Analysis of Marshall Characteristics on Asphalt Concrete:

Wearing Course with Addition of Plastic Bag Waste from

Pupuk Kalimantan Timur Companies

Ashadi Putrawirawan

1a

, Rahimah Bt. Muhammad

2b

and Tumingan

1c

1

Civil Engineering, Samarinda State of Polytechnic, Jalan Ciptomangungkusumo, Samarinda,

Kalimantan Timur, Indonesia

2

Razak Faculty of Technology and Informatics, Universiti Teknologi Malaysia, Jalan Sultan,

Yahya Petra, 54100, Kuala Lumpur, Malaysia

Keywords: Asphalt Concrete-Wearing Course, Plastic Bag Waste, Marshall, Optimum Asphalt Content.

Abstract: There have been many ways to reduce damage to road pavements, one of which is by adding additives to

asphalt, therefore, changing the properties of the asphalt mixture, especially hardness, sensitivity to

temperature, and peeling. This of course requires a high additional cost. One way is to add plastic bags as an

additive to the asphalt. The problem faced by Pupuk Kalimantan timur Companies is the amount of unused

plastic bags left due to abundant raw materials and production errors. This research was carried out by

designing the composition of the asphalt mixture, adding plastic bags with each variant of plastic 2%, 3%,

4%, 5%, and 6% of the asphalt weight using the dry process method. Based on the test results, the optimum

asphalt content value is 6.20% with stability value = 1381 kg, flow = 3.587 mm, VIM = 3.695%, VMA =

14.73%, VFA = 78.17%, and MQ = 391 kg/ mm and a maximum plastic content of 5%, with stability value

= 1426 kg, flow = 3.83 mm, MQ = 315.85 kg/mm, VIM = 4.44%, VMA = 16.81%, VFA = 73.58%. The

addition of plastic bags can increase the value and durability of the Asphalt Concrete Mixture.

1 INTRODUCTION

One of the components of flexible pavement, the use

of asphalt is relatively low, generally only 4%-10%

of the total weight or 10%-15% of the total volume,

but asphalt is an expensive material (Istiar, Adi, &

Sutikno, 2019). Asphalt is used in aggregates as a

binder and also acts as a filler and stabilizer in asphalt

mixtures. Offers permeability and particle adhesion

as asphalt fills voids (Akter & Efficacious, 2019.

Plastics are synthetic materials derived mainly from

refined crude oil products. High melting temperature,

high decomposition temperature, and resistance to

Ultra Violet radiation provide many benefits, but also

mean that plastic waste remains in the environment

for hundreds of years (Evode et al. 2014) creates

increasing environmental challenges. In addition, the

toxic chemicals in most plastics are bio-cumulative,

a

https://orcid.org/0000-0001-6163-4187

b

https://orcid.org/0000-0003-4061-2223

c

https://orcid.org/0000-0001-9279-1521

posing safety and security risks throughout the food

chain, including Humans (White & Reid, 2018). The

use of plastic as an additive in asphalt mixtures is

expected to provide stability and durability to the

mixture, so that it can be used widely and can reduce

the presence of waste that can endanger the safety of

ecosystems, the environment and humans.

In previous research, testing the characteristics of

Marshall with different percentages of plastic waste,

namely 4%, 6%, 8%, and 10% by weight of asphalt

as an additive. The results showed that the Optimum

Bitumen Content (OBC) of plastically modified

asphalt mixture at 4%, 6%, 8%, and 10% were 4.98,

5.44, 5.48, and 5.14, respectively. On the other hand,

the controlled specimens showed better volumetric

properties compared to the plastic mixtures.

However, the addition of 4% plastic showed that it

was better than the controlled one (Abd Kader et al.,

2017).

1006

Putrawirawan, A., Muhammad, R. and Tumingan, .

Analysis of Marshall Characteristics on Asphalt Concrete: Wearing Course with Addition of Plastic Bag Waste from Pupuk Kalimantan Timur Companies.

