Design and Analysis Go-Kart Chassis with Rear Movement on 150cc

Motor Engine

Sri Endah Susilowati

1

and Hendrickues Fernando

2

1

Universitas 17 Agustus 1945, Jakarta 14350, Indonesia

2

Department of Mechanical Engineering, 17 Agustus 1945 Jakarta University, Jakarta, Indonesia

Keywords: Go-kart, Rear Drive, Performance.

Abstract: Go-kart is a type of sports car, open vehicle, four wheeler, or quadracycle. The Go-kart chassis experiences

loads from, the engine, drivers and the mass of the chassis itself. In this design, the Go-kart frame is made

using hollow iron material 40 x 12mm, 1.2mm thick with a rear-wheel drive engine with a capacity of 150cc

combustion chamber. Steel plate material is used using SMAW welding with welding wire RB E6013 2.6mm

with a current of 70A, welding position 1G (or flat position). The test is carried out with the Universal Tensile

Testing Machine, the material is pulled past the maximum stretch elasticity limit until the test object finally

reaches the limit (break). Tensile testing takes approximately 3-5 minutes with a load of 10-20N. For the

chassis frame, the strength is done by knowing the magnitude of the bending moment acting on the chassis

frame and the maximum bending stress that occurs. With a driver's weight of 55 kg, the flexural stress received

is 300kg.m, and the maximum flexural stress received by the chassis is 0.4477kg/cm2, which is smaller than

the allowable stress for the material 5.7kg/cm2. From these results, the chassis design is considered safe.

1 INTRODUCTION

Go-kart is a simple, light, four wheeled sports car,

single seater racing car, without suspension and

differential gear and is used by people who are

interested in auto racing sports like Formula 1 or

Formula E etc(Krishnamoorthi et al., 2021;

Srivastava, J. P, 2021). This type of vehicle is

designed and manufactured specifically for racing

purposes. Go-karts are small racing vehicles without

suspension and are rarely used with differentials

(Shaik Himam Saheb et al., 2016; J.D. Andrew Pon

Abraham, 2017; Govardhana Reddy, 2016). Go-karts

are often used as light entertainment in spare time and

for racing sports that are included in the Formula 9

category (Prof. Ambeprasad Kushwaha, 2018; Syed

Azam Pasha Quadri, 2017; Harshal D. Patil, 2016;

V.S. Shaisundaram, 2020). Go-kart consists of

various types such as internal combustion engine,

electric powered, and Hybrid. Go-karts are compact,

simple, light and easy to operate vehicles, designed

for flat track racing so that the ground clearance is

very small compared to other vehicles(Koustubh

Hajare, 2016). The basic components are the chassis,

steering, axle, engine, bumper and wheels. The

vehicle is under a low speed race car which has low

ground clearance and hence no suspension system(U.

Kalita,2018).

The creation of this Go-kart is intended as a

learning tool for someone to start a racing career.

Some people ride it as entertainment or as a hobby by

non-professionals (S.A.P. Quadri, 2017). The car

chassis is analogous to the human body frame. The

chassis, also known as the 'Frame', is the basic

structure of any car that supports it from below. The

purpose of the chassis is to support the weight of the

car both in idle and dynamic conditions. As a result

of engine vibration, unbalanced mass, and irregularity

in the way the vehicle can experience complex

vibrations, which are detrimental to the health of

passengers and vehicle parts (M. Mohanta, 2018). In

addition, vibration cannot be completely eliminated

from the mechanical structure of the element, but can

be reduced (N. K. Saini, 2019). In general, suspension

systems are used to reduce vibration. However, the

Go-kart has no suspension. Therefore, it is very

important to control the vibration of the vehicle

within the permissible limits to protect the safety and

physical health of the driver. In the future composite

materials can be used to design Karts which will help

to reduce the weight of the frame material, have good

control and fast acceleration. Electric vehicles are

Susilowati, S. and Fernando, H.

Design and Analysis Go-Kart Chassis with Rear Movement on 150cc Motor Engine.

DOI: 10.5220/0011980400003582

In Proceedings of the 3rd International Seminar and Call for Paper (ISCP) UTA â

˘

A

´

Z45 Jakarta (ISCP UTA’45 Jakarta 2022), pages 307-311

ISBN: 978-989-758-654-5; ISSN: 2828-853X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

307

becoming the most promising in the current situation

as the industry turns to renewable and pollution-free

energy (Krishnamoorthi,2021).

