Feeder Automation Simulation Method and System Based on

LabVIEW

Jinliang Wang

1

, Xinting Luo

2

, Baolin Kang

1

and Tianhao Wang

3

1

State Grid of China Technology College, Shandong College of Electric Power, Jinan, China

2

Taishun branch of Wenzhou Tusheng power supply service Co., Ltd, Wenzhou, China

3

School of Automation and Electrical Engineering, Linyi University, Linyi, China

Keywords: Feeder Automation, System Simulation, Training and Teaching, Software.

Abstract: Based on LabVIEW software, a feeder automation simulation method and system are developed in this

paper, which truly simulates the feeder automation process and realizes the interaction with users, and is

used for the teaching and promotion of distribution automation. In this system, three programs

corresponding to the three modes of feeder automation "voltage time type", "current concentration type" and

"intelligent distribution" are made to simulate and reproduce. It shows the process of fault location, fault

isolation and power supply recovery under the condition of circuit accident.

1 INTRODUCTION

With the development of distribution automation,

the quality and efficiency of system operation are

improved, and unnecessary waste of human

resources is effectively avoided, thus saving the

economic cost of power enterprises to a certain

extent. Using automatic control technology to

manage power supply and distribution system is an

inevitable trend of social development. Therefore,

the power supply and distribution system continue to

develop and improve with the progress of various

power technologies (Gao., 2017). The power supply

and distribution system need to continuously

improve the automation service level. Feeder

automation is the foundation and most important to

realize it (Zhou et al., 2019). It is the key to

understand its role and function and in novate the

feeder automation function (Ju., 2021). The teaching

knowledge of distribution automation is the

cornerstone of development.

At present, the school's power distribution

automation courses mainly focus on theoretical

teaching and PPT viewing. In the teaching of feeder

automation in distribution automation, the principle

is explained and the form of describing the fault

handling process when three types of feeder

automation lines have permanent faults is adopted,

so that users can understand the difference and fault

handling process of the three types of feeder

automation. This traditional method is difficult to

understand, boring and uninteresting.

2 OVERALL SYSTEM DESIGN

In order to solve the technical problems in the above

background technology, this paper provides a feeder

automation simulation method and system, which

not only truly simulates the feeder automation

process, but also realizes the interaction with users,

which is helpful to the teaching and promotion of

distribution automation (Xu., 2017). A feeder

automation simulation system is established by

using the graphical development environment

LabVIEW and a simulation method is provided

(Wang,. 2006). Some basic principles and teaching

methods of feeder automation are studied (Chen,.

2018).

Figure1 is a schematic diagram of a feeder

automation simulation system. The whole system

covers the following aspects:

Three circuit models of feeder automation;

Time limit judgment;

Fault setting judgment;

Switch state control;

Process output;

Data dump;

342

Wang, J., Luo, X., Kang, B. and Wang, T.

Feeder Automation Simulation Method and System Based on LabVIEW.

DOI: 10.5220/0011924700003612

In Proceedings of the 3rd International Symposium on Automation, Information and Computing (ISAIC 2022), pages 342-347

ISBN: 978-989-758-622-4; ISSN: 2975-9463

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Sound output.

Figure 1: Schematic diagram of a feeder automation

simulation system.

3 DESIGN OF FEEDER

AUTOMATION SYSTEM

3.1 User Interface Overview

The simulation platform interface is divided into

four types: main interface, voltage time type, current

concentration type and intelligent distribution. The

main interface is the introduction interface of the

system as shown in the figure, which clearly

explains the three categories of feeder automation.

The remaining three interfaces are all operation

interfaces.

Figure 2: Simulation platform interface.

3.2 System Design

3.2.1 Three Circuit Models of Feeder

Automation

Through the three types of current concentration

type, voltage time type and intelligent distributed

feeder automation, the model is made to show that

the current type terminal needs reliable

communication and accurate analysis and

calculation to complete fault location, the voltage

type switch needs reclosing of the outgoing line

switch to coordinate fault location, and the voltage

time type needs to pass "N" for fault location.

