Analysis of Technical Aspects and Economic Aspects of Electrical

Energy Consumption in the Induction Stove Program

Edy Pratiknyo

1

, Alamsyah

2

and Ikhsan Kamil

2

1

Mahasiswa S2 Terapan Teknik Elektro, Politeknik Negeri Jakarta, Jl. Prof GA Siwabessy, Kampus UI Depok, Indonesia

2

Pengajar Department Teknik Elektro, Politeknik Negeri Jakarta, Jl. Prof GA Siwabessy, Kampus UI Depok, Indonesia

Keywords: Analysis, Induction Stove, Gas Stove, Energy Consumption, Cost.

Abstract: Stove is a cooking utensil for households to provide food to meet daily needs. LPG gas stoves are very

commonly used by various groups because they’re easy to buy and in terms of prices are very affordable

because of subsidies from government which makes gas prices very affordable because government still

provides subsidies for LPG for 3-kilogram. The government is now encouraging the Import-Based Energy

Transfer Program into Domestic-Based Energy through the Conversion of LPG Stoves to Induction Stoves to

support National Energy Security, and the conversion of LPG stoves to Induction cookers as one of the

strategies to reduce LPG imports. In previous studies, the performance of gas stoves and induction cookers

was tested, comparing energy consumption and economic aspects by testing them in boiling 1 liter of water.

From the results of research on technical aspects, it states that an induction stove can replace a 3-kilogram

LPG stove, the use of an induction cooker with a 2-burner design (1,000 Watt and 1,800 Watt), cooking costs

are more efficient Rp. 45,770/month for the power group of 450VA and Rp. 30,190/month for 900VA power

group households. The economic aspect has an impact on reducing LPG imports to meet national energy

needs.

1 INTRODUCTION

Stoves are daily necessities that are used by the

community as a tool to provide various foods to meet

basic needs. The use of gas stoves is very commonly

used by various groups because they are easy to buy

and in terms of cost are very affordable due to

subsidies from the government which causes gas

prices to be very affordable (Pawenary, 2020).

In Indonesia's efforts towards the transition of Net

Zero Emmision and supporting environmentally

friendly campaigns, the Government is now

encouraging the Transfer of Import-Based Energy to

Domestic-Based Energy through the Conversion of

LPG Stoves to Induction Stoves to support National

Energy Security, and the conversion of LPG stoves to

Induction stoves is one of the strategies to reduce

LPG lmpor tubes of 3 kg, which began with through

the movement of 1 million induction stove users in

2021 and starting in 2022, it will increase by 2 million

/ year so that it reaches 18.2 million induction stove

users in 2030. The Government's strategy in the LPG

stove conversion program to Induction stoves in

addition to aiming to save lpg import costs is also to

save significant LPG subsidies, because LPG

consumption in the household sector (LPG stoves)

has a portion of almost 96% of the total national LPG

consumption.

Based on the description above, it is necessary for

researchers to answer the problems mentioned above

through the analysis of technical aspects and

economic aspects of electrical energy consumption in

the induction stove program so that the public can

know the differences and advantages of using these

stoves.

This research will be conducted to compare and

the benefits of induction stoves and gas stoves such

as the amount of energy consumption and the costs

required in their use.

2 METHODOLOGY

The testing methods that will be carried out in this

study are as follows:

a. Heating water from temperature ± 20 °C to ±

90 °C;

b. Water mass weighing ± 2500 grams;

Pratiknyo, E., Alamsyah, . and Kamil, I.

Analysis of Technical Aspects and Economic Aspects of Electrical Energy Consumption in the Induction Stove Program.

DOI: 10.5220/0011906000003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 879-883

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

879

c. Using the same time/utensil tool (for testing

induction and LPG stoves);

d. Efficiency is calculated the ratio of the

displacement of the kalor (Q = m x cp x ∆T)

