Effect of Flywheel Weight on Generator Efficiency in Micro Hydro

Power Plants

Andi Ulfiana, Tatun Hayatun Nufus, Budi Santoso, Budi Yuwono and P. Jannus

Mechanical Engineering Department, Politeknik Negeri Jakarta, Jalan. Prof. Dr. G.A Siwabessy, Jawa Barat, Indonesia

Keywords: Flywheel, Weight, MHPP, Efisiensi, Generator.

Abstract: Micro Hydro Power Plant is a power plant that utilizes low-head hydropower to produce electrical energy.

The problem is the unstable rotation of the generator caused by changes in water flow, resulting in changes

in generator efficiency that affect the quality of electricity distribution. Therefore, in this study, a flywheel is

used to determine its effect on generator efficiency. This study uses a water turbine as a generator drive. The

flow of water falls into the turbine through pipes equipped with valves. The head and water flow are kept

constant by adjusting the valve opening. The generator is a 3-phase generator, 220 V (Y)/ 380 V (Δ), 4 Pole.

The flywheel weight is 0.5 kg, 2 kg, 2.2 kg, and 3 kg. The measuring instrument is a wattmeter to measure

the electrical power output, a torque meter to measure torque and a tachometer to measure the generator's

rotational speed. The torque and shaft rotation is used to calculate the mechanical power supplied to the

generator. The largest generator efficiency is at a flywheel weight of 0.5 kg. The smallest efficiency is at a

flywheel weight of 2.2 kg.

1 INTRODUCTION

Micro Hydro Power Plant (MHPP) has advantages,

namely being economical because it does not require

fuel, the technology is simple, easy to apply in remote

areas, and is environmentally friendly because the

energy source is water. Among several hydroelectric

power plants, MHPP is recommended to be used for

areas with lower heads and lower water flows to

generate electricity (

Satarkar, 2020), (Utama, 2018).

One of these is the negative environmental impact

of using fossil fuels, particularly climate change, and

the other is the depletion of the reserves of fossil

fuels. The most significant source of greenhouse gas

emissions is the combustion of fossil fuels like CO2,

which thus causes global warming (Rahman, 2017).

MHPP utilizes a small head of water, so it is suitable

for use in areas where the height of the waterfall is

relatively small (Dwiyanto, 2020). The results of the

MHPP planning, with a water discharge of 0.834

m3/second, produced an electric power of 39.36 kVA

(Likadja, 2019). In another study, with a water

discharge of 14 litres/minute, a 12 Volt generator

produced a voltage of 13.18 Volts and an average

current of 102.2 mA. (Akhwan, 2021). Micro-hydro,

hydro energy on a “small” scale, provides electricity

to small communities by converting hydro energy

into electrical energy. The resulting power is 5 – 100

kW (Anaza, 2017).

Hydropower causes the water discharge to be not

constant, which causes the turbine speed to be not

constant; hence the turbine connected to the generator

to generate electricity will cause the generator

rotation to become unstable, thus affecting the quality

of the electricity produced. In addition, sudden load

changes cause unstable generator rotation. Therefore,

an energy storage device is needed at the plant that

will provide additional energy if needed to maintain

the turbine rotation. Flywheel is one of the energy

storage media that can store excess energy and reuse

it when needed. The flywheel is a component of a

rotating machine, a disc that can withstand speed

changes so that the engine's rotational motion

becomes stable. The weight of the flywheel can resist

speed changes. The flywheel has a moment of inertia

that can withstand changes in engine rotational speed.

Flywheel energy is a generator's mechanical energy

converted into electrical energy (Tangko, 2019). A

mains motor of two horsepower capacity is used to

drive a series of belt and pulley drive, which form a

gear train and produces over twice rpm at the shaft of

an alternator. The gravity wheel or flywheel is

coupled with the gear train to produce more excess or

982

Ulfiana, A., Nufus, T., Santoso, B., Yuwono, B. and Jannus, P.

Effect of Flywheel Weight on Generator Efficiency in Micro Hydro Power Plants.