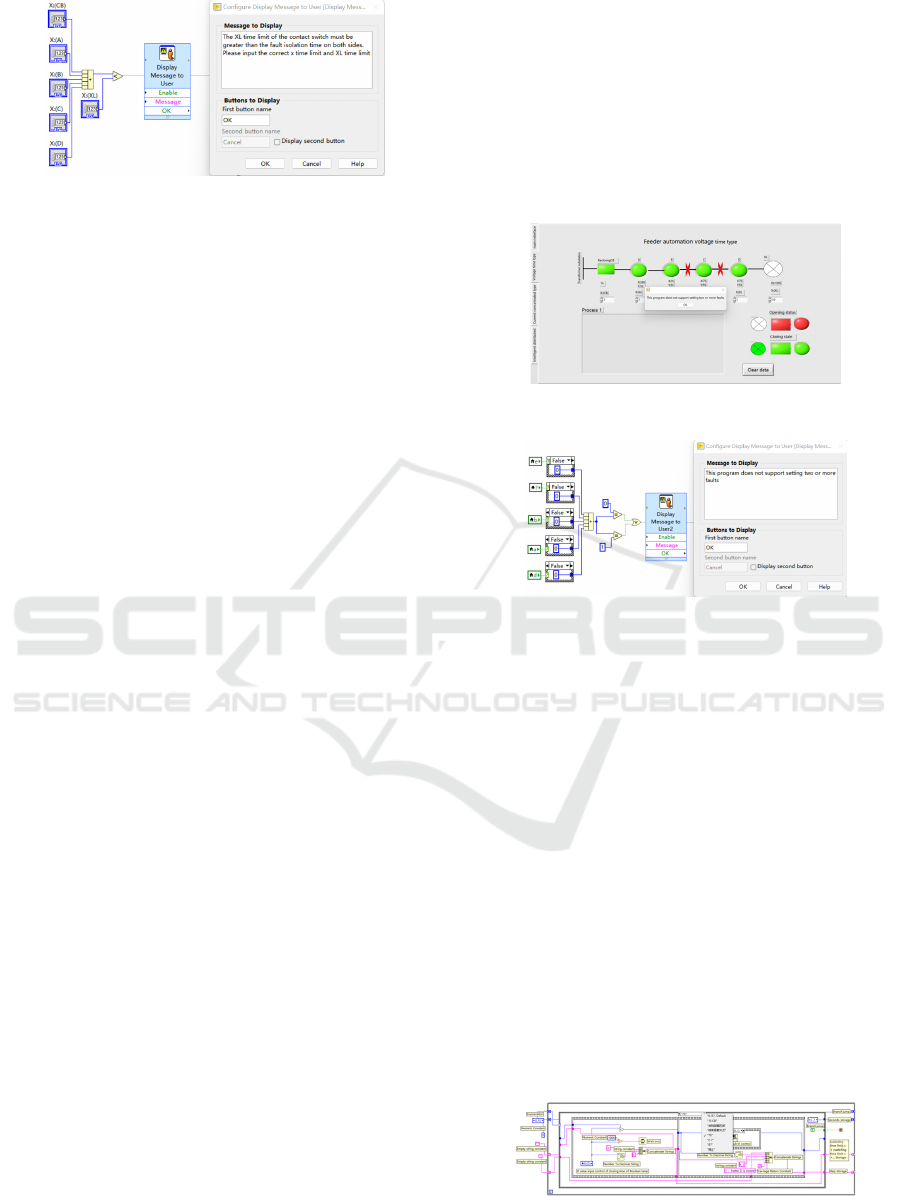

3.2.2 Time Limit Judgment

As shown in Figure 3, input the closing time limit

set by the reclosing CB and load switches A, B, C

and D into the composite operation control of the

programmed value, perform the operation of adding

the values to obtain the sum of the added values, and

input the less than control compared in the

programming together with the closing time limit set

by XL representing the interconnection switch to

perform the value comparison operation, Judge

whether the voltage time type simulation parameters

input by the user meet the requirements. If so,

execute the switch state control; otherwise, return

the prompt information.

