Stability of Circular Toroidal Shell Subjected to Uniform External

Pressure

Chengyuan Zhou and Shijie Su

Jiangsu University of Science and Technology, Zhenjiang, Jiangsu 212003, China

Keywords: Circular Toroidal Shell; Stability; Numerical Calculations; Shell Unit; Solid Unit.

Abstract: In this paper, the theoretical and numerical analysis methods for the stability of circular torodial shells under

external pressure are studied. Effects of unit type, unit density and boundary condition on the stability analysis

of circular toroidal shell are discussed. A reasonable method for establishing analysis model is proposed. The

theoretical and numerical solution are compared with the experimental value. The results show that the

numerical solution is consistent with the experimental result, while the theoretical solution calculated by the

Jordan’s formula has a large deviation.

1 INTRODUCTION

The circular toroida shell structure is widely used in

various industrial fields, such as underwater pressure

shells, reservoirs, tokamak devices, etc. The circular

toroida shell solved the problem of the overall

arrangement of space and personnel connection, thus

it became the main structural form in the underwater

space station.

Since the 1960s, the problem of the bowing of the

circular toroidal

shell has begun to receive attention.

Machnig first researched the buckling problem of a

circular toroidal shell under hydrostatic pressure in

1963. L.H. Sobel by expanding the buckling

displacement component along the direction of the

ring and meridian direction as a double triangle

number (

Flügge W, and Sobel, L. H,1965), the

stability equation of the circular toroidal shell under

uniform external pressure is processed, the stress state

before buckling is obtained by the no moment

solution. Fishlowitz, et al., proved that for less thin

ring shells, the buckling mode is rotationally

symmetric and antisymmetric to the equatorial plane

(

Fishlowitz,E.G,1972). Jordan derived the formula

for calculating the critical pressure based on the DMV

equation of the shallow shell (

Jordan,P.F,1973). Cui

and Du et al researched the stability of circular

toroidal shells by means of theoretical analysis,

numerical simulation and experimental verification

(

Du , 2015; Du, 2010).

Due to the complexity of the circular toroidal shell

structure itself, for its buckling problem, there is no

comprehensive and uniform standard. With the

development of simulation technology, scientists

have begun to use more and more methods of

numerical analysis and experimental verification to

conduct study. However, due to different constraints,

unit type, unit density, mesh generation and solution

methods are chosen by operators in numerical

analysis, it will lead to the results of numerical

analysis far apart.

In this paper, the stability of the circular toroidal

shell under external pressure was studied from

theoretical analysis and numerical calculation. The

buckling load prediction formula (Jordan formula) of

circular toroidal shell was analyzed and its

characteristics and applicability were studied;

numerical models of shell unit and solid unit of

toroidal shells were established to research the effects

of unit type, unit density and boundary conditions on

the stability of circular toroidal shell; different

thickness ratio t/r the circular toroidal shells were

established to analyze and compare the numerical

calculation results of the buckling load with the

calculation results of the Jordan formula.

Zhou, C. and Su, S.

Stability of Circular Toroidal Shell Subjected to Uniform External Pressure.

DOI: 10.5220/0011925300003536

In Proceedings of the 3rd International Symposium on Water, Ecology and Environment (ISWEE 2022), pages 117-122

ISBN: 978-989-758-639-2; ISSN: 2975-9439

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

117

2 THEORETICAL STUDY ON

STABILITY OF CIRCULAR

TOROIDAL SHELL

2.1 Structural Parameter of Circular

Toroidal Shell

A diagram of the circular toroidal shell structure is

shown in Fig. 1, P represents the static external

pressure, φ represents the meridian direction

coordinate, r is the radius of the circle midsection of

the shell, R is the distance from the center of the circle

to the axis of rotation, t is the thickness of the circular

toroidal shell, and θ is the ring direction.

(a) C-C cross-sectional view of toroidal pressure shell

(b) Top view of toroidal pressure shell

Figure 1: Diagram of the circular toroidal shell structure.