DOI: 10.5220/0011982800003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 982-985

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

free energy. Detail study is done to obtain the

maximum free energy out of the system using a

flywheel of 10 kg (Kattimani, 2019) and a flywheel

of 50 kg (Thakre, 2018). As a result, they have

obtained more electrical output, which is their free

energy. The AC generator has produced extra

electricity from a 1 HP motor using the flywheel. The

main advantage of the flywheel-free energy generator

is that it can generate energy without any extra

equipment. This free energy generation is non-

hazardous and environmentally friendly. The

flywheel with a weight of 7.74 kg is used in various

applications such as electric fuel cars, household and

industrial and increases the efficiency of traditional

electrical (Shinde, 2017). A flywheel in a four-

wheeled vehicle with a weight of 96.05 kg produces

an engine speed of 64.87 km /h, while a flywheel with

a weight of 86.24 kg produces an engine speed of

68.05 km/h (Ratnawati, 2019).

Micro-hydro power plants are the solution to

reach remote areas that the limited accessibility for

transport, technology, and cost (Elbatran, 2015),

(Marliansyah, 2018), (Timur, 2020).

Previous studies used flywheels in a weight range

of 7.74 kg to 96 kg. Therefore, this study analyzes the

effect of flywheel weight on MHPP using a flywheel

in the weight range of 0.5 kg to 3 kg.

2 METHOD

This study uses a water turbine as a generator drive.

Water flow falls into the turbine through pipes

equipped with valves that can be opened and closed.

The head and water flow are kept constant by

adjusting the valve opening. The generator is a 3-

phase generator, 220 V (Y)/ 380 V (Δ), 4 Pole. The

flywheel weight 0.5 kg, 2 kg, 2,2 kg, 3 kg. Flywheels

are used interchangeably to determine the effect of

flywheel weight on the MHPP turbine. Measurement

of the electric power output of the generator using a

wattmeter. Measurement of torque on the shaft using

a torque meter. Measurement of shaft rotation using

a tachometer. The results of the measurement of

torque and shaft torque are used to calculate the

mechanical power supplied to the generator.

The angular velocity:

2..

(1)

ω = angular velocity [rad/s]

n = shaft speed [rpm]

The mechanical power:

. (2)

Pm = mechanical power [Watt]

T = torque [Nm]

The efficiency:

ƞ

(3)

ƞ = efficiency [%]

P

e

= electrical power [Watt]