Since the time limit judgment is a unique

condition of the voltage time type, the above

purpose is to judge by adding values, so as to meet

the judgment condition that the time limit of the

interconnection switch XL is greater than the fault

isolation time on both sides. The system can only

operate when the time limit of the contact switch XL

is greater than the sum of the time limits of each X,

otherwise a prompt message will pop up. For

example, the dialog box "the time limit of the

contact switch XL must be greater than the fault

isolation time on both sides, please input the correct

x time limit and XL time limit" will pop up, as

shown in Figure 4 / 5.

Figure 3: Voltage time type feeder automation interface.

Figure 4: Unreasonable time limit setting.

Feeder Automation Simulation Method and System Based on LabVIEW

343

Figure 5: Judgment method and output result of time limit

setting.

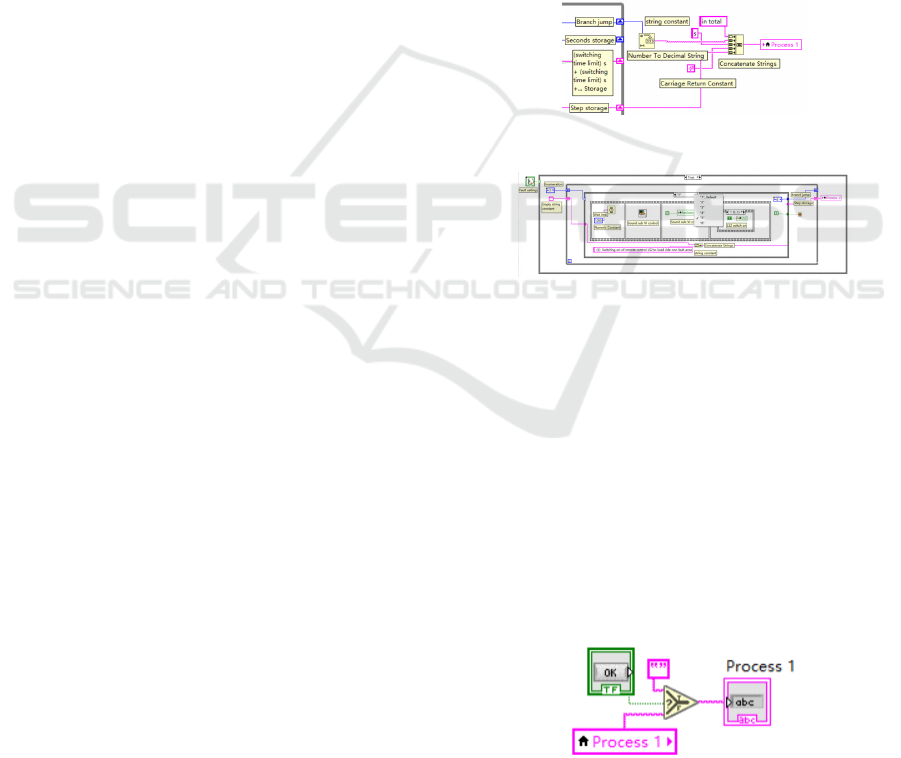

3.2.3 Fault Setting Judgment

Since the fault setting judgment of the three feeder

automation systems is the same, the voltage time

type is taken as an example (Chen,. 2017). As shown

in Figure 6, there are five switch Boolean lamps, the

first switch Boolean lamp, the second switch

Boolean lamp, the third switch Boolean lamp, the

fourth switch Boolean lamp and the fifth switch

Boolean lamp, and fault Boolean lamps are arranged

between them, which are represented by "line" or

"line fork", wherein "line fork" indicates that the

fault Boolean lamp is on, and "line" indicates that

the fault Boolean lamp is not on, as shown in Figure

6, There are five fault Boolean lights in total, and

two fault Boolean lights are on. The user can set the

fault by clicking the fault Boolean lamp to control

the lighting of the fault Boolean lamp.

