Preliminary Development of Concrete 3D Printing Machine

Controller Based on Mach3 Control Board

Herman Budi Harja

a

, Heri Setiawan

b

, Dede Buchori Muslim

c

, Akil Priyamanggala

d

and Rahma Dwi Kurniawan

e

Department of Manufacture Engineering, Politeknik Manufaktur Bandung, Kanayakan, Bandung, Indonesia

rahmadk2019.tmu@gmail.com

Keywords: PC Based, Concrete 3D Printing, X-Y-Z Axis, Extruder, Controller Configuration.

Abstract: The implementation of 3D printing concept for civil buildings significantly affects construction time, cost,

and design flexibility. This paper proposed the configuration of a concrete 3D printing controller using PC-

based and March 3 6 to control the X-Y-Z axis movement, sense the axis travel limit, and concrete nozzle

feeder. The component configuration of object study 3D printing use five MCDLT35SF as servo motor driver

of the X-Y-Z axis, five Panasonic AC servo motor as X-Y-Z axis actuator, one Nema motor stepper as an

extruder, eight limit switches as axis travel limit. The parameter configuration value has been determined

referring to the properties of actuator and sensor installed. Those parameters setting is slaving axis, port

address, kernel speed, and In-out pin setting. Slaving axis method is used to accommodate the axis that needs

two actuator motors, such as on X-axis and Y-axis machine. The proposed controller configuration was

verified experimentally, all actuators and travel limits could respond as a command.

1 INTRODUCTION

Additive Manufacturing (AM) can be the focus of

industry and government investment or can even be

used to make objects or components in everyday life

(Gibson, 2015).

One of the additive manufacturing technologies is

the 3D Printing Machine for Buildings. 3D printing is

a manufacturing activity that produces 3-dimensional

objects or products from a design program. The

printer will read the program design file and print

layer by layer made of geopolymer mortar until the

entire object is reached. The advantage of this

machine is that it can make buildings automatically

and quickly (Nithesh, 2018). The working principle

of 3D Printing for buildings is to print one layer to the

next according to the height, length, and height of the

3D object design according to the program specified.

Computer-based control is a development of

analog control in the past. Computer-based control

a

https://orcid.org/0000-0001-9746-2647

b

https://orcid.org/0000-0001-8767-1429

c

https://orcid.org/0000-0001-9872-7248

d

https://orcid.org/0000-0002-3453-0056

e

https://orcid.org/0000-0003-1493-5504

can provide input directly to the driving tool, besides

that this control can also receive input signals from

the correction tool used. One of the computer-based

controls is the Mach3 Novusun 6 Axis. This device

has the advantage of having 6-axis ports, and ease of

setting the parameters, besides that this device is

specifically designed for the use of CNC (Computer

Numeric Control). Its device is supported by Cura as

CAM software in the 3D printing process. Where the

G-code 3D printing that comes out on the Cura

software has been adjusted to the G-Code on this

device. With these advantages, Mach3 Novusun 6

Axis was chosen as the control device for concrete 3D

printing machine.

Several researchers have studied Mach 3

implementation as machine controller. Gonzale

developed CNC milling using March 3 and PLC

S71200 for controlling the three-axis movement of

CNC milling (Meza, 2018). Boral state

implementation of the Mach3 and the Smoothstepper

Harja, H., Setiawan, H., Muslim, D., Priyamanggala, A. and Kurniawan, R.

Preliminary Development of Concrete 3D Printing Machine Controller Based on Mach3 Control Board.

DOI: 10.5220/0011958800003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 931-936

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

931

controller is very effective and allows achieving the

high rotational speeds of motors without losing steps

(Boral, 2019). Alvares explained using Mach 3-

Matlab for retrofitting the industrial robot ASEA

IRB2-S6 (Alfares ,2017).

The aim of this research is to configure the

controller for concrete 3D printing machine using

March 3 control board and to ensure the performance

of device control runs properly and appropriately.

Hence, it is necessary to determine the appropriate

parameters.