with the use of real heat; and

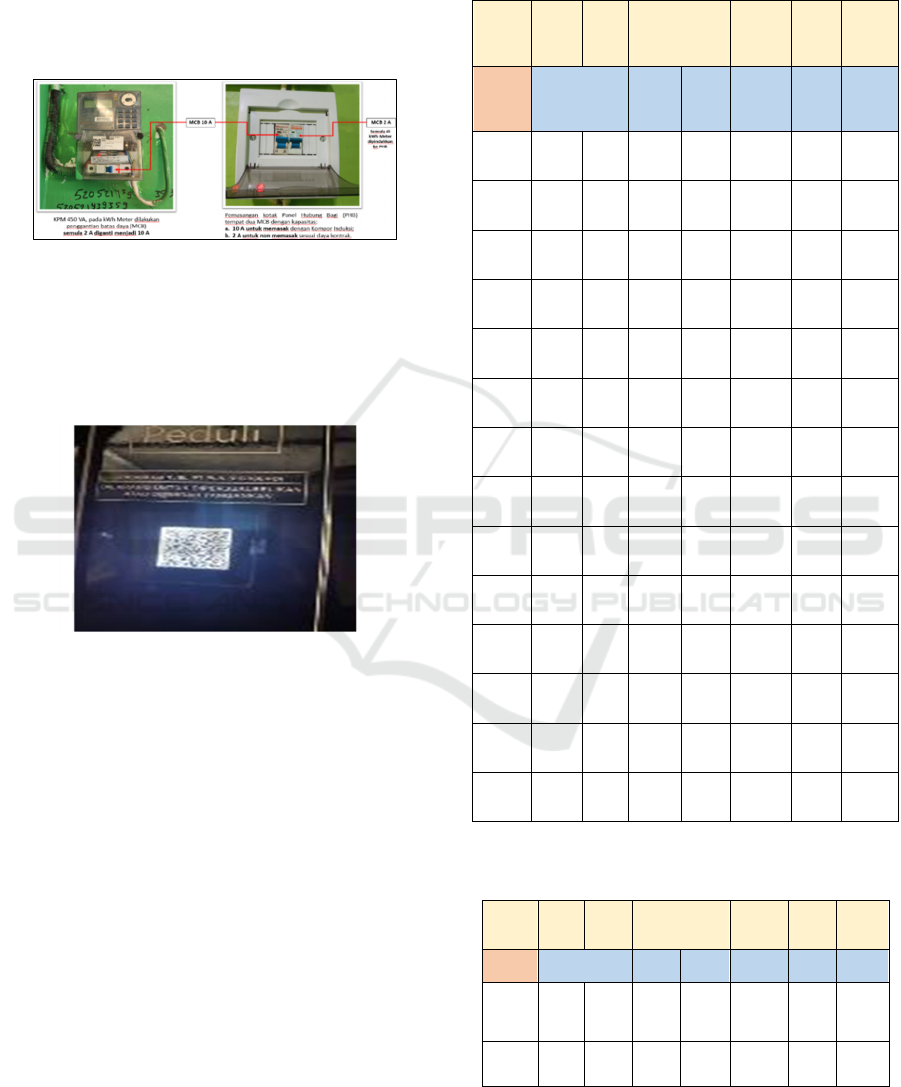

e. KPM 450 VA, on the kWh Meter was replaced

the original power limit (MCB) of 2 A was

changed to 10 A. Installation of a Split

Connect Panel box (PHB) where two MCBs

with a capacity of 10 A for cooking with

Induction Stoves and 2 A for non-cooking

according to contract power.

The stages of testing that will be carried out in this

study are as follows:

a. Induction stove measurement data collection

includes maximum power setting, maximum

rated power, time, energy consumption,

conversion, efficiency during the discharging

of the induction stove;

b. Taking gas stove measurement data includes

the mass of gas (before and after use) to

determine the magnitude of the amount of heat

used and data on time changes; and

c. Comparative Measurement of Energy Use and

Cost Results on Induction Stoves and Gas

Stoves on customers of 450 VA power and

900 VA power.

2.1 Equations Used in the Study

2.1.1 Effort or Electrical Energy

Effort or electrical energy can also be expressed in the

following, equation:

W = V.I.t (1)

Where:

I = Strong electric current (amperes)

V = Potential difference (volts)

t = time (second)

W = Electrical effort or energy (Watt.second or Joule)

2.1.2 Thermal Energy (Heat)

If a substance or object undergoes a change in shape

or form at a fixed temperature, a certain amount of

heat is needed in the process. The magnitude of the

required amount of heat can be expressed in the

following equation:

Q = m.L (2)

Where:

Q = Amount of heat released or absorbed (Joule)

m = Mass of an object or substance (kg)

L = The amount of heat released/absorbed any change

in the shape or form of a substance per unit mass or

can also be referred to as Heating Value (Joule/Kg).

