Research on Optimization of Stereoscopic Warehouse Delivery Mode

Based on EIQ Analysis

Lu Jiang

Department of Mechanical and Electrical Engineering, Shanghai Maritime Academy, Pudong New District, Shanghai,

China

Keywords: EIQ Analysis, Linear Regression, Stereoscopic Warehouse, Delivery Method, Optimization.

Abstract: In order to improve the shelf delivery efficiency of the stereoscopic warehouse, this paper proposes to

establish a discriminant model for the delivery mode based on EIQ analysis, establish a mathematical model

by linear regression fitting according to the data obtained from EIQ analysis, and verify the model in the

virtual center system according to a large number of actual operating data. The validity of the model is

verified by comparing the model calculation with the measured data.

1 INTRODUCTION

Stereoscopic warehouse, also known as elevated

warehouse or elevated warehouse, generally refers to

a warehouse that uses several, ten or even dozens of

layers of shelves to store goods, and uses

corresponding material handling equipment for

warehousing and outbound operations. The key to

improve the efficiency of warehouse out picking

operation is to select the appropriate warehouse out

method. There are two delivery methods: delivery

by order and delivery by consolidated order (An,

2014). Delivery by order picking results in low

efficiency due to too many operations. The use of

consolidated order delivery reduces the number of

operations, but the need for secondary sorting will

increase the cost. Therefore, an effective delivery

method discrimination model is needed to determine

the delivery method of orders in a certain time.

Assuming that the operating proficiency of the

staff is fixed, the optimal shipping method and the

fastest shipping time can be determined only by

determining the order information. In this paper, the

EIQ analysis of orders is proposed to determine the

functional relationship between order information

and delivery time, and the establishment of a

judgment model is a method to optimize the delivery

mode of stereoscopic warehouse.

The EIQ analysis method is a planning method

for the distribution center system under uncertain

and fluctuating conditions. It uses three key

elements, namely, Entry, Item and Quantity, to

discuss its operation mode and plan the logistics

system according to the distribution center

objectives. Combined with practice, a large amount

of real data of a distribution center operation is used

as the theoretical basis and modeling basis to build a

discrimination model for the delivery mode, and the

actual data is solved to verify the feasibility and

effectiveness of the model.

2 DISCRIMINANT MODEL OF

DELIVERY MODE BASED ON

EIQ ANALYSIS

2.1 Model Assumptions

All ordered items are stored in the three-dimensional

warehouse area. The operation proficiency of each

staff shall not be affected by the external

environment. The arrival time of each kind of goods

from the warehouse location to the shipping port is

the same. The minimum unit of outbound goods is

box.

76

Jiang, L.

Research on Optimization of Stereoscopic Warehouse Delivery Mode Based on EIQ Analysis.

DOI: 10.5220/0012025600003620

In Proceedings of the 4th International Conference on Economic Management and Model Engineering (ICEMME 2022), pages 76-82

ISBN: 978-989-758-636-1

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

2.2 Data Acquisition and Processing

2.2.1 Determination of Order Batch Time

Range

According to the principle of time window batch

method, the orders of the distribution center for one

day are batched. Suppose that the total number of

daily operation orders of a distribution center is

about 150, and the daily working hours are 12 hours.

Different time windows are set, the number of order

batches per day and the average number of orders

per batch are different, as shown in Table 1.

Table 1: Distribution center order batch time setting.

Time window

setting(min)

Daily order

batch (pcs)

Order of each

batch (piece)

40 18 8.33

30 24 6.25

20 36 4.17

When conducting EIQ analysis, if there are too

many batches, it is troublesome to handle, and the

batch results are meaningless; If it is too small, the

number of orders in each batch is large, and the

waiting time for orders is long. Taking Table 1 as an

example, you can set the time window to 30

minutes, that is, batch the received orders every 30

minutes.

2.2.2 EIQ Outbound Data Statistics

Suppose that a distribution center receives several

orders within a period of time after it starts operation

on a certain day, and makes statistics on the order

information of the first batch. There is an outbound

order E

m

(m=1, 2, 3...) in this batch. All the orders

involved in the shipment items include I

n

(n=1, 2,

3...). Q

mn

=quantity (order E

m

, item I

n

) is used to

represent the quantity of an item ordered by a single

order (Liu, 2010). A table is drawn after the order

information is counted, as shown in Table 2.

