Application of Different Materials for Carbon Capture

Rundong Tian

*

Guanghua Cambridge International School, Shanghai 201319, China

Keywords: Carbon Capture, Porous Materials, Application, Sorbents.

Abstract: Human activities have led to increasing CO

2

emissions, mainly coming from factories and plants. The

increasing concentration of carbon dioxide (CO

2

) in the atmospheric environment has become a severe

concern of the world due to the existing and potential consequences. Different carbon capture technologies

have been developed and used to remove CO

2

from the atmosphere. In addition, carbon capture can also solve

certain environmental pollution problems, by directly reducing CO

2

discharge from anthropogenic sources.

The research focuses on carbon capture techniques and corresponding materials (sorbents). The current

situations are stated and the significance of carbon capture is enhanced, while also giving brief introductions

on several sorbents. The amine method, which is conventional and the most frequently used, is discussed first.

Afterwards, porous materials including zeolites, activated carbons (AC) and metal-organic frameworks

(MOFs) are discussed, mainly focusing on the sorption mechanism, advantages, drawbacks and possible

corresponding solutions, specific examples and outlook. These porous materials hold great potential as solid

adsorbents for carbon capture, likely replacing conventional amines in the future. Further improvements and

evaluations will enable porous materials to be used in industrial applications.

1 INTRODUCTION

The issue of global warming has attracted great

attention since last century. Human beings have

already experienced the severe aftermath of global

warming and relevant climate changes, such as sea-

level rising, more frequent extreme weathers,

increased heat and drought and flooding. The

increase in concentration of greenhouse gases like

carbon dioxide (CO

2

) and methane present in

atmosphere contributes to global warming. The

global industrial development has led to increased

CO

2

emissions, mainly from anthropogenic sources

such as burning of fossil fuels. For example, global

CO

2

emissions reached 34.9 Gt in 2021 (Liu, 2022),

leading to a dramatic increase in the concentration of

CO

2

in the atmosphere. Possible solutions to the issue

include replacing conventional energy sources by

cleaner and more sustainable resources as well as

carbon capture and storage processes. The complete

treatment of carbon dioxide includes capturing CO

2

from various sources, regeneration of sorbents,

storage and transport of CO

2

and finally the

conversion of CO

2

into harmless or even valuable

products.

There are three common carbon capture

technologies. The post-combustion carbon capture

belongs to the most studied and applied one, being

considered the most in existing conventional power

units, such as amine method. The amine method is

through the use of aqueous alkanolamine absorbents.

Such chemical absorption carbon capture method has

been used for years in industry and still exists to be

the most recognizable one. Since the absorption

process involves chemical reactions, relatively large

amount of heat is released, where carbamate or

bicarbonate species are formed in the absorption

reactions, depending on the species of alkanolamine

used (Sumida, 2012). The amine method holds

several advantages, such as high process efficiency.

Moreover, they are commercially available and

improvements on the method have been made over

time. However, the existing amine methods do have

various problems and limitations. Such capture

process is very energy-consuming, specifically the

regeneration of absorbents, leading to high energy

requirements and costs. Furthermore, amine

solutions tend to be corrosive against vessels, and

also possess low thermal stability, shown by

decomposition under heating.

112

Tian, R.

Application of Different Materials for Carbon Capture.

DOI: 10.5220/0012003300003625

In Proceedings of the 1st International Conference on Food Science and Biotechnology (FSB 2022), pages 112-120

ISBN: 978-989-758-638-5

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Due to the energy-intensive nature of current

processes, new technologies are required to reduce

energy requirements. Porous materials have been

studied, aiming to replace aqueous absorbents, as

they have the potential to reduce the energy costs as

well as increasing the efficiency in carbon capture

processes. Zeolites are microporous aluminosilicate

minerals. As solids, zeolites have much lower heat

capacity, thereby leading to lower energy penalty for

regeneration. In addition, zeolites have a well-

developed structural chemistry, which could lead to

optimized zeolites for carbon capture processes.

Moreover, zeolites possess unified micropores,

resulting in rapid adsorption at relatively low

pressures. Zeolites are also relatively cheap to

produce on a large scale which makes them preferred

in industrial applications. However, zeolites’ main

limitation is the hydrophilic nature, so water vapor

would compete with CO

2

for adsorption sites and the

porous materials will get saturated with water vapor

eventually, leading to lower adsorption capacity for

CO

2

over time. They also undergo large enthalpy of

adsorption, which leads to high temperature required

for desorption of guest molecules. Activated carbons

(AC) are porous carbon materials produced from

carbonaceous source materials. Compared to

zeolites, activated carbons are hydrophobic, therefore

the issues from water vapor are not main concerns.

They can be used to lower uptake at low pressure

compared to adsorbents such as zeolites, hence they

are more suitable for high-pressure applications

(Sumida, 2012). Metal-organic frameworks (MOFs)

have been widely studied and engineered for various

applications in recent years, including carbon capture

processes. The MOFs is a kind of porous

coordination polymer, consists of metal clusters and

organic ligands in a crystalline structure. It holds

many advantages that makes it suitable for carbon

capture process, including a precise control over

structures that could be achieved through synthesis

and shaping, high pore volumes and surface areas,

tunable pore sizes by reticular chemistry, as well as

post-synthetic modifications optimizing MOFs for

different industrial environments of carbon capture

processes (Trickett, 2017). However, challenges do

exist for MOFs in various carbon capture processes,

specifically their low mechanical, thermochemical

and hydro-chemical stability, as well as relatively

low density due to the trade-off between pore volume

and density.

