Proposal to Improve Storage Management to Reduce Stock-Outs

Through the Use of the Reorder Point, Safety Stock and 5S in the

Plastic Sector

Cristhofer Valdivia Vargas

*a

, Cesar Seminario Cerna

†b

and Alberto Florez Perez

c

Facultad de Ingenieria y Arquitectura, Universidad de Lima, Lima, Peru

Keywords: Reorder Point, Safety Stock, ABC, 5S, EOQ, Inventory Control.

Abstract: In warehouse management lies mainly the absence of spare parts when they are needed for maintenance of

machinery or because a fault arose, and it is necessary to replace the parts. This cause must be reduced as it

generates a huge downtime of the machinery. In the present case study, the ABC was used to separate the

most important spare parts families, in addition, using the EOQ together with the reorder point was able to

efficiently supply the spare parts stores, to reduce stock breakages and, Also, the security stock was used.

Then, from implementing the improvement tools in the sourcing process, 5S and ABC methods were used to

organize the warehouses, obtaining in this way a considerable decrease in the stock break of approximately

42% and a reduction of the purchase orders by 58%.

1 INTRODUCTION

In Peru, the plastic industry contributes well,

accounting for 4% of Gross Domestic Product and

generating 200,000 jobs (Sociedad Nacional de

Industrias, 2019b). This is a good indicator as the

industry grows annually at a rate of 3.2% (Sociedad

Nacional de Industrias, 2019b), this is due to the

reactivation of the construction sector and the demand

for packaging for the agro-industry sector. Added to

this the plastics industry sector has a growing trend,

this is evidenced by the fact that the global plastic

production in volume of 2017 exceeded by 3.8% to

the production of 2016 (Sociedad Nacional de

Industrias, 2019a). However, this trend of growth in

production is affected by various problems, affecting

several products, this is mainly reflected in single-use

plastics as they are (Sociedad Nacional de Industrias,

2019a), that is why there is a tendency to reduce the

amount of plastics consumed, as evidence of this

trend are taxes and various restrictions, in the national

case, we have the law 30884 that estimates to reach a

reduction of 30% of plastics in the first year of

validity (Sistema Nacional de Información

Ambiental, 2019)

a

https://orcid.org/0000-0003-4907-4126

b

https://orcid.org/0000-0002-1971-2177

c

https://orcid.org/0000-0003-0813-0662

The above shows that companies in the plastic

sector, although they have global growth trends, also

have problems so it is sought to propose new

solutions, Part of these solutions focused on

innovation in creating new types of products such as

100% recyclable packaging and thereby promoting a

cycle of use and disuse.

It was identified that there are different factors

that affect the problem, such as the mean time

between breakdowns in each machine, stock breakage

and inefficient management in the supply plans,

significantly affecting the performance of the

injection molding machines and therefore production,

which is the reason for the increase in costs, generated

by an inadequate stock (Conceição et al., 2021).

With this established, the following structure is

presented for this article, which is divided into five

important parts which are: introduction, state of the

art, contribution, validation, and conclusions.

552

Valdivia Vargas, C., Seminario Cerna, C. and Florez Perez, A.

Proposal to Improve Storage Management to Reduce Stock-Outs Through the Use of the Reorder Point, Safety Stock and 5S in the Plastic Sector.

DOI: 10.5220/0011960200003612

In Proceedings of the 3rd International Symposium on Automation, Information and Computing (ISAIC 2022), pages 552-557

ISBN: 978-989-758-622-4; ISSN: 2975-9463

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

2 STATE OF THE ART

2.1 5S Methodology (5S) -Activity

Basic Costing in the Stores (ABC)

Based on the improvement in the warehouses, it was

found in the various case studies that the main flaws

are the lack of controls and the standardization of

processes, in addition to that only 5% of the activities

add value and 60% only add partial value (Marmolejo

et al., 2016), this means that many of the activities are

underutilized when adding value, and that there are

usually activities that do not generate value and these

should be eliminated since they only generate costs

that will not be paid by customers(Shahriar et al.,

2022).

The implementation of the 5S means that

everything that is considered waste is eliminated

(Sukdeo et al., 2020), but to start implementing the 5S

you first need to establish a language that everyone

can understand (Gupta & Jain, 2015), in order to

avoid confusion.

Because when properly implemented it not only

helps productivity, but also keeps the place clean and

organized (SOROOSHIAN & MAD ALI, 2017), it

helps to make working conditions better, improves

the usability of spaces and reduces downtime

(SOROOSHIAN & MAD ALI, 2017).

