A Collaborative Purification Device for Medical Exhaust Gas and

Wastewater based on Low Temperature Plasma Technology

Xinfei Zhangchen

1,a

, Xunchen Liu

1,b,*

, Yuan Fang

2,c

, Yuwen Shu

3,d

, Zeming Wang

1,e

and Kailin Han

1,f

1

Wuhan Institute of Technology, Wuhan, China

2

South-Central University for Nationalities, Wuhan, China

3

Wuhan University of Technology, Wuhan, China

b,

*Corresponding author: liuxunchen2021@163.com

Keywords: Medical Waste Gas and Wastewater, Collaborative Purification, Plasma, Graphite Fiber.

Abstract: With the continuous development of environmental protection and sustainable development strategy, the

traditional medical waste gas and wastewater discharge will not only pollute the environment, but also

seriously threaten human physical and mental health. It has become an urgent problem to control it

scientifically and deal with it reasonably. In this paper, an integrated device for treating medical waste gas

and waste water with low temperature plasma is designed, which uses silver-plated graphite fiber as electrode.

The device uses plasma to purify medical waste gas and wastewater, no secondary pollution, high efficiency

and environmental protection; through the atomization device is set to make waste water and waste gas

synergistic purification, improve purification efficiency; the modified graphite fiber electrode is adopted to

reduce energy consumption. This research improves the efficiency of waste water and waste gas treatment to

fill the current gap in the industry, and contributes to the sustainable development strategy.

1 INTRODUCTION

With the implementation of sustainable development

strategy in the world, people pay more and more

attention to sustainability. Under the background of

global environmental protection, how to scientifically

control and reasonably treat the organic waste gas and

medical waste water in the medical industry has

become an urgent problem (Wei, 2020).

Hospital sewage contains a large number of

pathogenic bacteria, viruses and chemical agents

(Lin, 2017), which is characterized by space

pollution, acute infection and latent infection (Yang,

2017). Medical waste gas is harmful gas produced by

combustion of medical waste (Zhang, 2019). Such

industrial waste gas contains alcohols, acids and

ketones, which will not only pollute the environment,

but also seriously threaten human physical and mental

health.

At present large hospital medical wastewater

treatment mainly using chlorine disinfectants for

disinfection, such as NaClO, ClO2, in which NaClO

in the process of using residual, easy to react with

organic matter in water generated in the process of

sterilization effect of chemicals cause cancer, birth

defects, there is a certain risk, the need of personnel

management. However, the traditional method has its

inevitable drawbacks in principle, such as high cost

of facility construction, maintenance and

management, multi-stage processing and complicated

process control.

In the processing of medical waste is the

traditional adsorption method, although adsorption

method has a very wide range of application and low

energy consumption, but if the exhaust gases contain

a variety of pollutants, the adsorption efficiency of

adsorption method would significantly reduce, and

adsorbent regeneration difficulty, easy to poisoning,

so led to the organic waste gas treatment lack of

quality assurance. So finding a new type of medical

waste gas, wastewater treatment technology is

imperative. Although there are many differences

between this research and our former study (Hua,

2022; Chen, Zhuang, 2021; Gu, 2021; Chen, Zhang,

2021), we still carry out the excellent research about

a collaborative purification device for medical

exhaust gas and wastewater based on low temperature

plasma technology.

Zhangchen, X., Liu, X., Fang, Y., Shu, Y., Wang, Z. and Han, K.

A Collaborative Purification Device for Medical Exhaust Gas and Wastewater Based on Low Temperature Plasma Technology.

DOI: 10.5220/0012011800003633

In Proceedings of the 4th International Conference on Biotechnology and Biomedicine (ICBB 2022), pages 5-11

ISBN: 978-989-758-637-8

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

5

2 DEVICE INNOVATION

With the support of the existing technology, we have

designed an integrated device for treating medical

waste gas and waste water using low-temperature

plasma with graphite fiber coated with silver as

electrode. Graphite fiber surface modification

technology was used to improve the plasma surface

discharge efficiency, and a liquid gasification device

was creatively added to the device, which could

further improve the common purification effect of

waste water and waste gas. And the plasma power and

purification rate were studied, and finally

successfully produced a set of waste water

gasification, low temperature and high efficiency

plasma water purification in one of the waste water

and waste gas treatment equipment, on the existing

basis to improve the purification rate and reduce the

energy required, the traditional purification device to

improve and upgrade.

