Growth Prevention System for Inhibiting Corrosion Rate in Ship

Operation

Didit Sumardiyanto

1

and Sri Endah Susilowati

2

1

Faculty of Engineering, 17Agustus 1945 Jakarta University, Sunter Permai Raya Street, Jakarta, Indonesia

2

Department of Mechanical Engineering, 17Agustus 1945 Jakarta University, Jakarta, Indonesia

Keywords: MGPS, biofouling, copper electrode RRY17.

Abstract: Marine Growth Prevention System (MGPS) is a system applied on ships to inhibit marine growth or

biofouling, namely colonies of marine animals and plants that grow and cover the surface of structures or

piping systems on ships that can cause corrosion. The reduced flow as a result of the appearance of

impurities on the inner wall of the cooling system pipe causes a failure in cooling the ship's engine, which

results in overheating. Another impact of reducing the inside diameter of the pipe, the pressure received by

the pipe on the discharge side becomes larger, and cavitation occurs in the suction side due to excessive

pressure drop. The purpose of this study was to determine the impact of the use of the Marine Growth

Prevention System which was applied to the MT ship. Savvy in inhibiting the corrosion rate on the JIS

F0507 type seawater pipe by using copper (Cu) electrode type RRY17 based on the ship speed variability

value. From the research, it was found that protection using the Marine Growth Prevention System carbon

anode (copper electrode) is very effective for protecting the pipes in the engine cooling system and ship hull

from marine animals and plants.

1 INTRODUCTION

The operation of a large ship is always equipped

with an engine cooling system and a ship balancing

system with fluid using seawater, so a piping system

is needed for the circulation of the cooling fluid.

This causes the growth of various marine biota

plants such as coral, barnacles, and marine algae that

trigger corrosion. The Motor Tanker (MT) Savvy

ship uses seawater as engine cooling medium and

also as ballast water. The pipe installation used is

JIS-F0507. The use of sea water causes the growth

of marine growth which triggers corrosion which

will affect engine performance and decrease

usability, especially engine effectiveness and cause a

lot of detrimental damage.

To protect against corrosion in the piping system,

MT. Savvy uses a type-SC MGPS mounted on a Sea

Chest (SC) which is equipped with an RRY17 type

copper (Cu) electrode each and an aluminum

electrode placed in strategic locations, as close as

possible to the area to be protected. The anode is

connected to a control panel that regulates the

current flowing to the anode. Ions produced by the

anode will be dispersed by seawater and create an

environment that is not conducive to marine growth

in the area. Another advantage is that the aluminum

hydroxide formed will create a protective layer on

the surface of the channel so as to prevent corrosion.

The use of a stable current on the copper

electrodes and aluminum electrodes on the hull will

produce copper and aluminum hydroxide ions to

protect the pipe from marine biota plants that can be

corrosive and form rust. This method of preventing

the development of corrosion is known as the

Marine Growth Prevention System (MGPS).

MGPS works with an electrolyte method or

principle that works to provide continuous

protection without the use of chemicals. The trick is

to combine two systems, namely the installation of

anti-fouling pipes and corrosion suppression. With

control from a low-voltage power supply panel that

is channeled to an anode which is connected directly

to the liquid in the pipeline to minimize the

influence of acidity of the liquid content on the

corrosion process along the pipeline installation. The

specialty of using this system is that it is

environmentally friendly, does not use chemicals to

neutralize the liquid condition, in accordance with

300

Sumardiyanto, D. and Susilowati, S.

Growth Prevention System for Inhibiting Corrosion Rate in Ship Operation.

DOI: 10.5220/0011980200003582

In Proceedings of the 3rd International Seminar and Call for Paper (ISCP) UTA â

˘

A

´

Z45 Jakarta (ISCP UTA’45 Jakarta 2022), pages 300-306

ISBN: 978-989-758-654-5; ISSN: 2828-853X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

the rules that apply to the classification of

international rules.