2 METHOD AND RESULT

Developing the controller configuration for a

concrete 3D printing machine has several stages:

identification of the certain input-output component

of machine, determination of wiring component

system, identification of detail component as pin

number and its function, determination of value for

each parameter set, and verification of the system

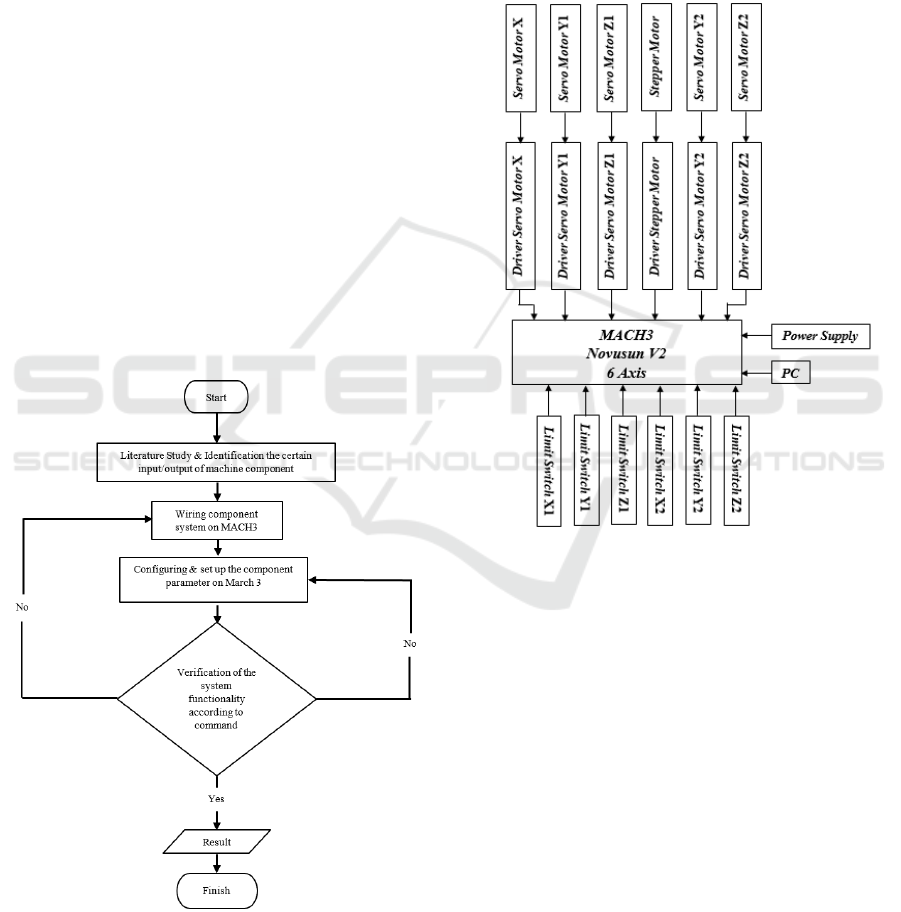

functionality. Figure 1 shows the stages of the

development study to configure and determine the

parameter setting of the concrete 3D printing

machines.

Figure 1: Development study to configure and determine

the parameter setting of concrete 3D printing machine.

The certain input-output component of concrete

3D printing has three axes movement actuator (X-Y-

Z axes), one nozzle actuator as feeder concrete, and

several limit switch sensors and others.

Figure 2 shows the wiring diagram of concrete 3D

printing machine. Mach3 control board is connected

to PC (Personal Computer), power supply, limit

switch of each axis, and servo motor driver.

Determination of the relation between components

system could be seen on wiring diagram.

Figure 2: Wiring diagram of concrete 3D printing machine.

