Combined Ferric Chloride and Phanerochaete Chrysosporium

Pretreatment on Corn Stalk Degradation

Pin Zhang

1,*

, Jie Lu

2

, Shengyong Liu

2

, Jiong Wang

2

and Shuqing Zhang

1

1

Henan University of Animal Husbandry and Economy, Zhengzhou, 450011, China

2

College of Mechanical and Electrical Engineering, Henan Agricultural University, Zhengzhou, 450002, China

Keywords:

Corn Stalk, Pretreatment, Ferric Chloride, Phanerochaete Chrysosporium.

Abstract:

In order to shorten the pretreatment cycle of microorganisms and enhance the pretreatment effect, the corn

stalk was pretreated by means of metal ions and microorganisms, the effects of combined pretreatment of

ferric chloride and white rot fungi on the degradation of 40 and 80 mesh corn stalks were studied. The content

of cellulose, hemicellulose and lignin changes and the yield of reducing sugar in the fermentation broth were

analyzed. The results showed that when the concentration of ferric chloride solution was 0.4mol/L, the solid-

liquid ratio was 1/20g/ml, and the 80 mesh corn stalk material was treated at 30 min at 100~108℃, the

cellulose content increased by 56.08%, the hemicellulose decreased by 13.06% and the lignin increased by

37.80%. When ferric chloride treated corn stalks were inoculated with Phanerochaete chrysosporium, the

reducing sugar content reached 2.52 mg/ml on the twelfth day, and the yield of reducing sugar was the highest

in the fermentation broth. The study opens up a new way for high efficiency, clean and low energy

consumption of biomass pretreatment technology of crop straw.

1 INTRODUCTION

China is rich in biomass raw materials, with an annual

output of approximately 700 million tons of crop

stalk, of which corn stalk accounts for approximately

35%. This represents a tremendous resource for

energy and environmental solutions in China. The

main components of crop stalk are cellulose,

hemicellulose, and lignin. Of these, hemicellulose

can be readily degraded into monosaccharides

(mainly xylose) and a small amount of arabinose,

mannose and galactose. Cellulose accounts for

approximately 40% of the total stalk weight; it

mainly consists of glucose, and its crystal structure is

difficult to degrade. Lignin is a phenolic polymer that

bonds cellulose to hemicellulose. To convert the

cellulose in corn stalk into fermentable sugars, the

stalk must be pretreated using a specialized method.

The lignin bound to the cellulose can only be broken

after the pretreatment, thus exposing the cellulose to

facilitate the subsequent enzymatic hydrolysis and

fermentation (Lissens, 2004; Palonen, 2004).

Pretreatment with metal ions is conducted under

normal conditions and is thus environmentally

friendly (Galbe, 2002; Bailey, 1996; Saricks, 1999),

with zero vapor pressure, high thermal stability and

catalytic function, and the pretreatment waste can be

recycled. The metal ion pretreatment reduces the

cellulose’s crystallinity, thus increasing its

accessibility and benefitting its subsequent

hydrolysis (Solomon, 2007). Lopez-Linares and

Romero of the University of Jaén, Spain, treated olive

tree biomass with metal ions at 0.265 mol/L for 30

min at 152.6 °C and achieved high rates of

hemicellulose removal and hydrolysis (López-

Linares, 2013). Zeng of Chongqing University,

China, treated biomass with 0.6 mol/L ferric chloride

solution for 15 min at 170 °C at a solid to liquid ratio

of 10:1 mL/g, increasing the relative cellulose

content by 72.19% and the reducing sugar yield by

131.6% (Zeng, 2013).

The biological treatment method has the

advantages of mild reaction conditions, low energy

consumption, environmental friendliness, and high

target product yield; thus, it has great potential for

development (Saha, 2016; Kim, 2008; Ranganathan,

2008; Henriksson, 2000). The degradation of lignin

by white rot fungi mainly uses peroxidase secreted by

white rot fungi to catalyze lignin oxidation. Lignin

peroxidase (LiP), manganese-dependent peroxidase

(MnP) and laccase (Lac) are the three main enzymes

for lignin degradation by white rot fungi (Wan,

Zhang, P., Lu, J., Liu, S., Wang, J. and Zhang, S.