(1) Plasma purification

Using plasma purification medical waste gas

waste water, no secondary pollution, and efficient

environmental protection: compared with the

traditional chemical precipitation method, using

plasma purification more green environmental

protection, in line with the requirements of energy

conservation and emissions reduction, oxidation and

plasma generated is strong gas efficient of

purification of bacteria, viruses and other organisms

that have slipped into the medical wastewater and

organic chemicals, achieve discharge standards.

(2) Modified graphite fiber electrode

Modified graphite fiber electrode is adopted to

reduce energy consumption. Compared with the

copper column, the surface of graphite fiber rod is

loose and porous, which is beneficial to generate

more plasma in dielectric barrier discharge and

improve the purification efficiency. Graphite fiber

itself is an excellent conductor of electricity, coating

its surface with silver can further reduce its resistivity,

but also improve its corrosion resistance, prolong the

service life. The experimental results show that the

low temperature plasma generator using modified

graphite fiber as electrode can save 20%~30% power

consumption compared with the similar device.

(3) Atomization device

Through atomizing device, waste water and waste

gas can be synergistically purified to improve

purification efficiency. The medical waste water is

mixed with the exhaust gas after pressurized

atomization, and the gas-liquid mixture phase enters

the static mixing tube at the same time with the air

after plasma treatment, and is mixed in the mixing

tube and fully reacts. This treatment method can

improve the utilization rate of plasma, reduce the

power consumption, and accelerate the reaction rate

of plasma and pollutants. Through experimental

calculation, the reaction rate is the fastest at the

interface between plasma and waste water. The

cooperative purification method of waste gas and

waste water of this device can greatly improve the

contact area of plasma air and waste water, accelerate

the reaction rate, and thus improve the purification

efficiency of the whole machine.

