

parameter; W, the fire resistance degree; 𝑅

, the

competency of the fire protection system.

For IR, we added the number of people as the

dynamic parameter of IR and multiplied it by 0.1 to

shrink the maximum value of IR to fit with the figure

interval of the x-axis.

𝐼𝑅 = 0.1𝐹 ∙ (𝐻 ∙ 𝜑) ∙ 𝐷 (2)

F, toxic degree of gases; H, the risk degree; 𝜑, the

number of people; D, the loss degree of property.

All value of each parameter above obeys some

regulations. The original parameters values are same

as the traditional Gustav method, while the figures of

adding parameters are according to the status quo of

building codes or other regulations. The details of the

figures are available on request.

4.2 The Procedure of Dynamic Fire

Risk Assessment of Modernized

Logistics Warehouses

The research above establishes a dynamic fire risk

assessment to fit modernized logistics warehouses.

Assessors should therefore know how to use it, and

the procedure of the method illustrates as follow.

Firstly, the assessor should investigate the basic

data of an assessed warehouse. At the same time, the

assessor should record the fire risk resources and

hidden hazards. In this step, the assessor can

determine some values of fixable parameters in the

modified Gustav method.

Secondly, the assessor should choose an area to

record the data of dynamic parameters at least two

days (without maximum limitation), including the

mobile fire loads, the number of workers. This helps

to bring out average value of each dynamic parameter

comes out.

Thirdly, the value of each parameter in the

modified Gustav method should be multiplied with

the corresponding weighted value in the index system,

to bring out the fire risk level comes out.

4.3 Empirical Study

The sorting center of JingDong Gu’an Logistics

warehouse was chosen. It is 20762.28m

2

, separated

into three fire compartments, and installs automatic

sorting equipment. This warehouse is used to sort

electronic household appliances, mobile phones,

laptops, foods, and some wine.

We chose 15-time points every day to record the

data of the mobile fire loads and the number of people,

and the recording work continued for one week.

Three periods, 01:00 to 7:00, 11:00 to 14:00, and

18:00 to 21:00 were deleted because workers rested

during these periods. It was assumed that there was

no fluctuation of fire risk, although some few parts

continued working actually.

According to the investigation of the sorting

center of the logistics warehouse, by adding data from

the record, each parameter’s value, the average value

Study on Logistics Warehouse Dynamic Fire Risk Assessment Based on Gustav Method

113

of one week’s records, in the modified Gustav

Method could be determined, as the table 2 shows.

Table 2: The value of GR & IR in Jingdong sorting center

of logistics warehouse.