According to the statistics results of EIQ delivery

data, specific analysis can be carried out, including:

Order quantity (EQ) analysis: analysis of the

shipment quantity of a single order (Fan, 2004).

Ordering item number (EN) analysis: analysis

of the number of items shipped from a single order

(Liu, 2005).

Item quantity (IQ) analysis: analysis of the

total quantity of each item shipped (Wei, 2013).

Analysis of the number of ordered items (IK):

analysis of the number of shipments of each item

(Li, 2009).

IQ and IK cross analysis.

Comparative analysis of EQ, EN, IQ and IK.

Table 2: EIQ data of the first batch of orders of a day.

Order

Item

Order

quantity

Order

item

I

1

I

2

… I

n

E

1

Q

11

Q

12

… Q

1n

DQ

1

N

1

E

2

Q

21

Q

22

… Q

2n

DQ

2

N

2

… … … … … … …

E

m

Q

m1

Q

m2

… Q

mn

DQ

m

N

m

Product

quantity

CQ

1

CQ

2

… CQ

n

Q N

Delivered

frequency

K

1

K

2

… K

n

- K

2.2.3 EN Analysis

EN analysis, which is based on the principle of order

processing, planning of the pick-up system, and

shipment and routing area planning, is usually

performed to understand the distribution of the

number of items ordered per order, using three

indices (Wu, 2011).

Number of goods delivered in a single order

(N

m

)

...3,2,1

0,...,,,

321

m

QQQQCOUNTN

mnmmmm

(1)

Total number of goods delivered (N)

0,...,,,

321

n

KKKKCOUNTN

(2)

Cumulative number of goods delivered by

order (GN)

m

NNNNN

...G

321

(3)

2.2.4 Establish the Judgment Model of

Delivery Method

(1) The method of ex warehouse by order is adopted

The total time required for a batch of orders to be

delivered by order is T

d

, mainly including T

1

(order

processing time), T

2

(stereoscopic shelf running

time), T

3

(goods unpacking time) and T

4

(review,

packaging, labeling and handling time).

4321

TTTTT

d

(4)

Order processing time(T

1

)

Research on Optimization of Stereoscopic Warehouse Delivery Mode Based on EIQ Analysis

77

Test the processing time t

1

of an order in the

virtual simulation system, and calculate the average

value after five tests, as shown in Table 3.

Table 3: Processing time of an order.

Test 1st 2nd 3rd 4th 5th Average

Time(s) 58 60 63 67 65 62.6

The average processing time of an order

calculated by the test is t

1

=62.6s, so the order

processing time is:

mmtT 6.62

11

(5)

m is the number of orders.

Running time of stereoscopic shelf (T

2

)

Test the running time t

2

of a single order

stereoscopic shelf in the virtual simulation system.

The time from the start of the stereoscopic shelf to

the time when the RGV trolley sends the tray to the

tray port, plus the time when the goods are sent back

to the stereoscopic warehouse after the tray is

removed, is the running time of the stereoscopic

shelf, excluding the time when the goods are

removed. The test data and results are shown in

Table 4.