Combined Ferric Chloride and Phanerochaete Chrysosporium Pretreatment on Corn Stalk Degradation.

DOI: 10.5220/0012013300003633

In Proceedings of the 4th International Conference on Biotechnology and Biomedicine (ICBB 2022), pages 69-76

ISBN: 978-989-758-637-8

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

69

2012). White rot fungi not only have unique lignin

degradation ability, but also, like most other fungi,

have the ability to degrade cellulose and

hemicellulose to provide carbon source for their own

growth. The degradation of cellulose by white rot

fungi depends on the cellulase secreted by white rot

fungi, and the degradation of hemicellulose depends

on the hemicellulase secreted by white rot fungi.

Cellulase from white rot fungi is also composed of

Endoglucanase (EG, EC 3.2.1.4), Cellobiohydrolase

(CBH, EC 3.2.1.91) and beta-glucosidase (EC

3.2.1.21) (Kirk, 1997). Cellulose endonuclease

hydrolyzes the amorphous region of cellulose

microfibers and releases new end of cellulose chain.

Cellulose endonuclease hydrolyzes the next

cellobiose unit from end of cellulose chain in turn,

and finally hydrolyzes to glucose under the action of

beta-glucosidase. Xu et al. pretreated corn stalk with

Irpex lacteus CD2 at a cellulase dosage of 20 filter

paper units (FPU)/g dry matter for 25 days to achieve

hydrolysis and reached a saccharification rate of

66.4% (Xu, 2010). Sun et al. pretreated corn stalk

with Trametes hirsuta yj9 to increase total sugar

conversion from enzymatic hydrolysis (Sun, 2011).

However, due to the long period of microbial

pretreatment, it is difficult to apply in large-scale

industrial production, which restricts the further

application and development of biological

pretreatment. Ferric chloride solution achieves the

purpose of pretreatment mainly by destroying

hemicellulose of straw. The treatment cycle of straw

treated with ferric chloride and inoculated with white

rot fungi will be shortened and straw will be further

degraded to enhance the effect of pretreatment. In this

study, we investigated the effect of the process and

parameters of the pretreatment using ferric chloride

combined with Phanerochaete chrysosporium on the

reducing sugar content of corn stalk after enzymatic

hydrolysis. The pretreatment ability was determined

by the content change of cellulose, hemicellulose and

lignin and the yield of reducing sugar. It opens up a

new way for high efficiency, clean and low energy

consumption of biomass pretreatment technology of

crop straw.

2 MATERIALS AND METHODS

2.1 Corn Stalk Raw Material

Corn stalk was collected from the experimental site

of the College of Mechanical and Electrical

Engineering of Henan Agricultural University, air-

dried, pulverized with a pulverizer, and sieved

through 40-mesh (0.425 mm) and 80-mesh (0.175

mm) standard sieves, and the siftage was dried at

75 °C to a constant weight. The main composition of

corn stalk was showed in Table 1.

Table 1. Main composition of corn stalk.

Raw material Cellulose (g) Hemicellulose (g) Lignin (g) Other (g)

40-mesh 0.252 0.315 0.127 0.306

80-mesh 0.255 0.314 0.127 0.304

Note: The total raw material weight used in the determination was 1.000 g.

2.2 P. chrysosporium Culture

P. chrysosporium (GIMCC No: GIM3.393) was

purchased from the Preservation Center of

Microorganisms of the Research Institute of

Microbiology of Guangdong Province. The

lyophilized P. chrysosporium mycelia were dissolved

in sterile water and revived. They were then

inoculated onto potato dextrose agar (PDA) slant

medium and cultured at 28 °C for 7 days, from which

the second-generation subculture was inoculated,

cultured for 7 days and then stored at 4 °C for later

use.