In this paper, a chassis for a Go-kart with rear

wheel drive is made which is driven by a 150cc motor

engine. The chassis is made of hollow steel measuring

40 x 12mm, 1.2mm thick, which is designed in such

a way that it can withstand the weight of the engine

and its drivers. In addition, to determine the

performance of the kart engine using 2 steps on a

150cc motorcycle engine, namely regarding the

strength of the welded connection and the strength of

the frame in accepting the load from the engine and

driver.

2 MATERIALS AND METHODS

Before the Go-kart making process is carried out, the

steps taken are to make the design of the main frame,

followed by the design of other supporting

components. The Go-kart chassis is made using

hollow steel with a size of 40 x 12 mm, 1.2 mm thick.

Hollow iron is made of carbon steel with 1.7% carbon

content and 1.65% manganese along with a number

of other alloying materials.

The Go-kart chassis was designed using the

AutoCAD 2017 computer application. The chassis

designed is a Go-kart for sprints so it uses a straight

frame, where the driver's position is in the middle.

The cut materials are joined by SMAW welding using

2.6 mm RB E6013 electrodes with a current of 70A.

The main part of the chassis frame is what supports

the engine, driver and other parts. Before being

assembled into a complete frame, the chassis material

is tested by welding to ensure that it has sufficient

strength. The tests carried out are tensile tests carried

out with the Universal Testing Machine (Figure 1).

The second testing stage is load testing, the passenger

weight is 56kg, and the engine weight is 40 kg. The

result is the chassis is able to withstand the load.

Figure. 1: Universal Testing Machine.

3 RESULTS AND DISCUSSIONS

The results of the design, assembly and welding of the

Go-kart chassis using SMAW welding can be seen in

Fig. 2 and Fig. 3, while the results of the tensile

testing can be seen in the Table 1.

Figure 2: Design of Chasis.

Figure 3a: Design result.

Figure 3b: Design result.

ISCP UTA’45 Jakarta 2022 - International Seminar and Call for Paper Universitas 17 Agustus 1945 Jakarta

308

Testing the strength of the welding results is

carried out by the tensile strength test method. The

results of the tensile test can be seen in Table 1 below:

Table 1a: Test result data.

Uji Sampel/

Test Point

Wo A L

(mm) (mm

2

) (mm)

Sample 1 25.4 50.8 35

Sample 2 25.4 50.8 34.8

Sample 3 25.6 50.8 34.9

Table 1b: Test result data.

Uji

Sampel/

Test Point

L

A

(mm)

Ɛ

(%)

F

max

(N)

σ

t Max

(Mpa)

Sample 1 35.6 1.017 25 0.49210

Sample 2 35.8 1.028 27 0.53149

Sample 3 35.5 1.017 26 0.51180

These data are calculated using the formula for strain

and stress as follows:

1. From the material sample 1 test data obtained:

Strain

𝜀

∆𝐿

𝐿

LA = 35.0 mm

LO = 36.5 mm

𝜀

𝐿

𝐿

𝐿

35.6 35.0

35.0

𝟏.𝟎𝟏𝟕%

Stress

𝜎

𝐹

𝐴

F = 9 N

A = 50.8 mm

2

𝜎

9

50.8

0.018065

𝑘𝑔

𝑚𝑚

0.17716 𝑀𝑃𝑎

𝜎

.

𝐹

𝐴

𝜎

.

25

50.8

0.0500182

𝑘𝑔

𝑚𝑚

0.𝟒𝟗𝟐𝟏 𝑴𝑷𝒂

With the same way, the calculation of the results of

welded joints on sample materials 1, 2 and 3, will

obtain the maximum stress values respectively as

follows: 0.4921 MPa, 0.53149 MPa and 0.5118 MPa.