As shown in the left figure of Figure 7, input the

on and off states of the five fault Boolean lamps into

the condition structure to judge whether they are on

or off. The operation is in the form of assignment of

on to 1 and off to 0. After the on and off results of

each fault Boolean lamp are obtained as 1 or 0, input

them into the compound operation control of the

value in the program to add and sum up. The sum is

determined as 0 or 1 in combination with the control

compared in the program to obtain the result, Judge

whether the voltage time type fault information set

by the user meets the requirements (Chen,. 2014). If

so, execute the switch state control step; otherwise,

return the prompt information.

As shown in the left figure of Figure 7, the

leftmost part is the local variable of the fault

Boolean lamp. This fault Boolean lamp is used for

fault setting. When the fault Boolean lamp is on, it is

in fault state. When it is not on, it is displayed in the

form of "line" and is in normal operation state. The

fault setting judgment is to prevent two or more fault

settings. The fault setting judgment consists of

conditional structure, compound operation and or

Boolean. If two or more faults are set, the composite

operation sum is not equal to 1 or 0, and a prompt

message will pop up. For example, the dialog box

"this program does not support setting two or more

faults" will pop up, as shown in the right figure of

Figure 7.

Fault setting: the system sets the fault condition

through the on and off state of the fault Boolean

lamp. In the program block diagram, while cycle,

condition structure and sequence structure are used

to show the fault location and fault interval isolation

of feeder automation in case of fault.

Figure 6: Unreasonable fault setting.

Figure 7: Judgment method and output result of fault

setting.

3.2.4 Switch State Control

As shown in Figure 8, based on the time limit of the

first switch Boolean lamp, the second switch

Boolean lamp, the third switch Boolean lamp, the

fourth switch Boolean lamp, the fifth switch

Boolean lamp and the sixth switch Boolean lamp

and the set voltage time type fault information,

combined with the voltage time type switching

control method of power distribution automation,

The working process of each switch in case of

permanent fault in distribution automation voltage

time type is shown.

The switch is controlled in the selector, and the

Boolean light of the switch is controlled to be on and

off through constant assignment of True / False,

which represents the opening and closing state of the

switch in the feeder automation system.

Figure 8: Schematic diagram of switch control state

program block diagram.

ISAIC 2022 - International Symposium on Automation, Information and Computing

344

3.2.5 Process Output

As shown in Figure 9, based on each branch of the

conditional structure, the state of each switch

Boolean lamp (step storage), branch jump, closing

time of each switch Boolean lamp (1s + 1s +...

Storage) and the sum of closing time limit (X time

limit) of each switch Boolean lamp (seconds

storage) are stored through the while cycle, and

combined with the numerical constant, string

constant Numeric conversion string control, enter

key constant control and connection string control,

connect the string into a paragraph, get the feeder

automation simulation process, and then output it to

the process string display control.

Where in the branch is a branch of a conditional

structure. Take the 123456 branch shown in Figure

10 as an example, because the conditional structure

branch in the LabVIEW system is true or false by

default. In order to achieve the goal of branch jump,

the implementation method is as follows: first, start

enumerating. There are added items in the

enumeration. A total of 6 items are added, and each

item is named with 1, 2, 3, 4, 5 and 6; Connect the

completed enumeration to the branch selector of the

conditional structure, the default branch of the

conditional structure will become 1, and then add

branches until there are six branches of the

conditional structure, and ensure that the names of

the six branches are 123456 in turn; Wrap a while

loop on the condition structure, delete the

connection between the condition structure and the

branch selector, add a shift register (left and right

two are a pair), connect the enumeration to the shift

register (left), and then connect the shift register to

the branch selector of the condition structure. At this

time, ensure that the enumeration item is 1, so as to

ensure that the program starts in the branch structure

with 1 first; To achieve the effect of branch jump,

copy the same enumeration again, and connect the

item of the enumeration with 2 to the shift register

(right); In the branch structure named 2, the item of

the enumeration connected to the shift register

(right) is 3, and so on, so as to achieve the result of

each branch jump.