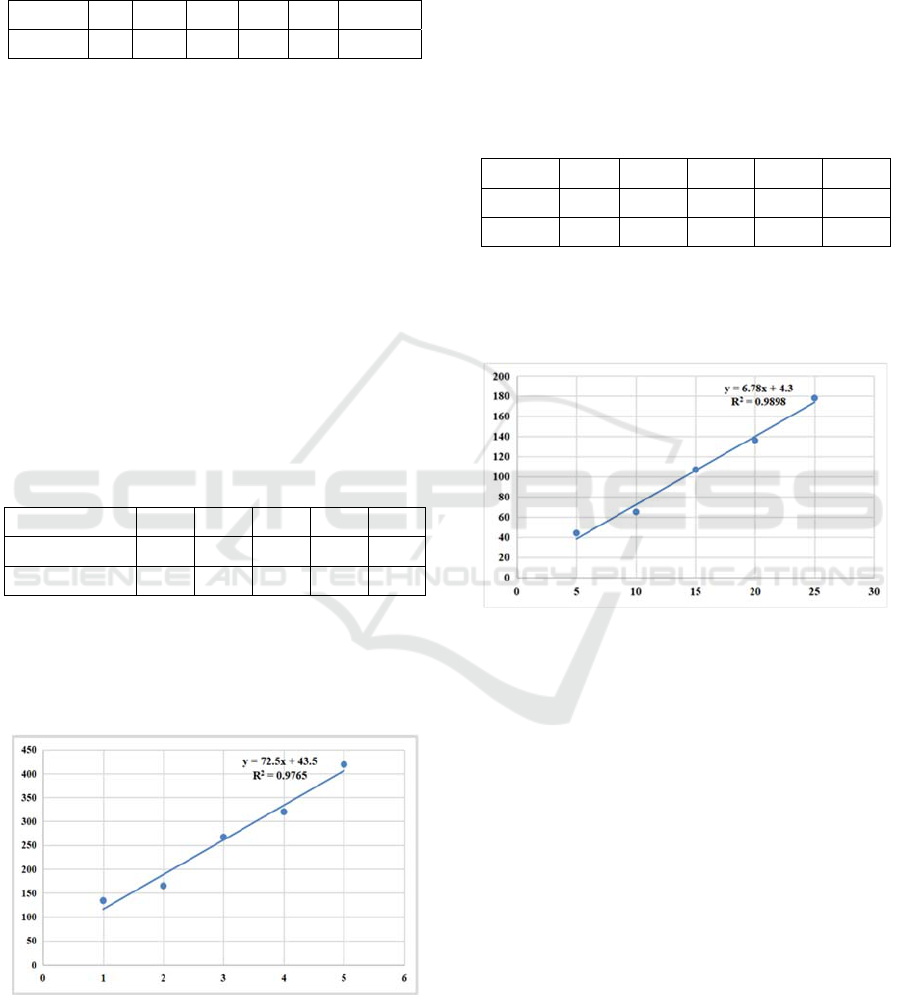

Table 4: Running time of stereoscopic shelf for one order.

No. order 1 2 3 4 5

items delivered 1 2 3 4 5

Time(s) 134 165 267 320 419

The running time t

2

of the three-dimensional

shelf of a single order has a linear relationship with

the number of items delivered from the order. The

linear regression method is used to fit, as shown in

Figure 1. a

1

=72.5, b

1

=43.5.

Figure 1: Fitting diagram of running time of three-

dimensional shelf for an order.

The stereoscopic shelf running time T

2

is the sum

of the stereoscopic shelf running time of all orders.

mNmbNaT 5.435.72

112

(6)

N is the total number of goods delivered.

Time of goods unpacking(T

3

)

In the virtual simulation system, test the time

T

3

required for disk disassembly. Add orders by

yourself for five experiments. The total shipment is

set to 5, 10, 15, 20, and 25 boxes. The test results

are shown in Table 5.

Table 5: Disengaging time corresponding to different total

shipments.

Test 1st 2nd 3rd 4th 5th

Total 5 10 15 20 25

Time(s) 44 65 107 136 178

The time of goods unpacking is approximately

linear with the total shipment, and the linear

regression is used to fit as shown in Figure 2.

a

2

=6.78, b

2

=4.3

Figure 2: Fitting Chart of Disengaging Time and Total

Shipments.

3.478.6

223

QbQaT

(7)

Q is the total shipment.

Review, packaging, labeling and handling

time(T

4

)

The test is carried out in the virtual simulation

system. The time from the time when the goods are

transported to the review port through the conveyor

belt to the time when the storage cage car is pushed

to the warehouse exit is the time for a review,

packaging, labeling and handling operation. Since

the next order has been processed since the review,

packaging, labeling and handling of each order starts,

the total review, packaging, labeling and handling

time T

4

only includes the operation time of the last

order. Add orders by yourself for 5 experiments, and

the test data are shown in Table 6.

ICEMME 2022 - The International Conference on Economic Management and Model Engineering

78

Table 6: Time for review, packaging, labeling and

handling of an order.

Test 1st 2nd 3rd 4th 5th

Total 2 4 6 8 10

Time(s) 115 132 159 180 214

The review, packaging, labeling and handling

time T4 are approximately linear with the shipment

quantity DQ

n

of the last order, and the linear

regression method is used for fitting, as shown in

Figure 3. a

3

=12.3, b

3

=86.2.