3 PURIFICATION PLANT

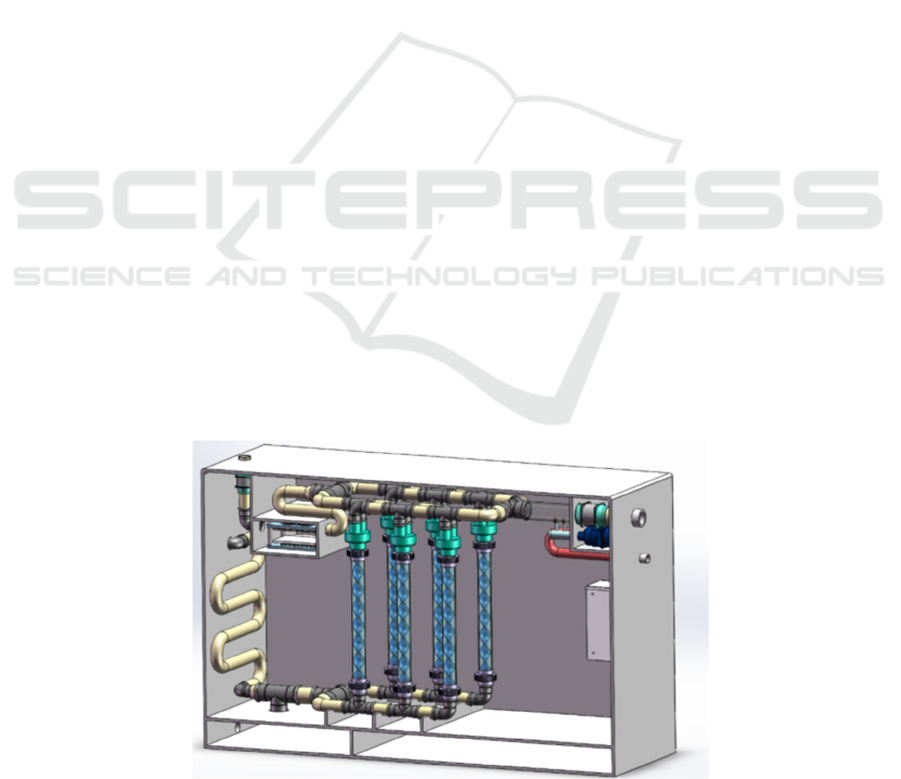

The purification device includes gas-liquid mixed

structure, plasma generator, mixed reaction structure

and condensation separation structure. Fig.1 is a

schematic diagram of the overall structure of the

device.

Figure 1: Cruise drone landing platform structure.

ICBB 2022 - International Conference on Biotechnology and Biomedicine

6

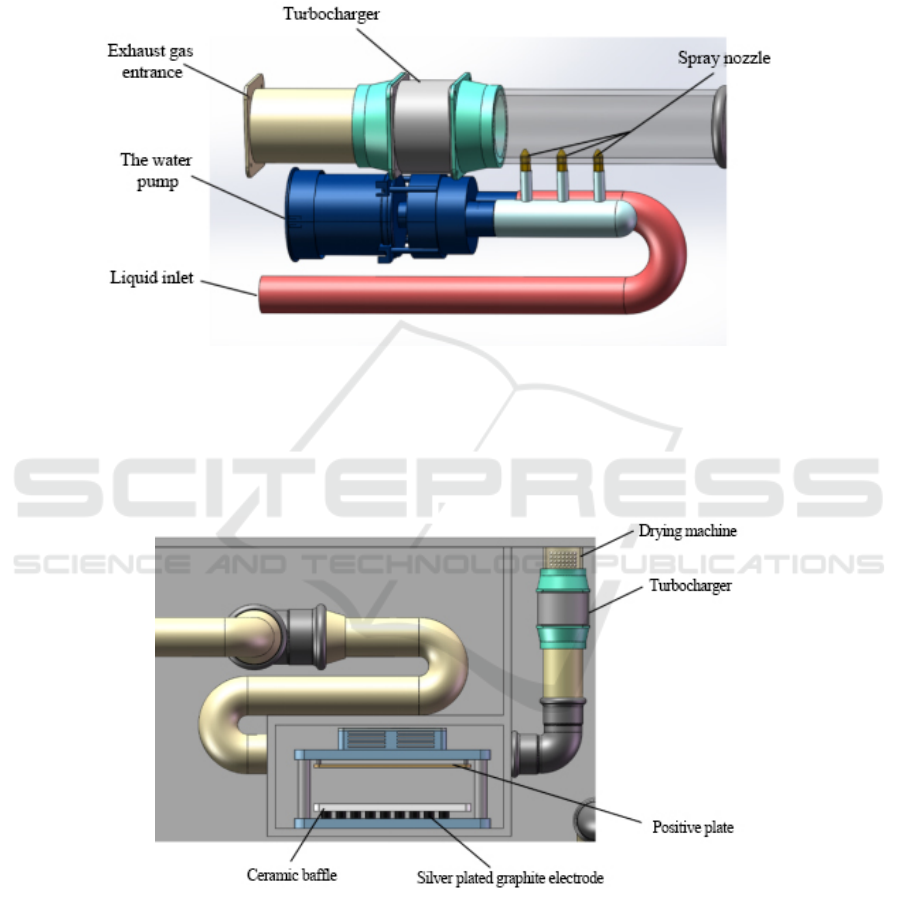

(1) Gas-liquid mixed structure

The gas-liquid mixing mechanism comprises a

gas input part and a liquid input part. Fig. 2 is a

schematic diagram of gas-liquid mixture structure.