DOI: 10.5220/0012002400003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 1006-1011

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

2 MATERIAL AND METHOD

2.1 Asphalt Concrete

Asphalt concrete is a layer on highway construction

consisting of a mixture of hard asphalt and well

graded aggregate, mixed, spread out in a hot state and

compacted at a certain temperature (Sukirman, 2003).

As a surface layer of road pavement, Asphalt concrete

(AC) has structural value, is waterproof and has high

stability. Another characteristic is that it has few

voids in its aggregate structure, interlocking with

each other, therefore asphalt concrete has high

stability and is relatively rigid.

2.2 Asphalt Concrete- Wearing Course

(AC-WC)

Asphalt Concrete - Wearing Course (AC-WC) is the

topmost pavement layer and functions as a wear layer.

Even though it is non-structural, AC-WC can increase

pavement resistance to quality degradation so that

overall it increases the service life of the pavement

construction. AC-WC has the smoothest texture

compared to other types of Asphalt Concrete

.

2.3 Plastic

Plastic is a polymer which has unique and

extraordinary properties.

PET materials such as

plastic bottles and plastic cups were used. Plastic

waste was collected from houses and schools. The

collected PET materials were chosen with a

maximum thickness of 60 micron. This would

facilitate mixing them with asphalt at the laboratory

under its softening point. Also, in order to provide

appropriate plastic particles, the bottles and cups were

cleaned then slashed into small pieces then crushed

and sieved such that it passes through 3-5 mm sieve

using shredding machine (Naghawi H. at al, 2018).

Asphalt and plastic waste coated aggregates caused

by the intermolecular bonding which improves

asphalt mix strength. This would be reflected in the

enhanced durability and stability of the asphalt mix

which would lead to enhancing pavement resistance to

fatigue cracking and rutting or permanent deformation

(Naghawi, Ajarmeh, Allouzi, & Alklub, 2018).

The local recycled wastes (PP, HDPE and LDPE)

were identified and handpicked from Dammam

municipality recycling programme. The processing

involved washing, shredding and grinding (Dahlat M.

et al, 2016). The effect of polypropylene, high-and

low-density polyethylene (PP, HDPE and LDPE)-

recycled plastic wastes (RPW) on the viscoelastic

performance of the local asphalt binder has been

investigated. The recycled plastics were obtained by

shredding and grounding the RPW to a desirable size

for easier blending with the asphalt binder (Dahlat &

Wahhab, 2015). Recycled plastic wastes (RPW) such

as polypropylene (PP), polyethylene (PE) packages

and polyvinyl chloride (PVC) has been previously

utilised to enhance the performance of asphalt

concrete (AC) (Dahlat & Wahhab, 2015).

Polypropylene when interacted with 80 pen base

bitumen enhances its performance characteristics

which were brought about by altered rheological

properties of the modified bitumen (Habib,

Kamaruddin, Napiah, 2011). Polypropylene can be

found in food packaging, microwave-proof

containers, pipes, and automotive parts. It has been

used as a mixture modifier through the wet process in

percentages that range between 0.5% and 11% by

weight of bitumen, while the most common

percentage used for the production of RPMB ranges

between 3% and 5% (Brasileiro et al, 2019).

Figure 1: Plastic Bag from Pupuk Kaltim Company.

In this study, 3 specimens were made from each

sample on variations in the asphalt content of the

plan, namely 4.7%, 5.2%, 5.7%, 6.2% and 6.7% to

find the optimum asphalt content value. The number

of tests as many as 15 samples. After getting the

optimum asphalt content, then making test specimens

with 5 variations of plastic content as additional

material in asphalt with variations of 2%, 3%, 4%,

5%, and 6%, the number of specimens as many as 15

samples. Before making the sample, the plastic bag is

cut into pieces with a size of 0.5-1.0 cm and then

considered according to the composition of the

mixture that has been determined. Designing the

composition of the mixture and then making a bricket

sample, then Marshall testing is carried out to

determine the Marshall properties and characteristics

of the asphalt mixture. The number of test objects as

many as 30 samples of the bricket.