The following sections of this research will

discuss current and prospective sorbents for carbon

capture. Specifically, amine-based solvents in

chemical-absorption-based carbon capture process,

zeolites, AC and MOFs in physical-adsorption-based

process and outlook for porous materials in the field

of CO

2

capture are given. And this research will only

concentrate on the CO

2

-capturing step and

regeneration of sorbents, since the regeneration

requirements are essential for determining the

viability of specific sorbents in industrial applications

2 AMINES-BASED SOLVENTS

Aqueous amines are mainly considered for post-

combustion CO

2

capturing, which is the only carbon

capture technique demonstrated at full commercial

scale at present. Amines are conventional solvents,

and still the mostly used in power plants. Different

amines, such as monoethanolamine (MEA),

diethanolamine (DEA), methyl diethanolamine

(MDEA) and ammonia (NH

3

), present different

properties, leading to different performances and

energy requirements in carbon capture processes

(Romeo, 2020). The chemical reaction between

amines and CO

2

is mainly because the lone pair

electrons of nitrogen, which act as Lewis bases, or

nucleophiles. The lone pair electrons attack the

partially-positive carbon atoms in CO

2

. And with

participation of water molecules, carbamate species

are formed while bicarbonate species are formed

when tertiary amines are used. Moreover, the usage

of primary and secondary amines can be used to

cause different kinetics of reactions, as the formation

of carbamate species is generally faster than the

formation of bicarbonate species. Evaluations have

been made for different amines (Romeo, 2020).

Primary amines appeared to possess the greatest

capabilities of capture CO

2

when used singly, since

they possess the highest reaction enthalpies among all

aqueous amines. High reaction enthalpies lead to the

favorable reaction kinetics. Hence a high degree of

CO

2

purity, high efficiency and fast absorption rates

of the capturing process might be achieved. However,

trade-off exists between reaction enthalpies, kinetics

and regeneration penalty, since high reaction

enthalpies would generally lead to high regeneration

temperature and energy requirements. Contrarily,

secondary amines possess less energy penalty as

lower regeneration temperature. Furthermore,

unstable carbamates formed in the reaction would

also lead to lower regeneration energy requirements

since backward reaction would be favored more, and

also lead to less favored absorption kinetics and

lower speed of capturing.

The technology of aqueous amines is mature, and

preferred for industrial applications among other

Application of Different Materials for Carbon Capture

113

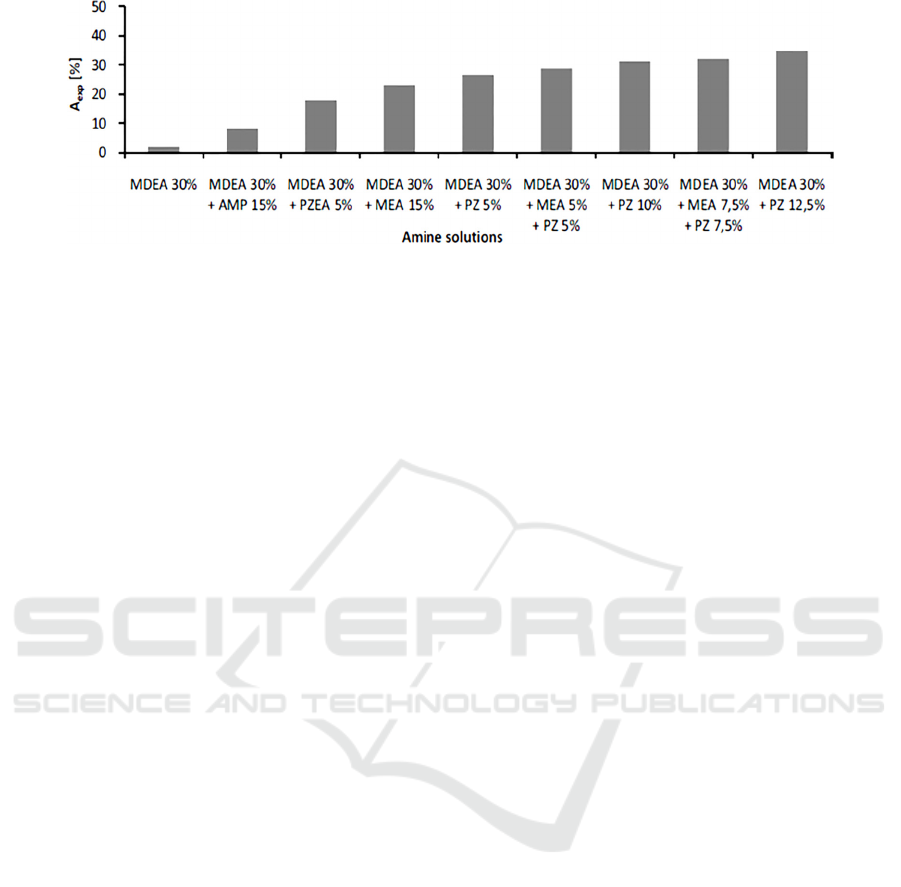

Figure 1: Experimental results of CO

2

absorption using different amine solutions (Dubois, 2011).

