Dual Environmental Regulation, Technological Innovation and Green

Total Factor Productivity of Manufacturing Industry:

Based on the Development Background of Information Technology

Kun Xie and Xiaoling Xu

*

School of Economics and Management, Shanghai Institute of Technology, Shanghai, China

Keywords: Dual Environmental Regulation, Technological Innovation, Manufacturing Green Total Factor Productivity,

Threshold Regression Model, Information Technology.

Abstract: In the context of the development of information technology, the impact of technological innovation on the

green transformation of manufacturing industry will be affected by the intensity of environmental regulation.

Therefore, based on the perspective of dual environmental regulation, the path of technological innovation

affecting green transformation of manufacturing industry is discussed. The empirical results show that

technological innovation has a significant promoting effect on the improvement of manufacturing total factor

productivity, and with the improvement of the formal environmental regulation level, the promoting effect of

technological innovation on improving manufacturing green total factor productivity is gradually weakened;

while in the informal environment When the level of regulation is between the second threshold and the third

threshold, technological innovation has the greatest effect on promoting green total factor productivity of

manufacturing; when the level of dual environmental regulation exceeds the threshold, the impact of

technological innovation on the improvement of green total factor productivity in manufacturing will also

reduce.

1 INTRODUCTION

In today's society, the development of manufacturing

industry is inseparable from the support of

information technology. The continuous innovation

and development of information technology also

promote the high-quality development of

manufacturing industry. Theoretical and practical

experience shows that technological innovation is not

only the source of power to transform the mode of

economic development, but also the main driving

force for the green transformation of the

manufacturing industry (Jaffe and Karen, 1997).

However, in fact, technological innovation is affected

by many factors in the process of promoting the

development of the manufacturing industry, among

which the most significant is the environmental

regulation factor. A major feature of the

transformation of the manufacturing industry is the

improvement of total factor productivity, and

technological innovation is mainly achieved through

technological progress and the improvement of

market competitiveness (Abramovitz, 1993). Under

the background of specialized division of labor, the

technological progress brought about by

technological innovation is the driving force for the

transformation of the manufacturing industry. The

realization of technological progress by increasing

R&D investment and independent research and

development can ensure that the output remains

unchanged, while reducing the production costs of

enterprises (Gallego et al. 2015). Since the 1990s,

with the introduction of the environmental Kuznets

curve, the research on environmental regulation has

gradually increased ( Moutinho et al. 2020).

Environmental regulation consists not only of formal

environmental regulation from the government, but

also informal environmental regulation formed by the

public (Tian and Feng, 2020) Due to the different

operating mechanisms of the two types of

environmental regulations, the impact mechanisms

on technological innovation and the green

transformation of manufacturing are also different.

According to the theory of "Porter Hypothesis"

(Porter and Linde, 1995) the impact of formal

environmental regulation mainly changes through the

288

Xie, K. and Xu, X.

Dual Environmental Regulation, Technological Innovation and Green Total Factor Productivity of Manufacturing Industry: Based on the Development Background of Information Technology.

DOI: 10.5220/0012029700003620

In Proceedings of the 4th International Conference on Economic Management and Model Engineering (ICEMME 2022), pages 288-294

ISBN: 978-989-758-636-1

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

game between the "compliance cost" effect and the

"innovation compensation" effect (Peuckert, 2014).

Under the appropriate formal environmental

regulation, in order to legally avoid the cost of

pollutant discharge, and to obtain government

environmental protection subsidy funds, enterprises

will increase technological innovation to improve the

production process (Porter and Linde, 1995).

However, when the intensity of formal environmental

regulation is unreasonable, enterprises often adopt

negative measures such as “tail-end governance” to

deal with formal environmental regulation, which

will lead to a reduction in enterprise output,

productivity and innovation motivation (Gray and

Ronald, 2003). Under the reasonable intensity of

informal environmental regulation, the government,

the public and enterprises form an organic whole, and

the green product consumption market is further

expanded. In order to maintain competitiveness in the

green market, enterprises must increase technological

innovation. Therefore, in the context of the rapid

development of information technology, the

relationship between technological innovation and

environmental regulation is more complex, which

leads to the path of technological innovation in

promoting green change in manufacturing industry

will change with the level of environmental

regulation.