Analysis of Marshall Characteristics on Asphalt Concrete: Wearing Course with Addition of Plastic Bag Waste from Pupuk Kalimantan

Timur Companies

1007

3 RESULTS AND DISCUSSION

3.1 Result of Testing Material

Based on the results of testing in the asphalt testing

laboratory, the values of specific gravity, penetration,

softening point and ductility meet the requirements of

asphalt, then the results of testing the physical

characteristics of aggregates that meet the

requirements of technical specifications can be seen

in the following tables.

Table 1: The Result of Asphalt properties.

No. Type of testing Requirement Result

1 Penetration, 25

o

C 60-70 68.2

2 Softening point (

o

C) Min. 48 51.63

3 Ductility 25

o

C (cm) Min. 100 125

4 Spcific Ggrafit

y

Mi. 1 1.031

Table 2: The results of testing the specific gravity and

absorption of coarse aggregate.

Type of testing Requirement Result

Dry bulk density Min. 2.5 2.64

Saturated surface dr

y

(

SSD

)

Min. 2.5 2.66

Apparent density Min. 2.5 2.70

Absorption Maks. 3% 0.77

Abration Maks. 40% 20.63

Table 3: The results of testing the specific gravity and

absorption of fine aggregate.

Type of testing Requirement Result

Dry bulk density Min. 2.5 2.65

Saturated surface dr

y

(

SSD

)

Min. 2.5 2.68

Apparent density Min. 2.5 2.73

Absorption Maks. 3% 1.01

Table 4: The results of testing the specific gravity and

absorption of Palu sand.

Type of testing Requirement Result

Dry bulk density Min. 2.5 2.55

Saturated surface dr

y

(

SSD

)

Min. 2.5 2.60

Apparent density Min. 2.5 2.68

Absorption Maks. 3% 1.83

3.2 Calculation of Optimum Asphalt

Content

Based on the results of calculations starting from the

combined gradation to find the composition of the

mixture, it was obtained that the design asphalt

content was obtained with variations of 4.7%, 5.2%,

5.7%, 6.2% and 6.7%. After that make a sample with

3 pieces in each variation of asphalt content so that

the number of samples is 15 pieces. From the results

of the marshal test, the asphalt content value is 6.20%,

while the results of the Marshall characteristic test

can be seen in table 5 below.

Table 5: The Results of Marshall Characteristic Asphalt

Concrete – Weraing Course.

Asphalt

(Pb) (%)

4.70 5.20 5.70 6.20 6.70 Spec.

Stability(kg)

1,181 1,350 1,1383 1.381 1,330

Min. 800

Flow (mm)

2.96 3.39 3.913

3.587 3.717

2 – 4

VIM (%)

3.020 3.038 3.292 3.695 3.762

3 – 5

VMA (%)

12.29 13.42 14.02 14.73 17.26

Min. 15

VFA (%)

75.83 78.32 79.06 78.17 78.84

Min. 65

MQ(kg/mm)

403 412 354 391 358

Min. 250

3.3 Marshall Characteristic

After getting the Optimum Asphalt Content value of

6.20%, then making samples with variations of plastic

bag of 2%, 3%, 4%, 5%, and 6%, while the

relationship between adding plastic bag and Marshall

characteristics can be described as follows:

3.3.1 Relation of Plastic Bag Waste with

Stability

Stability is the ability of the road pavement layer to

accept the load without deformation in accordance

with the planned traffic load level. Low stability will

facilitate the occurrence of deflection, on the other

hand, too high stability can cause the mixture to

become stiff and cause the mixture to crack relatively

quickly. Stability occurs due to shear between grains,

locking between aggregates and the binding capacity

of the asphalt.