The process output converts the string and value

stored in the while loop into a string and connects

them through a connection string. While loop is a

storage function with four functions: the first is to

control each branch of the condition structure

through while loop; The second is to record the total

time of the process from the beginning of the fault to

the end of the fault after the line fault; The third

stores the response time of each switch; The fourth

is to store the whole process, for example, the

process shown in the voltage time type:

13s in total;

In case of accident, CB trips, line loses voltage,

and contact switch starts timing;

1s (1s): switch CB is closed;

2s (1s + 1s): switch A is closed;

3s (1s + 1s + 1s): switch B is closed;

When the power is supplied to the fault section,

the substation will trip again, the line will lose

voltage, and the switch B and switch C will be

locked;

4s (1s + 1s + 1s + 1s): switch CB is closed;

5s (1s + 1s + 1s + 1s + 1s): switch A is closed;

6s (1s + 1s + 1s + 1s + 1s + 1s): Contact switch

XL is closed;

7s (1s + 1s + 1s + 1s + 1s + 1s + 1s): switch D is

closed.

Figure 9: Schematic diagram of process string output.

Figure 10: Schematic diagram of branch jump description.

3.2.6 Data Dump

As shown in Figure 11, if you click the OK button

Boolean control based on the selection control in the

comparison, the empty string constant will be output

in the process display control to obtain the result of

the blank process display control. On the contrary, if

you do not click, the result of the original process

display control will be obtained.

Data clearing consists of process display control

and OK button. If you click OK, the data will be

cleared; if not, the data in the process will be

retained.

Figure 11: Schematic diagram of data clearing program

block diagram.

Feeder Automation Simulation Method and System Based on LabVIEW

345

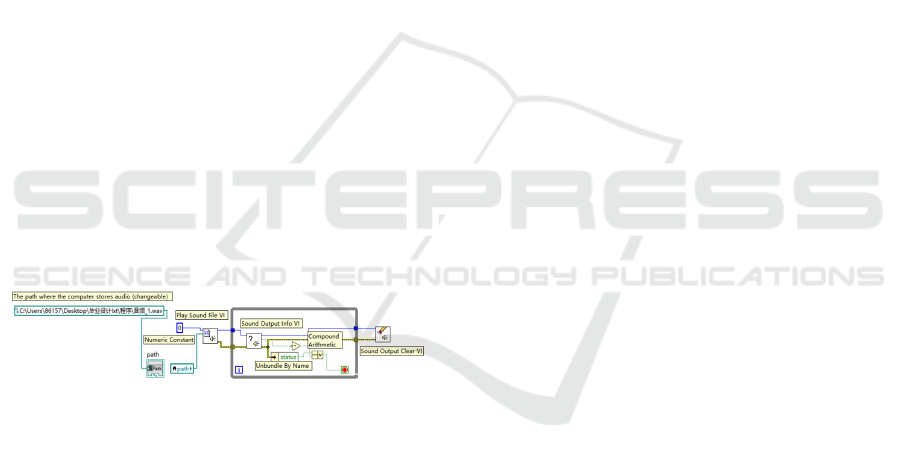

3.2.7 Sound Output

As shown in Figure 12, open the program block

diagram of the sound sub VI, copy and paste the

path where the sound wav file is located, and get the

result of pasting the path into the path constant of

the file constant. Based on the status of each switch

Boolean in the switch state control, combine the

while loop, play the sound file, sound output

information, unbind by name, non-comparison

control, compound arithmetic control and sound

make to sound output.

Sound output is a sub virtual instrument (VI),

which consists of two parts, one is the path, and the

other is the program for writing and output; the

sound path is variable. The left figure in Figure 12 is

a schematic diagram of the sound path of a

computer. After changing the computer login

program, first open the sound sub VI, write the path

of the sound in the path string, and then open the

main program to start the operation. The output

sound is the sound of the disconnector closing.