This system consists of a pair of copper and

aluminum called anodes which are attached to the

inlet filter of the liquid to be neutralized. The copper

anode produces ions that flow through a liquid

medium that is in direct contact with it. These ions

have the potential to inhibit the growth of shellfish

and barnacles along the anode current flow range.

Without anti-fouling protection, pipes can be full of

organisms which over time can cause blockages,

reducing system efficiency in pipe installations, with

the help of aluminum hydroxide as flocculation

released by copper. This is the so-called double

protection, where the system can benefit from being

protected from bio-fouling and corrosion processes.

In new installations the anodes are attached to the

sea chests using special retainers or a mounting

flange. Or if the system is installed before the

drydocking vessel, the anode can be installed in the

seawater filter. Another advantage is that it is easy to

replace a new anode.

Another study related to this problem was carried

out by Seung Jun Lee and Jun Lee Seong (2011)

which was about the effect of flow velocity on

marine growth using electrochemical alloy Al 5083-

H116 on the suction pipe. The results showed that

the corrosion rate increased linearly with flow

velocity compared to static conditions. Meanwhile,

other studies have shown that the installation of

aluminum alloy carbon anodes on the hull plate of

KM ADRI XLIV technically has good performance

and is very influential in slowing the corrosion rate

of ship steel plates (Nur Aziz, 2012).

This study aims to analyze the use of MGPS on

MT. Savvy at inhibiting the corrosion rate on the

ship engine cooling pipe due to Marine growth. The

method used is to calculate the corrosion rate in the

JISF0507 seawater pipe and weigh the decrease in

weight of the RRY17 type copper electrode based on

the value of ship speed variability.Be advised that

papers in a technically unsuitable form will be

returned for retyping. After returned the manuscript

must be appropriately modified.

2 RESEARCH METHODS

The research was conducted on the MT Savvy Ship,

which uses the MGPS system using a combination

of Aluminum (Al) and Copper (Cu) electrodes.

2.1 Equipment Used Tup

Megger insulation tester, 1 set

Multimeter, 1 set

Toll set, 1 box

Vernier calipers, 1pc

2.2 Mgps Materials

Prevent corrosion resistance electrode, type

RRY17, 1 pc

Pipe, JIS F 0507 standard pipe (the level of

UNS G10200 Carbon steel) with a diameter of

20 cm, a length of 150 cm as the sample metal

(seawater pipe).

2.3 Data Collection Techniques

Data collection through observation techniques and

field note documentation. This research instrument

emphasizes the observation technique because it is

considered in accordance with the characteristics of

action research.

2.4 Implementation of Corrosion Test

In the corrosion test, the normal concentration level

or the average pH of the seawater environment is 8.0

and the electrode sample (Cu) is immersed in a sea

chest box for 3 days or 72 hours non-stop with

several treatments for variations in seawater speed

based on the speed of ship movement, including:

Ship totally stop, moving water, 0.0m/s

Full speed ship, 12.9knots, or moving water

6.6363m/s.

Medium speed ship, 9.7knots, or water

moving 4.9901m/s.

Slow speed ship, 6.5knots, or water moving

3.3438m/s.

Dead speed ship, 3.3knots, or water moving at

1.6976m/s.

The condition in the case of sea chest intake is

not protected with MGPS as shown in Figure 1.

Growth Prevention System for Inhibiting Corrosion Rate in Ship Operation

301

Figure 1. Marine growth and its effects, (a) intake hole, (b)

pipe interior, (c) filter, (d) pole base plate

Ship particulars of MT. Savvy:

Specifications:

Tonnage, gross (6,694tons), nett (3,785tons),

displacement (13,263tons), dead weight (10,327

tons), lightship (2,935tons), length over all (120m),

length between perpendicular (114m), breadth

molded (20.50m), depth molded (10m), summer

draft (7.61 m), height from keel (29.16m).

