The Effect of Welding Electrode Variation on the Mechanical

Properties and Microstructure of API 5L Shielded Metal Arc Welds

Sri Endah Susilowati and Didit Sumardiyanto

Department of Mechanical Engineering, Universitas 17 Agustus 1945 Jakarta, Indonesia

Keywords: Electrodes, Weld Metal, Mechanical Properties, Micro Structure.

Abstract: Welding is a metallurgical bond on metal alloy joints that is performed while the metal alloy is melted or

liquid. The purpose of this research is to determine the effect of the electrode types E 6010 and E 7016 on the

mechanical properties and microstructure of API 5L low carbon steel during SMAW welding. The welding

electrodes are E 6010 and E7016, and the welding current is 110A. The welding seam used is a v-groove with

a 60o angle. Welding samples were cut and machined into standard configurations for tensile strength, impact,

and hardness tests, as well as SEM for microstructure analysis. The results show that the type of electrode has

a significant effect on mechanical properties such as tensile strength, impact, and hardness of the welding

metal. Welding electrodes of various types are used as the welding variable. The E 7016 electrode has the

highest tensile strength with a tensile strength value of 617 MPa, while the E 6010 electrode has a tensile

strength of 554 MPa, and the E 7016 electrode has the highest toughness with a toughness value of 1.856

Joules / mm2. The E 7016 weld metal area had the highest average hardness of186.9 VHN. SEM

microstructure analysis reveals several phases, including Acicular Ferrite (AF), Grain Boundary Ferrite

(GBF), and Bainite.

1 INTRODUCTION

Welding is a metallurgical bond on metal or metal

alloy joints which is carried out in a melted or liquid

state. In other words, welding is a local joint of

several metal rods using heat energy. Today, a variety

of different welding processes are available, such that

welding is extensively used as a fabrication process

for joining materials in a wide range of compositions,

part shapes and sizes. Welding is an important joining

process because of high joint efficiency, simple set

up, flexibility and low fabrication costs (Armentani,

2007). Welded joints are finding applications in

critical components where failures are catastrophe.

Hence, inspection methods and adherence to

acceptable standards are increasing. These ac‐

ceptance standards represent the minimum weld

quality which is based upon test of welded specimen

containing some discontinuities. Welding involves a

wide range of variables such as time, temperature,

electrode, pulse frequency, power input and welding

speed that influence the eventual properties of the

weld metal (Jariyaboon et al., 2007; Karadeniz et al.,

2007; Lothongkum et al 2001; Lothonhkum., 1999;

Mirzaei et al 2013; Sakthivel et al., 2009; Razal et al.,

2012; afolabi 2008). Welding of steel is not always

easy. There is the need to properly select welding

parameters for a given task to provide a good weld

quality. Welding is an efficient, dependable and

economical process. The electrodes used in SMAW

welding have different compositions of the

membrane and core wire. The chemical composition

and the magnitude of the current can affect the

mechanical properties welded material joints which

have an impact on the strength and toughness of the

welded joints. Selection of the right electrode will

produce good and perfect welding results, therefore

choosing the type of electrode is very important

before carrying out the welding process.

2 METHODS

The welding process uses SMAW (Submerged Arc

Welding) using a current of 110 A and the type of

electrode E 6010 and E 7016. The type of groove used

is v-groove with angles 600. The material used in this

study is API 5L Grade X 52 pipe with a diameter of 6

inches and a thickness of 8 mm which is welded with

312

Susilowati, S. and Sumardiyanto, D.

The Effect of Welding Electrode Variation on the Mechanical Properties and Microstructure of API 5L Shielded Metal Arc Welds.

DOI: 10.5220/0011980500003582

In Proceedings of the 3rd International Seminar and Call for Paper (ISCP) UTA â

˘

A

´

Z45 Jakarta (ISCP UTA’45 Jakarta 2022), pages 312-316

ISBN: 978-989-758-654-5; ISSN: 2828-853X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

E 6010 and E 7016 electrodes using 3 stages, namely

root, filler, capping . API 5L pipe material is a low

carbon steel pipe material with a carbon content of

0.25% and wear-resistant properties. The chemical

composition of API 5L pipe material is C (0,20%),

Mn (1.35%), P (0,025% max), S (0.01% max), and

Fe. The standard referred to is ASME (American

Society of Mechanical Engineers) Boiler and

Pressure Vessel Code Section IX, one of many used

in the oil and gas industry(Asme spec,2010). The

experiment was designed with the different types of

welding electrode as variables. The mechanical

properties of the weld zone, including tensile

strength, impact toughness, hardness, and the

microstructure with SEM, were observed.