2.2 Prediction Formula of Buckling

Load of Circular Toroidal Shell

Jordan proposed the following formula to predict the

buckling load of a circular shell (Jordan, 1973):

()

()

()

1/3

7

0

2

2

2

/

0.1738

/1

a

tr

Rr

P

ν

≈Ε

−

(1)

Where E is the modulus of elasticity and ν is Poisson's

ratio.

The eight test models in reference

were calculated

using Eq. (1) (

Fishlowitz, 1972), the results of which

are shown in Table 1. Comparing the test results of

P

e

, the errors ((P

e

- P

0a

) / P

0a

*100%) are -16%, 2%, -

5%, 4%, 4%, 12%, 32%, and 9%, respectively. It can

be seen from Table 1 that the results of the P

e

and

Jordan formulas of test models 1 and 7 are quite

different because model 1 experienced a premature

partial failure due to the existence of the exhaust pipe;

while model 7 experienced a stable post-buckling

deformation due to the small value of Rt/r

2

.

Experiments show that the Jordan formula can

effectively predict the buckling load of the circular

toroidal shell under external pressure within a certain

parameter range (Jordan,1973)

Table 1: Comparison of theoretical value P

0a

and Fishlowitz

test value P

e

(Jordan, 1973).

R/r r/t t P

0a

P

e

P

e/

P

0a

1 7.94 23.3 1.092 0.068 0.057 0.84

2 3.57 24.7 2.032 0.102 0.104 1.02

3 2.34 47.7 1.461 0.029 0.028 0.95

4 2.35 23.4 2.946 0.153 0.159 1.04

5 1.37 92.7 1.092 0.009 0.009 1.04

6 1.36 48.9 2.083 0.039 0.044 1.12

71.19

105.4

0.965 0.007 0.010 1.32

8 1.19 47.5 2.134 0.046 0.050 1.09

It is worth noting that Jordan formula is sensitive

to thickness to diameter ratio of circular shells, which

is t/r, however, if the change in thickness t occurs

away from the Gaussian curvature change point

(point C in Figure 1 (a)), the fluctuation of t will have

little effect on the buckling load (Jordan,1973). And

considering the Poisson's ratio ν is in the range [0,

0.5], and the Poisson's ratio of common metal

materials is around 0.3. Therefore, the Jordan formula

is not very sensitive to Poisson's ratio.

However, Jordan's prediction formula can’t be

generalized to the scope of thick shell, because it is

based on thin shell theory (

Galletly,1995; Jordan,

1965; Jordan, 1966

); even in the scope of thin shells,

the scope of the Jordan formula is also limited, when

Rt/r

2

is small, the calculation result is necessarily

conservative (

Jordan, 1973). Therefore, it is still

necessary to analyse the stability of the circular

toroidal shell under external pressure by using

numerical analysis.

3 NUMERICAL ANALYSIS OF

STABILITY OF CIRCULAR

TOROIDAL SHELL

Considering the comparison between Fishlowitz’s

experimental and existing analysis and the

"perfectness" of the test model, the numerical

analysis model uses the parameters of the model 8 of

the Fishlowitz test. (The test value is P

e

=0.0504MPa),

the specific parameters are as follows: R=120.6mm,

r=101.3mm,t=2.134 mm,E=2240.8MPa,ν=0.4.

ISWEE 2022 - International Symposium on Water, Ecology and Environment

118

3.1 Type of Shell Unit

Creo was used to establish a three-dimensional model

of the surface structure. When modelling, the circular

toroidal shell was artificially divided into two parts

from the Gaussian curvature point, then it was

imported into ANSA for mesh division to generate an

INP file, which was finally imported into ABAQUS

(K.Hibbitt, 2006). In addition, the calculated load was

applied to the outer surface of the circular toroidal

shell with a uniform pressure. Three-dimensional

model and meshing are shown in Figure 2.

Figure 2: Three-dimensional model and meshing.