Machineries:

Main engine, Hanshin, LH46LG, power:

3,960hp, speed: 220rpm (1 unit), Auxiliary

engine,Yanmar, 6LAAL-DTN, power: 250kW,

speed: 1,200 rpm (3 units), Harbor generator,

Yanmar, 6CHL-TN 80 kAV, power: 75kW, speed:

1,800rpm (1unit), Emergency generator, Mitsui

Deutz, F4910, power: 40 kW, speed: 1,800 rpm (1

unit)), Bow thruster engine, Yanmar, 6KY-ET1

4CyC, power: 370kW, speed: 2,040rpm (2 units),

Cargo pump, screw type, CSL- 1000P, speed: 600

rpm, pressure: 0.98MPa, capacity 1,000m3/h (2

units), Stripping pump, screw type, CSL-300, speed:

600rpm, pressure: 0.98MPa, capacity: 300 m3/h (1

unit), air conditioner (Daikin Ind US20H, power:

75kW (2 units), Fan, power: 2.5kW (1 unit).

Tanks:

Cargo tank, capacity: 13,307m3, slop tank,

capacity: 1,476m3, MFO tank, capacity: 8,300liter +

343.22m3, MDO tank, capacity: 6,000 liter + 76m3,

ballast tank, capacity: 4,264m3.

Application of MGPS on MT. Savvy

Application of the MGPS pipe guard system on

MT. Savvy uses Hikari production Sangyo Co., Ltd.

Japan with two combination types of installation,

namely:

a. Typical seachest anode arrangement

Copper anodes and aluminium anodes are

installed in the sea chest if the tanker is planned for

drydocking for less than 5 years, assuming there is

sufficient space available.

Figure 2. Type of anode installation on sea chest

Typical strainer anode arrangement

The advantage of the filter mount system is that

the anode can be changed at any time without the

need for drydocking. In this case, the sea water

coming from the sea chest must still be ensured free

from dirt and contamination.

Figure 3. Type of anode installation on filter strainer

Figure 4. MGPS copper electrode and aluminum electrode

Measurement/identification

The dimensions and mass of the electrodes are

measured before carrying out the test. Dimensions

are measured using a vernier caliper and steel ruler.

Figure 5. Dimensional measurement of copper electrode

RRY17

ISCP UTA’45 Jakarta 2022 - International Seminar and Call for Paper Universitas 17 Agustus 1945 Jakarta

302

3 RESULT AND DISCUSSION

The chemical composition of the electrodes used is

obtained from the delivery order sheet, as follows:

Table 1. Chemical composition of copper electrode

RRY17.

The form should be completed and signed by one

author on behalf of all the other authors.