3 RESULT AND DISCUSSIONS

3.1 Tensile Properties

Tensile testing is performed using a servopulser

machine at a scale of 10 tons and at room temperature.

The tensile test is used to determine the tensile

strength of low alloy steel produced by SMAW

welding with various electrodes. The effects of

different types of welding electrodes at a specific

current of 110A on the tensile strength of the weld

metal were studied. Each condition was run three

times, for a total of six sets. The result was

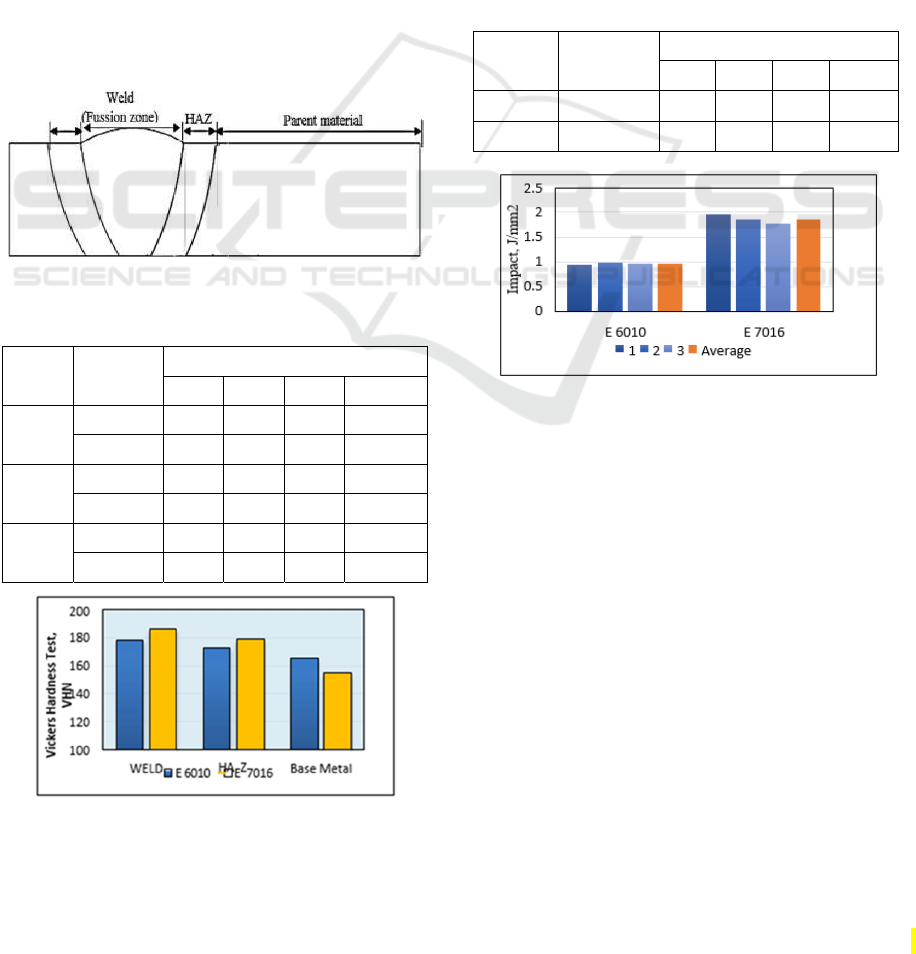

summarized in Table 1 and Figure 1.The different

electrode usage produce significantly different tensile

strength values. The tensile strength value of the E

6010 type of electrode has a value of 554 MPa and for

the E 7016 type of electrode is 617 MPa. There is a

difference in the valueof tensile strength by 11,5% of

the two electrodes, where the E7016 electrode has a

greater value than E 6010. The main variables in the

SMAW process can be described as weld electrode,

flux and welding parameters (Kanjilal et al., 2006).

The welding parameters of SMAW are current,

polarity, voltage, weld groove, travel speed, distance

between electrodes, electrode extension, angle and

diameter [Candel et al., 1997; Kolhe et al., 2008].

Table 1: Test Results for Tensile Strength in the Weld

Metal.

Electrode Welding

Current (A)

Tensile Strength, MPa

1 2 3 Average

E 6010 110A 563 545 554 554

E 7016 110A 627 609 614 617

Figure 1 shows that the E 6010 welding electrode

produces a lower tensile strength value than the

E7016 welding electrode both in tests 1, 2 and 3. The

average tensile strength of the E 6010 welding

electrode is 554 MPa, while for the E 7016 electrode

it is 617 MPa . The significant difference is 11.5%.