In theory, the circular toroidal shell is

unconstrained under external pressure, in order to

eliminate the rigid displacement of the model without

hindering the relative deformation (

Jian Zhang,

2015

), this paper referred to the Chinese ship

classification society's constraint on the spherical

shell and the reference

the suggestion for the

constraint position and the suggestion of applying

symmetric boundary condition or antisymmetric

boundary condition in the analysis of symmetric

structures (

Blachut,2000). The three-point constraint

and the four-point constraint with 90° symmetry of

the spherical shell were set, and the linear buckling

analysis was carried out in ABAQUS, namely

eigenvalue buckling prediction analysis. Single factor

control variable method was used to analyse the

influence of unit type, unit density, boundary

condition on the stability of the circular toroidal shell.

The traditional method that seeds were arranged

along R and r directions were used for meshing, this

method is the same as the random division method.

Unit type was selected as 4-node fully integrated

linear universal shell unit (S4), and the number of

mesh units was 53424, and the boundary conditions

of three-point constraint and four-point constraint

were set, corresponding to plan 1 and plan 2.

Unit type was set as 4-node fully integrated linear

universal shell unit (S4), 4-node reduced integral

linear universal shell unit (S4R), 4-node degree

reduced integral linear thin shell unit with 5 degrees

of freedom per node unit (S4R5), 8-node reduced

integral linear thick shell unit (S8R), 8-node degree

reduced integral linear thin shell unit with 5 degrees

of freedom per node (S8R5),the number of units is

53424, the boundary condition are all four-point

constraint, corresponding to plan 2, plan 3, plan 4,

plan 5 and plan 6.

Meshes with average sizes of 3mm, 5mm, 7mm,

9mm, 11mm, 13mm and 5mm were set to research

mesh convergence. Unit types were all S8R, The

boundary condition were all four-point constraint,

corresponding to plan 5, plan 6, plan 7, plan 8, plan9,

plan10, plan11, plan12. The above shell unit plan and

numerical analysis results are shown in Table 2.

Table 2: Shell unit plan information and numerical analysis results.

Plan Boundary condition

Number of

units

Unit

type

P

c

(MPa) (P

c

-P

e

)/P

e

(P

c

-P

0a

)/P

0a

1 three-point constraint

53424(3)

S4 0.050601 0.4% 6.14%

2 four-point constraint

53424(3)

S4 0.050601 0.4% 6.14%

3 four-point constraint

53424(3)

S4R 0.050549 0.3% 6.03%

4 four-point constraint

53424(3)

S4R5 0.050515 0.2% 5.96%

5 four-point constraint

53424(3)

S8R 0.050445 0.09% 5.81%

6 four-point constraint

53424(3)

S8R5 0.050466 0.13% 5.86%

7 four-point constraint

19456(5)

S8R 0.050473 0.15%(0.84%) 5.87%

8 four-point constraint

9720(7)

S8R 0.050517 0.23%(1.55%) 5.96%

9 four-point constraint

5880(9)

S8R 0.050576 0.35%(2.46%) 6.09%

10 four-point constraint

3944(11)

S8R 0.050652 0.50%(3.53%) 6.25%

11 four-point constraint

2784(13)

S8R 0.050749 0.69%(5.11%) 6.45%

12 four-point constraint

2100(15)

S8R 0.050865 0.92%(6.69%) 6.69%

Note: The third column of parentheses is the average size of the unit, the sixth column of brackets is the error comparison between the

numerical calculation value of S4 unit and the test result, P

c

represents the result of numerical analysis

Stability of Circular Toroidal Shell Subjected to Uniform External Pressure

119

3.2 Type of Solid Unit

The plan of the solid unit mesh can be obtained by

using the Create Bottom-Up Mesh in Mesh model in

ABAQUS, to offset the shell unit mesh alone the

thickness direction. And the material, mesh type and

boundary conditions were redefined.

The unit types were set as 8-node linear solid unit

(C3D8), 8-node reduced integral unit t (C3D8R), 20-

node complete integral unit (C3D20), 20-node

quadratic reduction integral unit (C3D20R), and 8-

node linear non-coordinating mode solid unit

(C3D8I), corresponding to plan 13, plan 14, plan 15,

plan 16 and plan 17.