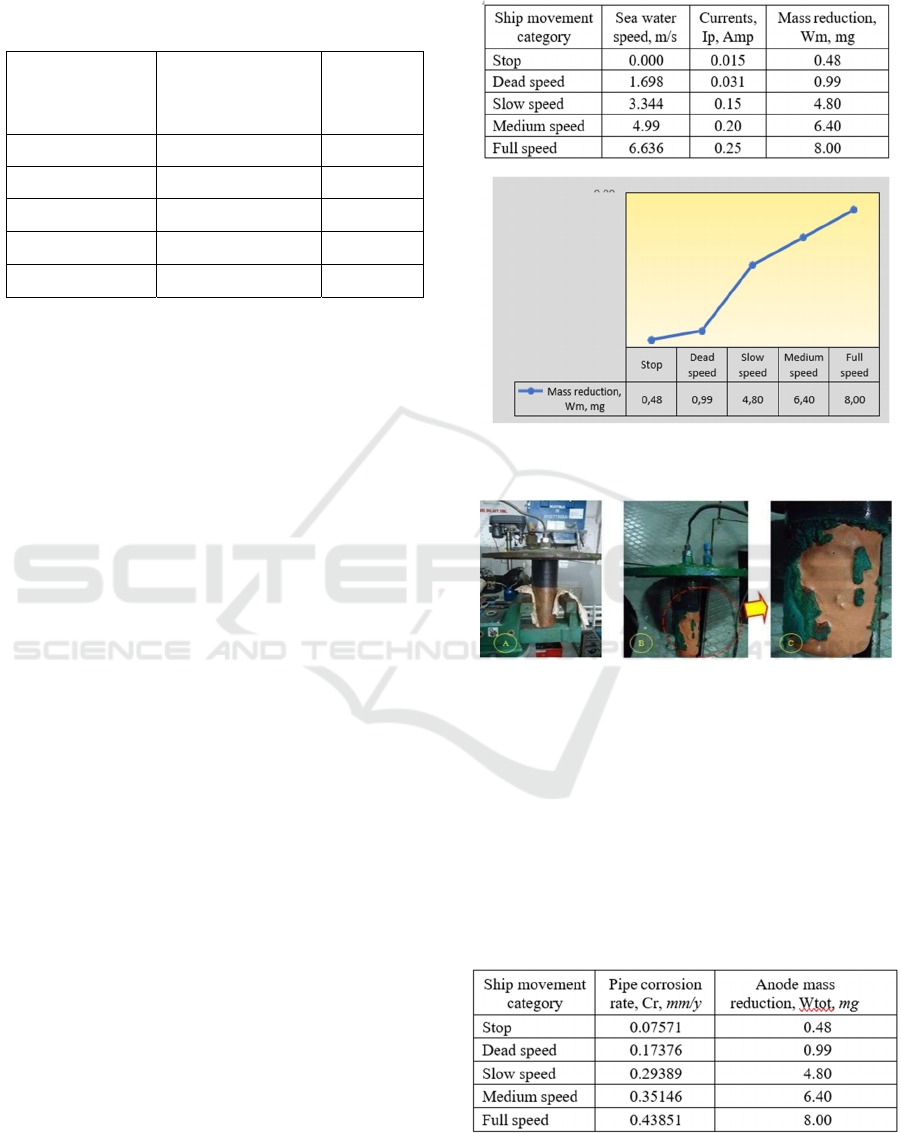

The electrodes (samples) were immersed in a sea

chest box with variations in seawater discharge

based on the speed of the ship for 72 hours. After

observing the data obtained in the form of reduction

of the anode mass as shown in table 2 below:

Table 2. Mass reduction in seawater pipes (JIS F-0507)

Table 3. Corrosion rate in seawater pipes (JIS F 0507)

Figure 6. Effect of ship speed on corrosion rate in

seawater pipes

Steel pipe in seawater (NaCl) environment will

corrode due to the presence of Cl ions. These ions

will break down the passive layer on the seawater

pipe steel (JIS F 0507). When in contact with metal

surfaces, Cl- ions will dissolve metal ions and make

it easier to enter the solution. From Figure 6, it can

be seen that the corrosion rate of the seawater pipe

(JIS F 0507) will increase along with the increase in

the value of the seawater speed, as a modeling of

ship movement

Other research conducted by Seung-Jun Lee et al

also showed that the corrosion rate that occurred in

the sea chest of the ship increased with increasing

flow velocity compared to the static state. When the

ship is traveling at full speed away, the propulsion

engine burns more fuel, thus requiring a cooling

fluid, which in this case is seawater, with a larger

flow capacity, and causes the velocity of the water

flow in the pipe to increase.

2. Weight Reduction on RRY1 Copper

Electrode

The total weight of the anode, Wtot required for

protection can be calculated by the equation:

Wtot = I p Y C

Explanation:

dimana Ip = A Cd

1000

Ip, the current strength needed for protection Y, test

time = 3days or 0.008year

C, anode reduction number = 3.6kg/Amp.y

Cd, electric current density (console panel), mA/m2

A, seawater pipe area = 0.09425m2

µ, utilization factor = 90%

Growth Prevention System for Inhibiting Corrosion Rate in Ship Operation

303

The following is the current density data (Cd) from

various ship speeds as shown in Table 4 below.