Figure 2: Graph of the relationship between stability and

variations in use of plastic bags.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

1008

Figure 2. Shows that with various variations in the

content of plastic bag it can show an increasing trend.

This is because plastic waste at the time of mixing and

compaction of some plastics has occurred, causing

obstacles to one another which can increase the effect

on high values. The highest stability was achieved by

a mixture of 6% asphalt content, which was 1438.49

kg, while the lowest stability value was achieved by a

mixture of 2% plastic content with a stability value of

1321.36 kg. All variations of this grade of plastic bag

content have met the specification requirements.

3.3.2 Relation of Plastic Bag Waste with

Flow

Flow is the amount of deformation that occurs in the

pavement layer due to holding the load it receives.

Good mix density, sufficient asphalt content and good

stability will have an effect on decreasing the flow

value. A low flow value can cause the mixture to

become stiff so that the pavement layer becomes easy

to crack, while a high flow value will produce a

plastic pavement layer so that the pavement will

easily deform such as waves (wash boarding) and

grooves (rutting).

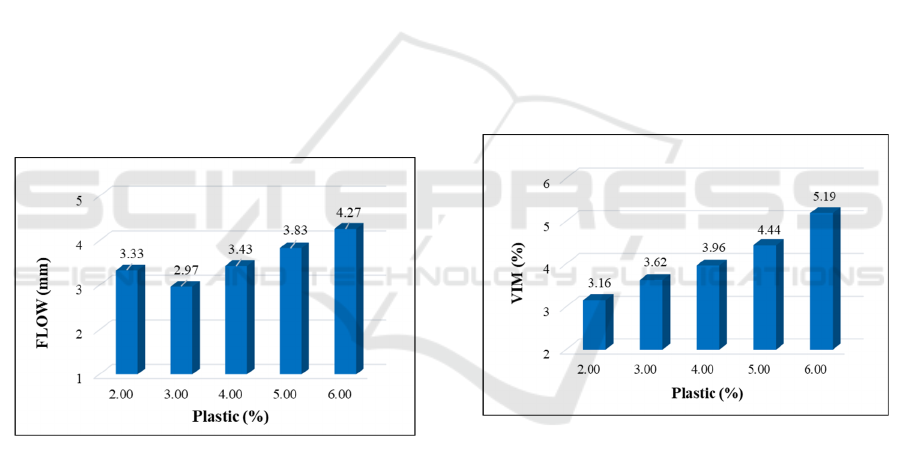

Figure 3: Graph of the relationship between Flow and

variations in use of plastic bags.

Based on Figure 3 shows that the addition of

plastic bag into the concrete mixture can increase the

value of melting, the more the addition of plastic

bags, the higher the melting value of the test object.

The average flow value of the mixture with a plastic

bag content of 2%, 3%, 4%, 5%, 6% was 3.33 mm,

2.97 mm, respectively. 2.93 mm, 2.77 mm, 3.63 mm,

while the flow value without plastic mixture is 3.9%.

The flow value at the highest plastic bag content was

obtained 6%, which was 4.27 mm but did not meet

the requirements of the 2018 General Specifications,

namely a minimum of 2.0 mm and a maximum of 4.0

mm and the lowest value in the mixture of adding 3%

plastic bag, which was 2.97 mm.

A mixture that has a flow value that is too high

can cause the aggregate grains to be more easily

shifted from their position, this shows that the locking

properties between aggregates are low so that the

aggregates easily shift when loaded with traffic.

However, if the amount of compaction is increased,

the asphalt mixture will become denser so that the

vertical deformation decreases.

3.3.3 Relation of Plastic Bag Waste with

Void in Mixture (VIM)

Voids in the mixture (VIM) is the percentage of voids

present in the total mixture. The VIM value affects

the durability of the pavement, the higher the VIM

value means the larger the cavity in the mixture. This

causes the mixture to become less dense so that water

and air can easily enter the cavities in the mixture and

cause the mixture to be porous. VIM value that is too

low will cause bleeding due to high temperatures, so

asphalt viscosity will decrease according to its

thermoplastic properties.