2.1.3 Efficiency

Efficiency is calculated by comparing the heat

transfer with the use of real heat.

Q = m x cp x T (3)

Where:

Q = Heat needed or released

M = mass

Cp = calorific type of substance

∆T = the difference between the initial temperature

and the final temperature.

2.2 Equipment Specification on

Induction Stove Testing

1. Type/Brand of Induction Stove: Induction Stove

1 Furnace (@ 1,000 Watt).

a. Maximum Power: 1200 Watt -2000 Watt

b. Customer Electrical Power: 450 VA and 900

VA

c. Basic Electricity Tariff: Rp. 160/kWh and

1,352/kWh.

Figure 1: Induction stove 1 furnace.

2. Type/Brand of Induction Stove: Induction Stove

2 Furnace (@ 1,800 Watt + 1,000 Watt).

a. Maximum Power: 1200 Watt - 2000 Watt.

b. Customer Electrical Power: 450 VA and 900

VA.

c. Basic Electricity Tariff: Rp. 160/kWh and

1,352/kWh.

Figure 2: Induction stove 2 furnace.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

880

3. Replacement Power limit: KPM 450 VA, on

kWh Meter is done replacement of the power

limit (MCB).

a. MCB I: 10 A for cooking with Induction

Stove;

b. MCB II: 2 A for non-cooking according to

contract power.

Figure 3: Replacement of the KPM Power Meter to KPM

Power Limit 450 VA (ESDM, 2022).

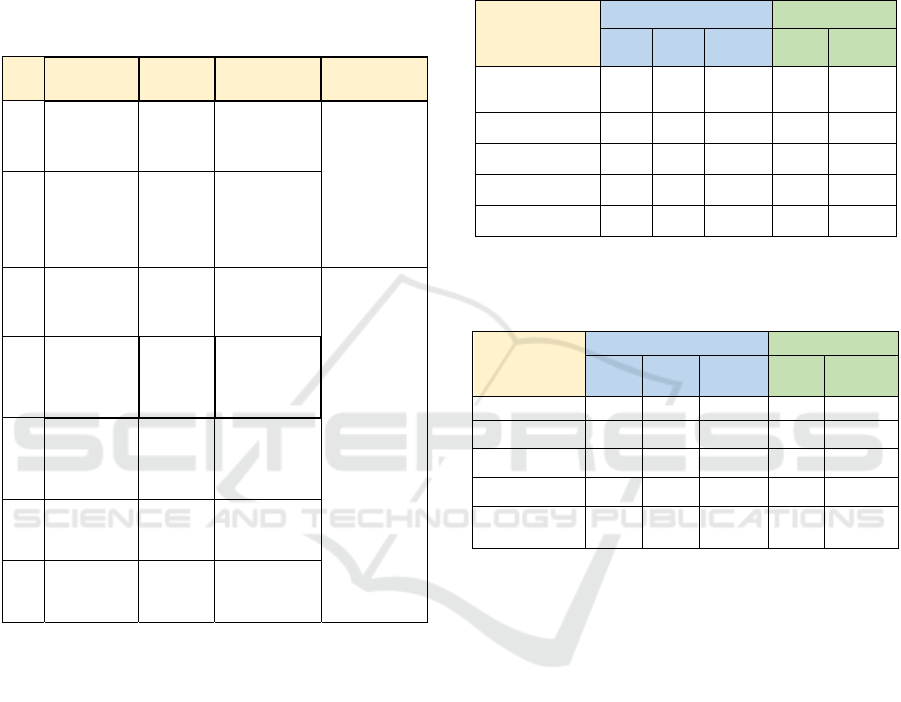

4. The IoT module for reading induction cooker

electricity consumption provides information on

kWh usage data by bluetooth or Scan QRcode

on each induction cooker that can be monitored.

Figure 4: The IoT feature of reading electricity

consumption on an induction cooker (ESDM, 2022).

2.3 Equipment Specifications on Gas

Stove Testing

1. Type/Brand of Gas Stove: Gas Stove 1 Furnace.

2. Gas Cylinder Mass Before use: 8 Kg.

3. Gas Content/Composition: 30% Propane and 70%

Butane.