Mesh sizes with average sizes of 3mm, 5mm,

7mm, 9mm, 11mm, 13mm and 15mm were set to

research mesh convergence, unit types were all

C3D20R, the boundary condition were all four-point

constraint, corresponding to plan 16, plan 18, plan 19,

plan 20, plan21, plan22, plan23. The load and

materials of all solid unit plans were consistent with

the shell unit, constraint mode was four-point

symmetric constraint, along the corresponding shell

unit, and solid unit symmetrically offset 3 layers in

the thickness direction. This above unit plan and

numerical analysis results are shown in Table 3.

Table 3: Solid unit plan and numerical analysis results.

Plan Number of units Unit type

P

c

(MPa)

(P

c

-P

e

)/P

e

(P

c

-P

0a

)/P

0a

13

160272(3)

C3D8 0.067913 34.75% 42.45%

14

160272(3)

C3D8R 0.046867 -7.01% -1.69%

15

160272(3)

C3D20 0.050621 0.44% 6.18%

16

160272(3)

C3D20R 0.050612 0.42% 6.16%

17

160272(3)

C3D8I 0.050728 0.65% 6.41%

18

58368(5)

C3D20R 0.050600 0.40%(1.02%) 6.14%

19

29160(7)

C3D20R 0.050580 0.36%(1.68%) 6.10%

20

17640(9)

C3D20R 0.050556 0.31%(2.72%) 6.05%

21

11832(11)

C3D20R 0.050892 0.98%(4.87%) 6.75%

22

8352(13)

C3D20R 0.051067 1.32%(8.03%) 7.12%

23

6300(15)

C3D20R 0.051160 1.51%(12.24%) 7.31%

Note: The second column of parentheses is the average size of the unit. The fifth column of brackets is the error comparison

between the calculated value of the C3D8I unit and the test result. P

c

indicates numerical analysis results.

3.3 Analysis of Numerical Analysis

Results

3.3.1 Shell Unit Numerical Result Analysis

Five different types of shell elements were compared

in plan 2 - plan 6, it would be found that the error

between numerical calculation results and test results

of universal shell unit (S4 and S4R), thin shell unit

(S4R5 and S8R5) and thick shell unit (S8R) is less

than 1% by comparing with Fishlowitz experimental

values, considering the precision and efficiency of

numerical calculations, S8R should be selected as the

unit type for numerical analysis of circular toroidal

shell stability under external pressure.

The numerical results of the average size of the

seven units are compared in plan 6 - plan 12 for mesh

convergence analysis, the comparison between the

numerical calculation results of some unit types and

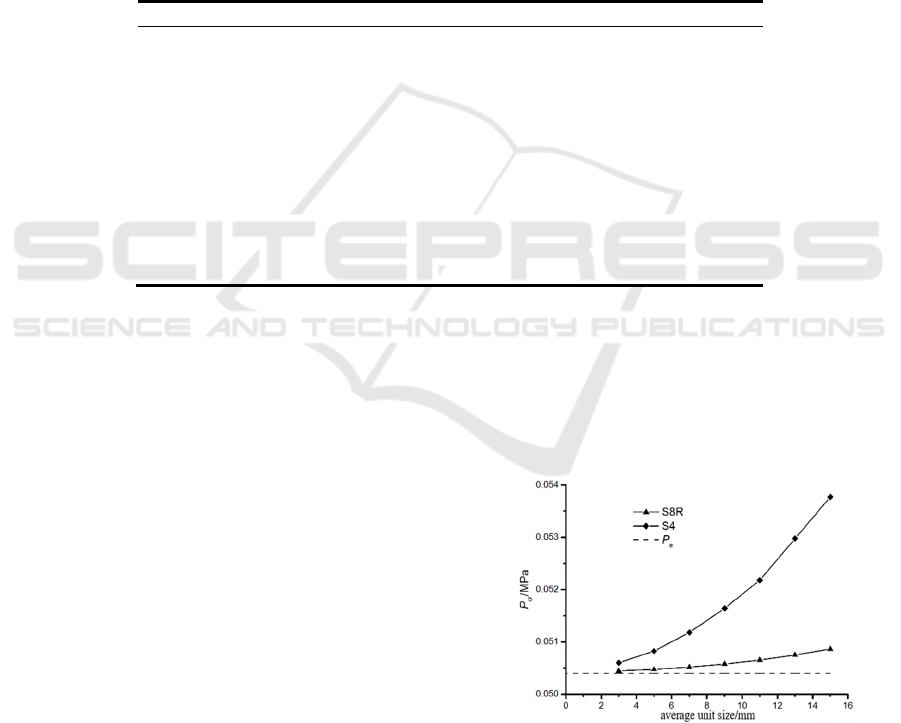

the experimental results is shown in Fig. 3.