sorbents, due to high CO

2

affinity possessed by

amines (KUROPKA, 2011). MEA, as a primary

amine, holds merits of high chemical reactivity

against CO

2

as well as high reaction enthalpies,

leading to high absorption rates. While MDEA, as a

tertiary amine, ensures the appreciable absorption

capacity, therefore the combination of the two

different amines leads to excellent performance of

CO

2

capture. Another specific example is KM-CDR

technology, which uses KS-1™ instead of MEA,

achieving higher energy-efficiency (Kadono, 2013).

Moreover, KS-1™ tends to be less corrosive and

more resistant against O

2

degradation compared with

MEA. Recent research has focused on mixing amines

with other solvents, which refers to solvent blends.

By combining types properly, a better absorption

performance can be achieved, specifically producing

solvents with both high absorption rates and

absorption capacities. For instance, a higher

absorption rate is achieved by mixing MEA with a

little PZ (Vega, 2018). In Fig. 1, it is evidently

demonstrated that CO2 absorption increases

significantly by using various solvent blends,

compared to singly using 30 wt.% MDEA, due to

activation phenomenon.

Although the amine method is well-developed

and used in carbon capture plants worldwide, several

drawbacks and challenges have always existed for

aqueous amines, most significantly the energy

penalty of the regeneration process. This issue is

caused by various factors. The chemisorption nature

and high reaction enthalpies lead to high energy

requirements of backward reaction, referring to the

desorption process. The amines are corrosive toward

the vessels, so the concentration of amine species has

to be limited. A lower concentration of amines in the

solution means a larger volume of water, which has

relatively high heat capacities among all liquids. A

larger volume of water is required to be heated to

regenerate the sorbents, causing high energy

requirements and therefore severe energy penalty.

Furthermore, the solutions are unstable toward

heating, therefore the temperature available for full

regeneration is limited, leading to incomplete

desorption of carbon dioxide from the solutions.

Amines will also decompose under heating, leading

to poorer performance over time and shorter life time

of such sorbents.

There are several ways to deal with the drawbacks

and reduce massive energy penalty, including

replacing conventional amines with less corrosive

and more thermally-stable ones, decreasing the

stripper temperature to achieve lower corrosion rate,

as well as discovering ways to increase the

concentration of amines (reducing volume of water)

in solution. NH

3

is considered as a potential

alternative to MEA because of its low-cost, less

corrosive and less likely to degrade under heat, hence

greater stability compared with MEA. Moreover, it

holds relatively high CO

2

absorption capacity which

could lead to better process efficiency. Most

excitingly, NH

3

can react with NO

2

and SO

2

in flue

gas, forming ammonium sulfates and ammonium

nitrates, hence not only removing impurities, but also

directly producing usable and useful fertilizers. This

property of NH

3

is able to greatly reduce the costs in

solvent regeneration, CO

2

compression and storage.

They are far less corrosive compared to conventional

amines like MEA, resulting in green and sustainable

chemistry. Amino-functionalized ionic liquids have

been designed and absorption capacity is highly

enhanced since one amine is able to bind with two

carbon dioxide molecules (Luo, 2019), compared to

the 1:1 or 2:1 stoichiometry of conventional amines.

Overall, different aqueous amines should be

examined multidimensionally before being used in

CO

2

capture processes. Besides absorption capacities

and rates, other key parameters include corrosiveness,

resistance towards O

2

degradation, thermal stability,

tolerance to impurities, recovery in regeneration,

process efficiency and energy efficiency in cycle.

FSB 2022 - The International Conference on Food Science and Biotechnology

114

3 POROUS MATERIALS

Since aqueous absorbents such as amines require high

energy input for regeneration, as the so-called energy

penalty, sorbents with higher energy efficiency are

considered for carbon capture processes. The main

kind of solid adsorbents is porous materials, capturing

CO

2

by either physical adsorption or chemical

adsorption. As solids, porous materials have

significantly lower heat capacity than aqueous

absorbents which involve large volume of water.

Adsorption, in contrast with absorption, refers to the

enrichment of adsorbates (guest molecules) on the

internal or external surface of adsorbents. Hererin,

three common porous materials will be discussed in

the article, zeolites, AC and MOFs, though have

different chemical compositions and structures, all

uptake CO

2

gas molecules by physical adsorption

generally. Key parameters to evaluate solid

adsorbents with best CO

2

capture performance

include adsorption capacities, adsorption kinetics

(rates of adsorption and desorption) and selectivity

towards CO

2

. Moreover, since the solid adsorbents

are to be used in practical applications, other

industrial and engineering evaluations need to be

made. Stability under specific environments and

conditions is highly important, specifically towards

water vapor and moisture as well as other impurities

in gas mixtures. Thermal stability and mechanical

stability also greatly affect the life cycle of adsorbents

and their performance over time, since they might

frequently undergo high temperature and high

pressure. Due to the presence of pores, the density of

porous materials is relatively low, which is not

positive. Low density of sorbents leads to lower

volumetric uptake of gas than expected, hence an

optimized sorbent for industrial application should

have a balanced pore volume and density.