2.3 Ferric Chloride Pretreatment

Five grams of dried corn stalk powder sieved through

40-mesh or 80-mesh filters was placed into a 500-mL

Erlenmeyer flask, to which ferric chloride solution of

different concentrations (0.1, 0.2, 0.3, 0.4, or 0.5

mol/L) was added at a solid to liquid ratio (g/mL) of

1/10 (a) or 1/20 (b). The sample was then mixed

thoroughly and treated at 100–108 °C for 15 (c) or 30

min (d). The cellulose, hemicellulose and lignin

contents were determined after the above

pretreatment.

ICBB 2022 - International Conference on Biotechnology and Biomedicine

70

2.4 P. chrysosporium Pretreatment

After rinsing to neutral pH, corn stalk siftage after the

ferric chloride pretreatments or 5 g of dried corn stalk

siftage sieved through 40-mesh or 80-mesh filters

was placed in a 300-mL Erlenmeyer flask, to which

distilled water was added at a solid to liquid ratio of

1:5. The flask was sealed with a sterile membrane and

treated at 121 °C for 1 h. Next, P. chrysosporium

growing in the logarithmic phase was punched with a

puncher, and several punch disks were inoculated

into 6 flasks and cultured at 28 °C. On days 6, 12, 18,

24, and 30 after inoculation, the reducing sugar

content was determined.

2.5 Determination Methods

The cellulose, lignin and hemicellulose contents in

the corn stalk were determined per the method of

Wang (Wang, 1987). The reducing sugar content in

the hydrolysate was determined using the 3, 5-

dinitrosalicylic acid colorimetric method on a Model

752 spectrophotometer (Ghose, 1987).