When the switch is closed or separated, the sound

will be emitted first, which can better simulate the

opening and closing of the circuit. This output is

reflected in VI. put the sound in the file. Because the

path of the sound is different in each computer, the

VI should be heard first when running the program.

Enter the path text into the path, and then run the

program.

Figure 12: Flow diagram of sound sub VI.

3.3 Storage Devices and Media

The feeder automation simulation system is

developed based on LabVIEW software and requires

a computer-readable storage medium, in which a

computer program is stored. When the program is

executed by the processor, the steps in a simulation

method for the three types of feeder automation

described above are realized. There is also a need for

a computer device, including a memory, a processor,

and a computer program stored on the memory and

executable on the processor. When the processor

executes the program, it realizes the steps in a feeder

automation simulation method as described above.

4 DESCRIPTION

The system is divided into three steps:

Step 1: in response to the user's main interface

selection instruction, after entering the main

interface, in response to the user's mode click

instruction, obtain and display the stored operation

state diagram of the corresponding mode. Figure 2

shows the main interface corresponding to the main

module of the feeder automation simulation training

system of the present invention. The right side of the

main interface is composed of three determination

buttons, namely "voltage time type", "current

concentration type" and "intelligent distribution".

User can obtain the mode selection instruction by

clicking the corresponding determination button.

The system stores the operation state diagram

corresponding to each mode, as shown in the left

side of Figure 2.

Step 2: in response to the selected feeder

automation mode (voltage time type, current

concentration type or intelligent distribution), return

to the graphical interactive interface (intelligent

distributed interface, voltage time type interface or

current concentration type interface) corresponding

to the selected feeder automation mode with the

connection relationship between the switch Boolean

lamp and the fault Boolean lamp; Obtain the user's

click instruction for each fault Boolean lamp in the

graphical interactive interface and return to the

interactive interface for display to obtain the status

(fault information) of all fault Boolean lamps.

Step 3: input the states of all fault Boolean lights

into the composite operation control for addition and

summation, and judge whether the states of all fault

Boolean lights meet the requirements according to

the summation results. If the requirements are not

met, a prompt message is returned. If the

requirements are met, based on the status of all fault

Boolean lamps, the switch status control under the

corresponding mode is carried out to obtain the

status of each switch Boolean lamp and the feeder

automation simulation process to display the feeder

automation simulation results.

5 CONCLUSIONS

A feeder automation simulation method and system

based on LabVIEW software are proposed, and the

functions of the software platform are given. Based

on the simulation system, three modes of feeder

automation can be simulated, and the purpose of

ISAIC 2022 - International Symposium on Automation, Information and Computing

346

teaching and promoting distribution automation can

be achieved while interacting with users.

REFERENCES

Zhixin Zhou(2019). Development trend of automatic

control of power supply and distribution system.

Electronic technology and software engineering, 2019

(11): 153-154.

Xiangrong Gao(2017). Development trend of power

supply and distribution system in automation control.

Electronic testing, 2017 (1): 91-92.

Hao Ju, Hongwei Jia, et al(2021). Design of feeder

automation simulation platform. Scientific and

Technological Innovation Information, 2021(3):56-57.

Biao Xu(2017). Discussion on feeder Automation of

Distribution Automation. Construction engineering

technology and design, 2017(10):3676-3676.

Ye Wang(2006). Application of LabVIEW in Power

system. Xidian University, 2006.

Jianlin Chen(2018). Research on feeder automation

analysis platform based on LabVIEW. Shandong

University of Technology, 2018.

Jianlin Chen, Shulian Yang(2017). Implementation of

improved Fault location algorithm based on LabVIEW.

Shandong Industrial Technology, 2017(21):135-136.

Jiming Chen, Zhihua Ji, et al(2014). Design of Relay

Protection experiment system based on LabVIEW.

China Electric Power Education, 2014,(35).

Feeder Automation Simulation Method and System Based on LabVIEW

347