Analysis of China's Textile Printing and Dyeing Industry Based on

the Input-Output Method

Qian Yang

†

, Rutao Zhou

‡

and Yaxin Lu

*

Business School Beijing Institute of Fashion Technology, Beijing, China

*

sxylyx@bift.edu.cn

Keywords: Textile Printing and Dyeing Industry, Input-Output Method, Industry Affiliation, Industrial Ripple Effects.

Abstract: The textile printing and dyeing industry is an important part of the textile industry chain. The industry is

linked upstream to production materials such as spinning and weaving, and downstream to finished products

such as garments and home textiles. In 2021, in the face of complex and changeable domestic and foreign

situations and various risks and challenges, China's printing and dyeing enterprises will actively adjust their

development strategies. The output of printing and dyeing cloth has maintained a good growth trend. The

export scale of main products will be further expanded than before the epidemic, and major economic

indicators will continue to recover, the level of corporate profitability has improved significantly. Therefore,

it is particularly important to study the current development of the textile dyeing and printing industry in

China. In this paper, macroeconomic data are processed for "China's input-output table in 2018". The input-

output model is used to study the textile printing and dyeing industry. From the perspective of industrial

linkages and industrial fluctuation effects, the authors explore the relationship between China's textile printing

and dyeing industry and other industrial sectors of the national economy. Through the measurement of six

related indices, the analysis concludes that the textile printing and dyeing industry is a raw material-based

industrial sector with low value-added characteristics. The results of the study indicate that the textile printing

and dyeing industry has a strong pulling and driving effect on China's economy, and its contribution to social

employment is at an intermediate level.

1 INTRODUCTION

The textile printing and dyeing industry is an

important part of the textile industry, for clothing,

home textiles, technical textiles, and other

downstream industries to provide important technical

support, to meet the new consumer demand for textile

products, leading the new trend of green fashion to

provide important protection. Although the

transformation and upgrading of the textile printing

and dyeing industry have achieved remarkable results

in recent years, there are still many problems that

attract attention. This paper will explore the current

situation and development of the textile printing and

dyeing industry from the perspective of input and

output for the first time. The paper will mainly

measure and analyze the complete consumption

coefficient, intermediate demand rate, intermediate

input rate, impact coefficient, inductivity coefficient,

*

Corresponding author

and complete employment contribution model, and

finally come up with more practical suggestions for

development.

2 OVERVIEW OF TEXTILE

PRINTING AND DYEING

INDUSTRY

In recent years, the transformation and upgrading of

the textile printing and dyeing industry have been

promoted in-depth, the level of innovation has been

steadily improved, green development has achieved

excellent results, and the industry has further

developed towards the goal of high quality. the

printing and dyeing industry has been running

smoothly overall between 2015 and 2019, with

indicators such as scale and efficiency remaining

168

Yang, Q., Zhou, R. and Lu, Y.

Analysis of China’s Textile Printing and Dyeing Industry Based on the Input-Output Method.

DOI: 10.5220/0012027500003620

In Proceedings of the 4th International Conference on Economic Management and Model Engineering (ICEMME 2022), pages 168-173

ISBN: 978-989-758-636-1

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

within a reasonable range. The output of printing and

dyeing fabric of enterprises above the scale increased

by 1.4% annually, the sales profit margin increased

from 5.2% to 5.6%, the export quantity of eight major

products of textile printing and dyeing increased by

6.8% annually, and the export value increased by

3.0% annually. 2020, the operating income of

enterprises above the scale of the textile printing and

dyeing industry was 254.13 billion yuan, and the total

profit was 12.67 billion yuan, the operating income

accounted for 5.6% of the whole textile industry.

5.6%. 2021 green laws and regulations are

implemented to make sustainable development more

important, and enterprises in the industry increase

energy saving and emission reduction.