3 RESULTS AND DISCUSSION

3.1 Effects of Different Ferric Chloride

Pretreatment Conditions on

Cellulose and Hemicellulose Yields

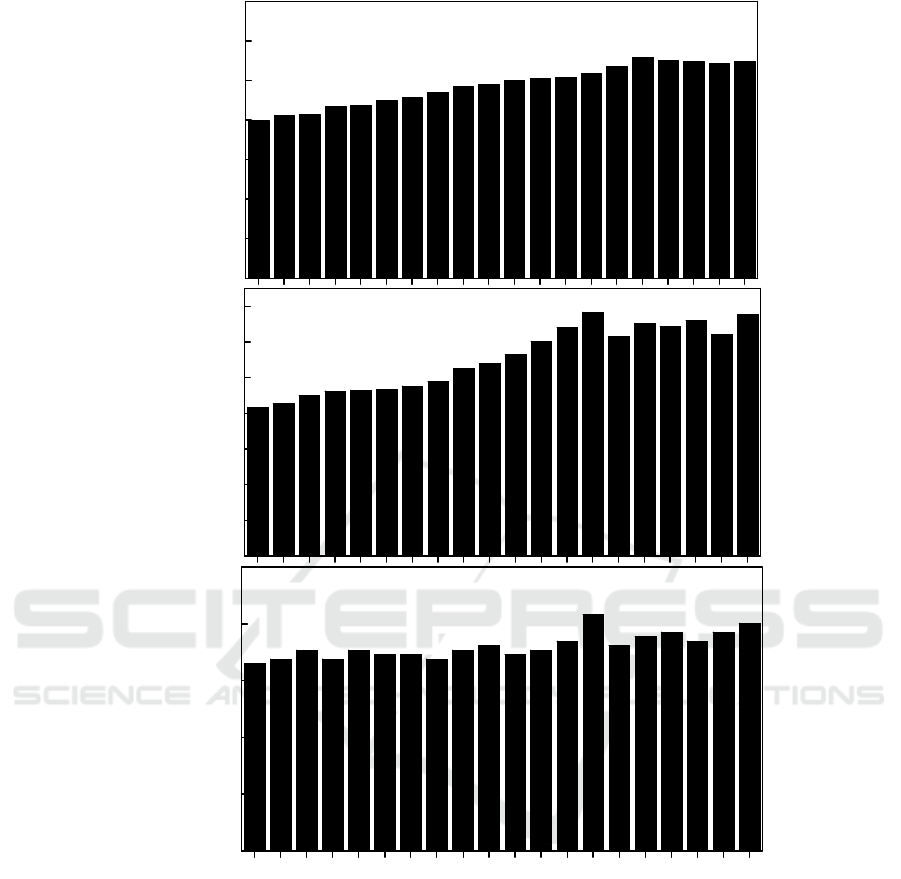

The changes in cellulose, hemicellulose and lignin

contents of the 40-mesh corn stalk siftage treated

with ferric chloride are shown in Fig.1 After ferric

chloride treatment, the cellulose content increased in

all treatment groups, with little variation in

increments among the groups. The highest content

was 0.385 g, and the lowest content was 0.359 g,

which was a significant increase compared with the

original content of 0.252 g in the raw material. The

hemicellulose content for all treatment groups

decreased, while the lignin content increased because

the ferric chloride pretreatment destroyed the

scaffolding structure of the cellulose, lignin and

hemicellulose in the corn stalk, partially releasing

hemicellulose and increasing the cellulose content

while releasing more lignin. The cellulose and lignin

contents of the corn stalk treated with 0.5 mol/L ferric

chloride solution at 100–108 °C for 30 min at a solid

to liquid ratio of 1/20 g/mL increased significantly by

52.78% and 37.80%, respectively, relative to those of

the raw material, while the hemicellulose content

decreased by 12.06% compared with that of the raw

material.

0

10

20

30

40

50

60

70

ac

cellulose conversion rate(%)

bd

ad

bc

ac

bd

ad

bc

ac

bd

ad

bc

ac

bd

ad

ad

bc

ac

bd

bc

0

2

4

6

8

10

12

14

hemicellulose conversion rate(%)

0

10

20

30

40

50

0.5 mol/LFeCl

3

0.5 mol/LFeCl

3

0.5 mol/LFeCl

3

0.5 mol/LFeCl

3

0.4 mol/LFeCl

3

0.4 mol/LFeCl

3

0.4 mol/LFeCl

3

0.4 mol/LFeCl

3

0.3 mol/LFeCl

3

0.3 mol/LFeCl

3

0.3 mol/LFeCl

3

0.3 mol/LFeCl

3

0.2 mol/LFeCl

3

0.2 mol/LFeCl

3

0.2 mol/LFeCl

3

0.2 mol/LFeCl

3

0.1 mol/LFeCl

3

0.1 mol/LFeCl

3

0.1 mol/LFeCl

3

lignin conversion rate(%)

0.1 mol/LFeCl

3

Figure 1: Conversion rate of each component of 40-mesh

corn stalk siftage treated with ferric chloride.

The changes in cellulose, hemicellulose and

lignin content of the 80-mesh corn stalk siftage

treated with ferric chloride are shown in Fig. 2 After

ferric chloride treatment, the cellulose content

increased in all treatment groups, and the increments

varied little among the groups. The hemicellulose

content decreased in all treatment groups, while the

lignin content increased. The cellulose and lignin

contents of the corn stalk treated with 0.5 mol/L ferric

chloride solution at 100–108 °C for 30 min at a solid

to liquid ratio of 1/20 g/mL increased significantly by

56.08% and 37.80%, respectively, compared with

those of the raw material, while the hemicellulose

content decreased by 13.06% compared with that of

the raw material. This treatment effect was the best.

Combined Ferric Chloride and Phanerochaete Chrysosporium Pretreatment on Corn Stalk Degradation

71

0

10

20

30

40

50

60

70

ac

cellulose conversion rate(%)

bd

ad

bc

ac

bd

ad

bc

ac

bd

ad

bc

ac

bd

ad

ad

bc

ac

bd

bc

0

2

4

6

8

10

12

14

hemicellulose conversion rate (%)

0

10

20

30

40

50

0.5 mol/LFeCl

3

0.5 mol/LFeCl

3

0.5 mol/LFeCl

3

0.5 mol/LFeCl

3

0.4 mol/LFeCl

3

0.4 mol/LFeCl

3

0.4 mol/LFeCl

3

0.4 mol/LFeCl

3

0.3 mol/LFeCl

3

0.3 mol/LFeCl

3

0.3 mol/LFeCl

3

0.3 mol/LFeCl

3

0.2 mol/LFeCl

3

0.2 mol/LFeCl

3

0.2 mol/LFeCl

3

0.2 mol/LFeCl

3

0.1 mol/LFeCl

3

0.1 mol/LFeCl

3

0.1 mol/LFeCl

3

lignin conversion rate(%)

0.1 mol/LFeCl

3

Figure 2: Conversion rate of each component of 80-mesh corn stalk siftage treated with ferric chloride.