These results are similar to studies conducted by

several other investigators [14-16]. The E 6010

electrode material is composed of C (0.08%), Mn

(0.5%), Cr (0.06%), and Si (0.3), whereas the E7016

electrode is composed of C (0.1%), Mn (0.9%), and

Cr (0.14%), Si (0.3). (0.7). The results show that the

welding electrode E 6010 has a lower tensile strength

than E 7016 because its composition of C, Mn, and

Cr is lower [17]. This study demonstrated that

increasing Mn, C, or Cr individually can increase

tensile strength and hardness values of welded joints

[18].

Figure 1: Tensile Strength of Weld Metal.

3.2 Hardness

Hardness testing was performed at several points in

each specimen. The point is parent material/base

metal, HAZ and weld (fussion zone). Vickers

hardness testing area identification scheme with

electrodes E7016, and E 6010 is shown in Figure 2.

The Vickers HVN hardness test results of each

electrode type in the welding area ,HAZ, and parent

material are shown in Table 2and Figure 3. The

Vickers hardness value of the E7016 electrode

welded metal area is 186.9 VHN, higher than the

E6010 electrode type of 178.4 VHN. This result is

similar to research conducted by several other

researchers [Bracarense et al., 1994; Sarian et al.,

1999; Talabi et al.,2014; Tahir et al., 2018]. During

the welding process, a thermal cycle occurs in the

weld metal area and the HAZ includes heating to a

certain temperature. This affects the microstructure

and mechanical properties of the weld metal and

HAZ, so that the weld metal will undergo a phase

transformation. The thermal cycle is thawing then

Tensile strength,

The Effect of Welding Electrode Variation on the Mechanical Properties and Microstructure of API 5L Shielded Metal Arc Welds

313

freezing. This condition causes changes in the

microstructure of the metal concerned, while changes

in grain size and structure formed in the

microstructure results in different mechanical

properties values. The hardness value of the HAZ

region for each electrode is lower than that of the weld

metal region. This is due to the fact that in the HAZ

area there is an increase in the size of ferrite grains

compared to the weld metal, so it can affect the nature

of hardness in the HAZ area. In the HAZ area, there

is an enlargement of the ferrite grain size compared

to the weld metal, so that it affects the hardness

properties in the HAZ area. Since thegrain size

becomes coarse when welding current increase, the

mechanical properties such as hardness value, impact

and tensile strength value reduce (Bodude et al., 2015

& Gharibshahiyan et al., 2011). As the heat energy

input was increased, the mechanical properties for

tensile strength, impact and hardness decrease due to

microstructure of coarse pearlite in ferrite matrix

become coarse as the grain size increase(Asibeluo et

al., 2015).

Figure 2: Hardness testing point.

Table 2: The Result of Vickers Hardness Test

Area Electrode Vickers Hardness Test (VH)

1 2 3 Average

Weld

E 6010 173,9 187,4 173,9 178,4

E 7016 189,2 185,7 185,7 186,9

HAZ

E 6010 170,7 175,9 170,7 172,4

E 7016 170,5 183,6 183,6 179,2

Base

Metal

E 6010 165,9 163,8 165,9 165,2

E 7016 152,5 159,5 152,5 154,8

Figure 3: The Vickers Hardness Test.

3.3 Impact Toughness

Toughness is the ability of a material to absorb energy

before it breaks or toughness is the ability of a weld

to permanently deform while absorbing energy before

fracturing, specifically when stress is applied

rapidly—typically, in under one second. Impact test

was conducted to know the mechanical properties of

low carbon steel material as a test material in this

research. In general, materials with a body center

cubic (bcc) crystal structure such as low carbon steel

and alloy steel show brittle properties at low

temperatures.The result of the impact test is generally

the toughness parameter (notch blow value). Table 3

and Figure 4 summarize the effects of electrode types

on weld metal impact toughness. Each condition was

replicated three times. The figure depicts a profile that

is similar to that of the hardness properties.

Table 3: The result of The Impact Toughness Test.

Electrode Welding

Current (A)

Impact J/mm

2

1 2 3 Average

E 6010 110A 0,9432 0,9844 0,9592 0,96

E 7016 110A 1,9544 1,8478 1,7670 1,85

Figure 4: The Impact Toughness Test.