Figure 4: Graph of the relationship between VIM and

variations in use of plastic bags.

Figure 3 shows that the value of VIM has

increased with respect to the addition of plastic bag

content. The highest VIM value is the addition of 6%

plastic sack content, which is 5.19% but does not

meet the requirements of the 2018 General

Specifications, which is a minimum of 3% and a

maximum of 5%. mm while the lowest value for

adding 2% plastic bag content is 3.16%, this is due to

the increasing levels of plastic bag causing the asphalt

to not optimally fill the voids in the aggregate because

it has a larger cavity and the less asphalt content is

filled making the mixture less dense because

interconnected and broken aggregates due to

imperfect compaction process.

Analysis of Marshall Characteristics on Asphalt Concrete: Wearing Course with Addition of Plastic Bag Waste from Pupuk Kalimantan

Timur Companies

1009

3.2.4 Relation of Plastic Bag Waste with

Void in Mineral Agregat (VMA)

Voids Mineral aggregate (VMA) are air voids that

exist between the particles of the asphalt aggregate

mixture that have been compacted including the space

filled with asphalt which is expressed in percent of

the total volume of the mixture. The expected value

of VMA in the asphalt mixture is the minimum

possible, with the aim of providing sufficient space

for the asphalt to adhere to the aggregate.

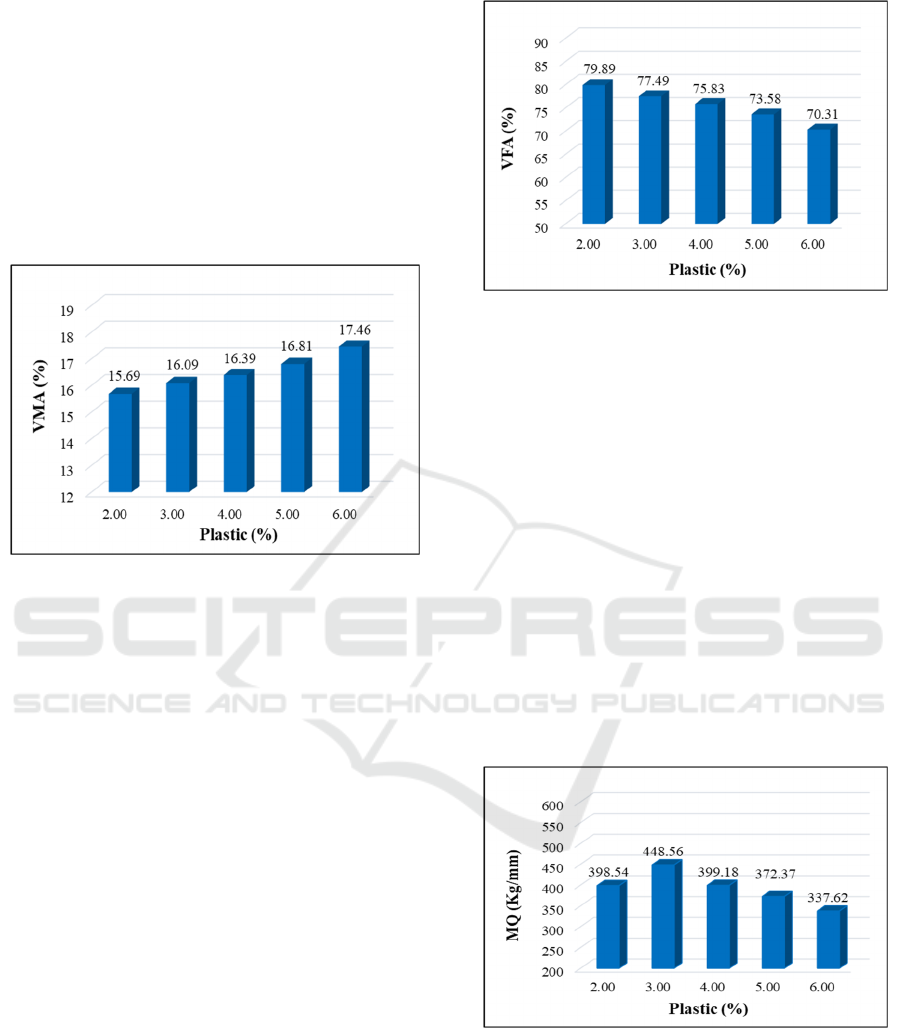

Figure 5: Graph of the relationship between VMA and

variations in use of plastic bags.

Figure 5 the basic material that adding the value of

plastic bag as an added causes VMA to tend to

increase with the addition of plastic bags. The VMA

values for plastic content of 2%, 3%, 4%, 5%, 6%

were 15.69%, 16.09%, 16.36%, 16.81%, 17.46%,

respectively. A VMA value that is too high indicates

that the air voids between mineral aggregates are

larger, this condition will cause the pavement to not

last long. The VMA results still meet the

requirements of the 2018 Bina Marga General

Specification for the mixture, which is at least 15%.

3.2.5 Relation of Plastic Bag Waste with

Void Filled with Asphalt (VFA)

Void filled with asphalt (VFA) is the percentage of

the void that can be filled with asphalt. The higher the

VFA value, the more voids in the mixture filled with

asphalt, so that the mixture's resistance to water and

air is also higher, but VFA value that is too high will

cause bleeding. VFA value that is too small will cause