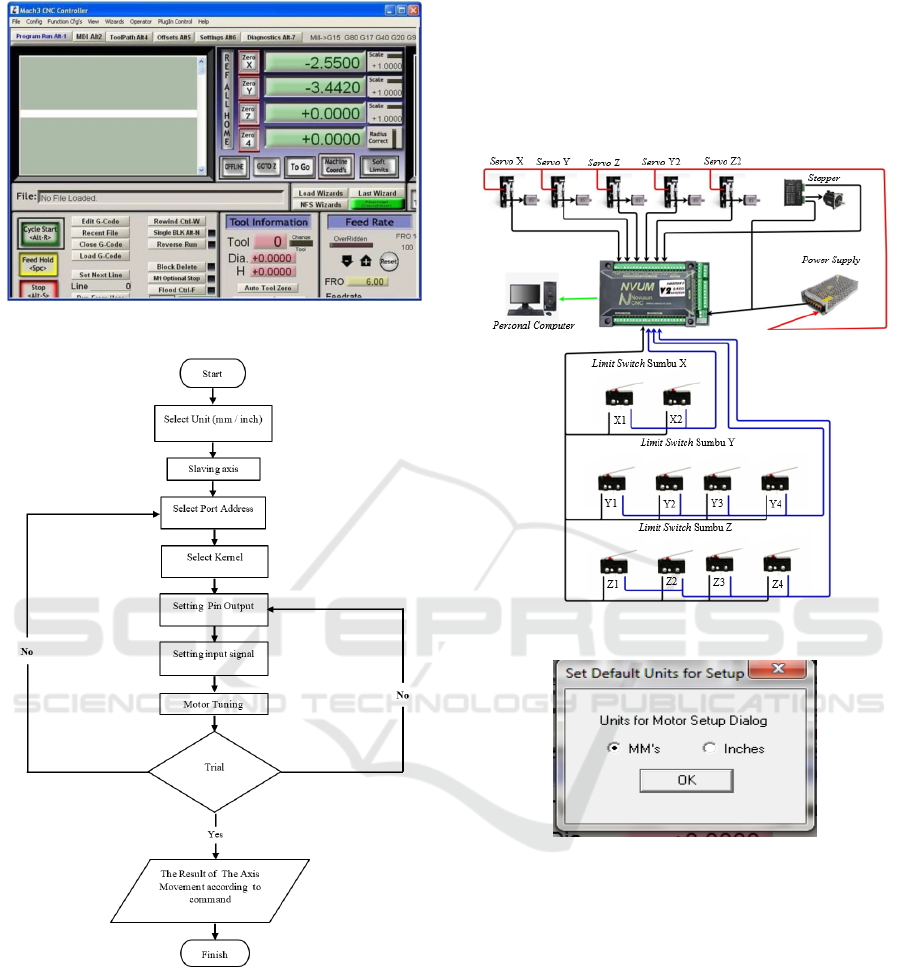

MACH 3 is designed to control machine tools

such as lathes, plasma cutting machines, and 3D

printers (Gorman, 2017). MACH3 mostly works on

PCs with windows operating systems to control the

movement of stepper motors and servo motors by

processing G-code data. Mach3 software display is

seen in Figure 3.

Several parameters on the MARCH 3 breakout

board system should be set up such as unit, port

address, slaving unit, kernel speed, input and output

pin, and motor tuning. Figure 4 shows the setting

stages of MARCH 3 parameters.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

932

Figure 3: March 3 software display (

ArtSoft

, 2008).

Figure 4: Setup March 3 parameter.

The control system uses Novusun 6 Axis Mach3

BOB as the controller. It is connected to 5

MCDLT35SF servo motor drivers (X, Y, Z, B, and C

axis), 1 TB6600 stepper motor driver (A axis), 5

Panasonic AC Servo Motors 750W (X, Y, Z, B, and

C axis), 1 Nema 34 Stepper Motor (A axis), 8 Limit

Switches, and 24V Power Supply. Figure 5 is

illustrated the March 3 wiring diagram for 3D

printing.

The main menu of Mach 3 has a "config" menu

which has a "Select Native Unit" sub-menu. The

menu is provided to determine the standard unit of

measure to be used. In this feature there are two units,

namely mm and inch (ArtSoft, 2008). The features of

the native unit can be seen in Figure 6.

Figure 5: Wiring diagram March 3.

Figure 6. Native unit setting.