From Table 2 and Figure 3, it can be seen that for

the S8R unit type, the mesh refinement operation has

little effect on the convergence of the numerical

analysis results, even if the division is very “rough”

mesh, such as plan 12, the error between the

numerical analysis results and the test results is still

less than 1%, the superiority of the S8R in numerical

analysis was proven again.

Figure 3: Comparison of numerical calculation results of

some unit types with experimental results.

Combined with the comparison results of the

universal shell unit S4, the unit average length is

preferred to select the two unit numerical results and

ISWEE 2022 - International Symposium on Water, Ecology and Environment

120

the test result error is less than 1% of the 5mm length

dimension. In the circular toroidal shell, since R>r, it

is more reasonable to evaluate the average size of the

unit with taking r as a reference, so, 5% of the r size

should be prioritized as average unit size for

numerical analysis of circular toroidal shell stability

under external pressure.

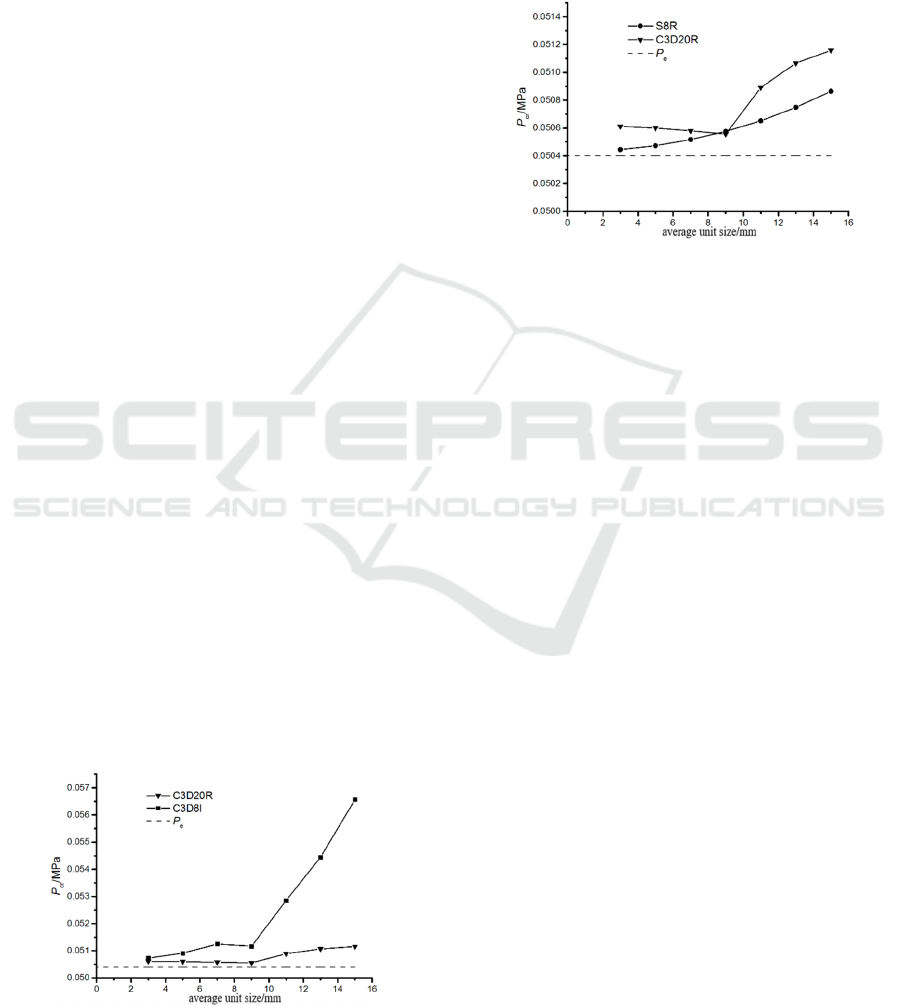

3.3.2 Solid Unit Numerical Result Analysis

By comparing plan 13 - plan 17, the results of

numerical analysis using C3D8 and C3D8R were

found to be significantly different from the

experimental results of Fishlowite, especially the

C3D8, the error was 34.75%. The numerical analysis

results using the C3D20, the C3D20R, and the C3D8I

are highly consistent with the results of using the shell

unit, the error with the results of Fishlowite

experimental was less than 1%.

Due to the huge computational workload of the

C3D20, the relative computational efficiency is much

lower than that of the C3D20R and the C3D8I,

comparison of errors with the results of Fishlowite

test, obviously, the C3D20R is the first choice for the

numerical analysis of the stability of the circular

toroidal shell under external pressure.

By comparing plan 16-plan 23, it can be found that

for the C3D20R, with mesh refinement,numerical

analysis and test results vary from large to small, then

from small to large ,the error is the smallest when the

average mesh size is 9mm, which is 0.31%.

However, considering the average size of 5mm,

the calculation error of the C3D8I unit is close to 1%

and the calculation efficiency of the unit is higher

[18]

.

It should be mentioned that in the case of a small unit

distortion (C3D8I unit is sensitive to distortion), a

C3D8I (0.05r) unit with an average size of 5mm

should be considered first; otherwise the C3D20R

unit with an average size of 9mm (0.09r) should be

chosen. The comparison between the numerical