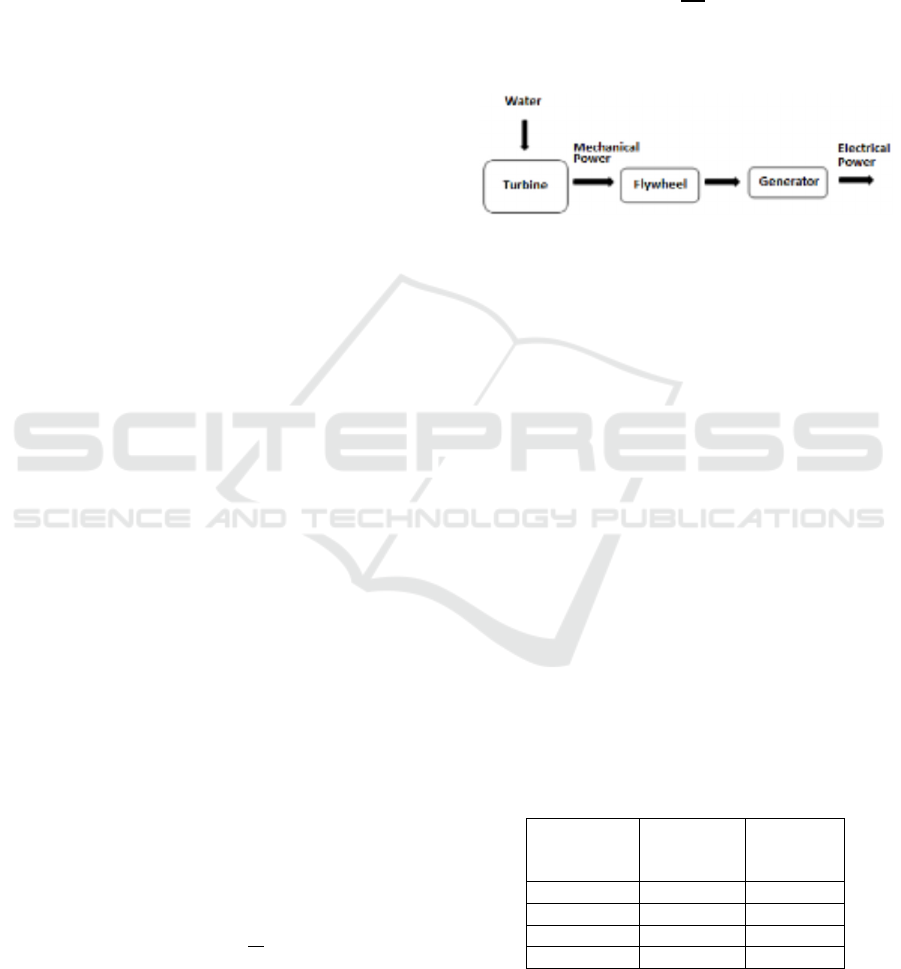

Figure 1: MHPP System Diagram.

Figure 1 shows the flywheel mounting position

between the turbine and generator. Water flowing

into the turbine causes the turbine to rotate and

generate mechanical power, turning a generator to

produce electrical power. The flywheel is used to

maintain the stability of the generator rotation.

3 RESULTS AND DISCUSSION

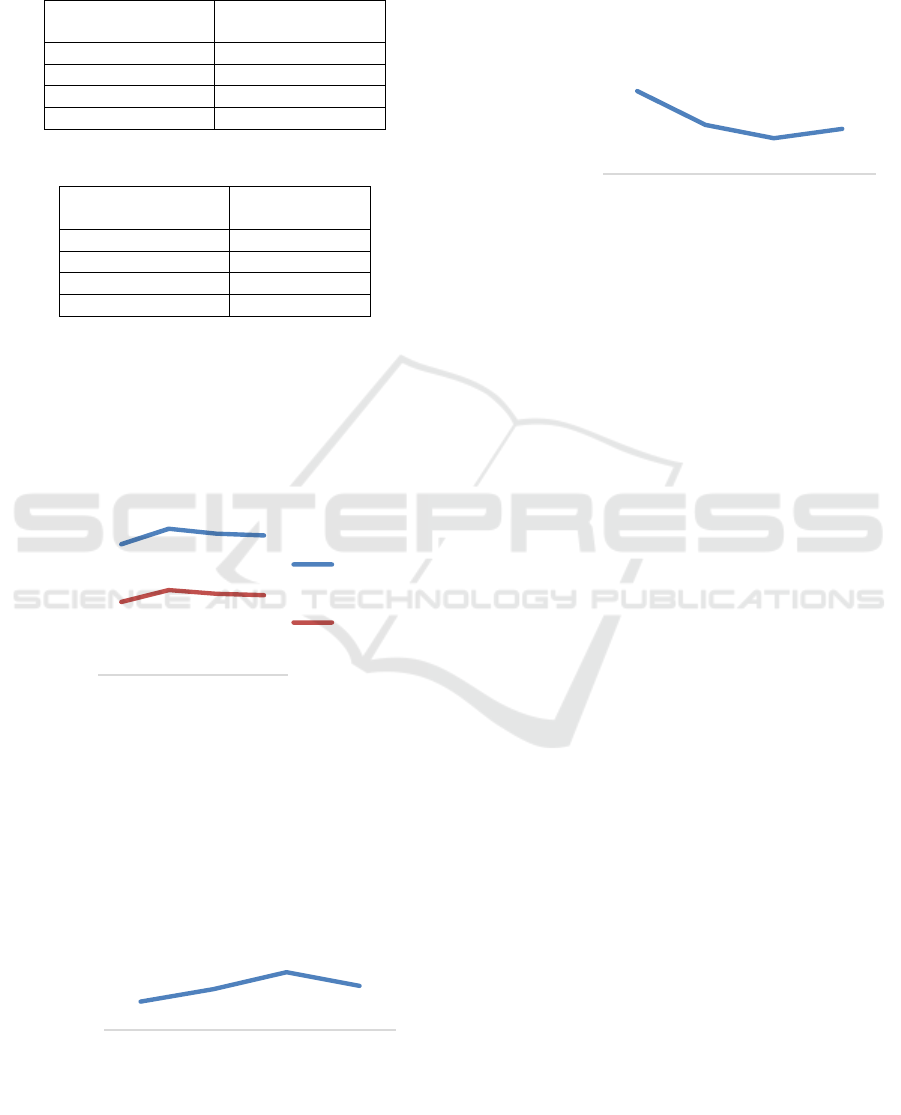

The results of measurements and calculations are

summarized in Table 1, Table 2, and Table 3. The

angular velocity in Equation (1) is used to calculate

the mechanical power. The mechanical power is

calculated using Equation (2) and entered into table

1.