Figure 3: Fitting Chart of Operation Time of Checking,

Packaging, Labeling and Handling with Shipping Volume.

2.863.12

334

nm

QbDQaT

(8)

(2) Use the consolidated order delivery operation

Method

The total time required for the delivery of a batch

of orders using consolidated orders is T

h

, mainly

including T

1

' (order processing time), T

2

'

(stereoscopic shelf running time), T

3

'(goods

unpacking time), T

4

' (review, packaging, labeling

and handling time) and T5 '(wave sorting system

time).

,

4

,

3

,

2

,

1

TTTTT

h

(9)

Order processing time(T

1

')

Add orders in the virtual simulation system for

five experiments, and the number of consolidated

orders in each experiment is 2, 3, 4, 5, and 6

respectively. The test data is shown in Table 7.

Table 7: Processing time of consolidated orders.

Test 1st 2n

d

3r

d

4th 5th

Total 2 3 4 5 6

Time(s) 72 75 89 88 94

The order processing time T

1

'is approximately

linear with the number of orders m, and the data

obtained from the test are fitted, as shown in Figure

4. a

4

=5.7 and b

4

=60.8.

8.607.5

44

,

1

mbmaT

(10)

Figure 4: Fitting Chart of Consolidated Order Processing

Time.

Running time of stereoscopic shelf (T

2

')

In the consolidated order picking method, the

wave order is regarded as an order for one delivery,

so the running time of the three-dimensional shelf

has the same rule as the data tested in the delivery by

order, that is, the parameters are the same.

5.435.72

11

'

2

mbmaT

(11)

Time of goods unpacking(T

3

')

Under the condition that the operator's

proficiency remains unchanged, the time of goods

unpacking is approximately proportional to the total

shipment volume. Since the total shipment volume

remains unchanged, the time of goods unpacking is

the same as that of goods unpacking in the picking

by order method, as shown in Formula 7.

Review, packaging, labeling and handling

time(T

4

')

After the operation of the wave sorting system is

completed, recheck, packaging, labeling and

handling operations are carried out. The time T4 'is

proportional to the order quantity m. Add order

information by yourself and test the review,

packaging, labeling and handling operation time in

the virtual simulation system. Set the number of

orders in each experiment to be 1,2,3,4,5. The test

results are shown in Table 8.

Table 8: Review, packaging, labeling and handling time

for different order quantities.