Another problem is the lack of organization in the

warehouses, where we find that the big mistake that

is made is to give all items the same treatment

(Conceição et al., 2021), to solve this applies the

order based on the ABC, which serves to separate the

items that are stored, based on which have greater

financial relevance (Conceição et al., 2021).

2.2 Reorder Point – Economic Order

Quantity (EOQ)

Due to the uncertainty of demand, the application of

the reorder point and the EOQ for forecasts were

found in different case studies. Based on different

market conditions, companies face a demand that

cannot be accurately predicted(Sorooshian & Jadidi,

2021). In addition, the security stock must be used

when sales are greater than the sales planned to fulfill

the customer’s orders.

Based on actual demand, the moving average

forecast was made for the last three periods. The EOQ

was then calculated to determine the lot size and

reduce inventory-related costs(Rodríguez et al.,

2020), taking a fixed cost and the annual maintenance

cost per unit. Finally, taking the lead time of the

supplier proceeds to calculate the reorder point,

which is important since this is the time to order the

material, to have them at the optimal time(Conceição

et al., 2021).

However, because of the oscillating demand, it is

necessary to have a safety stock, since stocks are

required to deal with unplanned situations(Rusman et

al., 2019).

2.3 Inventory Control- Stock Safety

(SS)

To reduce the costs of a company, the management of

its warehouses is one of the necessary activities

(Salee & Chutima, 2021). For the proper management

of inventories, it should be taken into account that the

main objective is to maximise profitability by

reducing storage costs (Kheireddine &

Bouchelaghem, 2020) , in addition to this it should be

taken into account that poor management produces

negative effects such as material shortages

(Rodríguez et al., 2020) , this is why a good inventory

policy must be chosen that can respond to demand,

without breaking stock and reducing costs to the

maximum (Paredes Rodriguez et al., 2019). For this

to happen, it must be accompanied by a safety stock,

which will be responsible for anticipating the

uncertainties of the future as there may be delays and

thereby reduce the risk (Conceição et al., 2021)

3 CONTRIBUTION

3.1 Fundamentals of the Model

For the development of our improved inventory

management, we took into account various types of

papers that were especially related to the safety stock,

reorder point, EOQ, ABC and 5S. These articles

provided the necessary knowledge for

implementation and possible outcomes. As for the

differentiation with other jobs of this type is the

implementation of the ABC tool as a complement to

the 5S, since it was seen that not only enough with the

organization of the warehouses but also, the time lost

in the search for spare parts must be minimised,

however, the importance of this work lies in the

combination of the various tools already mentioned

and their adaptation for use in a company in the

plastic sector, achieving a significant improvement in

the supply of spare parts needed by the company,

being the most outstanding tools the reorder point

which is the level of spare parts calculated to request

another multiorder to the supplier based on its lead

time and the safety stock that will ensure us keep the

necessary stocks for the machines to continue

functioning.

Proposal to Improve Storage Management to Reduce Stock-Outs Through the Use of the Reorder Point, Safety Stock and 5S in the Plastic

Sector

553

3.2 Basis

The proposed model is developed based on the

following tools: 5S and ABC for the order of

warehouses and the distribution of spare parts, with

the ABC tool in charge of distributing the various

types of spare parts, this will depend on the frequency

of use of the spare parts.

Supply and control of warehouses spare parts, the

reorder point tools, safety stock and EOQ were used,

these tools being responsible for determining when

the next order must

Table 1: Comparative matrix of cause VS State of art.

Authors

Inventory

planning

Improveme

nt in

inventory

manageme

nt

Warehouse

disorder

D. Sobyaa, S.

Nallusamyb,

and Partha

Sarathi

Chakraborty

(2021)

5S, Line

Balancing

R Hanafi, F

Mardin, S

Asmal, I

Setiawan and S

Wijaya (2019)

EOQ

SS,

Reorder

Point

ABC

M Rusman, S

Mangengenre,

SM Parenreng,

I Setiawan y A

Pertiwi (2019)

Normal

Distribution,

SS

EOQ,

Reorder

point

A.M. Paredes-

Rodríguez;V.

L. Chud-

Pantoja; J.C.

Osorio E

(2019)

Inventory

control

System of

inventories,

Q

Proposal

Inventory

Control & SS

EOQ &

Reorder

Point

5S & ABC.