Engineering evaluations should also include the costs

in various processes, such as large-scale production,

transportation and regeneration of adsorbents.

3.1 Zeolites

Zeolites belongs to microporous crystalline materials

that consist of silicon, aluminum and oxygen, and the

porous framework can accommodate various cations,

such as Na

+

, Ca

2+

and Li

+

. Zeolites are initially

explored as natural minerals, but have been studied

and manufactured artificially for decades as

adsorbents and catalysts. Zeolites hold a well-

developed surface chemistry, as their porous

structures and chemical compositions can be

precisely altered, leading to different properties for

various industrial applications. Moreover, they are

produced on a large scale commercially and are

relatively cheap among all solid adsorbents.

Both chemical and structural factors determine the

adsorption capacity to zeolites. Because of the

charges on cations and the charges induced by cations

within the structures, a diverse of different gas

molecules can be adsorbed in different amounts.

Zeolites with low and high Si/Al ratios are

categorized into X and Y respectively, while different

Si/Al ratios lead to different adsorption capacities

(Férey, 2008). Adsorption capacities can also be

increased by substitution of cations (Walton, 2006),

resulting in higher charge densities and stronger

attractions. Adsorption capacities of zeolites are

determined by pore structures as well, larger specific

surface area and pore volume will likely promote

adsorption capacities. The CO

2

/N

2

separation

selectivity of zeolites is affected by K/Na ratio, as

CO

2

and N

2

uptake might vary significantly between

low and high K/Na ratios. Furthermore, selectivity

towards CO

2

is also affected by pore size (pore

diameter). Different pore sizes lead to different

diffusion rates and selectivity. Trade-off exists

between diffusion rates and selectivity, as larger pore

sizes generally result in faster diffusion rates while

lower selectivity towards CO

2

, and vice versa.

Zeolites hold advantages including high porosity,

uniform pore size and distribution, and most

significantly high capacities. Good CO

2

capture

performance is achieved by strong interactions and

molecular sieving effect. Moreover, low Si/Al ratio is

preferred due to greater aluminum content, which

leads to stronger basicity, hence better CO

2

capture.

Zeolites are mainly used for low-pressure adsorption

due to their microporous nature which limits the

uptake at high pressure, as the pores will be saturated.