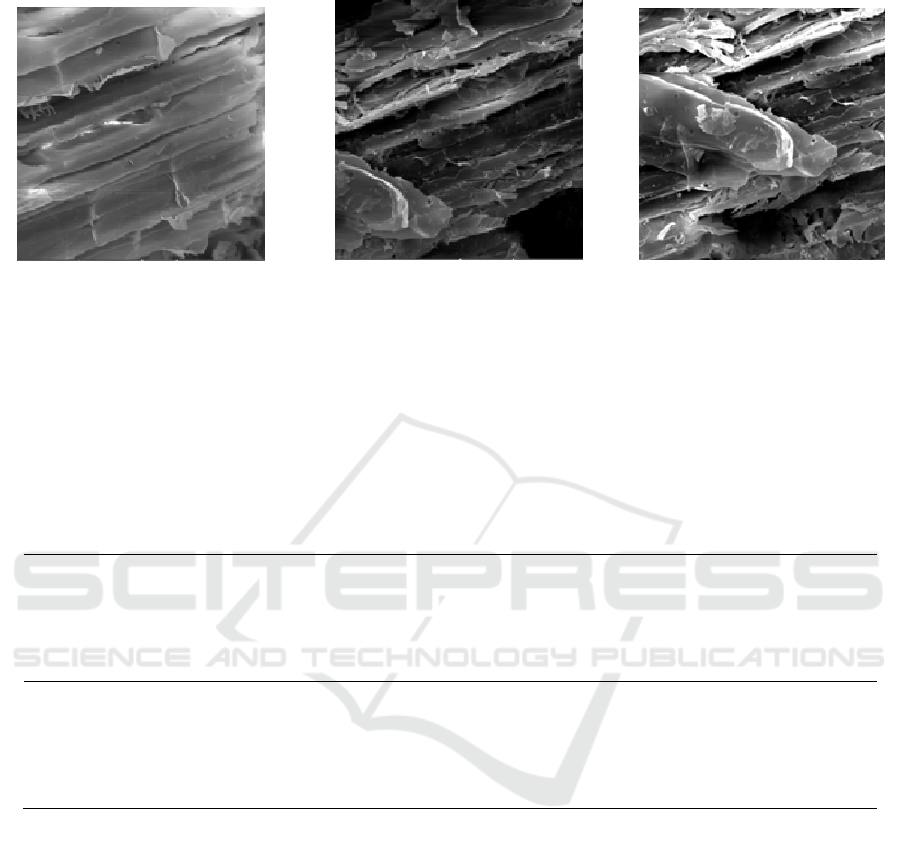

After treatment with ferric chloride, the corn stalk

material’s morphology changed markedly (Fig.3).

The untreated 40-mesh corn stalk siftage showed a

smooth, flat, uniform, and undamaged surface, while

the treated corn stalk siftage showed a rough surface,

with disoriented surface structure texture, holes and

longitudinal fiber breakage. The treated 80-mesh

corn stalk siftage showed remarkable changes in

surface structure, with highly disarrayed texture in its

surface structure and holes in the partially fishnet-

shaped skeleton. The ferric chloride pretreatment not

only destroyed the surface structure of the corn stalk

raw material but also enlarged the size of pores on the

surface, thus increasing the specific surface area.

Compared with the 40-mesh corn stalk siftage treated

with ferric chloride, the 80-mesh corn stalk siftage

treated with ferric chloride showed more complete

and profound breakage, indicating that the lignin

ICBB 2022 - International Conference on Biotechnology and Biomedicine

72

component was destroyed more effectively for the

smaller sized corn stalk.