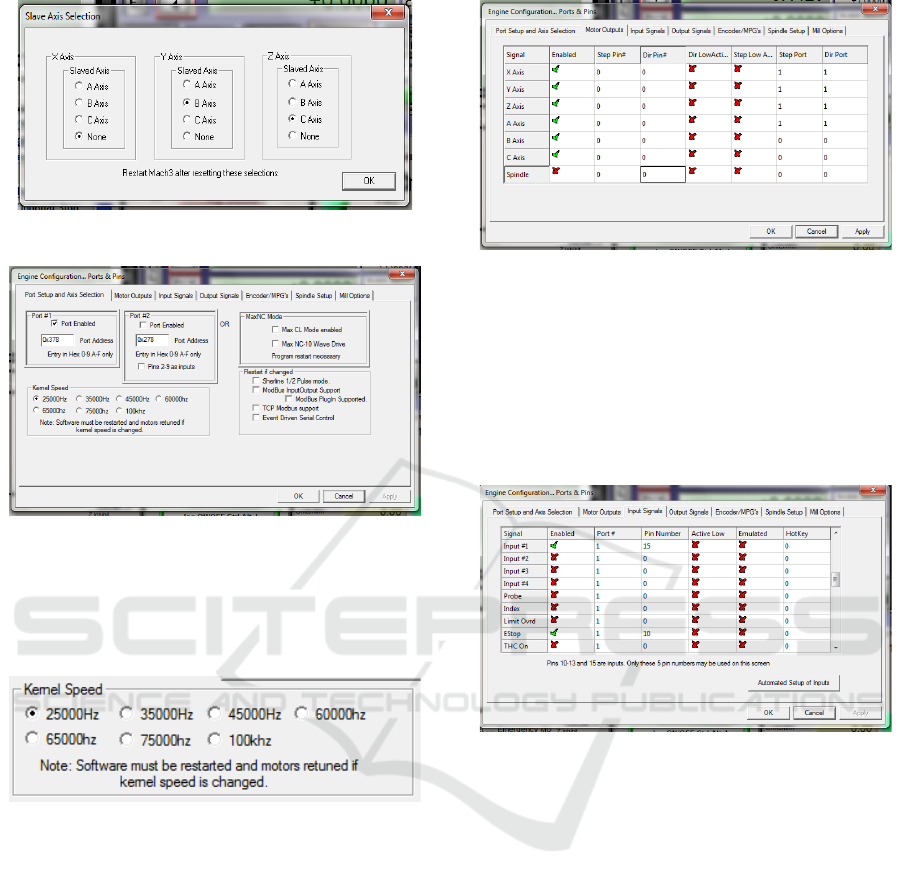

The axis of large machines often requires two

actuator motors installed on each side of axis slider.

It could use the Config>Slave Axis dialog to

configure Mach 3, hence one axis movement (ex. X-

axis) is the main motor and supports another motor

(perhaps the C axis is configured as linear rather than

rotary) (ArtSoft, 2008). The parameter setting is

shown in Figure 7.

The port address on March 3 is set with a value of

the parallel port address of the PC author. If the PC

author has a parallel port address of 0x378, hence the

port address should be set to 0x378 as shown in

Figure 8.

Preliminary Development of Concrete 3D Printing Machine Controller Based on Mach3 Control Board

933

Figure 7: Slaving axis unit setting.

Figure 8: Port address setting.

Kernel speed is the speed parameter of the signal

number that is sent from the computer to the Mach 3

BOB. It is adjusted to the capacity of our computer

processor [3]. This setting can be seen in Figure 9.

Figure 9: Kernel speed setting.

Determine where the motors for your X, Y, and Z

axes are connected, and click in the Enabled column

to get a checkmark to enable these axes. If any axes

are enabled that are not supposed to be, click on the

Enabled column to change the green tick to a red “X”

[3]. The output motor pin settings that the author did

can be seen in Figure 10.

Figure 10: Pin-out motor setting.

The input signal will provide an input signal to the

Mach 3 program. Pin numbering refers to the port

address used. In the author's trial, the author uses a

limit switch as a sensor for the limit of the axis

movement and the Push Button Emergency Stop as

an emergency switch. The input signal settings that

the author made can be seen in Figure 11.

Figure 11: Input signal axis setting.

2.1 Calculation of the Motor Tuning

Motor tuning aims to set the step value of each axis.

The motor tuning value is calculated based on several

parameters such as output driver pulse, tooth pitch of

timing belt, and number of teeth on the slider drive

gear. Several formulations for the calculation of servo

motor tuning are shown in formulas (1), (2), (3), and

(4).