Zeolite 13X has been one of the most studied and

synthesized zeolites, with outstanding adsorption

capacities. Moreover, zeolite 13X can hold high

contents of alkali- and alkali-earth cations such as

sodium cations, which contributes to the strong

interactions with guest molecules, enhancing the

adsorption capacities as well. There have been intense

researches on cation exchange, aiming to improve

adsorption capacities by introducing cations with

higher charge densities into the structure. Cations

with smaller ionic radii and higher ionic charges are

generally preferred. Kongnoo et al. further enhanced

the adsorption capacity of zeolite 13X by acid

activation in the preparation from palm oil mill fly ash

(Kongnoo, 2017), which promoted the adsorption

capacity of zeolite 13X by 22% compared with the

initial (unactivated) zeolite 13X. Type 13X zeolite

Application of Different Materials for Carbon Capture

115

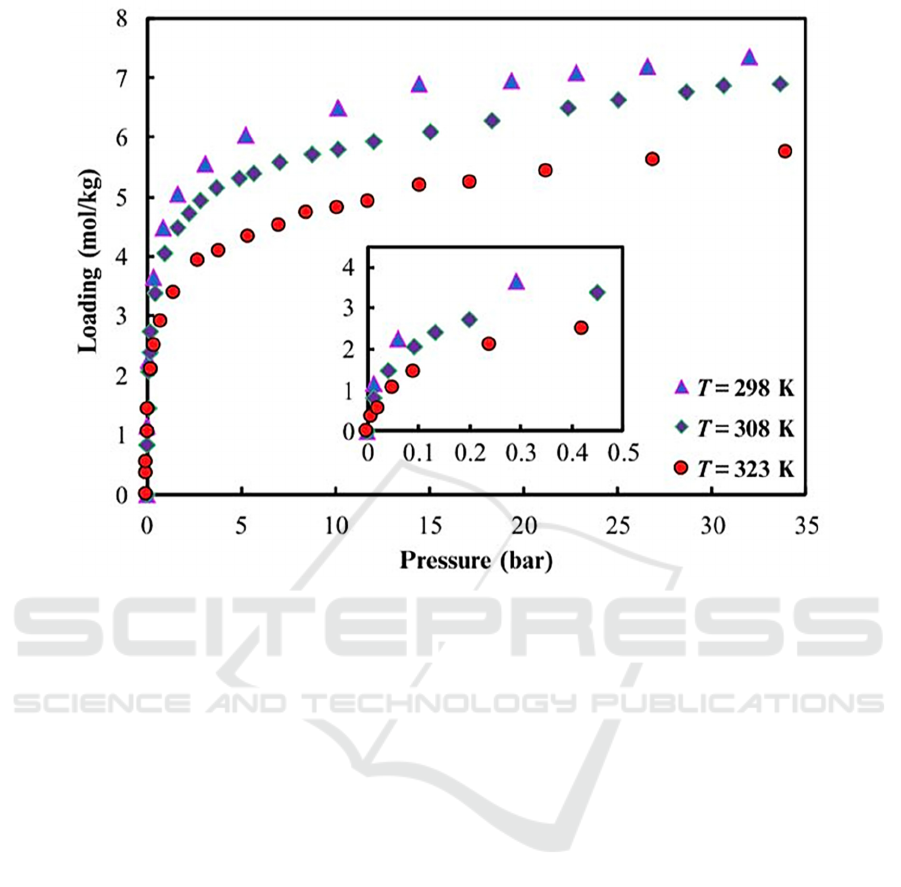

Figure 2: Adsorption isotherm of zeolite 13X for CO

2

(Cavenati, 2004).

manufactured by Ceca has gravimetric capacity of

2.05 mol/kg at temperature 298 K and pressure of 0.1

bar (Cavenati, 2004). From Fig. 2, most of the

adsorption process takes place at low pressure as

shown by a steep rise on the curve. Moreover, the

results show that CO

2

adsorption capacity for 13X

zeolite at room temperature (298 K) is significantly

higher than that at elevated temperatures.

The major drawback of zeolites is their

hydrophilic nature which leads to lower adsorption

capacities and selectivity toward CO

2

when moisture

and other impurities are present. Due to the cations

and induced charges within the porous structures of

zeolites, various polar molecules are favorably

adsorbed, including H

2

O, NO

x

, SO

x

and H

2

S, which

compete with CO

2

molecules for adsorption sites.

Moreover, such characteristics also lead to

regeneration penalty, as higher regeneration

temperatures are required in order to remove water

molecules adsorbed in the pores. Besides higher

energy requirements, the recovery of capacities and

other properties after desorption is also an issue, as

some zeolites lose evident adsorption capacities after

regeneration process under high temperature, which

will generate greater costs, since the adsorbents have

to be replaced more frequently. One solution to the

issue is by incorporating amine functional groups into

the mesopores of zeolites. After amine grafting,

interactions with CO

2

molecules tend to be

chemisorption, involving chemical reactions between

CO

2

molecules and amines, hence less affected by

H

2

O molecules. Moreover, adsorption capacity is

enhanced significantly by amine impregnation, and

water molecules can even promote the uptake,

according to experimental data. Overall, evaluations

of zeolites for industrial applications should not only

be conducted under ideal CO

2

/N

2

or CO

2

/CH

4

gas

mixtures, but also include all the substances that

appear in practical working environments, such as

water vapor, moisture and other impurities.

3.2 Activated Carbon

Activated carbon (AC) is another kind of

conventional solid adsorbent, used for gas storage, air

purification, solvent recovery and water purification.