The gas input part consists of a turbocharger, which

rotates to input the exhaust gas; The liquid input part

is composed of a water pump and a number of

atomizing nozzles arranged on the pipe wall, through

which the waste liquid is pumped into the pump, and

then the waste liquid is changed into mist through the

nozzle, and mixed with the waste gas.

Figure 2: Gas-liquid mixed structure.

(2) Plasma generator

Plasma generator by DBD low temperature

plasma generator, turbocharger, desiccant, through

the turbocharger will input air, the air through the

desiccant to remove moisture, and DBD low

temperature plasma generator to produce plasma,

input the air generator within the plasma transfer and

fresh air to produce new plasma. Fig. 3 is a schematic

diagram of plasma generator.

Figure 3: Plasma generator.

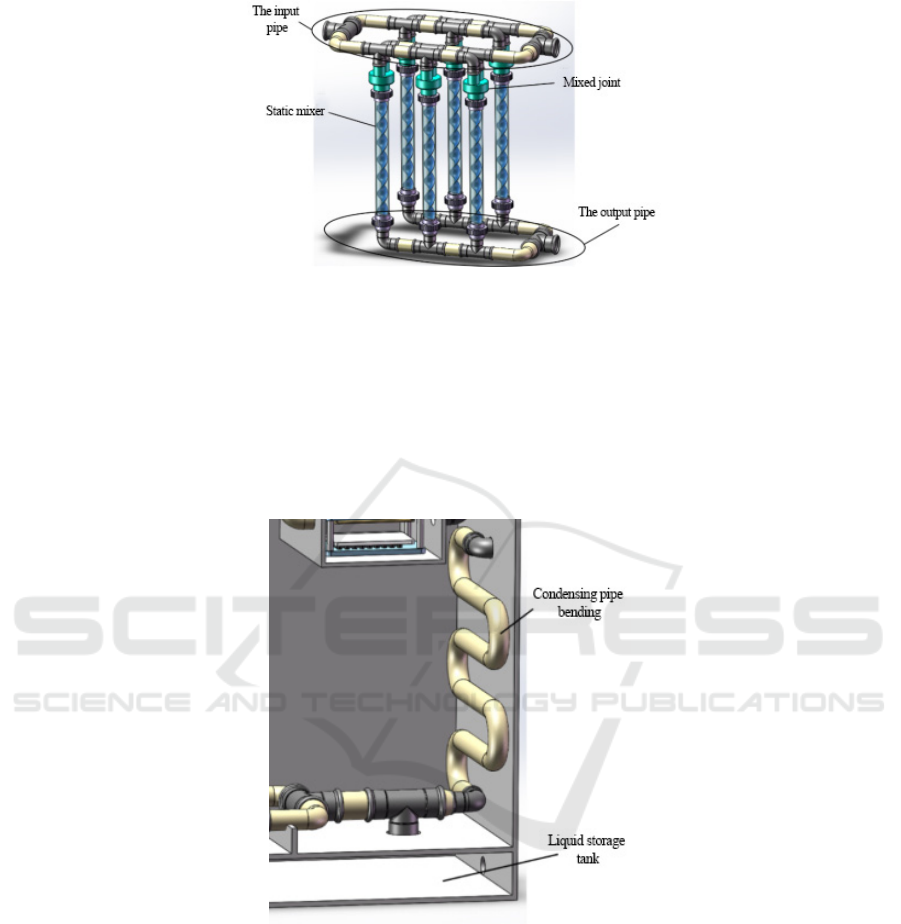

(3) Mixed reaction structure

The mixing structure consists of an input tube,

several static mixers and an output tube. Fig. 4 is a

schematic diagram of mixed reaction structure. Each

static mixer tube inlet connection by two inputs, input

contains plasma of air and waste gas and waste liquid

atomization of mixed gas, the static mixer with

multiple mixing unit, overlapping, can instantly at

very good mixing effect, including plasma air and

steam mixed fully response, the output pipe will count

all products in the static mixer.

A Collaborative Purification Device for Medical Exhaust Gas and Wastewater Based on Low Temperature Plasma Technology

7

Figure 4: Mixed reaction structure.