Test 1st 2n

d

3r

d

4th 5th

Total 1 2 3 4 5

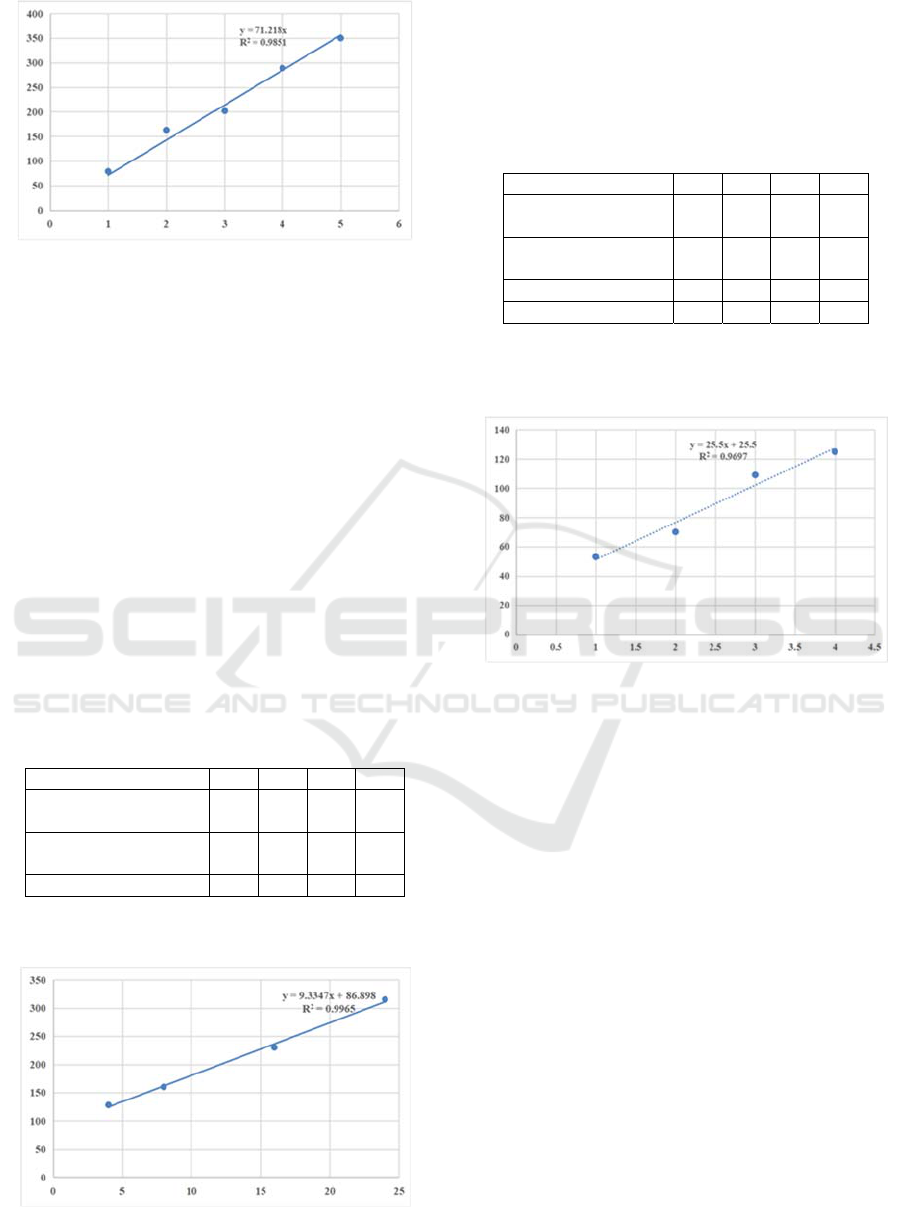

Time(s) 79 163 202 289 350

Carry out linear regression fitting according to

the test results, as shown in Figure 5. Set the

intercept of the regression linear equation to zero,

and a

5

=71.218.

Research on Optimization of Stereoscopic Warehouse Delivery Mode Based on EIQ Analysis

79

Figure 5: Fitting Chart of Review, Packaging, Labeling

and Handling Time.

mmaT 218.71

5

'

4

(12)

Wave sorting system time(T

5

')

The time for wave sorting of goods of the nth

item is t

5n

, which has the following relationship with

the shipment quantity CQ

n

and the shipment times

K

n

of the item:

6665

CKbCQat

nnn

(13)

In order to measure the values of a

6

, b

6

and c

6

,

using the control variable method, first set the

number of single product shipments K

n

as a fixed

value, change the value of single product shipments

CQ

n

, and add order information to test the single

product wave sorting time t

5n

in the virtual

simulation system. The test result data are shown in

Table 9.

Table 9: Control the number of shipments of single items,

wave sorting time.

Items I

1

I

2

I

3

I

4

frequency of Product

shi

p

ments

4 4 4 4

Quantity of Product

shi

p

ments

4 8 16 24

Time

(

s

)

128 160 230 315

Carry out linear regression fitting according to

the test data, as shown in Figure 6. a

6

=9.3347.

Figure 6: Fitting Chart of Controlling the Number of

Shipments of Single Items and Wave Sorting Time.

Set the single product shipment quantity CQ

n

as

a fixed value, change the value of single product

shipment times K

n

, and measure the single product

wave sorting time t

5n

. The test results are shown in

Table 10.

Table 10: Control shipment volume wave sorting time.

Items I

1

I

2

I

3

I

4

frequency of

Product shi

p

ments

1 2 3 4

Quantity of Product

shi

p

ments

4 4 4 4

Time

(

s

)

53 70 109 125

Carry out linear regression fitting according to

the test data, as shown in Figure 7. b

6

=25.5,

C

6

=25.5.

Figure 7: Fitting Chart of Wave Sorting Time for

Controlling Single Product Shipment.

)5.255.253347.9(

)(

666

5

'

5

KnCQ

cKbCQatT

n

nn

n

(14)

(3) Objective function formula

The shortest delivery time T of a batch order is

the shortest of the two delivery methods.

),min(

hd

TTT

(15)

By comparing the size of T

d

and T

h

, we can

determine which delivery method is more efficient,

and select the appropriate delivery method according

to the characteristics of the order.