The AC is produced from various carbonaceous

source materials, such as coconut husk, bamboo,

wood and coal, which than undergo physical

FSB 2022 - The International Conference on Food Science and Biotechnology

116

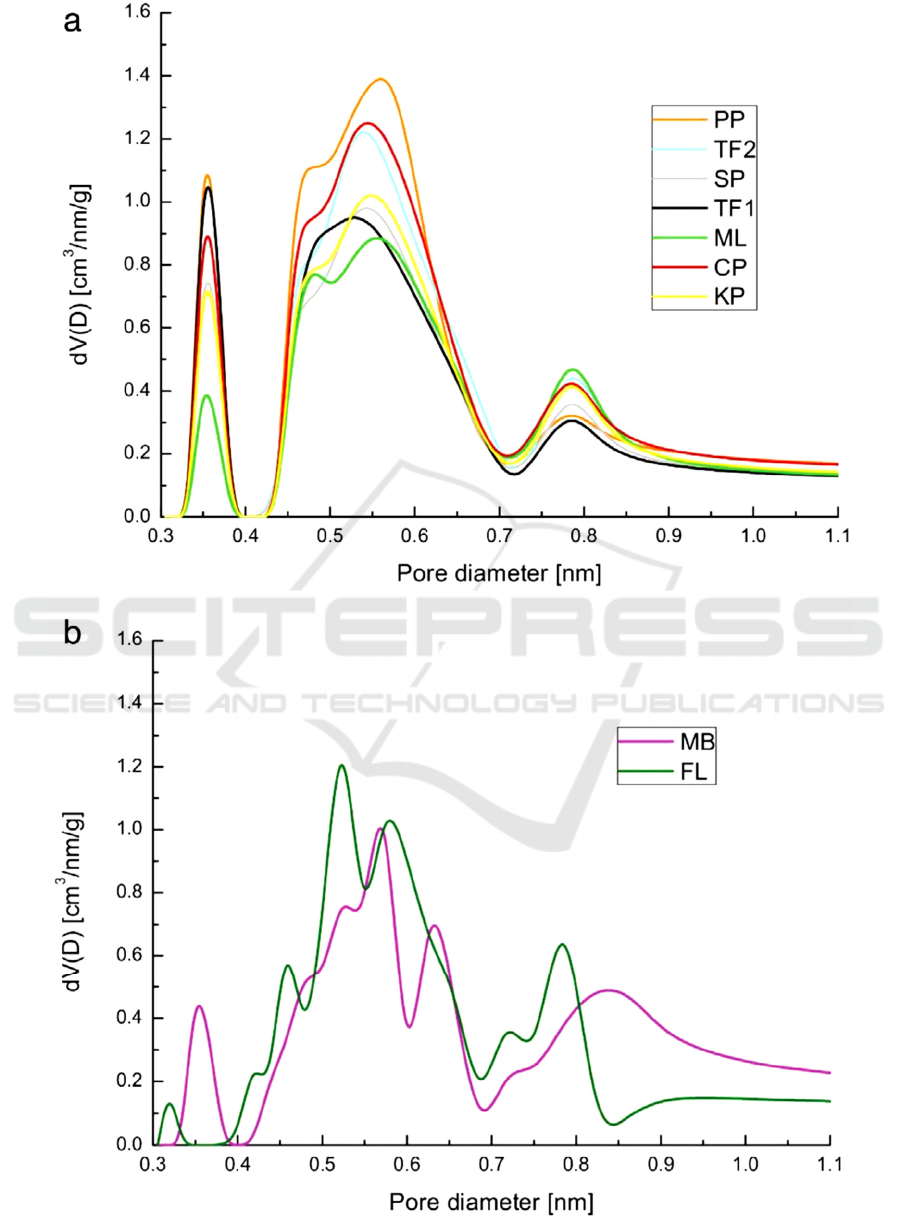

Figure 3: Different pore size distributions of the prepared AC (Serafin, 2017).

Application of Different Materials for Carbon Capture

117

activation and/or chemical activation. Activation

results in high porosity and large surface areas, with

pores of different shapes and sizes. The AC uptake

guest molecules by physisorption, as the interactions

are caused by Van der Waal forces and induced

dipoles. Textural properties, doped nitrogen contents

and ultra-microporosity all affect CO

2

capture

performance of AC. Pore characteristics depend on

carbon precursors, preparation (activation)

techniques and further modifications. Fig. 3 shows

that different carbon precursors (biomass here) can be

used to control different pore size distributions within

AC.

The merits of using AC for carbon capture

processes include high adsorption capacities, high

thermal stability as well as high stability in moist

conditions due to high hydrophobicity, well-

developed production technologies leading to

optimized porous structures and surface chemistry.

Moreover, AC generally require mild conditions for

regeneration because of low enthalpy of adsorption,

which is caused by relatively low CO

2

affinity

compared to other solid adsorbents, while also

exhibiting good recovery of adsorption properties

after regeneration, resulting in relatively high process

efficiency. Most importantly, low costs and broad

availability make AC the most frequently considered

solid adsorbent in industry on a commercial scale.

Adsorption capacities and selectivity of AC can

be enhanced by applying various functional groups

into the porous structures. Nitrogen functionalities

are the most common ones introduced into AC,

achieved by heat treatment with gaseous ammonia at

elevated temperatures. Experimental results show

that N-doped AC demonstrate improved CO

2

affinity

hence higher uptake at low pressures, but slightly

lower adsorption capacity. After amination of the

sample AC, adsorption capacity was significantly

increased (Plaza, 2009). Greater CO

2

affinity

improves selectivity towards CO

2

as well. Similar

effects can also be achieved by doping sulfur atoms

(oxidized-S). KOH activation is another technique to

improve AC’s CO

2

adsorption performance.

Adsorption capacities of various ACs are

significantly improved as KOH activation develops

pore network, specifically micropores and

mesopores. A series of chemical reactions take place,

generally favored by high temperatures. After the

reactions, the carbons are washed in order to remove

metallic potassium and other K compounds, resulting

in porous carbon lattices with high microporosity.

Moreover, KOH-activated AC exhibit high recovery

of CO

2

adsorption capacities after multiple

adsorption/desorption cycles.

3.3 Metal-organic Frameworks

Different from zeolite and activated carbon, MOFs is

a novel porous material, mostly developed in the 21st

century, exhibiting exciting properties that are

suitable for a broad range of applications, including

chemical sensing, drug delivery, gas separations, gas

storage and CO

2

capture, owing to MOFs’ tunable

textural properties and surface chemistry. Highly

flexible modifications are available to achieve

optimized MOFs for specific applications, since there

is a great variety of building blocks.