In this paper, according to the National Economic

Classification of Industries (GB/T 4754-2017), the

main products of the printing and dyeing industry

include cotton textile and dyeing finishing (C171),

wool textile and dyeing finishing (C172), hemp textile

and dyeing finishing (C173), silk and silk textile and

dyeing finishing (C174), chemical fiber weaving and

dyeing finishing (C175). In the "2018 Input-Output

Table" the textile industry is subdivided into 8

categories, and since only two of the 8 categories in

aggregate fall within the scope defined in this paper,

the data explored in this paper are taken only from the

2 categories in aggregate for cotton, chemical fiber

textile and printing, and dyeing finishing products and

wool textile and dyeing and finishing products. The

following section will analyze the current situation of

the industry development through the input-output

method, to put forward reasonable suggestions in a

more scientific and targeted manner.

3 TEXTILE PRINTING AND

DYEING INDUSTRY INPUT

AND OUTPUT INDICATOR

CONSTRUCTION

The data in this paper use the Input-Output Tables

2018 published by the National Bureau of Statistics,

in which 153 national economic sectors are published.

To be able to study the relationship between the sector

and other industries more clearly, this paper

collectively integrates 153 subdivision categories into

92 major categories according to the National

Economic Classification of Industries (GB/T 4754-

2017), according to which subsequent studies will be

more integrated output table for measurement.

3.1 Industry Linkages Analysis of

Indicators

Equation 1 to Equation 5 are calculated using Lu A et

al (Lu, 2013). The equations are as follows.

𝑏

denotes the coefficient of complete consumption.

𝑎

denotes the coefficient of complete consumption.

∑

𝑏

𝑎

is the indirect consumption

coefficient, which indicates the total indirect

consumption of product i buy production unit j formed

by k intermediate products.

𝑏

=𝑎

+

∑

𝑏

𝑎

(𝑖,𝑗 = 1,2,⋯,𝑛)

(1)

𝐺

denotes the intermediate demand rate for

industry sector i.

∑

𝑥

denotes the sum of the

intermediate demand for the product of industry sector

i by each industry sector.

∑

𝑥

+𝑌

denotes

the total output of products in industry sector i.

𝐺

=

∑

∑

(𝑖,𝑗 = 1,2,…,𝑛) (2)

𝐹

denotes the intermediate input rate of industry

sector j.

𝐷

denotes the full depreciation cost of

industrial sector j (1 year).

𝑁

denotes the value

created by industrial sector j.

𝐹

=

∑

∑

(𝑖,𝑗 = 1,2,…,𝑛)

(3)

3.2 Industry Wave Analysis Indicators

Inductance Coefficient is the degree of ripple effect of

production demand on various sectors of the national

economy when a unit of final product is added to the

textile printing and dyeing industry. 𝑒

is the

Inductance Coefficient of industry j; 𝐶

is the

number in the Leontief inverse matrix table; i and j are

the rows and columns in the input-output table

respectively; n is the total number of sectors in the

input-output table.

𝑒

=

∑

∑∑

(𝑖,𝑗 = 1,2,…,𝑛) (4)

𝑒

is the Reaction Coefficient of industry i; i and

j are the rows and columns in the input-output table; n

is the number of industrial sectors in the input-output

table; and 𝐶

is the element in the Leontief inverse

matrix table C.

𝑒

=

∑

∑∑

(𝑖,𝑗 = 1,2,…,𝑛) (5)

In this paper, we use the employment contribution

model of Yin F C et al (Yin, 2010), where the

compensation received by workers is used to explore

the contribution of the industry to society. 𝐷𝐿

=

Analysis of China’s Textile Printing and Dyeing Industry Based on the Input-Output Method

169

(𝑖 = 1,2,⋯,𝑛) , 𝐷𝐿

represents the direct

employment contribution. Its economic significance

indicates the direct employment generated by sector i

for the national economy. 𝑊

denotes the total

remuneration received by workers in sector i. The total

input in sector i is 𝑋

. H is a matrix consisting of ℎ

,

ℎ

represents the ratio of the quantity of sector i's

output that is used as intermediate goods by sector j to

the total output of sector i. GL indicates the full

contribution to employment.