Table 4. Test results for copper (Cu) RRY17 electrodes

Ship

movement

category

Sea water

speed, m/s

C

d

,

mA/m

2

Stop 0.000 157.89

Dead speed 1.698 333.16

Slow speed 3.344 1,591.51

Medium speed 4.990 2,122.01

Full spee

d

6.636 2,652.52

Then the value of Wtot for various ship speeds:

a. Water is still or when the ship stops (0m/s)

Cd = 157.89mA/mm

So:

Ip = 0.09425 157,89 = 0.015 Amp

1000

Wtot = 0.015 0.008 3.6 = 0.48 mg

0.90

b. Dead slow ship, 3.3knots (1.698m/s)

Cd = 333.156mA/m2,

so :

Ip = 0.031Amp

Wtot = 0.99mg

c. Ship slow ahead, 6.5 knots (3,344 m/s)

Cd = 1591.51mA/m2,

so :

Ip = = = 0.15 Amp

Wtot = = 4.8mg

d. Half ahead, 9.7 knots (4.99 m/s),

Cd = 2122.01mA/m2,

so:

Ip = = 0.20Amp

Wtot = 6.4mg

e. Full away ship, 12.9knots (6,636m/s),

Cd = 2652.52mA/m2,

so:

Ip = 0.25Amp Wtot = 8.0mg

Table 5. mass reduction of RRY17 copper (Cu) anode at

various vessel speeds

Figure 7. The effect of ship speed on the reduction of the

anode mass of copper (Cu) RRY17

Figure 8. Weight reduction on the copper electrode

RRY17, (A). Initial conditions, (B). Condition after 72

hours, (C). Image magnification B

From the calculation results of the relationship

between the corrosion rate of seawater pipes (JIS F-

0507) compared to the reduction in mass of the

copper anode (Cu) RRY17 as shown in Table 6 and

Figure 9 below.

Table 6. Reduction of mass of copper anode (Cu) RRY17

and corrosion rate of seawater pipe (JIS F-0507) at various

ship speeds

ISCP UTA’45 Jakarta 2022 - International Seminar and Call for Paper Universitas 17 Agustus 1945 Jakarta

304

Figure 9. Reduction of mass of RRY17 copper anode (Cu)

and corrosion rate of seawater pipe (JIS F-0507)

If you look at the mass reduction value at the JIS F-

0507 seawater pipe cathode in Table 6, it is clear

that the reduction that occurs is very large when

compared to the mass reduction that occurs at the

copper (Cu) RRY17 anode. Steel pipe for seawater

pipe JIS F 0507 is at the top of the table and has the

most negative electrode potential value when

compared to copper (Cu) RRY17. Thus, (Fe) is the

most reactive when compared to (Cu). This causes

the cathode weight reduction (JIS F-0507) to be

greater when compared to the RRY17 copper anode

weight reduction. Likewise with (Al), aluminum has

a more negative electrode potential than copper

which is more positive when compared to (Fe).

When comparing the anode weight reduction value

obtained in the field and the anode weight reduction

value obtained from the formula calculation, it is

seen that there is a difference in the anode weight

requirement value. This happens because the

formula does not take into account the speed of the

sea water (ship speed), while the data in the field

shows that the speed of the sea water greatly affects

the weight requirements of the anode. The higher the

speed of the water (vessel speed), the higher the

anode weight requirement which is used to prevent

the growth of marine growth that causes corrosion.

4 CONCLUSIONS

Corrosion rate of seawater pipe (JIS F 0507) on MT.

Savvy increases with increasing sea speed (ship

speed). At the stop speed (0.0m/s) corrosion rate is

0.07571mm/y, at full speed (6636m/s) corrosion rate

is 0.43851mm/y.

The reduction in the mass of the copper (Cu)

RRY17 electrode is higher or faster in proportion to

the speed of sea water (ship speed). At the stop

position (0.0 m/s) the reduction in the mass of the

electrode (Cu) RRY17 is 0.48 mg and the current at

the electrode is 0.015 Ampere. Meanwhile, at full

speed (6.636 m/s) the reduction in the mass of the

electrode (Cu) RRY17 is 8.0 mg and the current at

the electrode is 0.25 Ampere.