Figure 4 shows that the electrode E 6010 has the

lowest average impact toughness value of 0.96

J/mm2. However, E7016 has the highest average

impact toughness value, which is approximately 1.85

J/mm2 because contains large Mn elements, 0.9% and

silicon (Si) content of 0.7%, higher thanthe content of

the E6010 electrode, namely Mn elements by 0.5%

and Si by 0.3%. The function of the Mnelement is to

bind carbon (C) to form manganese carbide (Mn3C)

which can increase the strength, toughness of steel

and increase hardness. The function of the elemental

content of silicon is to form a verystrong ferrite and

also to strengthen steel.

3.4 Weld Metal Microstructure

The passage of a welding arc produces three zones in

ISCP UTA’45 Jakarta 2022 - International Seminar and Call for Paper Universitas 17 Agustus 1945 Jakarta

314

the welding process: (1) the weld metal, or fusion

zone, (2) the heat-affected zone, and (3) the

unaffected zone, or base metal. The weld metal is the

part of the joint that has been melted during the

welding process. The heat-affected zone is a region

adjacent to the weld metal that has not been welded but

has changed in microstructure or mechanical

properties as a result of welding heat. The unaffected

material is one that was not sufficiently heated to

change its properties. In welded metals, the

microstructure typically consists of two or more

phases, namely grain boundary ferrite, ferrite

widmanstatten, acicular ferrite, bainit, and

martensite. The acicular ferrite has a random

direction orientation and is intragranular in size.

Typically, acicular ferrite microstructures are formed

around 650°C and have the highest toughness

compared to other microstructures(Abson et al.,

2013). Figure 5a depicts the weld metal microstructure

with an E 6010 electrode. There is a significant

amount of fine bainit and some acicular ferrite (AF).

Figure 5b depicts the microstructure of weld metal

with E7016 electrode, which contains a significant

amount of fine acicular and some minor grain

boundary ferrite (GBF). Acicular ferrite is a

microstructural constituent that is commonly formed

in low alloy steel weld metal deposits and has a direct

impact on mechanical properties, particularly

toughness and hardness (Sumardiyanto et al., 2018;

Maksuti).

a b

Figure 5: Microstructure Weld Metal: a.With E 6010

Electrode and b. E 7016 Electrode.

4 CONCLUSIONS

Welding parameters (electrode type and heat input /

welding current) have a significant effect on the

tensile strength, hardness, and impact of the welded

metal on API 5L low carbon steel via SMAW

welding. The optimum tensile strength for welding

metal is produced by the welding electrode E7016 at

110A with 617 MPa, while the lowest value is 554

MPa (decline of 11.4%) for E6010 at 110A, the

optimum hardness is produced by E7016 at welding

current of 110A with 186.9 VHN, while the lowest is

178,4 VH (decline of 4.8%) for E6010 at 110A, and

impact toughness is 1.85Joules/mm2 by E7016 at

110A while the lowest 0.96 J/mm2. SEM

microstructure analysis reveals several phases,

including Acicular Ferrite ( (AF), Grain Boundary

Ferrite (GBF) and Bainite.

REFERENCES

Armentani, E., Esposito, R., Sepe, R. (2007). The effect of

thermal properties and weld efficiency on residual

stresses in welding, Journal of Achievements in

Materials and Manufacturing Engineering, Vol. 20, No.

1-2, 319-322.

Jariyaboon, M., Davenport, A.J., Ambat, R., Connolly,

B.J.,Williams, S.W., Price, D.A. (2007). The effect of

welding parameters on the corrosion behaviour of

friction stir welded. AA2024-T351, Corrosion Science,

Vol. 49, No. 2, 877-909, doi: 10.1016/

j.corsci.2006.05.038.

Karadeniz, E., Ozsarac, U., Yildiz, C. (2007). The effect of

process parameters on penetration in gas metal arc

welding processes, Materials & Design, Vol. 28, No. 2,

649- 656, doi:10.1016/j.matdes. 2005.07.014.

Lothongkum, G., Viyanit, E., Bhandhubanyong, P. (2001).

Study on the effects of pulsed TIG welding parameters

on delta-ferrite content, shape factor and bead quality in

orbital welding of AISI 316L stainless steel plate,

Journal of Materials Processing Technology, Vol. 110,

No. 2, 233-238, doi: 10.1016/S0924-0136(00)00875-X.

Lothongkum, G., Chaumbai, P., Bhandhubanyong, P.

(1999). TIG pulse welding of 304L austenitic stainless

steel in flat, vertical and overhead positions, Journal of

Materials Processing Technology, Vol. 89-90, 410-414,

doi: 10.1016/S0924-0136 (99)00046-1.