Shaft revs/unit = 1/ (tp x Ns) (1

)

M

otor revs/unit = shaft revs/unit x (Ns/Nm) (2

)

Pulse/motor revs = PPR x 4 (3)

Step/unit = Pulse/motor revs x Motor

revs/unit

(4)

If the output driver is 2500 pulse per rotation [p/r],

tooth pitch of timing belt is 0.2inchi or 5.08mm, teeth

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

934

number on motor is 20. Using formulation (1) until

(4), the value of motor tuning is shown.

• Shaft revs/ unit = 1/ (5.08 x 90) = 0.00218

rev/mm.

• Motor revs/unit = 0.00218 x (90/20) = 0.00981

revs/mm

• Pulse/ motor revs = 2500 x 4 = 10,000 pulse/revs

• Step/ unit = 10,000 x 0.00981 = 98.1 steps/mm

Motor tuning of the stepper motor is calculated by

formulas (5), (6), (7), and (8).

Screw revs/unit = 1/

p

itch (1)

Motor revs/unit = screw revs/uni

t

(2)

Motor step/revs = 360°/step moto

r

(3)

Step/unit = Motor step/revs x Motor

revs/unit

(4)

Several values of motor stepper are known, such

as step motor is 1.8° and screw pitch is 45mm. Hence

the motor stepper value can be calculated.

• Screw revs/unit = 1/45 =0.022 revs/mm.

• Motor revs/unit = 0.022 revs/mm.

• Motor step/revs = 360°/1.8° = 200 steps/revs

• Step/ unit = 200 x 0.022 = 4.44 step/mm.

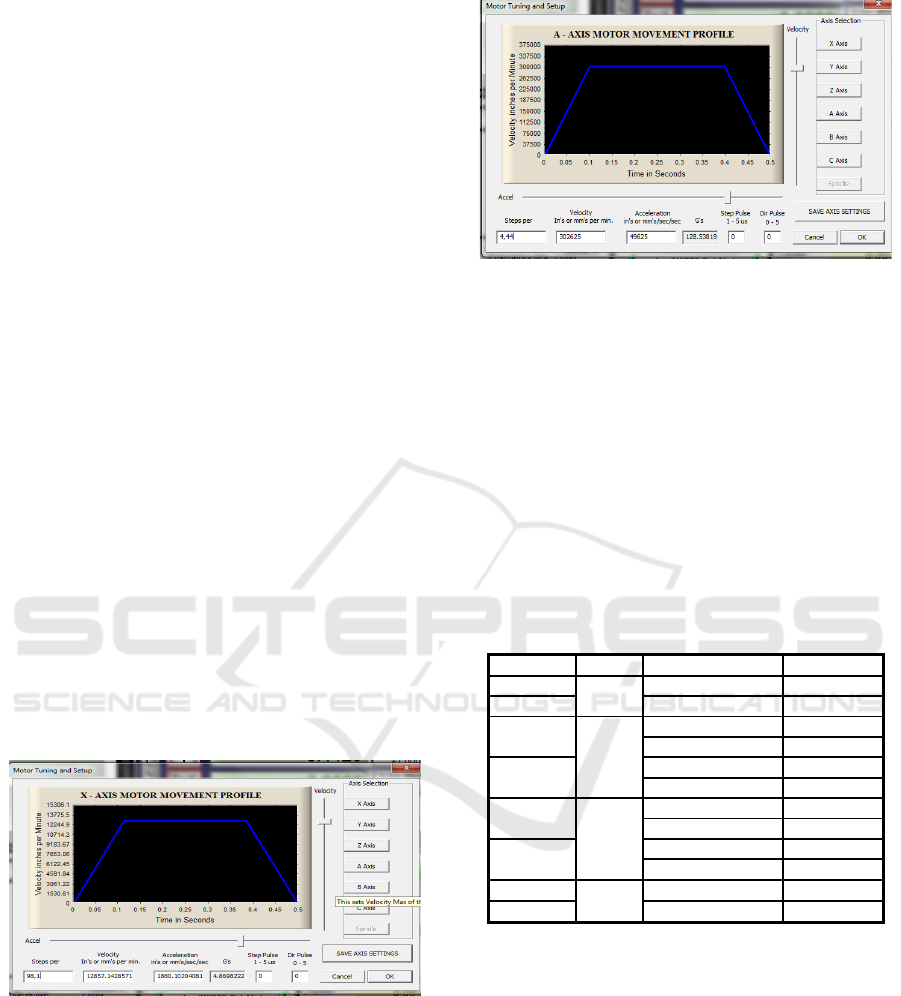

Figure 12 shows the servo motor setting for X-

axis. The motor tuning value is set at 98.1 step/mm.