4. Price of 3 kg LPG gas: Rp.21.000 (subsidized).

3 RESULTS AND DISCUSSION

3.1 Induction Cooker Testing

Testing on induction stoves was carried out as many

as 13 times measurements with different stove power

(ESDM, 2022). Measurements are carried out with

measurement parameters as described in the table

below.

Table 1: Testing data of 1 furnace induction stove with a

power of 1,200-2,000 watts.

Brand

Max

Power

settin

g

Max

Pow

er

r

ate

d

Time T20-

T90

Energy

Consu

mption

Conv

ersion

Efficien

c

y

Stove

1

Furnac

e

Watt kWh Kcal

Stove

A

1200 1200

14

minute

s

10

secon

ds

0,279 242 72%

Stove

B

1300 1230

13

minute

s

53

secon

ds

0,273 235 75%

Stove

C

1300 1294

13

minute

s

15

secon

ds

0,275 237 74%

Stove

D

1500 1292

13

minute

s

42

secon

ds

0,289 249 71%

Stove

D1

1500 1621

9

minute

s

24

secon

ds

0,252 216 81%

Stove

E1

1600 1548

10

minute

s

26

secon

ds

0,265 228 77%

Stove

D2

1800 1828

8

minute

s

23

secon

ds

0,254 218 80%

Stove

E2

1800 1759

8

minute

s

58

secon

ds

0,256 221 79%

Stove E 2000 1918

8

minute

s

12

secon

ds

0,250 215 81%

Stove

F

2000 1879

8

minute

s

40

secon

ds

0,270 228 77%

Stove

G

2000 1916

8

minute

s

38

secon

ds

0,268 231 76%

Stove

H

2000 2025

7

minute

s

56

secon

ds

0,261 225 78%

Stove I 2000 1903

8

minute

s

16

secon

ds

0,257 221 79%

LPG

10

minute

s

58

secon

ds

0,0347

kg

391 45%

Table 2: Testing data for 2 furnaces induction stoves with 2

x 2000 watts of power.

Brand

Max

Power

setting

Max

Power

rated

Time T20- T90

Energy

Consump

tion

Conver

sion

Efficien

cy

Stove 2

Furnace

Watt kWh Kcal

Stove

AB

(@1000

W)

2 x

1000

Watt

1988

21

minutes

35

seconds

0,680 585 60%

LPG

10

minutes

58

seconds

0,0347 kg 391 45%

Analysis of Technical Aspects and Economic Aspects of Electrical Energy Consumption in the Induction Stove Program

881

3.2 Comparison of Test Data for a 1

Furnace Induction Cooker with a

Power of 1,200 – 2,000 Watt

Comparison of test data for a 1 furnace induction

stove with a power of 1,200 - 2,000 Watts (ESDM,

2022) as described in the table below.

Table 3: Comparison of 1 furnace induction stove test data

with power 1,200-2,000 Watts.

No. Parameters

Stove

LPG 3 kg

Induction

Cooker

Information

1.

Time

required to

cook

10

minutes

8 minutes

(Power

1,800 Watts)

Induction

Stove faster

cooking

boiling

water 90 °C

compared

to 3 kg LPG

Tube stove

2.

Energy

Consumpti

on

391

Kcal.

218-221

Kcal

3.

Monthly

energy

consumption

11.4 Kg

82 kWh

(equivalent

to 11.4 Kg)

The cost of

cooking with

an induction

stove is more

efficient than

a 3 Kg LPG

stove

4.

Cooking

Costs

Power 450

VA

Rp.

79.800/

month

Rp.34.030/

month

5.

Cooking

Costs

Power 450

VA

Rp.

79.800/

month

Rp.49.610/

month

6.

450 VA

cook cost-

effective

-

Rp45.770/

month

7

900 VA

cook cost-

effective

-

Rp30.190/

month (Gol

900 VA)

3.3 Average User of Subsidized

Household Induction Stove

Data on the average household cooking per day 2-

furnace induction stove is 2 hours on per day (ESDM,

2022).

So the data on the average monthly use of an

induction cooker for cooking are: (2 JN x 1,8 kw x 30

days x 0,76) = 82 kWh. Where: 1.8 kw is the optimal

power capacity of induction cooker discharging 2

furnaces.