(4) condensation separation structure

The condensation separation structure consists of

a liquid storage tank and a condensation bend. Fig.5

is a schematic diagram of the condensation separation

structure. After treatment, the mixed steam condenses

in atomized droplets after passing through the

condensing bend and flows into the liquid storage

tank, while the gas phase continues to pass through

the bend and is finally discharged from the gas outlet.

The waste liquid in the liquid storage tank is

discharged through the liquid outlet after reaching a

certain amount. Sensors are installed on the wall of

the liquid storage tank, which can monitor the

pollution components in the waste liquid in real time

to ensure that the liquid after treatment meets the

discharge requirements.

Figure 5: Condensing separation structure.

(5) Purification process of medical waste gas and

waste liquid

The working process is as follows: the waste gas

generated after the incineration of medical appliances

will be removed through activated carbon before

entering the device, and the solid residue in the waste

liquid will be removed through coarse filtration

before entering the device to ensure that the liquid

entering the device only contains liquid phase.

Medical waste liquid by the liquid inlet through the

pump pumping unit, by several nozzle jet again in

fog, waste gas from waste gas entrance from the

turbocharger suction device, mixed with mist waste

liquid in nozzle place, and at the other side of the

device, DBD plasma plasma generator, air drawn in

by the turbocharger after drying device, mixed with

plasma plasma mixture formation, Then, the mixed

phase reacts fully with the waste gas liquid in the

mixed reaction structure, and finally separates the gas

liquid in the condensation separation structure. After

treatment, the waste liquid and waste gas are

discharged from the liquid outlet and the gas outlet

respectively. Fig. 6 is the schematic diagram of the

device.

ICBB 2022 - International Conference on Biotechnology and Biomedicine

8

(Note 1: Turbocharger 2: atomizer 3: DBD plasma generator 4: Turbocharger 5: desiccants 6: water pump 7:

static mixer 8: condensing bend 9: liquid storage box 10: sensor)

Figure 6: Schematic diagram of device principle.

4 CONTROL MODULE

The control module is used to control each step of the

whole device. This module is composed of

STM32F103C8T6 single chip microcomputer and

connected high-voltage power supply, water pump,

turbocharger, voltage matching circuit, temperature

and humidity sensor, button, OLED display screen

and so on.

Power control circuit is used to realize the control

of low voltage, small current controller circuit to

power circuit, through the control of high voltage

module, water pump, turbocharger, etc., to achieve

the control of current, water flow and air.

As shown in Fig.7, the high voltage module, water

pump and turbocharger are connected with 12V

power supply and controlled by relays SR

1

, SR

2

, SR

3

and SR

4

, which are driven by triodes current amplifier

circuit.

Figure 7: Power control circuit.

A Collaborative Purification Device for Medical Exhaust Gas and Wastewater Based on Low Temperature Plasma Technology

9

When the level of GPIO port corresponding to the

single chip is 0, the base level of Q

1

is pulled down,

Q

1

is in cut-off state, and the relay is open. When the

level of GPIO port corresponding to the single chip is

1, the base level of Q

1

rises, and the control current is

generated. Q

1

turns on and the relay pulls in. When

the level of the corresponding GPIO port changes

from low to high, the relay pops open to produce a

high counter electromotive force. At this time, diode

D

1

turns on to absorb the current and avoid burning

the transistor and MCU.

5 EXPERIMENT AND TEST

RESULTS

The experimental materials were silver nitrate and

acetone, which were analytically pure. Polypropylene

(PP) emulsion (91735), solid content in 30%~33%.

Graphite fiber and deionized water are self-made by

the laboratory. The resistivity of graphite fiber is

about 13.5×10

6

Ω∙m. Epoxy sizing agent is removed

with acetone before use.

(1) Experimental process

The preparation of silver-containing slurry, PP

emulsion as the main raw material, PP/H2O emulsion

prepared for graphite fiber impregnation coating.