The weight of the flywheel ranges from 0.5 kg to

3 kg. Changes in flywheel weight cause changes in

mechanical power and electrical power, as shown in

Table 1.

Table 1: Measurement Result of Mechanical Power and

Electrical Power.

Flywheel

Weight (kg)

Mechanical

Power

(Watt)

Electrical

Power

(Watt)

0.5 83.279 64.125

2 88.393 68.0625

2.2 86.786 66.825

3 86.182 66.36

The results of the turbine shaft rotational speed (shaft

speed) measurement are shown in Table 2. Variations

Effect of Flywheel Weight on Generator Efficiency in Micro Hydro Power Plants

983

in flywheel weight cause changes in the rotational

speed of the turbine shaft.

Table 2: Measurement Result of Shaft Speed.

Flywheel Weight

(kg)

Shaft Speed (rpm)

0.5 702

2 725

2.2 756

3 731

Table 3: Result of Efficiency.

Flywheel Weight

(kg)

Efficiency

(%)

0.5 77.0002

2 76.99988

2.2 76.99975

3 76.99984

Efficiency in Table 3 is calculated based on Equation

(3).

Based on Table 1, Table 2, and Table 3, the

mechanical power, the shaft speed, and the efficiency

versus flywheel weight graph are obtained as shown

in the Figure 2, Figure 3, and Figure 4.

Figure 2: Mechanical Power (Shaft Power) and Electrical

Power versus Flywheel Weight.

In Figure 2, the lowest mechanical power and

electrical power is at a flywheel weight of 0.5 kg,

while the highest mechanical power and electrical

power is at a flywheel weight of 2 kg.

Figure 3: Shaft Speed versus Flywheel Weight.

In Figure 3, the lowest shaft speed is at a flywheel

weight of 0.5 kg, and then the shaft speed increases

when a flywheel weight of 2 kg. The highest shaft

speed is at a flywheel weight of 2.2 kg and then

decreases as the flywheel weight increases to 3 kg.

Figure 4: Efficiency Versus Flywheel Weight.

Figure 4 shows the efficiency of the MHPP generator.

The highest efficiency at a flywheel weight of 0.5 kg.

Efficiency decreases with increasing flywheel

weight, but at 3 kg, the efficiency rises to 76.99984

%. Efficiency changes for the flywheel weight of 2

kg, 2.2 kg and 3 kg are relatively small.

4 CONCLUSION

Changes in flywheel weight cause changes in shaft

rotation speed, mechanical power, electrical power,

and generator efficiency. The lowest mechanical

power and electrical power is at a flywheel weight of

0.5 kg, while the highest mechanical power and

electrical power is at a flywheel weight of 2 kg. The

lowest shaft speed is at a flywheel weight of 0.5 kg,

and then the shaft speed increases when a flywheel

weight of 2 kg. The highest shaft speed is at a

flywheel weight of 2.2 kg and then decreases as the

flywheel weight increases to 3 kg. The highest

efficiency is at a flywheel weight of 0.5 kg. The

changes are due to the relatively small difference in

flywheel weight. It is hoped that further research will

use a significant difference in flywheel weight to

determine its effect on the efficiency of the MHPP

system.

REFERENCES

Akhwan, Gunari, B., Sunardi, & Wirawan, W.A. (2021).

Rancang Bangun Pembangkit Listrik Tenaga

Mikrohidro (PLTMH) Politeknik Perkeretaapian

Indonesia Madiun. EKSERGI Jurnal Teknik Energi,

17(1), 15-24.

40

50

60

70

80

90

100

0,522,23

Mechanical and

Electrical Power (Watt)

Flywheel Weight (kg)

Mechanical

Power

Electrical

Power

650

700

750

800

0,522,23

Shaft Speed (rpm)

Flywheel Weight (kg)

Shaft Speed

76,9994

76,9996

76,9998

77

77,0002

77,0004

0,522,23

Efficiency (%)

Flywheel Weight (kg)

Turbine Efficiency

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

984

Anaza, S.O., Abdulazeez, M.S., Yisah, Y.A., Yusuf, Y.O.,

Salawu, B. U. & Momoh, S.U. (2017). Micro Hydro-

Electric Energy Generation- An Overview. American

Journal of Engineering Research (AJER), 6(2), 05-12.