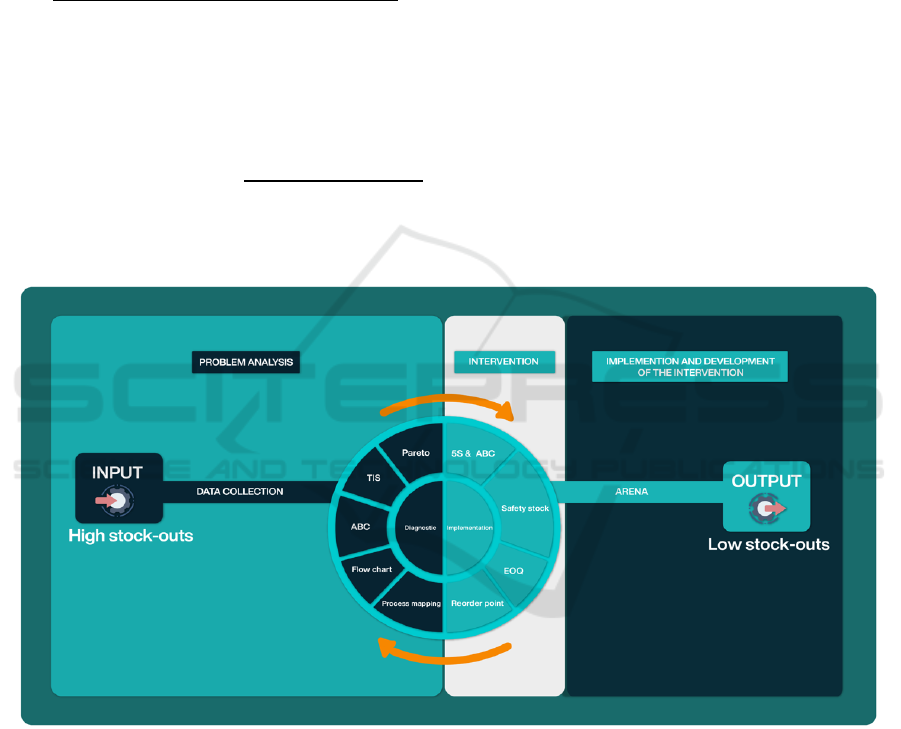

3.3 Proposed Model

The proposed model is developed based on the

following tools: 5S and ABC for the order of

warehouses and the distribution of spare parts, with

the ABC tool in charge of distributing the various

types of spare parts, this will depend on the frequency

of use of the spare parts.

Supply and control of warehouses spare parts, the

reorder point tools, safety stock and EOQ were used,

these tools being responsible for determining when

the next order must be made and the concrete quantity

to be able to supply the warehouse s, without having

to fall into a cost overrun caused by parts that are

never used.

3.4 Components of Model

3.4.1 Component 1: Analysis of the Problem

At this point we analyzed the current situation of the

company and how the stock breaks arise, so that we

could determine why these values are so high.

In order to detect the existing stock break, the

number of times the spare parts needed for the

machines could not be properly supplied was taken.

With this it was determined, the techniques to use to

solve it, in the case of our improvement were used the

inventory control, the stock of safety and the point of

reorder, in order to reduce the times that the

warehouse is left without spare parts. And the 5S and

ABC tools will be used for the reduction of disorder,

elimination of unnecessary processes, for the

distribution of places for the various types of spare

parts and for the standardization of all these processes

3.4.2 Component 2: Intervention

In this component, the application of tools to solve the

problem that was analyzed in the diagnosis is given.

First, the 5S will be used to start with a clean,

organized, and standardized environment, along with

the ABC to classify the resistance family according to

its rotation. Secondly, the safety stock will be

calculated to have a spare parts stock in any

emergency. Thirdly, we will proceed to calculate the

EOQ to know the optimal lot of purchase. Finally, the

reorder point will be calculated, which will be the

notice to make the purchase during the lead time of

the supplier to deliver the order.

3.4.3 Component 3: Implementation and

Development of the Intervention

This last part is the implementation of the

improvement, for this you will have to use the

ARENA simulator, which seeks to observe the

improvements obtained after the implementation of

the entire improvement plan in the company, this will

require a comparison of indicators before and after

improvements.

ISAIC 2022 - International Symposium on Automation, Information and Computing

554

3.5 Indicators

The following indicators were used to evaluate the

performance of the improvements made

- Stock out: Measure the quantity of

unsolicited spare parts ordered over the total

spare parts supplied.