3 INSPECTION OF DELIVERY

METHOD JUDGMENT MODEL

The judgment model of delivery mode is a

mathematical model based on the time

decomposition and summation of the operation

process and the simplification and abstraction of the

ICEMME 2022 - The International Conference on Economic Management and Model Engineering

80

actual operation process. The parameters of the

model are calculated based on the data obtained

from many experiments. In order to prove the

rationality and practicability of the model, the

correctness of the model is verified by substituting

the actual order information.

The system pre recorded four orders for EIQ

analysis, and the analysis results are shown in Table

11. The data obtained are substituted into the

delivery method judgment model.

Table 11: Statistics of EIQ data pre-recorded by the system.

m I

1

I

2

I

3

I

4

Q

m

N

m

1 2 2 2 5 11 4

2 3 2 0 6 11 3

3 1 0 4 6 11 3

4 3 1 2 5 11 4

CQ

n

10 5 9 22 Q N

K

n

4 3 3 4 44 14

(1) Delivery Time by Order (T

d

)

)(52.19635.22162.30211894.250

)2.86113.12()3.44478.6()45.43145.72(46.62

)2.863.12()3.478.6()5.435.72(6.62

4321

s

DQQmNm

TTTTT

m

d

(16)

(2) Consolidated order delivery time (T

h

)

)(39.87886.32201.18667.14885.220

)5.2545.25223347.9()5.2535.2593347.9(

)5.2535.2553347.9()5.2545.25103347.9(

)5.255.253347.9(

'

5

s

KnCQT

n

(17)

)(98.188239.87887.28462.3025.3336.83

39.8784218.71)3.44478.6()5.4345.72()8.6047.5(

218.71)3.478.6()5.435.72()8.607.5(

,

5

,

5

,

4

,

3

,

2

,

1

s

TmQmm

TTTTTT

h

(18)

It can be seen from the calculation results that

the delivery time Th of consolidated orders is

slightly less than the delivery time Td of orders, so it

is more efficient to select the delivery method of

consolidated orders.

The time calculated by the model is compared

with the data obtained from the actual experiment.

The comparison results are shown in Table 12.

Table 12: Time comparison table between the time

calculated by the four order models pre recorded by the

system and the actual time.

Model

calculation

Actual

measurement

error Error

rate

T

d

(s) 1963.52 1778 185.52 10.43%

T

h

(s) 1882.98 1638 244.98 14.95%

Although there is some difference between the

time spent in calculation and the actual operation,

about 10.43%, the result of using this model to

calculate the difference in delivery time is in line

with the actual situation.

4 CONCLUSIONS

In this paper, theoretical analysis and mathematical

modeling are closely linked when solving the issue

efficiency comparison problem between the

proposed issue by order method and the issue by

consolidated order method. With a large number of

specific data obtained through practical operation as

the theoretical basis, a discrimination model of

delivery mode based on EIQ analysis is established,

and the data is brought into the model for solution.

Qualitative analysis and quantitative calculation are

combined, and its effectiveness is confirmed through

verification.

REFERENCES

An Bin. Design and application of high-speed sorting

system simulation platform [D]. Shandong: Shandong

University, 2014.

Fan Qiyin. Research on sorting system of finished tobacco

distribution center [D]. Yunnan: Kunming University

of Technology, 2004.

Li Feng. Research on replenishment scheduling and

automatic sorting algorithm of tobacco distribution

center [D]. Hunan: Central South University, 2009.

Liu Jun. Application of EIQ Analysis Method in the

Planning of Cigarette Distribution Center [D]. Beijing

University of Posts and Telecommunications, 2010.

Liu Youquan. Application of EIQ Analysis Method in

Chain Operation Distribution Center and Case Study

[D]. Hubei: Huazhong University of Science and

Technology, 2005.

Research on Optimization of Stereoscopic Warehouse Delivery Mode Based on EIQ Analysis

81

Wei Xiaoqing. Application Research on Optimization of

Warehouse Location Operation Method of Finished

Product Warehouse in a Manufacturing Factory [D].

Shanghai: Shanghai Jiaotong University, 2013.

Wu Jing. Application of greedy algorithm based linear

programming in cargo location optimization [D].

Shanghai Jiaotong University, 2011.

ICEMME 2022 - The International Conference on Economic Management and Model Engineering

82