Then impregnated coating treatment, graphite fiber is

fixed on the bracket, put into the slurry containing

silver, through repeated impregnation to make the

slurry evenly coated on the fiber surface. Graphite

fibers were impregnated with PP/H2O emulsion

slurry with silver nitrate content of 5%. Finally, the

graphite fiber after impregnation coating treatment

was placed in high temperature tubular furnace (GSL-

1700X) for pyrolysis. The graphite fibers were fixed

at both ends on the support, and a certain tension was

applied. The temperature was heated to 500℃ at a

rate of 10 K/min in nitrogen atmosphere, and the

temperature was kept for 10min.

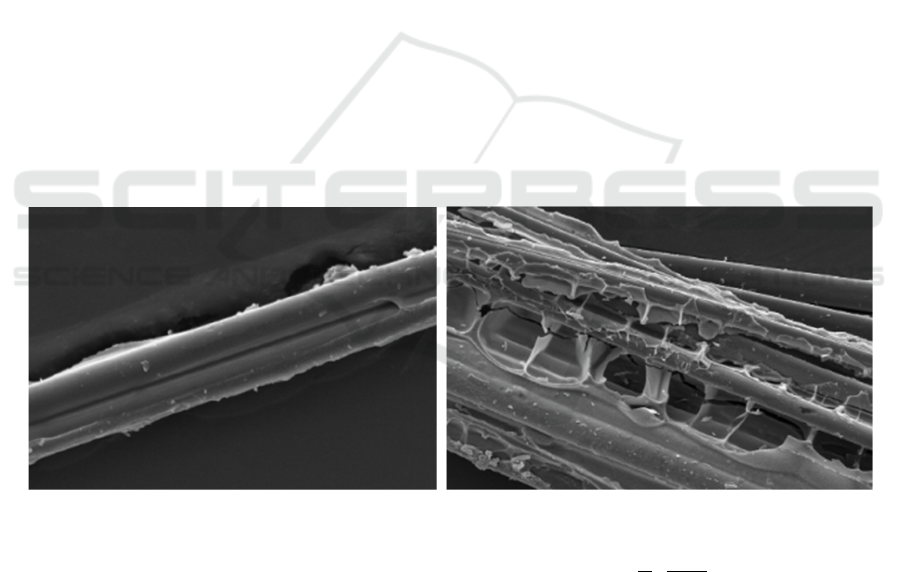

(2) By scanning electron microscope (SEM) test

characterization

The fibers were glued to the sample table with

conductive adhesive and observed at a constant

temperature of 50℃. Fig.8 shows SEM images of

graphite fiber GF-1 before and after treatment. As can

be seen from the figure, the surface of untreated

graphite fiber is very smooth, while many foreign

bodies can be observed on the surface of coated and

pyrolyzed graphite fiber. In this device, the polymer

in the slurry acts as a binder to make the silver nitrate

adhere to the surface of the graphite fiber. Silver

nitrate is converted to elemental silver by pyrolysis.

Figure 8: SEM photos before and after treatment (untreated on the left, silver plated on the right).

It can be seen that the silver is mainly distributed

evenly on the surface of the graphite fiber coated by

PP/H2O emulsion in the form of fine nanoparticles.

(3) Resistivity test

The self-made fiber resistivity tester and DC dual

probe method were used to test the resistivity of the

fiber sample. The test length was 10cm, and the DC

current was adjusted to 0.05a after the power was

turned on. The voltage was read and the resistivity

was calculated. The calculation formula of resistivity

is as follows:

𝜌

𝑈

𝐼

⋅

𝑌

𝐷⋅𝐿

10

Where, ρ is the resistivity (ω ∙m); U is voltage (V);

I is the current (A); Y is fiber linear density (g/1 000

m); D is fiber body density (g/cm3); L is fiber test

length (cm).