The adsorption performance of MOFs can be

improved by various modification techniques. For

example, surface modification for MOFs will

polarize the surfaces and lead to larger initial isosteric

heats, as adsorption of CO

2

tends to be

chemisorption. Enhanced adsorption and higher

affinity lead to higher selectivity towards CO

2

, as

well as greater capacity at low pressures. Moreover,

N

2

adsorption will decrease at all pressures due to

lower surface areas as the amine functionalities

occupy empty spaces, while smaller pore sizes also

result in decreased CO

2

uptake in relatively high CO

2

partial pressures, hence amine grafting is more

suitable for MOFs used for post-combustion CO

2

capture processes. Amine incorporation also

possesses other advantages. Generally, solid

adsorbents such as zeolites are concerned for their

hydrophilicity as well as other impurities competing

for adsorption sites. However, various amine-grafted

MOFs are not affected and even showed better

performance in the presence of water vapor. For

instance, moisture actually promotes CO

2

adsorption

capacity of TEPA-grafted Mg

2

(dobdc), due to

complex mechanisms. The results show that CO

2

is

preferably adsorbed to the grafted amine groups

under humid conditions, resulting in greater

adsorption capacity (McDonald, 2015). Furthermore,

amine-appended materials exhibit better CO

2

capture

performance with mixture gas. Amine groups can

also be incorporated onto organic ligands by click

reaction, enhancing the basic property within the

porous structures. Generally, amine binding with

metal clusters leads to greater improvement on

capacity while amine binding with ligands is more

stable. Amine-grafted MOFs should undergo

breakthrough experiments and dynamic cycling in

order to examine recovery over

adsorption/desorption cycles as well as the

relationship between amine loading and amine

efficiency.

FSB 2022 - The International Conference on Food Science and Biotechnology

118

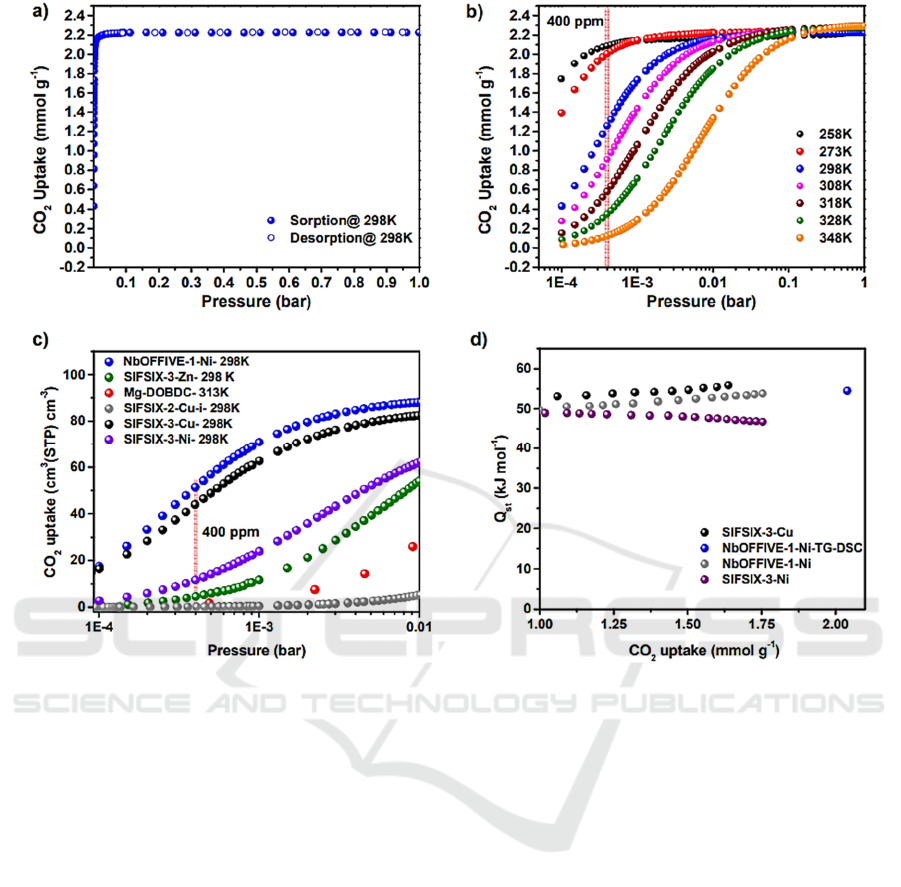

Figure 4: CO

2

adsorption isotherm, uptake and heat of adsorption for the prepared materials (Bhatt, 2016).

Adsorption performance of MOFs can also be

promoted by activating open metal sites, which would

lead to higher charge density and more favorable CO

2

uptake. Open metal sites are achieved either by

desolvation, specifically removing solvent molecules

in vacuum, or inserting metal cations into the porous

structures. Due to the presence of unsaturated

coordinate metal sites, CO

2

molecules transfer

electrons to them, leading to stronger interactions.

Pore size adjustment and distribution of adsorptive

sites also play a key role in improving CO

2

adsorption. Homogenous distribution of adsorption

sites is required in order to achieve identical

interaction strengths, so that high selectivity towards

CO

2

is maintained throughout wide pressure ranges.

Favorable uptake across great pressure range leads to

greater working capacity, which can lower capture

costs. SIFSIX-3-Cu exhibits ultra-microporous

structures and uniform distribution of adsorptive sites

(Bhatt, 2016), with a 54 kJ/mol Qst value leading to

high CO

2

uptake at low pressures, as shown in Fig. 4.

By using NbOF clusters, greater adsorption capacity

(1.3 mmol/g) is achieved, because of the high charge

densities within the one-dimension microchannels

accommodating CO

2

molecules, and the pore size is

smaller than the kinetic diameter of CO

2

molecule,

leading to slow gas diffusion and enhanced

interactions.