Calculation of Chassis / Frame Strength due to

Loading

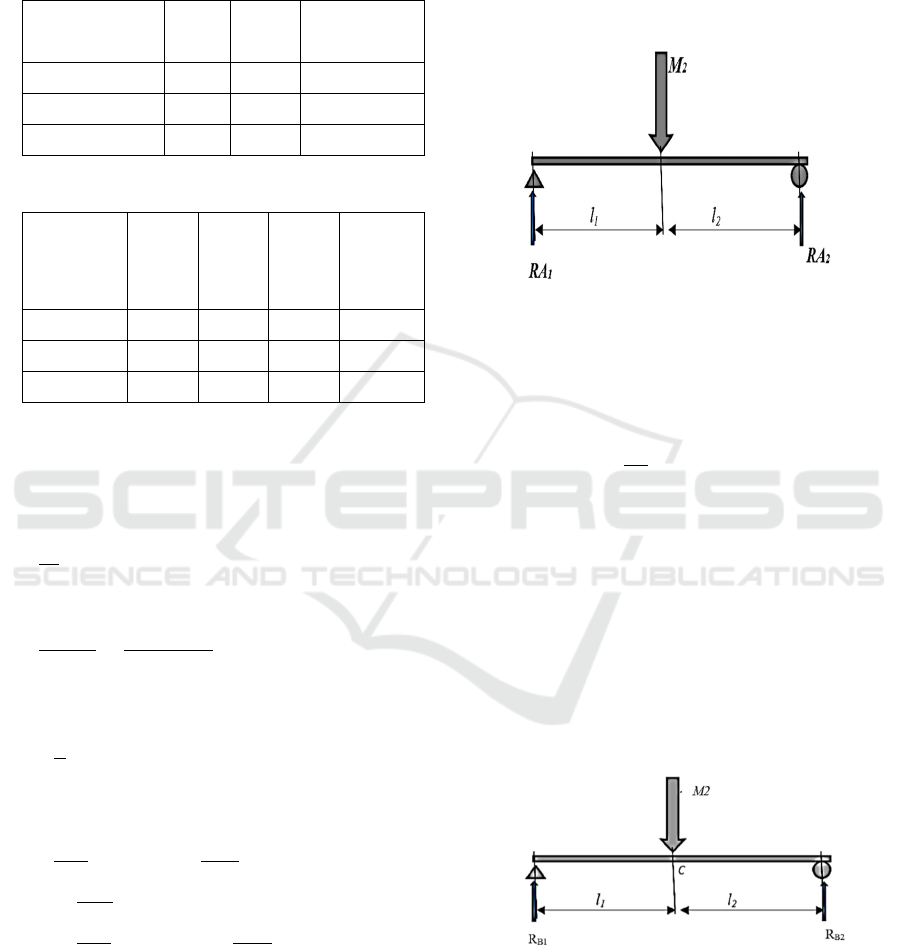

3.1 Loading on Transverse Frame

3.1.1 Distribution of Engine Load on

Vehicle Chassis

M

2

= 40 kg (machine weight)

𝑙

𝑙

17 𝑐𝑚

Figure 4: Front View of Machine Load.

Reaction force at the end of the frame

ΣMA

1

= 0

(M

2

. l

1

) – (RA

2

.(l

1

+ l

2

)) = 0

40 x 17 – RA

2

x 34 = 0

RA2

20 kg

l

1

= l

2

,

So:

RA

1

= RA

2

= 20 kg

Bending moment in C

M

C

= 17 x 20 = 340 kg.cm

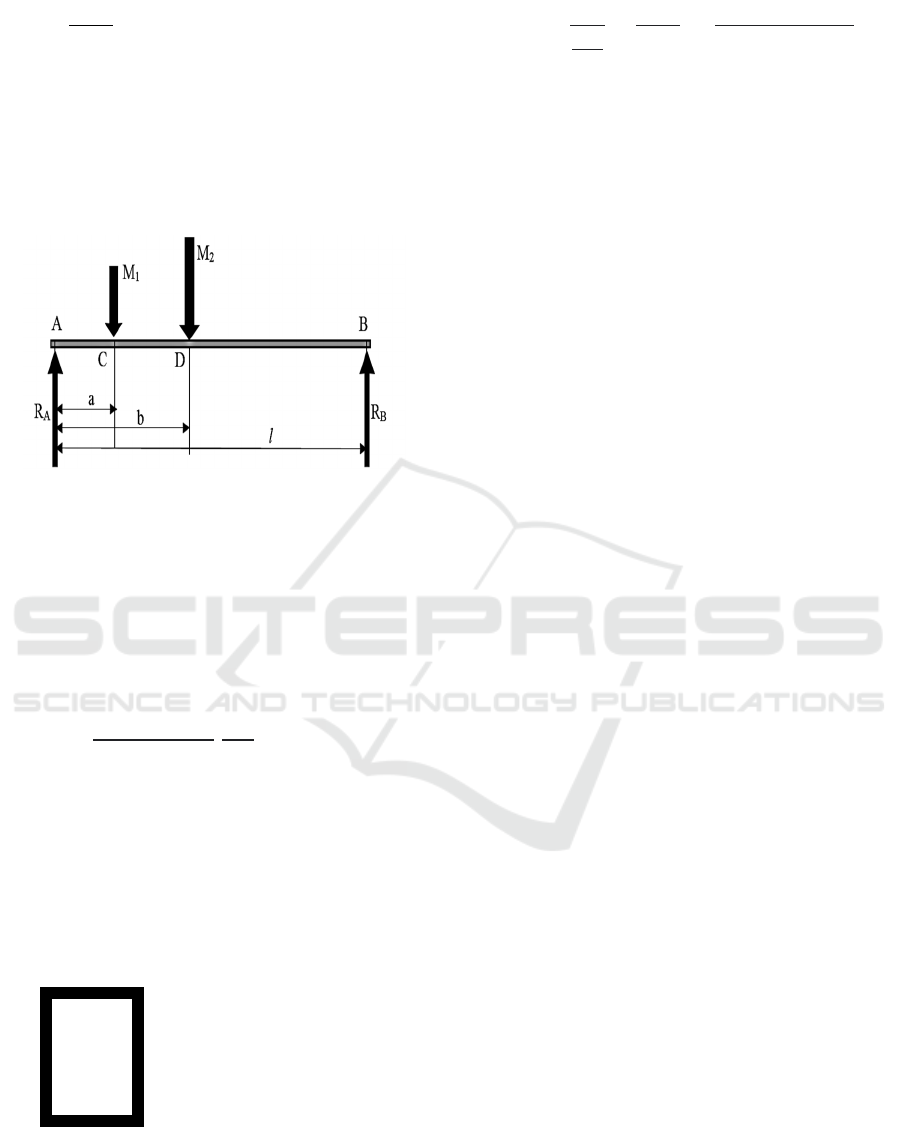

3.1.2 Load Due to Driver's Weight

M

1

= 56 kg

l

1

= l

2

= 30 cm

Figure 5: Front view driver's weight load.

Reaction force at the end of the frame

ΣMA = 0

M

1

x l

1

– (R

B2 x

(l

1

+ l

2

)) = 0

56 x 30 – R

B2

x 60 = 0

Design and Analysis Go-Kart Chassis with Rear Movement on 150cc Motor Engine

309

RB2

1680

60

28 kg

R

B1

= R

B2

= 28 kg

Bending moment at point C

M

C

= 28 x 30 = 840 kg.cm = 8.4 kg.m

3.2 Calculation of the Load on the Side

Frame

Figure 6: Frame load from side view.

M

1

(Mass of Engine) = 56 kg

M

2

(Mass of Driver) = 40 kg

3.2.1 Reaction Force at Point A and Point B

ΣM = 0

(M

1

x a) + (M

2

x b) – R

B

x l = 0

(56 x 40) + (40 x 75) – R

B

x 175 = 0

RB

30 k

R

A

= M

1

+ M

2

– R

B

= 56 + 40 – 29,94 ≈ 66 kg

3.2.2 Bending Moment

M

C

= R

A

x a = 66 x 0,40 = 26,4 kg.m

M

D

= R

B

x (l – b) =30 x ((175-75))/100=300 kg.m

The greatest bending moment occurs at point D

Bending Stress

4

cm

1,2 cm

σb

M

bh

6

M . 6

bh

300

0,012 x 0,04

4.477 kg/m

0,4477 kg/cm

4 CONCLUSIONS

In a very competitive world of racing, it takes a Go-

kart that is safe, comfortable, and has good engine

performance when driven in the racing arena. To

determine the reliability of the chassis from the

design results, it is carried out through a load test on

the chassis/Go-kart frame and a road test. Go-kart

engine used is a static engine with a capacity of 150

cc and a maximum power of 6 HP with a transmission

using a chain. The results of the chassis test with a

driver weight of 56 kg, experienced a very small

deflection, so it could be ignored, the turning

behavior was known that the kart was oversteered, the

results of the frame strength test found that the kart

had a deflection in the frame, it is recommended that

the maximum driver weight be 55 kg.