analysis results and the test results of C3D20R unit

and C3D8I unit is shown in Fig. 4.

Figure 4: Comparison of numerical results and test results

of different unit types

.

It is worth noting that in the numerical calculation

of all shell unit types, only the calculation result of

the solid unit C3D8R is smaller than the test result.

It can be seen from Table 2, Table 3 and Figure 5,

for the thin shell type to circular toroidal shell (such

as this example), the numerical calculation accuracy

and efficiency of the shell unit are higher than the

solid unit.

Figure 5: Comparison of numerical results and test results

of shell elements and solid units.

It can find out that the error between numerical

results and experimental results was within 1% (In

addition to plan 13, 14) the results are highly

consistent by synthesizing the last two columns of

Tables 2 and 3(comparison of experimental results,

Jordan formula results with numerical results) ,the

error between the calculated value of the Jordan

formula and the experimental result is 9% (Table 1),

and the Jordan formula results are more conservative

than the numerical results, it can be seen that the

Jordan formula predicts the buckling load of the

circular toroidal shell more easily, but numerical

analysis methods are more accurate.

4 EFFECT OF PARAMETER t/r

ON STABILITY OF CIRCULAR

TOROIDAL SHELL UNDER

EXTERNAL PRESSURE

The thickness of the circular toroidal shell has a great

correlation with the buckling behavior of the shell, the

theoretical formula and numerical solution of the

buckling load of thin shell are discussed before in this

paper, and the stability analysis of thick shell circular

toroidal shell is carried out here. Its parameters are as

follows:

R=60mm, r=24mm, t=2 mm, E=2500MPa, ν=0.4,

among them , r/t=12 belongs to the thick shell

category. The results of comparing Jordan formula

are shown in Table 4.

Stability of Circular Toroidal Shell Subjected to Uniform External Pressure

121

Compared with the numerical calculation results,

the numerical calculation result of S8R unit type has

the smallest difference with Jordan formula results,

for the circular toroidal shells of the given thick shell

type, the buckling load P

cr

should be 0.88973MPa.

Comparing the numerical results of plan 1 with plan

2-5, the errors are 1.460%, 1.389%, 1.268% and

1.263% respectively. Although the error is small, it

can still be proved that even for thick-shell type

circular toroidal shells, the S8R is still suitable as a

unit type for establishing a circular toroidal shell

numerical solution under external pressure.