the mixture to be less impermeable to water and air

because the asphalt film layer will become thin and

will crack easily when receiving additional loads so

that the asphalt mixture is easily oxidized which

ultimately causes the pavement layer to not last long.

Figure 6: Graph of the relationship between VMA and

variations in use of plastic bags.

Figure 6 shows that the VFA value decreased along

with the addition of plastic bag, namely 6% by

70.31% while the VFA value of normal asphalt

content without plastic mixture was obtained at 79%.

The VFA value for each plastic bag content still meets

the general specifications for 2018 which is at least

65%. VFA value that is too high will cause bleeding.

3.2.6 Relation of Plastic Bag Waste with

Marshall Quotient (MQ)

Marshall Quotient (MQ) is the quotient between

stability and flow. Marshall Quotient value will give

mixed flexibility value. The larger the Marshall

Quotient value, the more rigid the mixture will be,

conversely the smaller the Marshall Quotient value,

the more flexible the mixture will be.

Figure 7: Graph of the relationship between MQ and

variations in use of plastic bags.

Based on Figure 7 shows that the use of plastic bags

resulted in the Marshall Quotient value decreased.

The highest Marshall Quotient value was at 3%

plastic sack content, which was 448.56 kg/mm, while

the MQ value at normal asphalt content without

mixture was 390%. The Marshall Quotient value

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

1010

shows a decrease because as the percentage of the

addition of plastic bags to asphalt increases, this

indicates that the mixture tends to become stiff when

the asphalt mixture increases in the amount of

compaction.

4 CONCLUSIONS

The test results of the Asphalt Concre – Wearing

course (AC-WC) with addition of plastic bag can

affect the value of Marshall characteristics. Based on

the test results, the optimum asphalt content value is

6.20% with stability value = 1381 kg, flow = 3.587

mm, VIM = 3.695%, VMA = 14.73%, VFA =

78.17%, and MQ = 391 kg/ mm and a maximum

plastic content of 5%, with stability value = 1426 kg,

flow = 3.83 mm, MQ = 315.85 kg/mm, VIM = 4.44%,

VMA = 16.81%, VFA = 73.58%. The addition of

plastic bag can increase the value and durability of

Asphalt Concrete mixture.

ACKNOWLEDGEMENTS

The outhors of this paper would like to thank

Samarinda State Polytechnic (POLNES) and

Universiti Teknologi Malaysia (UTM) for the support

and sponsor.