(a) 40-mesh corn stalk (b) 40-mesh corn stalk siftage treated (c) 80-mesh corn stalk siftage

Siftage with ferric chloride treated with ferric chloride

Figure 3: Electron scanning microscopy of the corn stalk raw material.

After determining the cellulose, hemicellulose

and lignin contents of the 40- and 80-mesh corn stalk

siftages treated with ferric chloride, the optimal

combination of the treatment conditions was

determined and used in combination with the

subsequent P. chrysosporium treatment for corn stalk

degradation. The cellulose, hemicellulose and lignin

contents of the 40- and 80-mesh corn stalk siftages

treated with ferric chloride under the optimal

conditions are shown in Table 2.

Table 2: Optimal conditions for the ferric chloride treatment.

Stalk

particle

size

Ferric chloride

concentration

mol/L

Solid to

liquid

ratio

g/mL

Temperature/°C Time/min Cellulose/g Hemicellulose/g Lignin/g

40-

mesh

0.5 1/20 100–108 30 0.385 0.276 0.175

80-

mesh

0.4 1/20 100–108 30 0.398 0.273 0.175

3.2 Effect of P. chrysosporium

Pretreatment Conditions on the

Reducing Sugar Yield

Fig.4 shows the changes in the reducing sugar content

of the 40-mesh and 80-mesh corn stalk siftages

treated with P. chrysosporium over time. The

reducing sugar content first decreased, then

increased, again decreased, and finally stabilized.

This occurred because P. chrysosporium first

consumed small molecular carbon sources in the

substrate to propagate, thus decreasing the reducing

sugar content. After the mycelia matured, the fungus

began degrading the corn stalk, which increased the

reducing sugar content. As shown in Fig.4, on day 6

after fungal inoculation, the reducing sugar content

was high, peaking at 1.13 mg/mL for the fungus-

treated 40-mesh corn stalk siftage and at 1.20 mg/mL

for the fungus-treated 80-mesh corn stalk siftage,

although at this time, the stalk degradation was

incomplete. The reducing sugar content of the

fungus-treated 40-mesh corn stalk siftage reached its

lowest point at 0.39 mg/mL on day 12, while that of

the fungus-treated 80-mesh corn stalk siftage reached

its lowest point at 0.71 mg/mL on day 18. The

reducing sugar content in the corn stalk then rose

again, peaking at 0.97 mg/mL and 0.99 mg/mL for

the fungus-treated 40-mesh and fungus-treated 80-

mesh corn stalk siftages, respectively, on day 24, then

declined and gradually stabilized over days 24–30.

Combined Ferric Chloride and Phanerochaete Chrysosporium Pretreatment on Corn Stalk Degradation

73

0 6 12 18 24 30

0.4

0.6

0.8

1.0

1.2

Content of reducing sugar(mg/mL)

t(d)

40-mesh stalk siftage

80-mesh stalk siftage

Figure 4: Changes in the reducing sugar content in corn

stalks treated with P. chrysosporium over time.

Comparison of the fungus-treated 80-mesh and

40-mesh corn stalk siftages shows that on day 12, the

reducing sugar contents of the fungus-treated 40-

mesh and fungus-treated 80-mesh corn stalk siftages

were 0.41 mg/mL and 0.95 mg/mL, respectively,

with the largest gap at 0.54 mg/mL, likely because

the 80-mesh corn stalk siftage was smaller than the

40-mesh corn stalk siftage, which is conducive to

fungal growth. During days 6–12, the fungus grew

rapidly. On day 12, it had already finished degrading

the 80-mesh corn stalk siftage, yielding a higher

reducing sugar content.