Dwiyanto,V., Indriana D.K., & Tugiono, S. (2016).

Analisis Pembangkit Listrik Tenaga Mikro Hidro

(PLTMH). JRSDD, 4(3), 407 – 422.

Elbatran A.H., Yaakob O.B., Ahmed Y.M., & Shabara

H.M. (2015). Operation , Performance and Economic

Analysis of Low Head Micro-Hydropower Turbines for

Rural and Remote Areas : A review. Renew Sustain

Energy Rev. Elsevier., 40-50.

Kattimani,M.A, & Inayath, M.A. (2019, October). Free

Energy Generation Using Flywheel. International

Journal of Scientific Research in Science and

Technology, 200-210. doi: 10.32628/IJSRST196522

Likadja, F.J., Sampeallo, A., & Amaral, C.R.D.N.R.

(2019). Perencanaan Pembangkit Listrik Tenaga Mikro

Hidro (Pltmh) Memanfaatkan Outlet Kondensor PLTU

Ii NTT di Desa Bolok Kecamatan Kupang Barat,

Kabupaten Kupang. Jurnal Media Elektro, VIII(2).

Marliansyah, R., Putri, D. N., Khootama, A., &

Hermansyah, H. (2018). Optimization Potential

Analysis of Micro-hydro Power Plant (MHPP) from

River with Low Head. Energy Procedia, 153, 74-79.

Diambil kembali dari https://doi.org/10.1016/

j.egypro.2018.10.021.

Rahman, M.S., Nabil, I.M., & Alam, M.M. (2017). Global

Analysis of a Renewable Micro Hydro Power

Generation Plant. AIP Conference Proceedings.

Diambil kembali dari https://doi.org/10.1063/1.501

8532.

Ratnawati , Septiani M., & Fitria. (2019). Analisa Pengaruh

Berat Roda Daya terhadap Akselerasi Kendaraan

Toyota Kijang. TURBO, 8(1), 8-14. Diambil kembali

dari http://ojs.ummetro.ac.id/index.php/turbo.

Satarkar, P.P., Lonkar, R.B., Sargar, H.D., Sarda, R.R., &

Yadav, S.B. (2020). Study of Micro Hydro Power Plant

for Rural Electrification. International Research

Journal of Engineering and Technology (IRJET),

07(07), 5559-5563.

Shenel Bankston, Changki Mo. (2015). Geometry

Modification of Flywheels and its Effect on Energy.

Energy Research Journal, 6(2), 54-63. doi:DOI:

10.3844/erjsp.2015.54.63.

Shinde, A., Rawat, K.S., Mahajan, R. , Pardeshi, V.,

Kamanna, B., & Sheravi, S. (2017, May). Design and

Analysis of Flywheel for Different Geometries and

Materials. Global Journal of Enterprise Information

System. doi:DOI: 10.18311/gjeis/2017/15872.

Tangko J., Tandioga, R. , Djufri, I., & Haardiyanti, R.

(2019). Analisis Pembangkit Listrik Berbasis Flywheel.

SINERGI, 17(1), 77-83. doi:http://dx.doi.org/10.319

63/sinergi.v17i1.1598.

Thakre, P.S.B., Zode, M.S.H., Singh, A.S., & Ingole, S.R.

(2018, January). Self Generator Free Energy Flywheel.

International Research Journal of Engineering and

Technology (IRJET), 05(01), 1062-1065.

Timur, L., Hindarti, F., & Indrawati, R. (2020). Feasibility

Study of Micro Hydro Power Plant Capacity in

Blumbang Banjararum Kalibawang Kulonprogo.

ASEAN Journal of System Engineering, 4(2), 44-50.

Diambil kembali dari http://journal.ugm.ac.id/index.

php/ajse.

Utama, K.A., & Husnan, R. (2018). Feasibility Analysis Of

Micro-hydro Power Plant Development to Achieve The

Electricity Independence at Mongiilo Village-Bone

Bolango District-Gorontalo Province. Journal of

Sustainable City and Urban Development, 1(1), 13-22.

Effect of Flywheel Weight on Generator Efficiency in Micro Hydro Power Plants

985