REFERENCES

Abdullah, M. E., Abd Kader, S. A., Putra Jaya, R., Yaacob,

H., Abdul Hassan, N., & Che Wan, C. N. (2017). Effect

of Waste Plastic as Bitumen Modified in Asphalt

Mixture. MATEC Web of Conferences, 103 (April).

https://doi.org/10.1051/matecconf/201710309018

Adday, F. A. (2019). Short Term Freeze - Thaw Effect on

Waste Plastic Bags and Industrial Polyethylene

Modified Hot Mix Asphalt (HMA) . International

Journal of Current Research, 3010-3016.

Akter, R., Islam, M. R., & Manjur, K. A. (2019). Improfing

the Propertis of Asphalt Concrete Using Waste Plastic

Bottle as Additive. International Journal of Scientific

& Engineering Research, 1510-1515.

Brasileiro, at al (2019), Reclaimed Polymers as Asphalt

Binder Modifiers for More Sustainable Roads.

Sustainablility, 11, 646; doi; 10.3390/su11030646

Dahlat, M., & Wahhab, A. A. (2015). Performance of

Recycled Plastic Waste Modified Asphalt Binder in

Saudi Arabia. International Journal of Pavement

Engineering, 1-8.

Gidigasu M. D (1976), Laterite Soil Engineering,

Pedogenesis and Engineering Principles, Elsevier

Scientific Publishing Company, Amsterdam

Habib, N. Z, Kamaruddin, I, Napiah, M, and Tan, M. I.

(2011) Effect of Mixing Process on Polypropylene

Modified Bituminous Concrete Mix Properties.

International Journal of Civil and Envieronmental

Engineering Vol:5, No:10,2011.

Naghawi, Ajarmeh, R. A., Allouzi, R., & Alklub, A. (2018).

Plastic Waste Utilization as Asphalt Binder Modifier in

Asphalt Concrete Pavement. International Journal of

Civil Engineering and Technolgy, 566-571.

Istiar, Adi, T. J., & Sutikno. (2019). The Effec Of Laterite

Stone as Filler on Marshall Stability hot mix asphalt

AC-WC. MATEC Web of Conferences , (pp. 1-8).

Surabaya.

PU, D. J. (2018). Spesifikasi Umum 2018. Jakarta:

Direktorat Jenderal Bina Marga.

Sukirman, S. (2003), Beton Aspal Campuran Panas, Granit,

2003

West, T., Jenbarimiema, Nyebuchi, & Azeruibe, D. (2020).

Laterite Rock Modified Asphalt Concrete Mix Design

Properties and Swell Behaviour under Soaked

Conditions for Rural Roads. International Journal of

Constructive Research in Civil Engineering, 11-25.

Khammarnia, M., Haj Mohammadi, M., Amani, Z.,

Rezaeian, S., & Setoodehzadeh, F. (2015). Barriers to

implementation of evidence based practice in Zahedan

teaching hospitals, Iran, 2014. Nursing research and

practice, 2015.

Chen, C., Meng, Q., Xia, Y., Ding, C., Wang, L., Dai, R.,

... & Liu, C. (2018). The transcription factor POU3F2

regulates a gene coexpression network in brain tissue

from patients with psychiatric disorders. Science

translational medicine, 10(472), eaat8178.

Evode, N., Qamar, S. A., Bilal, M., Barceló, D., & Iqbal, H.

M. (2021). Plastic waste and its management strategies

for environmental sustainability. Case Studies in

Chemical and Environmental Engineering, 4, 100142.

White, G., & Reid, G. (2018, April). Recycled waste plastic

for extending and modifying asphalt binders. In 8th

Symposium on Pavement Surface Characteristics

(SURF 2018), Brisbane, Queensland, Australia (pp. 2-

4).

Analysis of Marshall Characteristics on Asphalt Concrete: Wearing Course with Addition of Plastic Bag Waste from Pupuk Kalimantan

Timur Companies

1011