𝐺𝐿 = (1 − 𝐻)

⋅𝐷𝐿

(6)

4 EMPIRICAL ANALYSIS

4.1 Linkage Analysis of the Textile

Printing and Dyeing Industry

4.1.1 Complete Consumption Factor

The top 5 coefficients of complete consumption in the

textile printing and dyeing industry, calculated

according to formula 1, as published in Table 1. The

textile printing and dyeing industry has the highest

coefficient of complete consumption at 0.51, which

shows that the restructuring of the industry needs to

start from its own internal structure and develop in a

coordinated manner between industries. The next

industries in the complete consumption coefficient

table are agriculture (0.28), chemical raw material and

chemical product manufacturing (0.19) and chemical

fibre manufacturing (0.19), which indicates that the

textile dyeing and printing industry is more dependent

on these industries. It is therefore possible to focus on

developing and structuring the primary and secondary

industrial chains to create a linkage and optimistic

effect.

Table 1: Complete consumption factor (partial).

NO. Industry

Textile printing

and dyeing

industry

1

Textile printing and dyeing

industry

0.514241

2 Agriculture 0.278538

3

Chemical raw materials and

chemical products

manufacturing

0.19458

4 Chemical fiber manufacturing 0.187906

5

Agriculture, forestry, animal

husbandry, and fishery services

0.088117

4.1.2 Intermediate Demand Rate and

Intermediate Input Rate

For reasons of space, only the relevant indices for the

relevant sub-sectors of the textile industry are

disclosed in this article. The intermediate demand rate

for the textile printing and dyeing industry, calculated

according to formula 2, is 0.92, ranking 9th out of all

industries with an intermediate demand rate of less

than 1, indicating that more of the textile printing and

dyeing industry's products are used in the production

of other sectors. It is thus clear that the textile printing

and dyeing industry is a sector with the nature of a raw

material industry. At present, the export market share

of textile printing and dyeing products in the world

remains basically stable, and the industry should speed

up the transformation from a quantitative scale to a

quality and efficiency one.

Table 2: Intermediate demand and intermediate input

indicators (partial).

Industry

Intermediate

demand rate

Intermedia

te input

rate

Textile printing and

dyeing industry

0.925838 0.823406

Hemp, silk, and silk

textiles and processed

products

0.962609 0.803244

Knitting or crochet and

its products

0.619587 0.865804

Textile finished products 0.442756 0.818988

Leather, fur, feathers,

and their products and

footwear industry

0.426331 0.801408

Textile clothing apparel 0.416231 0.824878

Using formula 3, the textile printing and dyeing

industry (0.82) is ranked 5th out of 92 industry sectors,

which is a relatively high ranking and represents a low

value added rate for the industry. This leads to the

conclusion that the textile printing and dyeing industry

should optimize its product structure, improve its

ability to supply high quality products and enhance its

product value and market control.

4.1.3 Summary

According to the results of the above empirical

analysis, it is indicated that although the textile

printing and dyeing industry has a closer relationship

with other industries, this dependency is much smaller

than its dependency with its own industry. This

ICEMME 2022 - The International Conference on Economic Management and Model Engineering

170

reveals that we should strengthen the optimization and

upgrading within the industry, extend the industrial

chain and help deepen the coordinated development

with other industrial sectors. The intermediate demand

rate of textile printing and dyeing industry is in the

middle and upstream position, because the textile

printing and dyeing industry has certain characteristics

of raw material industry sector, often as raw materials

into other industrial sectors industry chain. China's

textile printing and dyeing industry is still in the stage

of low value-added, but the textile printing and dyeing

industry wants to break the low value-added situation

needs to face a huge transformation challenge.

4.2 Empirical Analysis of the Ripple

Effect of Textile Printing and

Dyeing Industry

4.2.1 Reaction Coefficient and Inductance

Coefficient

The textile dyeing and printing industry has an impact

factor of 1.246402, ranking 16th out of the 92 industry

sectors studied. This indicates that the industry has a

higher influence on other industrial sectors than the

social average (the social average is 1) and has a

greater pull on the economy. Textile printing and

dyeing are in the middle of the textile industry chain

structure, the upstream of which is dominated by

weaving fabric, dyestuff, and dyeing auxiliaries, while

the downstream is concentrated in apparel, home

textile, and auto textile fields. China is the world's

largest producer and exporter of textiles and garments,

of which the demand for raw materials is also large. In

2021, in the face of complex and changing domestic

and international situations and various risk

challenges, China's printing and dyeing enterprises

actively adjusted their development strategies,

printing and dyeing fabric production maintained a

good growth trend. This background makes the textile

printing and dyeing industry also has an important

influence in China.