3.3 Effect of the Combined Ferric

Chloride and P. chrysosporium

Pretreatment on the Reducing

Sugar Yield

Fig.5 shows that as the treatment time increased, the

reducing sugar contents of the 40-mesh and 80-mesh

corn stalk siftages treated with the combined P.

chrysosporium and ferric chloride increased, then

decreased, and finally stabilized. This occurred

because on day 6, the fungus had already matured and

begun to degrade the corn stalk during days 6–12,

thus increasing the reducing sugar content in the

substrate. On day 12, the reducing sugar contents of

the 40-mesh and 80-mesh corn stalk siftages peaked

at 1.92 mg/mL and 2.52 mg/mL, respectively,

subsequently reaching their respective lowest points

at 1.41 mg/mL and 1.69 mg/mL on day 18. On day

24, the reducing sugar content of the 40-mesh corn

stalk siftage increased slightly and then stabilized,

while that of the 80-mesh corn stalk siftage showed

little change and remained stable during days 18–24.

0 6 12 18 24 30

1.2

1.6

2.0

2.4

2.8

Content of reducing sugars(mg/mL)

t(d)

40-mesh stalk siftage

80-mesh stalk siftage

Figure 5: Changes in reducing sugar content of the 40-mesh

and 80-mesh corn stalk siftage treated with the combined

P. chrysosporium and ferric chloride pretreatment over

time.

The reducing sugar contents of the 40-mesh and

80-mesh corn stalk siftages treated with combined P.

chrysosporium and ferric chloride differed little on

days 6, 12, 18, 24, and 30; however, on day 6, the

reducing sugar contents of the 40-mesh and 80-mesh

corn stalk siftages were 1.33 mg/mL and 1.18

mg/mL, respectively. The reducing sugar content of

the 40-mesh corn stalk siftage was higher than that of

the 80-mesh corn stalk siftage, likely because after

the ferric chloride treatment, the cell wall of the 80-

mesh corn stalk siftage was destroyed more

completely than that of the 40-mesh corn stalk

siftage, and the smaller particle size was more

conducive to mycelial propagation and growth. On

day 6, the fungus had already matured and begun to

degrade the 80-mesh corn stalk siftage. In summary,

after the combined pretreatment, the 80-mesh corn

stalk siftage produced more reducing sugars than did

the 40-mesh corn stalk siftage and showed the highest

reducing sugar content on day 12 after fungal

inoculation.

3.4 Effect of Different Treatments on

the Reducing Sugar Yield of Corn

Stalk

As shown in Fig.6, the reducing sugar contents of the

corn stalk with different treatments exhibited

different change trends. When treated with P.

chrysosporium alone, the reducing sugar contents of

the 40-mesh and 80-mesh corn stalk siftages first

decreased, then increased, decreased again and

finally stabilized. This occurred because shortly after

being inoculated into the corn stalk, the fungus fed on

the reducing sugars to grow while producing

reducing sugars by degrading the corn stalk. In the

combined treatment, the reducing sugar content of

ICBB 2022 - International Conference on Biotechnology and Biomedicine

74

the treated corn stalk increased first, peaked on day

12, then decreased and finally stabilized. This

occurred because after being treated with ferric

chloride, the corn stalk’s cell wall structure was

destroyed, allowing the fungus to directly and rapidly

degrade the lignin and cellulose to form

polysaccharides. Therefore, after being treated with

ferric chloride, treating the corn stalk again with P.

chrysosporium significantly improved the reducing

sugar production yield and cycle.

0 6 12 18 24 30

0.0

0.5

1.0

1.5

2.0

2.5

Content of reducing sugars(mg/mL)

d(t)

40 mesh,p.chrysosporium alone

80 mesh,p.chrysosporium alone

40 mesh,combined treatment

80 mesh,combined treatment

Figure 6: Comparison of the reducing sugar content of the

corn stalk with different treatments

4 CONCLUSION

In this study, corn stalk was combined pretreated by

ferric chloride and P. chrysosporium. The reducing

sugar content of the P. chrysosporium-treated 80-

mesh corn stalk siftage previously treated with ferric

chloride was 2.52 mg/mL on day 12 after the fungal

inoculation when the reducing sugar content in the

fermentation broth was the highest.

ACKNOWLEDGMENTS

This study was sponsored by Science and technology

cooperation of Henan Electric Power Surveying and

Design Institute (2018015); National "863" project

sub-plan (2012AA051502-02) and 2019 PhD

research start-up funding of Henan University of

Animal Husbandry and Economy

(2019HNUAHEDF16); Scientific and technological

project of Henan Province (212102110228).