3.4 Comparison of Energy Use Results

and Costs on Induction Stoves and

Gas Stoves on Customers of 450 VA

Power and 900 VA Power

The comparison results of the calculation of energy

consumption and costs on induction stoves and gas

stoves on customers of 450 VA power and 900 VA

power are shown in the following table.

Table 4: Data on the results of the comparison of energy

consumption and costs on induction stoves and gas stoves

on customers of 450 VA power and 900 VA power from the

consumer side.

Consumer Side

Induction cooker LPG 3 kg

Group

450 VA

Group

900 VA

Unit Massive Unit

Energy

consumption/month

(

e

q

uivalent

)

82 82 Kwh 11.4 Kg

Energy prices in

consumers

415 605 Rp/kWh 7.000 Rp/kg

Cooking cost per

month

34,030 49,610 Rp/month 79,800 Rp/month

Save on cooking

costs

45,770 30,190 Rp/month

Break Even Point

(BEP)

2,7 4,1 Year

Table 5: Data on the comparison of energy use and costs on

induction stoves and gas stoves for customers with 450 VA

power and 900 VA power from the APBN side.

State Budget Side

Induction cooker LPG 3 kg

Group

450 VA

Group

900 VA

Unit Massive Unit

Economic pricing 1,640 1,640 Rp/kWh 17,208 Rp/kg

*)

Subsidized Energy

Prices

415 605 Rp/kWh 4,250 Rp/kg

Subsidies per

volume

1,225 1,035 Rp/kWh 2,958 Rp/kg

Subsidies per

month

100,411 84,831 Rp/month 147,721 Rp/month

Save on subsidies

compared to 3kg

LPG

7,310 62,890 Rp/month

4 CONCLUSIONS AND

SUGGESTIONS

Based on the research that has been carried out, it can

be concluded that:

The use of induction stoves with a design of 2

furnaces (1,000 Watts and 1,800 Watts) (ESDM,

2022), then:

a. The cost of cooking with an induction cooker is

IDR 45,770/month for a household with a 450

VA power group compared to using a 3

kilogram tubes gas stove with liquefied

petroleum gas; and

b. The cost of cooking with an induction cooker is

IDR 30,190/month for a household with a power

of 900 VA power group compared to using a 3

kilogram liquefied gas fuel stove;

The use of energy on induction stoves can replace 3

kilogram tubes LPG gas stoves, this is from the

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

882

results of research to save subsidies compared to 3

kilogram LPG, then:

a. The cost of cooking with an Induction Cooker

can save more in subsidies of IDR.

47,310/month for 450 VA power group

households; and

b. The cost of cooking with an Induction Cooker

can save more in subsidies of IDR.

62,890/month for 900VA power group

households.

REFERENCES

Azzahra, S., Azis, H., Sitorus, M. T. B., & Pawenary, P.

(2020). Uji Performa Kompor Induksi dan Kompor Gas

Terhadap Pemakaian Energi dan Aspek

Ekonomisnya. ENERGI & KELISTRIKAN, 12(2), 149-

155. ESDM 2022, Energy Policy, August 1, 2022;

Center for LKFT Studies., Universitas Gajah Mada. (2022).

Study of the Potential for Foreign Exchange Savings

and Subsidies by Transferring LPG Utilization to

Induction Stoves. January 19, 2022;

Dimas Cahyo Kumolo., (2021). Induction Stove

Performance Test. downloaded on October 25, 2021

athttps://dspace.uii.ac.id/handle/123456789/28028;

UP2M UI., (2020). Study of Jabodetabek Community

Perceptions of Induction Stoves. October 25, 2020;

Rahma, N., (2018). Design of Electrical Energy Use

Monitoring Equipment Using Power Meter and

Mivicon 11.3 Software at PT Mannasatria Kusumajaya

Perkasa, Journal of Electrical Systems POLINEMA

Vol. 7 No. 1, ISSN: 2407-232X, E-ISSN: 2407-2338;

Hasanah., (2016). Comparison of energy efficiency and

costs in induction stoves against electric stoves and gas

stoves;

Koko, H., (2016). Smart Meter to Monitor and Identify

Electrical Energy Consumption in the Household

Sector Using Neural Network Backpropagation,

Department of Electrical Engineering, Paper Faculty of

Industrial Technology, Sepuluh Nopember Institute of

Technology (ITS).

Analysis of Technical Aspects and Economic Aspects of Electrical Energy Consumption in the Induction Stove Program

883