The inductivity coefficient of the textile printing

and dyeing industry is 1.898089, which is higher than

the social average level of 1 and ranks 11th. The

degree of sensitivity to the demand for economic

development is greater, so the industry has a pillar role

in the industrial sector of the national economy and

has a greater role in promoting the development of the

national economy. From the results of the coefficient

of complete consumption, we can analyze that the

industries such as agriculture, chemical fiber

manufacturing, and self-consumption within the

industry account for a larger proportion of the demand

for textile printing and dyeing. These industries

account for a relatively large share of GDP, so their

consumption is also large, which laterally explains the

large inductivity coefficient of the textile printing and

dyeing industry.

Table 3: Reaction Coefficient and Influence Coefficient

(partial).

Industry

Reaction

Coefficient

Influence

Coefficient

Textile printing and dyeing

industry

1.898089 1.246402

Hemp, silk, and silk textiles

and processed products

0.572981 1.145388

Knitting or crochet and its

products

0.503255 1.411436

Textile finished products 0.481902 1.339618

Textile clothing apparel 0.776402 1.350662

Leather, fur, feathers, and

their products and footwear

industry

0.6166 1.264972

4.3 Full Employment Contribution

Rate

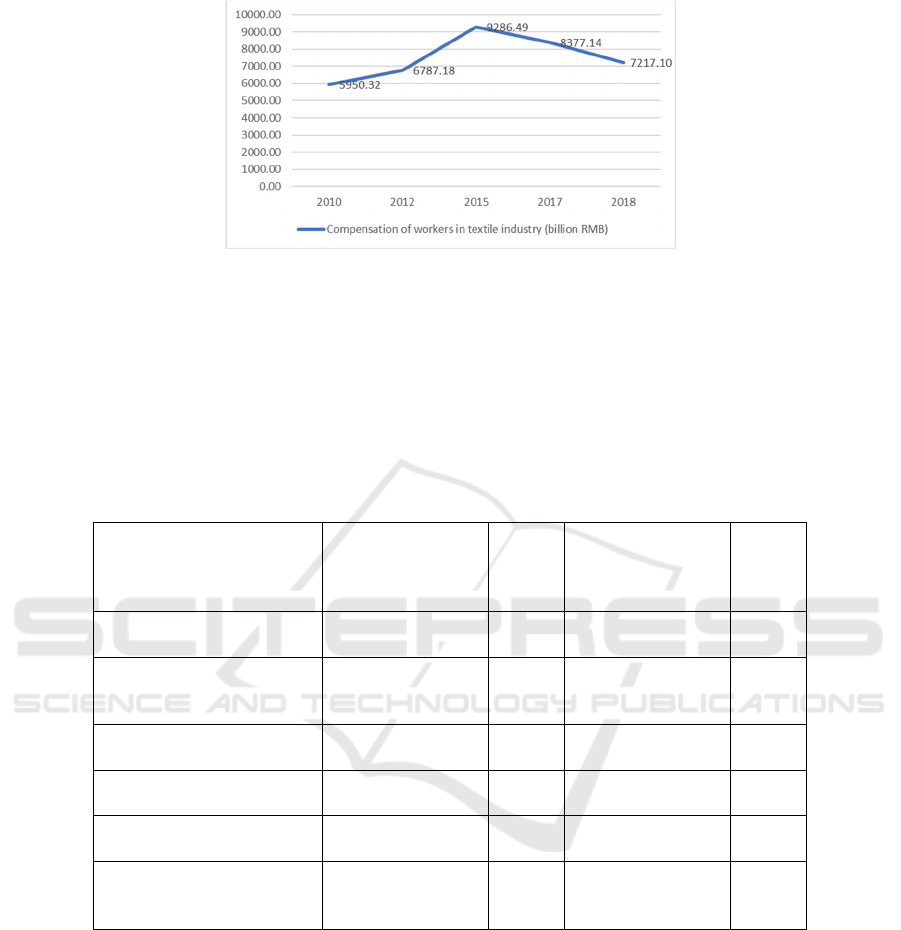

In our study of the compensation of labor in the textile

industry in the input-output table over the years, we

found that the overall compensation of labor in the

textile industry declined from 2015 onwards. The

study found that the decline in overall labor

compensation against the backdrop of a gradual rise in

labor wages indicates that the number of workers is

shrinking. According to the China Printing and

Dyeing Industry Association, the construction of

intelligent production lines has achieved obvious

results. The construction of intelligent workshops has

reduced the number of employees, helped solve the

problem of large-scale personalization, and enabled

further optimization of production efficiency and

quality.