Time GR IR Time GR IR

7:00 0 0 17:00 3.99 2.16

8:00 0.35 2.16 18:00 5.32 1.08

9:00 1.24 2.16 21:00 3.11 2.16

10:00 1.95 2.16 22:00 3.73 2.16

11:00 2.57 2.16 23:00 2.84 2.16

14:00 2.75 1.08 00:00 1.15 2.16

15:00 2.40 2.16 01:00 0.53 2.16

16:00 3.19 2.16

—

—

—

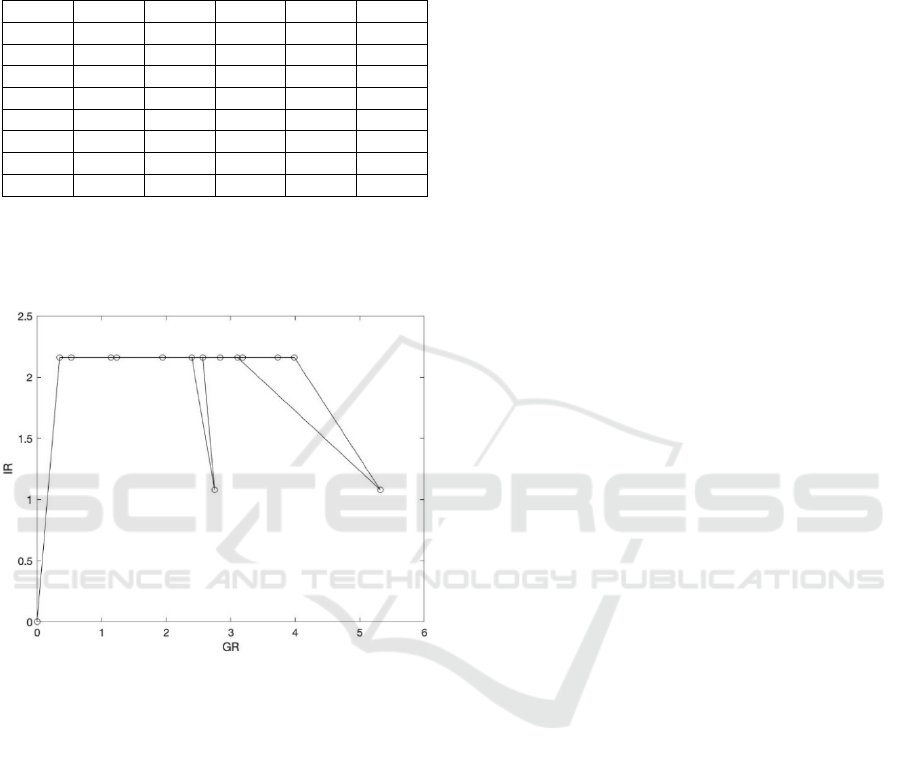

Putting all the figures into x-axis and y-axis

respectively, a graphic, implying the fluctuation of

fire risk in sorting center of logistics warehouse, is

shown as Figure 3.

Figure 3: The fluctuation of fire risk level in sorting center

of logistics warehouse.

According to Figure 3, three points are lower than

others, respectively corresponding to 7:00, 14:00, and

18:00. It is obvious that when the sorting center is

operating, the fire risk is higher. However, comparing

the three lower points, the fire risk at night is still

higher relative to the morning. The manager said that

the reason might be that some orders, paid through the

e-commerce platform, were at night. When the

worker picked out the goods and transported them to

the sorting center, the workers had to work overtime,

but the extra time was excluded from the record.

5 CONCLUSIONS

The research develops a dynamic fire risk assessment

method based on the Gustav method.

Firstly, based on investigations of fire accidents

and reports of modernized logistics warehouses, the

research implies the status quo of fire safety, analyses

the fire features, and concludes special characteristics

for different links in logistics warehouses.

Secondly, the research constructs a new index

system of modernized logistics warehouses, and

emphasizes the effect of warehouse types, packing

garbage, operating processes, and fire roller shutters.

Thirdly, the research modifies the Gustav method

by adding dynamic fire risk factors, mobile fire loads,

and the number of workers. Through the assessment

of the fire risk in Jingdong Gu'an sorting center of

logistics warehouses, the result validates the

reliability and efficacy of the new assessment

method.

When reviewing the research, we think some

aspects could be improved. In the empirical study, the

type of the function area is too single to make a

comparison, and the time length of the record is too

short to find enough routines of fluctuation. And the

research started on a general workday, not on a

special days like shopping festivals, which may raise

the peak figure of the mobile fire loads. Moreover, the

new method could be modified to be a quantitative,

provided enough data of logistics warehouses and

change the method of calculating the weight of

parameters. Other details pertaining to investigation

and calculation that were not presented in this paper

are available on request, if needed.

REFERENCES

Moore, R., Lopes, J., 1999. Paper templates. In

TEMPLATE’06, 1st International Conference on

Template Production. SCITEPRESS.

Smith, J., 1998. The book, The publishing company.

London, 2

nd

edition.

Melendez O, Maria F., 2001. Bonded Logistics Zone under

the Influence of Basic Traffic Construction. J.

Log&Trans.Rev. 21 1-4.

M.Dai.s C., 2010. Study on Layout Optimization of the

Regional Logistics System Master’s Thesis. J. Bus.

Log. 11 43-5.

NFPA, 2000. Standard for the Fire Protection of Storage.

American Elsevier.

Standardization administration, 2017. Classification and

Planning Fundamental Requirements of

Logistics

Park. China: Standards Press of China.

Wenhui J. and Yifu L., 2017. Conf. 3rd E-commerce &

Contemporary Economic Development (China: Xi’an)

p 216-21.

Wenhui J., 2016. Proc. Engineering vol 135 (China:

Guangzhou/ American Elsevier) p 417-25.

ISAIC 2022 - International Symposium on Automation, Information and Computing

114