The motor stepper tuning value of the A-axis with

4.44 step/mm is shown in figure 13.

Figure 12: Servo motor setting.

Figure 13: The setting of motor stepper.

2.2 Verified the Functionality of

System

Experimentally verified was conducted for (i)Testing

of axis movement direction and (ii) Rotation speed of

axis motor. Each servo motor axis such as X-axis, Y-

axis, and slave Y-axis (or B-axis), Z-axis and slave Z-

axis (or C-axis), and A-axis were tested in clockwise

and counterclockwise direction. Table 1. Show tested

data of movement direction motor axis. The

experiment results show that each axis servo motor

has been rotated refer to G-code command.

Table 1: Tested data of movement direction.

Command Axis Drive Moto

r

Direction

X-50

X

Axis motor X CCW

X50 Axis motor X CW

Y-50

Y

Axis motor Y CCW

Axis motor B CW

Y+50

Axis motor Y CW

Axis motor B CCW

Z-50

Z

Axis motor Z CCW

Axis motor C CW

Z+50

Axis motor Z CW

Axis motor C CCW

A-50

A

Axis motor A CCW

A+50 Axis motor A CW

Testing of rotation speed of axis servo motor was the

way to verify the velocity parameter of axis

movement without mechanical components of axis

machine. Three velocity parameters were tested, 62.3

mm/second, 187.24 mm/second, and 249.69

mm/second. The specification of servo motor has 98

steps per unit and 2500 pulse per rev, hence rotation

speed could be calculated. Experimentally tested

rotation speed was measured by tachometer.

Preliminary Development of Concrete 3D Printing Machine Controller Based on Mach3 Control Board

935

3 CONCLUSIONS

The controller of concrete 3D printing has been

developed using Mach 3 control board with PC-based

type and supported by Cura as CAM software in the

3D printing process. The parameter setup has been

properly determined; hence each X-Y-Z axis machine

actuator, extruder actuator, and each limit sensor are

well connected with controller. The proposed

controller configuration was verified experimentally,

all actuators and travel limits could respond as

commands.

REFERENCES

Alvares, A. J., Toquica, J. S., Lima, E. J, and Bomfim, M.

H. S. (2017). Retrofitting of ASEA IRB2-S6 industrial

robot using numeric control technologies based on

Linux CNC and Mach3-Matlab. IEEE International

Conference on Robotics and Biomimetrics ROBIO.

Macau.

Arifin, Z. (2016). Penggunaan ARTSOFT MACH3 Untuk

Gerak Pada Simulator CNC. Tesis. Department of

Mechanical Engineering. Sepuluh Nopember Institute

of Technology. Surabaya.

ArtSoft. (2008). Mach 3 CNC Controller Software

Installation and Configuration. 3

rd

ed. ArtSoft USA.

Boral, P. [2019]. The design of the CNC milling machine.

MATEC Web of Conferences 254.

Deck, K. (2020). Determine RPM stepper Motor.

https://sciencing.com/determine-rpm-stepper-motors-

10033323.com. Access on 21 July 2022.

Gibson, I., Rosen, D. and Stucker, B. (2015). Additive

Manufacturing Technologies. Springer New York

Heidelberg Dordrecht. London.

Gorman, W., Hasting, C., and Pfaff, D. (2017). Building a

3D Printer: Motors and Controls. Worcester

Polytechnic Institute.

Harizal, I. (2017). Rancang Bangun Sistem Kontrol Mesin

CNC Milling 3 Axis Menggunakan Close Loop System.

Thesis. Department of Mechanical Engineering. Riau

University. Riau.

Meza, G., Carpio, C. D., Vinces, N., and Klusmann, M.

(2018). Control of three-axis CNC machine using PLC

S7 1200 with the Mach 3 software adapted to a modus

TCP/IP network. IEEE XXV International Conference

on Electronics, Electrical Engineering and Computing

INTERCON. Peru.

Nithesh, N. (2008). Development of concrete 3D printing.

Thesis. Aalto University.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

936