Analysis of China’s Textile Printing and Dyeing Industry Based on the Input-Output Method

171

Figure 1: Summary of labor compensation in the textile industry in the input-output table over the years.

The full employment contribution coefficient of

the textile printing and dyeing industry ranks 69th out

of 92 national economy industries, and the overall

employment contribution to society is at an

intermediate level. The coefficient indicates that when

the textile and dyeing industry invests RMB10,000,

the contribution to the employment of society will

increase by 0.4287. The overall trend of labor

compensation in the textile industry is decreasing.

This is mainly related to the digital development of the

industry, which makes high-tech equipment replace

the previous low labor force gradually become the

main production force.

Table 4: Employment contribution of the main sectors of the textile industry.

Contribution rate index

Direct employment

contribution rate

NO.

Full employment

contribution rate

NO.

Textile printing and dyeing

industry

0.0954 69 0.4287 57

Hemp, silk and silk textiles and

processed products

0.0830 78 0.4295 56

Textile clothing apparel 0.1180 61 0.3230 80

Textile finished products 0.1084 65 0.3129 81

Knitting or crochet and its

products

0.0763 69 0.2735 85

Leather, fur, feathers and their

products and footwear industry

0.1155 62 0.2423 86

5 CONCLUSIONS

The intermediate input rate and intermediate demand

rate of textile printing and dyeing industry are greater

than 0.5, so it belongs to the intermediate product

secto

r (Ning, 2004). Generally speaking, the higher

the intermediate input rate is, the lower its added value

is. From the value point of view, China's textile

printing and dyeing industry is still in the stage of low

added value. From the Reaction Coefficient and

Influence Coefficient, it has strong pulling and driving

characteristics to economic growth. From the

measurement result of employment contribution rate,

the full employment contribution rate of textile

printing and dyeing industry is in the middle and lower

status quo.

It can be concluded that the textile printing and

dyeing industry is a major pillar industry in China, and

its ripple effect on various sectors is more obvious.

Although the textile printing and dyeing industry has

a closer relationship with other industries, this

dependency is much smaller than its dependency with

ICEMME 2022 - The International Conference on Economic Management and Model Engineering

172

its own industry. This reveals that we should

strengthen the optimization and upgrading within the

industry, extend the industrial chain and help deepen

the coordinated development with other industrial

sectors (Li, 2018).

In the future, the government can build innovative

production parks to promote the effective connection

between the upper and lower industrial chains of the

printing and dyeing industry. And they take the lead in

providing an exchange platform for enterprises and

universities to promote the rate of transformation of

the results of technological research and development

of universities and broaden the access of enterprises to

high technology. Enterprises should increase

investment in technology research and development to

set up special funds to encourage technological

innovation of R&D personnel. The product side

through sufficient preliminary market research, clear

user portrait and consumer needs, targeted product

design and accurate market segmentation, timely

grasp of consumer needs and preferences. Promote the

quality and efficiency of the industry to achieve

industrial value chain upgrading.

ACKNOWLEDGMENT

Support by: Postgraduate Thesis Project of Beijing

Institute of Fashion Technology (Project No.:

110501990112).

REFERENCES

Li M. J. Lu A., Study on the development of textile

manufacturing industry in Zhejiang Province based on

input-output analysis. [J]. Wool Textile Journal, March

2018, pp 79-84.

Lu A. Hao S L., Clothing industry histology, [M]. Beijing:

People's Publishing House, March 2013.

Ning J., Economics of the apparel industry. [M]. China

Textile & Apparel Press, January 2004.

Yin F. C. Wang Y C., Huang J Y., Research on employment

pulling effect based on input-output employment

contribution model [J]. Statistics and Decision, April

2010, pp 108-110.

Analysis of China’s Textile Printing and Dyeing Industry Based on the Input-Output Method

173