Target: Reduce stock break to 5%

=

𝑆𝑝𝑎𝑟𝑒 𝑝𝑎𝑟𝑡𝑠 𝑜𝑟𝑑𝑒𝑟𝑒𝑑 𝑏𝑢𝑡 𝑛𝑜𝑡 𝑑𝑒𝑙𝑖𝑣𝑒𝑟𝑒𝑑

𝑆𝑝𝑎𝑟𝑒 𝑝𝑎𝑟𝑡𝑠 𝑠𝑢𝑝𝑝𝑙𝑖𝑒𝑑

- Number of orders served: Determines the

fulfillment of orders placed by technicians

Target: Orders served increased to 98%

% 𝑂𝑟𝑑𝑒𝑟𝑠 𝑓𝑢𝑙𝑓𝑖𝑙𝑙𝑒𝑑 =

𝑁° 𝑜𝑟𝑑𝑒𝑟𝑠 𝑑𝑒𝑙𝑖𝑣𝑒𝑟𝑒𝑑

𝑁° 𝑜𝑟𝑑𝑒𝑟𝑠 𝑝𝑙𝑎𝑐𝑒𝑠

For the mutual benefit and protection of Authors and

Publishers, it is necessary that Authors provide

formal written Consent to Publish and Transfer of

Copyright before publication of the Book. The signed

Consent ensures that the publisher has the Author’s

authorization to publish the Contribution.

The copyright form is located on the authors’

reserved area.

The form should be completed and signed by one

author on behalf of all the other authors.

4 VA L I D AT I O N

4.1 Diagnosis Inicial

To begin with, it must be understood that the reorder

point is the main tool and the safety stock a

complement and as established from the beginning,

the main objective is the reduction of stock break to

acceptable levels, for the plastics production sector.

Figure 1: Management Model

But, to achieve this must take into account various

factors such as whether the company applies policies

of inventories suitable for its type of demand, in the

case of this company was opted for the creation of a

new policy of stock of safety and a policy of point of

reorder, this was intended to significantly reduce

stock breakage and the costs of not owning the right

types of spare parts when breakdowns occur. This

was established after analyzing the company and

understanding that the biggest of its problems was the

policy of acting in a corrective manner generating a

lack of policies of replenishment of spare parts

4.2 Design Validation and Comparison

with Diagnostics

For this segment the sand software was used, in which

the initial form of the company was modeled and then

another where the corresponding improvements were

Proposal to Improve Storage Management to Reduce Stock-Outs Through the Use of the Reorder Point, Safety Stock and 5S in the Plastic

Sector

555

applied, managing to obtain data for the validation of

the system.

For the first simulation, the necessary information

was collected to establish the initial indicators and the

conditions with which they were obtained, this served

us for the subsequent analysis and comparison with

the data collected in the second scenario, in which it

is evidenced the enormous importance of having a

policy of rearrangement point and complement with

the stock of security, with this reduce the number of

times that happen the breaks and reach a value less

than 5% of break.

4.3 Enhancement- Simulation of

Improvement

As specified in the previous point the simulation was

done with the Arena software, in which the first

scenario is the model without improvement, is the

model that the company used and in the second

scenario, the proposed improvements were

established, some 212 simulations were made, of

about 24 hours a day in the span of one year in order

to have a truthful simulation.

Taking into account that the main variables are the

number of orders placed and the demand for spare

parts for each order made.

With these data, the following table was

established showing a comparison of the pre-

improvement situation vs the improved situation

using the KPIs or the indicators proposed above, this

in order to establish a numerical sample in the

improvements obtained after the simulation.

Once the table has been made and analyzed, it is

possible to observe a considerable improvement in

the main indicator after the improvements were

applied in the spare parts warehouse, achieving in this

way to have a breaking percentage of 2.13% being

considerably lower than the current break of 48.52%,

likewise it was found that this decrease in stock break

increased the orders requested by technicians by

90.11%.

Table 2: Current simulation against the improved situation

Process Current Improved %

Stock

Outs

48.52% 2.13% -95.61%

Orders

served

51.48% 97.87% 90.11%

5 CONCLUSIONS

The aim of the present investigation was to reduce

stock breakages in a spare parts warehouse for

injectors. Based on a quantitative and qualitative

analysis of the company’s demand and case studies,

it was calculated that the company had 48.52% of

orders not delivered to the maintenance area and after

applying the improvements was able to reduce the

stock break to 2.13%. Achieving in this way meet the

main objective of reducing at least 5% of stock break.

Another of the improvements achieved, along

with the improvement of the reduction of stock

breakage there is an improvement in the decrease of

orders made purchases, where in the pre-

improvement was had 37 purchase orders and after

the improvements applied was had 16 purchase

orders, thus obtaining a reduction of 58.33% in terms

of the orders made.

This research was applied in a plastic sector

company, and it was possible to demonstrate the great

synergy that the tools of the reorder point have with

that of the stock of security, because as seen in the

scenarios of the discussion, no single one can reach to

eliminate stock breakage since while the reorder point

tries to avoid stock breakage through orders, the

security stock serves as an additional insurance.