REFERENCES

Krishnamoorthi, S., Prabhu, L., Shadan, M. D., Raj, H., &

Akram, N. (2021). Design and analysis of electric Go-

Kart. Materials Today: Proceedings, 45, 5997-6005.

Srivastava, J. P., Reddy, G. G., & Teja, K. S. (2021).

Numerical investigation on vibration characteristics

and structural behaviour of different go-kart chassis

configuration. Materials Today: Proceedings, 39, 176-

182.

Shaik Himam Saheb, RavSandeep Kumar Kona, Md.

Hameed Beretta, J. (2016). Design report of a Go Kart

vehicle Vol. 1, Issue 9, ISSN No. 2455-2143, Pages 95-

102.

Kiral Lal, O.S. Abhishek, (2016). Design, analysis and

fabrication of Go-Kart, Int. J. Sci. Eng. Res., Volume 7,

Issue 4, ISSN 2229-5518.

J.D. Andrew Pon Abraham, S. John Alexis, C. Naveen

Kumar, G. Rajkumar, R. Kishore. (2017) Design and

analysis of Lcv Chassis (Tata 407), J. Adv. Res.

Dynam. Control Syst. Vol. 9. Sp– 14.

Govardhana Reddy, Md. Hameed.(2016) Design report of

a go kart vehicle, Int. J. Eng. Appl. Sci. Technol., Vol.

1, Issue 9, ISSN No. 2455-2143, Pages 95- 102

Prof. Ambeprasad Kushwaha & Prof. Avinash Chavan

Tapeshwar A. Das, Shubham S. Kenjale, Jay A. Patel,

Pradeep R. Prajapati. (2018). Design and fabrication of

cost effective electric Go Kart, Int. Res. J. Eng.

Technol. (IRJET) eISSN: 2395-0056, p-ISSN: 2395-

0072 Volume: 05 Issue: 04.

ISCP UTA’45 Jakarta 2022 - International Seminar and Call for Paper Universitas 17 Agustus 1945 Jakarta

310

Syed Azam Pasha Quadri, Appam Nihar, Md Khader Mohi

Uddin, Nadeem Khan, Muzamil Ahmed, Syed Nomaan

Qureshi.(2017). Design and analysis of electric Go-

Kart Chassis, Int. J. Res. Appl. Sci. Eng. Technol.

(IJRASET), IC Value: 45.98 ISSN: 2321-9653,

Volume 5 Issue I.

Harshal D. Patil, Saurabh S. Bhange, Prof. Ram, Ashish S.

Deshmukh (2016). Design and analysis of Go-Kart

using finite element method, Int. J. Innov. Emerg. Res.

Eng., Volume 3, Special Issue 1, ICSTSD 2016.

V.S. Shaisundaram, M. Chandrasekaran, S. Mohan Raj, R.

Muraliraja, Investigation on the effect of thermal

barrier coating at different dosing levels of cerium

oxide nanoparticle fuel on diesel in a CI engine, Int. J.

Ambient Energy 41 (1) (2020) 98–104.

Koustubh Hajare, Yuvraj Shet, Ankush Khot, “A Review

Paper On Design And Analysis Of A Go-Kart Chassis”,

IJETMAS, Volume 4, ISSUE 2, ISSN 2349-4476,

February 2016

U. Kalita, Y.S. Teja, D. Sri, V. Venkata, Design and

analysis of Go-Kart chassis, IJEDR 6 (2) (2018) 290–

295.

S.A.P. Quadri, M.Y. Ahmed, M. Salman, Design and

analysis of Go-Kart chassis, Iarjset 4 (5) (2017) 28–36.

M. Mohanta, G. Setu, V. Ranjan, J.P. Srivastava, P.K.

Sarkar, Indian railway track analysis for displacement

and vibration pattern estimation, Vibroeng. Procedia

21 (2018) 71–76.

N. K. Saini, M. S. Panwar, A. Maurya, P. A. Singh,

‘‘Design and Vibration Analysis of Go-kart Chassis

Design and Vibration Analysis of Go-kart Chassis,” no.

July, 2019.

Design and Analysis Go-Kart Chassis with Rear Movement on 150cc Motor Engine

311