According to the resistivity test results of

untreated and silver-plated graphite fibers, compared

with the untreated graphite fiber, the resistivity of the

silver-plated graphite fiber decreased. The resistivity

of the silver-coated graphite fiber prepared by

PP/H2O emulsion coating decreased significantly,

ICBB 2022 - International Conference on Biotechnology and Biomedicine

10

and the resistivity of the silver-coated graphite fiber

decreased about 40.7% compared with that before

treatment.

6 CONCLUSION

(1) The device uses the principle of dielectric barrier

discharge (DBD), which produces both low-

temperature plasma and a large amount of ozone. At

the same time, the discharge effect at the electrode

can be reduced, so that the discharge is concentrated

on the electrode surface to form a more uniform

discharge.

(2) The air containing plasma is mixed with the

waste gas liquid mixture in the mixed reaction vessel

to form activated water. The water activated by low

temperature plasma has certain bactericidal ability

and can be used in the treatment of medical

wastewater. Moreover, plasma activated water has

obvious bactericidal effect on Staphylococcus aureus,

Escherichia coli and pseudomonas aeruginosa.

(3) The power consumption of the existing

medical wastewater treatment system is 120kwh/d,

and the electricity consumption is 84 yuan /d based

on 0.7 yuan/KWH, and the daily drug consumption is

78 yuan /d, with a total cost of 162 yuan /d. The power

consumption of the low-temperature plasma

purification system is 78 yuan /d, and there is no need

to add pharmaceutical costs, and the cost is reduced

about 61%.

(4) Compared with the existing medical

wastewater treatment system, the low-temperature

plasma wastewater treatment system has a higher

removal rate of pollutants in the medical wastewater,

and can basically remove the components of COD,

BOD5 and Escherichia coli that are harmful to the

environment in the medical wastewater. The removal

of BOD5 indirectly reduces the survival rate of

microorganisms in wastewater, makes wastewater

discharge to meet national standards, and reduces the

pollution of wastewater to the environment. At the

same time, the device will be mixed with waste water

and waste gas at the same time, improve the treatment

efficiency of waste water and waste gas, with good

social benefits.

ACKNOWLEDGMENTS

The authors would like to thank Natural Science

Foundation of Hubei Province (No. 2020CFB389) for

the support given to this research.

REFERENCES

Chen M , Xiong X , Zhuang W . Design and simulation of

meshing performance of modified straight bevel gears

[J]. Metals, 2021, 11(1): 33.

Chen M , Zhuang W , Deng S , et al. Thermal analysis of

the triple-phase asynchronous motor-reducer coupling

system by thermal network method [J]. Proceedings of

the Institution of Mechanical Engineers, Part D: Journal

of Automobile Engineering, 2020, 234(12): 2851-2861.

Chen M , Zhang X , Xiong X , et al. A multifunctional fast

unmanned aerial vehicles-unmanned surface vehicles

coupling system [J]. Machines, 2021, 9(8):146.

Gu Z , Chen M , Wang C , et al. Static and dynamic analysis

of a 6300 KN cold orbital forging machine [J].

Processes, 2021, 9(1):7.

Hua L , Chen M , Han X , et al. Research on vibration model

and vibration performance of cold orbital forging

machines [J]. Proceedings of the Institution of

Mechanical Engineers, Part B: Journal of Engineering

Manufacture, 2022, 236(6-7): 828-843.

Lin M , Wang Z , Zhang K , et al. Study on electrooxidation

coupled ceramic membrane treatment of wastewater

from a hospital in South China [J/OL]. Water treatment

Technology. 2017.214(07):35-38.

Wei B . Introduction to the generation and daily disposal of

"three wastes" in general hospitals [J]. Resource

Conservation and Environmental

Protection,2020(05):74.

Yang J . Design and analysis of radioactive wastewater

treatment system in general hospital [J]. China hospital

architecture & equipment, 2017,18(07):62-64.

Zhang F . Study on treatment measures of waste gas in

microwave disinfection treatment of medical waste [J].

Shanxi chemical industry, 2019,39(06):152-154.

A Collaborative Purification Device for Medical Exhaust Gas and Wastewater Based on Low Temperature Plasma Technology

11