REFERENCES

Conceição, J., de Souza, J., Gimenez Rossini, E., Risso, A.,

& Beluco, A. (2021). Implementation of inventory

management in footwear industry. Journal of Industrial

Engineering and Management, 14(2).

https://doi.org/10.3926/jiem.3223

Gupta, S., & Jain, S. K. (2015). An application of 5S

concept to organize the workplace at a scientific

instruments manufacturing company. International

Journal of Lean Six Sigma, 6(1).

https://doi.org/10.1108/IJLSS-08-2013-0047

Kheireddine, A., & Bouchelaghem, A. (2020, December 2).

Amelioration of Reorder Point replenishment method

of an unstable production system. 2020 IEEE 13th

International Colloquium of Logistics and Supply

Chain Management (LOGISTIQUA).

https://doi.org/10.1109/LOGISTIQUA49782.2020.935

3929

Marmolejo, N., Milena Mejía, A., Peréz-Vergara, I. G.,

Caro, M., & Rojas, J. A. (2016). Mejoramiento

mediante herramientas de la manufactura esbelta, en

una Empresa de Confecciones. Ingeniería Industrial,

37(1), 1.

http://scielo.sld.cu/scielo.php?script=sci_arttext&pid=

S1815-59362016000100004&lang=es

ISAIC 2022 - International Symposium on Automation, Information and Computing

556

Paredes Rodriguez, A. M., Chud Pantoja, V. L., & Osorio,

J. C. (2019). Sistema de control de inventarios

multicriterio difuso para repuestos. Scientia et

Technica, 24(4).

https://doi.org/10.22517/23447214.22331

Rodríguez, S., Lopez, H., Viacava, G., & del Carpio, C.

(2020). [Inventory planning and management in the

automotive after-sales supply chain]. Proceedings of

the LACCEI International Multi-Conference for

Engineering, Education and Technology.

https://doi.org/10.18687/LACCEI2020.1.1.178

Rusman, M., Mangengenre, S., Parenreng, S. M., Setiawan,

I., & Pertiwi, A. (2019). Inventory planning analysis for

vehicle spare parts by using Continuous Review

method: A green engineering approach. IOP

Conference Series: Earth and Environmental Science,

343(1). https://doi.org/10.1088/1755-

1315/343/1/012006

Salee, S., & Chutima, P. (2021). Warehouse Management

Improvement for A Leather Dyeing Factory. 2021 3rd

International Conference on Management Science and

Industrial Engineering, 139–145.

https://doi.org/10.1145/3460824.3460846

Shahriar, M. M., Parvez, M. S., Islam, M. A., & Talapatra,

S. (2022). Implementation of 5S in a plastic bag

manufacturing industry: A case study. Cleaner

Engineering and Technology, 8, 100488.

https://doi.org/10.1016/j.clet.2022.100488

Sistema Nacional de Información Ambiental. (2019, July

31). Ley N° 30884 regula consumo de bienes de

plástico de un solo uso que generan riesgo para la

salud pública y/o el ambiente.

https://sinia.minam.gob.pe/novedades/ley-ndeg-

30884-regula-consumo-bienes-plastico-un-solo-uso-

que-generan

Sociedad Nacional de Industrias. (2019a). Fabricación de

productos de plástico. https://www.sni.org.pe/wp-

content/uploads/2019/07/Reporte-Sectorial-

Plásticos_2019.pdf

Sociedad Nacional de Industrias. (2019b, April 25).

Industria del plástico genera alrededor de 200 mil

puestos de trabajo. https://sni.org.pe/industria-del-

plastico-genera-alrededor-200-mil-puestos-trabajo/

Sorooshian, S., & Jadidi, O. (2021). Supply Reorder Point

in Response to Lead-Time Uncertain Demand. Journal

of Engineering Science and Technology, 2(0), 59–60.

http://www.jestr.org/downloads/Volume14Issue2/fullt

ext81422021.pdf

SOROOSHIAN, S., & MAD ALI, S. A. (2017). Lean

Practices Pertaining Hard and Soft Factors in Service

Sectors. QUALITY MANAGEMENT, 18, 80–86.

Sukdeo, N., Ramdass, K., & Petja, G. (2020).

APPLICATION OF 7S METHODOLOGY: A

SYSTEMATIC APPROACH IN A BUCKET

MANUFACTURING ORGANISATION. South

African Journal of Industrial Engineering, 31(4).

https://doi.org/10.7166/31-4-2283

Proposal to Improve Storage Management to Reduce Stock-Outs Through the Use of the Reorder Point, Safety Stock and 5S in the Plastic

Sector

557