Table 4 solid unit plan and numerical analysis results

Plan Average size of units Unit type

P

c

(MPa)

P

0a

(MPa) (

P

c

-

P

0a

)/

P

0a

1 1.2mm(0.05

r

) S8R 0.88973 0.803688 10.71%

2 1.2mm(0.05

r

) C3D8I(2layers) 0.90272 0.803688 12.32%

3 1.2mm(0.05

r

) C3D8I(2layers) 0.90209 0.803688 12.24%

4 2.2mm(0.09

r

) C3D20R(2layers) 0.90101 0.803688 12.11%

5 2.2mm(0.09

r

) C3D20R(2layers) 0.90097 0.803688 12.10%

5 CONCLUSIONS

Comprehensive consideration of the calculation

accuracy and efficiency of numerical simulation, it is

recommended to use the S8R unit type with four-

point constraint and unit average size of 0.05r to

establish the shell unit numerical plan of the circular

toroidal shell under external pressure.

Comparing shell unit and solid unit, it is

recommended to choose a shell type in the circular

toroidal shell in the thin shell category to establish a

numerical model; for the thick shell category and the

circular toroidal shell near the boundary line

[20]

between the thin shell and the thick shell (r=20t), the

shell unit and the solid unit numerical model can be

simultaneously established, and the unit type with

smaller result is selected.

Compared with the Jordan formula, the numerical

results differ from the experimental results by a small

difference; Jordan formula can be used to predict

buckling load when t/r < 1/14, this is more efficient;

when t/r ≥ 1/14, the numerical calculation method

should be used to predict the buckling load.

ACKNOWLEDGEMENTS

This work was supported by the Natural Science

Foundation of Jiangsu Province [grant number

BK20211343]

.

REFERENCES

Flügge W., and Sobel, L. H., Locheed Missiles and Space

Company Report 6-75-65-12 (Mar.1965).

Sobel L. H., and Flügge, W., AIAA, S (1967), 425-431.

Fishlowitz, E.G., NSRDC Rept.3338, April(1972), Dept.of

the Navy, Naval Research and Development Center,

Washington,D.C.

Jordan, P.F. Buckling of circular toroidal shells under

hydrostatic pressure. AIAA Journal, 1973, 11(10):

1439-1441.

Du Q H, Cui W C, Zhang B. Buckling characteristics of a

circular toroidal shell with stiffened ribs. Ocean

Engineering, 2015, 108:325-335.

Du Q H, Cui W C, Wan Z Q. Nonlinear Finite Element

Analysis of acircular toroidal shell with Ring-Stiffened

Ribs Asme International Conference on Ocean.

American Society of Mechanical Engineers, 2010.

Galletly G D, Blachut J. Stability of Complete Circular and

Non-Circularcircular toroidal shells. Proceedings of the

Institution of Mechanical Engineers, Part C: Journal of

Mechanical Engineering Science, 1995, 209(4):245-

255.

Jordan, P.F. Analytical and experimental investigation of

pressurised circular toroidal shells. NASA CR-261,

1965.

Jordan, P.F. Stiffness of thin pressurised shells of revolution.

Am. Inst. Aeronaut. Astronaut.1965,3,899-906.

Jordan, P. F. and Shelley, P. E. Stabilisation of unstable two-

point boundary value problems. Am. Inst. Aeronaut.

Astronaut.1966,4.923-924.

K.Hibbitt, S.Inc, ABAQUS-Theory and Standard User’s

Manual Version 6.3, USA,2006.

Zhang J, Gao J, Wang W. Investigation on mechanical

properties of deep sea spherical pressure shell. China

ship building, 2015,56(04):129-140.

Blachut,J., Jaiswal O R. On buckling of circular toroidal

shells under external pressure. Computers & Structures,

2000, 77(3):233-251.

TOMAS A, TOVAR J P. The influence of initial geometric

imperfections on the buckling load of single and double

curvature concrete shells. Computers & Structures,

2012, 96(97):3445.

China Classification Society Diving System and

Submersible Classification and Construction

Specifications. BeiJing: People's communications

publishing house, 1996.

ISWEE 2022 - International Symposium on Water, Ecology and Environment

122