Mirzaei, M., Arabi Jeshvaghani, R., Yazdipour, A.,

Zangeneh-Madar, K. (2013). Study of welding velocity

and pulse frequency on microstructure and mechanical

properties of pulsed gas metal arc welded high strength

low alloy steel, Materials & Design, Vol. 51, 709-713,

doi: 10.1016/j.matdes.2013.04.077.

Sakthivel, T., Sengar, G.S., Mukhopadhyay, J. (2009).

Effect of welding speed on microstructure and

mechanical properties of friction-stir-welded

aluminum, The Internation al Journal of Advanced

Manufacturing Technology, Vol. 43, No. 5-6, 468- 473,

doi: 10.1007/s00170-008-1727-7.

Razal Rose, A., Manisekar, K., Balasubramanian, V.

(2012). Influences of welding speed on tensile

properties of friction stir welded AZ61A magnesium

alloy, Journal of Materials Engineering and

Performance, Vol. 21, No. 2, 257-265, doi:10.1007

/s11665- 011-9889-0.

Afolabi, A.S. (2008). Effect of electric arc welding

parameters on corrosion behaviour of austenitic

stainless steel in chloride medium, AU Journal of

Technology, Vol. 11, No. 3, 171-180.

The Effect of Welding Electrode Variation on the Mechanical Properties and Microstructure of API 5L Shielded Metal Arc Welds

315

ASME Boiler and Pressure Vessel Code Section IX –

Welding and Brazing Qualification, 2010.

Kanjilal P, Pal TK, Majumdar SK (2006) Combined effect

of flux and welding parameters on chemical

composition and mechanical properties of submerged

arc weld metal. J Mater Process Technol 171: 223–231.

Chandel RS, Seow HP, Cheong FL (1997) Effect of

increasing deposition rate on the bead geometry of

submerged arc welds. J Mater Process Technol 72:124–

128.

Kolhe KP, Datta CK (2008) Prediction of microstructure

and mechanical properties of multipass SAW. J Mater

Process Technol 197:241–249.

Bracarense, A. Q., and S. Liu. "Control of covered electrode

heating by flux ingredients substitution" Welding and

Metal Fabrication 62.5 (1994).

Sarian, S. A., and L. A. De Vadia. "All Weld Metal Design

For AWS E10018M, E11018M And E12018M Type

Electrode." Welding Research Supplement (1999):

217- 219.

Talabi, SIa, et al. "Effect of welding variables on

mechanical properties of low carbon steel welded

joint." Advances in Production Engineering &

Management 9.4 (2014): 181-186.

Tahir, Abdullah Mohd, Noor Ajian Mohd Lair, and Foo Jun

Wei. "Investigation on mechanical properties of welded

material under different types of welding filler

(shielded metal arc welding)." AIP Conference

Proceedings. Vol. 1958. No. 1. AIP Publishing, 2018.

Bodude, M. A., and I. Momohjimoh. "Studies on Effects of

Welding Parameters on the Mechanical Properties of

Welded Low-Carbon Steel." Journal of Minerals and

Materials Characterization and Engineering 3.03

(2015): 142.

Gharibshahiyan, E., Raouf, A.H., Parvin, N., Rahimian, M.

(2011). The effect of microstructure on hardness and

toughness of low carbon welded steel using inert gas

welding, Materials & Design, Vol. 32, No. 4, 2042-

2048, doi 10.1016/j.matdes.2010.11.056.

Asibeluo, I. S., and E. Emifoniye. "Effect of Arc welding

current on the mechanical properties of A36 carbon

steel weld joints." SSRG International Journal of

Mechanical Engineering (SSRGIJME)–volume 2

(2015). American Journal of Materials Science 2019,

9(1): 15-21

Abson, D. J., & Pargeter, R. J. (2013). Factors influencing

as-deposited strength, microstructure, and toughness of

manual metal arc welds suitable for C-Mn steel

fabrications. International Metals Reviews, 31(1), 141-

196.

Sumardiyanto, D., Susilowati, S. E., & Cahyo, A. (2018).

Effect of Cutting Parameter on Surface Roughness

Carbon Steel S45C. Journal of Mechanical Engineering

and Automation, 8(1), 1-6.

Maksuti, R. Impact Of The Acicular Ferrite On The Charpy

V-Notch

ISCP UTA’45 Jakarta 2022 - International Seminar and Call for Paper Universitas 17 Agustus 1945 Jakarta

316