Major drawbacks of MOFs include low

mechanical stability and low density, which can be

solved by monolith production and help from

machine learning to make deterministic predictions

for materials’ performance. Monoliths are produced

through the mild drying of wet gel produced from the

gelation of primary particles, leading to robust,

densely packed MOFs (Tian, 2018). Compared with

MOF powders and pellets which contain glue or

binders that take up great volume leading to poor

volumetric performance and low mechanical

stability, MOF monoliths exhibit great energy density

as well as high stability, hence maximized

performance. Machine learning constructs neural

networks from database to automatically sort out

MOFs fulfilling specific requirements efficiently and

effectively, as the trade-off between density and pore

Application of Different Materials for Carbon Capture

119

volume can be balanced computationally, and

predictions can be further translated into applications.

4 CONCLUSION

Overall, this research discusses four carbon capture

techniques and relevant materials, specifically

aqueous amines for chemical absorption, zeolites, AC

and MOFs, which are porous materials, for physical

adsorption. The amine method is the mostly used one

in industry nowadays, generally for post-combustion

capture. However, more plants and factories are now

considering to replace aqueous amines with porous

materials. Intense researches have been conducted in

recent decades, which greatly improve properties of

several porous materials for carbon capture

applications. More and more suitable porous

materials have appeared, exhibiting optimized

characteristics. If porous materials are to be used

industrial applications, engineering evaluations are

required and the scaling up of production is also an

issue. In the near future, mature porous materials will

be able to replace present aqueous amines, which will

greatly reduce regeneration costs and save energy.

REFERENCES

Bhatt, P. M., et al. (2016). A fine-tuned fluorinated MOF

addresses the needs for trace CO

2

removal and air

capture using physisorption. Journal of the American

Chemical Society, 138(29), 9301-9307.

Cavenati, S., Grande, C. A., & Rodrigues, A. E. (2004).

Adsorption equilibrium of methane, carbon dioxide,

and nitrogen on zeolite 13X at high pressures. Journal

of Chemical & Engineering Data, 49(4), 1095-1101.

Dubois, L., & Thomas, D. (2011). Carbon dioxide

absorption into aqueous amine based solvents:

modeling and absorption tests. Energy Procedia, 4,

1353-1360.

Férey, G. (2008). Hybrid porous solids: past, present,

future. Chemical Society Reviews, 37(1), 191-214.

KUROPKA, J. (2011). Możliwości Ograniczania Emisji

Ditlenku Węgla ze Spalin Energetycznych. Korea, 1, 70.

Kadono, K., et al. (2013). New energy efficient processes

and newly developed absorbents for flue gas CO

2

capture. Energy Procedia, 37, 1785-1792.

Kongnoo, A., Tontisirin, S., Worathanakul, P., &

Phalakornkule, C. (2017). Surface characteristics and

CO

2

adsorption capacities of acid-activated zeolite 13X

prepared from palm oil mill fly ash. Fuel, 193, 385-394.

Liu, Z., Deng, Z., Davis, S. J., Giron, C., & Ciais, P.

(2022). Monitoring global carbon emissions in 2021.

Nature Reviews Earth & Environment, 3(4), 217-

219.

Luo, X. Y., et al. (2019). Designing amino‐based ionic

liquids for improved carbon capture: One amine binds

two CO

2

. AIChE Journal, 65(1), 230-238.

McDonald, T. M., et al. (2015). Cooperative insertion of

CO

2

in diamine-appended metal-organic frameworks.

Nature, 519(7543), 303-308.

Plaza, M. G., et al. (2009). Development of low-cost

biomass-based adsorbents for postcombustion CO2

capture. Fuel, 88(12), 2442-2447.

Romeo, L. M., Minguell, D., Shirmohammadi, R., &

Andrés, J. M. (2020). Comparative analysis of the

efficiency penalty in power plants of different amine-

based solvents for CO

2

capture. Industrial & Engineering

Chemistry Research, 59(21), 10082-10092.

Sumida, K., et al. (2012). Carbon dioxide capture in metal–

organic frameworks. Chemical reviews, 112(2), 724-781.

Serafin, J., Narkiewicz, U., Morawski, A. W., Wróbel, R. J.,

& Michalkiewicz, B. (2017). Highly microporous

activated carbons from biomass for CO

2

capture and

effective micropores at different conditions. Journal of

CO

2

Utilization, 18, 73-79.

Tian, T., et al. (2018). A sol-gel monolithic metal-organic

framework with enhanced methane uptake. Nature

Materials, 17(2), 174-179.

Trickett, C. A., et al. (2017). The chemistry of metal-

organic frameworks for CO

2

capture, regeneration and

conversion. Nature Reviews Materials, 2(8), 1-16.

Vega, F., Cano, M., Camino, S., Fernández, L. M. G.,

Portillo, E., & Navarrete, B. (2018). Solvents for carbon

dioxide capture. Carbon dioxide chemistry, capture and

oil recovery, 142-163.

Walton, K. S., Abney, M. B., & LeVan, M. D. (2006). CO

2

adsorption in Y and X zeolites modified by alkali metal

cation exchange. Microporous and Mesoporous

Materials, 91(1-3), 78-84.

FSB 2022 - The International Conference on Food Science and Biotechnology

120