The amount of current density (Cd) depends on

the effect of the environment, maintenance and

coating, in this case the speed of the ship is very

influential because when the ship stops the Cd value

is 157.89 mA/m2 while at full speed Cd is 2652.52

mA/m2.

REFERENCES

Borys, B., Jared. C, S. Subramanian, Therese van der

Hoorn, Waheed Zaman., 2015, Corrosion and

Prevention Methods In Desalination Plants,

http://group16chem 409.wikispaces.com

Cheremisinoff., Nicholas, et all, 1983. Cooling Towers-

Selection, Design and Practice. Michigan: Ann Arbor

Science.

Dalimunthe, I., 2004, Kimia dari Inhibitor Korosi, Medan:

USU Digital Library.

Deviyani, Larisa dan Isdiriayani Nurdin., 2006, Inhibisi

Korosi Baja Dalam Air Laut Mengandung Sulfida

Menggunakan Glutaraldehida. Jurnal Teknik Kimia

Indonesia 5 (1) 341-349. Bandung: ITB.

Djatmiko, Eddy dan Budiarto., 2009. Analisis Laju Korosi

dengan Metode Polarisasi dan Potensiodi- namik

Bahan Baja SS 304L, Prosiding Seminar Nasional ke-

15 Teknologi dan Keselamatan PLTN Serta Fasilitas

Nuklir ISSN: 0854 - 2910 . Jakarta: UP dan BATAN.

Fontana, G. Mars and Norbert. D. Greene., 1988.

Corrosion Engineering 2nd , International Student

Edition. Jurong: McGraw-Hill Int. Book. Co.

Geiger, Gary and Mel. J. Esmacher, P.E., 2012,

Controlling Corrosion in Cooling Water Systems-

Part2: Inhibiting and Monitoring Corrosion. New

York: American Institute of Chemical Engineers.

Herro, Harvey. M and Robert D. Port., 1993, The Nalco

Guide to Cooling Water System Failure Analysis,

New York, McGraw-Hill Inc.

Heusler, K.E and L. Fischer. 1976. Kinetics of Pit

Initiation at Passive Iron. Journal Materials and

Corrosion 27 (8) 551–556. Weinheim: Verlag GmbH

& Co. KGaA.

NALCO., 1987, Standard Manual Procedure for Corrosion

Coupon Rate, Illinois, Nalco. Co.

Nur Aziz O., 2012, Studi Pengaruh Laju Alir Fluida

Terhadap Laju Korosi Baja Api SL X-52

Menggunakan Metode Polarisasi Pada Lingkungan

NaCl 3,5% Yang Mengandung Gas CO2. Universitas

Indonesia

Olmsted, John and Greg Williams., 2007, Handbook of

Chemistry and Physics, 5th edition, New York: CRC

Press-Taylor & Francis Group.

Growth Prevention System for Inhibiting Corrosion Rate in Ship Operation

305

Priyotomo, Gadang., 2015, Korosi, Serpong: Pusat

Penelitian Metalurgi & Material LIPI. Rozenfeld, I. L.,

1988, Corrosion Inhibitors, New York: McGraw-Hill

Co, Inc.

Seung Jun Lee and Jun Lee Seong, 2011, Effects of flow

velocity on electrochemical behavior of sea chest

5083-H116 Al alloy for ship, Transactions of

Nonferrous Metals Society of China, Vol. 21 (8) p.

1703-1709.

Uhlig, H.H and Robert W. Revie., 2008, Corrrosion and

Corrosion Control, An Introduction to Corrosion

Science and Engineering, 4th Edition, New Jersey:

John Willey and Sons. Inc.

Yari, Mehdi., 2015, An Intro to Pipeline Corrosion in

Seawater, Ontario: University Of Western Ontario.

ISCP UTA’45 Jakarta 2022 - International Seminar and Call for Paper Universitas 17 Agustus 1945 Jakarta

306