REFERENCES

Bailey, B. K., 1996. Performance of ethanol as a

transportation fuel. In:Wyman CE(ed) Handbook

on bioethanol: production and utilization. Bristol.

Galbe, M., Zacchi, G., 2002. A Review of the Production

of Ethanol from Softwood. Appl Microbiol Biotechnol

59, 618-628.

Ghose, T. K., 1987. Measurement of cellulase activities.

Pure Applied Chemical 59, 257-268.

Henriksson, G., Johansson, G., Pettersson, G., 2000. A

critical review of celliobiose dehydrogenases. Journal

of Biotechnology 78(2), 93-113.

Kim, Y., Hendrickson, R., Mosier, N. S., et al., 2008.

Enzyme hydrolysis and ethanol fermentation of liquid

hot water and AFEX pretreated distillers grains at high-

solids loadings. Bioresource Technology 99(12), 5206-

5215.

Kirk, T. K., Cullen, D., 1997, Enzymology and Molecular

Genetics of Wood Degradation by White-Rot Fungi.

Environmentally Friendly Technologies for the Pulp

and Paper Industry, John Wiley & Sons. 590-592.

Lissens, G., Thomsen, A. B., Baere, L. D., et al, 2004.

Thermal wet oxidation improves anaerobic

biodegradability of raw and digested biowaste.

Environ. Sci. Technol. 38, 3418-3424.

López-Linares, J. C., Romero, I., Moya, M., et al., 2013.

Pretreatment of olive tree biomass with ferric chloride

prior enzymatic hydrolysis. Bioresource Technology

128, 180-187.

Palonen, H., Thomsen, A. B., Tenkanen, M., et al, 2004.

Evaluation of wet oxidation pretreatment for enzymatic

hydrolysis of softwood. Appl. Biochem. Biotechnol.

117, 1-17.

Ranganathan, S. V., Narasimhan, S. L., Muthukumar, K.,

2008. An overview of enzymatic production of

biodiesel. Bioresource Technology 99(10), 3975-3981.

Saricks, C., Santini, D., Wang, M., 1999. Effects of fuel

ethanol use on fuel-cycle energy and green house gas

emission. Fuel Mixtures 65(1), 137-174.

Saha, B., 2016. Biological pretreatment of corn stover with

white-rot fungus for enzymatic hydrolysis and

bioethanol production. International Biodeterioration

& Biodegradation 109, 29-35.

Solomon, B. D., Barnes, J. R., Halvorsen, K. E., 2007.

Grain and cellulosic ethanol: History, economics, and

energy policy. Biomass and Bioenergy 31, 416-425.

Sun, F. H., Li, J., Yuan, Y. X., et al., 2011. Effect of

biological pretreatment with Trametes hirsuta yj9 on

enzy matic hydrolysis of corn stover. International

Biodeterioration & Biodegradation 65(7), 931-938.

Wan, C., Li, Y., 2012. Fungal pretreatment of

lignocellulosic biomass. Biotechnol. Adv. 30, 1447-

1457.

Wang, Y. W., Xu, W. W., 1987. Quantitative Analysis

Procedure of Hemicellulose, Cellulose and Lignin in

Lignocellulose Solid Matrix Fermentation.

Microbiology China 2, 82-84.

Xu, C., Ma, F., Zhang, X., Chen, S., 2010. Biological

pretreatment of corn stover by Irpex lacteus forenzy

Combined Ferric Chloride and Phanerochaete Chrysosporium Pretreatment on Corn Stalk Degradation

75

matic hydrolysis. Journal of Agricultural and Food

Chemistry 58, 10893–10898.

Zeng, G. M.; Wang, Y. L.; Zhang, M. L.; Zheng, Y. X.;

Xing, J.; Ma, Y. F.; Xu, H. J., 2013. Thermal

degradation and structural characteristics of corn stover

after ferric chloride solution pretreatment. Asian

Journal of Chemistry 25(5), 2431-2434.

ICBB 2022 - International Conference on Biotechnology and Biomedicine

76