2 MODEL CONSTRUCTION AND

INDICATOR SELECTION

Based on the above analysis, to empirically test

whether there is a threshold effect of environmental

regulation when technological innovation promotes

the green transformation of the manufacturing

industry, the following panel threshold regression

model is established for research:

01 1 2

123 2

()

()()

it it it

it

mitit

Green lnT I ER lnT

IER lnTIER

Controls V

αα

γ

α

γγα γ

αμε

=+ × ≤ +

×<≤+ × >

++++

01 1

21 2

32

()

()

()

it it

it

it

mitit

Green lnT I INER

lnT I IN E R

lnT I IN E R

Controls V

ββ γ

βγ γ

βγ

βμ

ε

=+ × ≤ +

×< ≤

+× >

++++

01 1

21 2

32

()

()

()

it it

it

it

mitit

Green lnT I CossER

lnT I CossER

lnT I CossER

Controls V

χχ γ

χγ γ

χγ

χμ

ε

=+ × ≤

+×< ≤

+× >

++++

Among them, Green

it

is the green total factor

productivity of manufacturing, t represents the year, i

represents the province, β0 represents the intercept

term, Controls represents all control variables, Vi

represents the individual effect, and ɛit represents the

random disturbance term. γi represents the i threshold

values (i=1, 2, 3), I(·) is the indicator function, and µi

represents the time fixed effect. The threshold

variables of the above models are formal

environmental regulation (ER) and informal

environmental regulation (INER) and dual

environmental regulation (CossER) expressed as

(ER×INER).

Explained variable: manufacturing green total

factor productivity (Green). Its calculation method

relies on the EBM-GML model. The measurement of

total factor productivity will inevitably involve the

input and output in the production process, and one of

the characteristics of green total factor productivity is

that the output indicators take into account the

unexpected output.

Capital input is represented by the total social

fixed asset investment in the manufacturing industry

in each province; labor input is measured by the

average number of workers employed in the

manufacturing industry in each province; since there

is no statistical data on direct manufacturing energy

input in each province, this paper draws on Zhang and

Qiao (2021)

The method of estimating the final

energy consumption of the manufacturing industry in

each province is used to characterize the energy input

index.

The expected output is measured by the operating

income of the manufacturing industry, and the

undesired output mainly refers to the output of

pollutants in the production process, which is

generally represented by the "three wastes"

emissions. Characterization of carbon dioxide

emissions.

Since the direct result measured by the EBM-

GML model is the growth rate of green total factor,

the green total factor productivity of each year is

calculated based on the multiplication method of Lei

et al. (2020).

Core explanatory variable: technological

innovation (T). In the existing research on measuring

technological innovation indicators, it is mainly

measured from the perspective of input and output.

This paper uses the internal expenditure of

manufacturing R&D funds in each province to

measure, in order to avoid the biased results caused

by data heteroscedasticity, logarithmic processing.

Core explanatory variable: dual environmental

regulation (CossER). Based on the research purpose

of this paper, the characterization variables of

environmental regulation are selected from both

Dual Environmental Regulation, Technological Innovation and Green Total Factor Productivity of Manufacturing Industry: Based on the

Development Background of Information Technology

289

formal and informal aspects. Formal Environmental

Regulation (ER). Calculated as follows:

*

it

it

it

ER

ER

R

=

Among them, ER

it

*

is the ratio of industrial

pollution control investment to gross industrial output

value, and R

it

is the ratio of gross industrial output

value to regional GDP. The larger the ER

it

value, the

greater the intensity of formal environmental

regulation in the region.

Informal Environmental Regulation (INER).

Referring to the research of Wheeler and Pargal

(1996), the indicators of income level, education

level, and population density were selected, and the

entropy weight method was used to combine the three

indicators into one indicator to represent informal

environmental regulation variables.

Controls: Referring to existing research, the

regional economic development level (PGDP),

government intervention (GOV), human capital

(HUM) and transportation infrastructure level

(ROAD) were used as control variables in this study.

The specific meaning of each control variable

indicator: the per capita GNP of each province is used

to reflect the regional economic development level,

and the logarithm is used to process it; the ratio of

government fiscal expenditure to regional GDP is

used to measure government intervention; the

average education years of each province is used to

express Human capital; the ratio of the mileage of

railways and highways in each province to the

provincial area is used to represent the level of

transportation infrastructure.

Most of the sample data mentioned above can be

obtained from the 2012-2021 China Industrial

Statistical Yearbook, the China Science and

Technology Statistical Yearbook, the China Statistical

Yearbook, the 2012-2020 China Environmental

Statistical Yearbook, and China 30 Statistical

yearbook query for each province (because of the

limited availability of relevant data in Tibet and Hong

Kong and Macao), and use interpolation method to

supplement individual missing values in the data. The

data of the price variables involved are uniformly

based on 2011 Flatten. Table 1 shows the descriptive

statistics of the main variables.

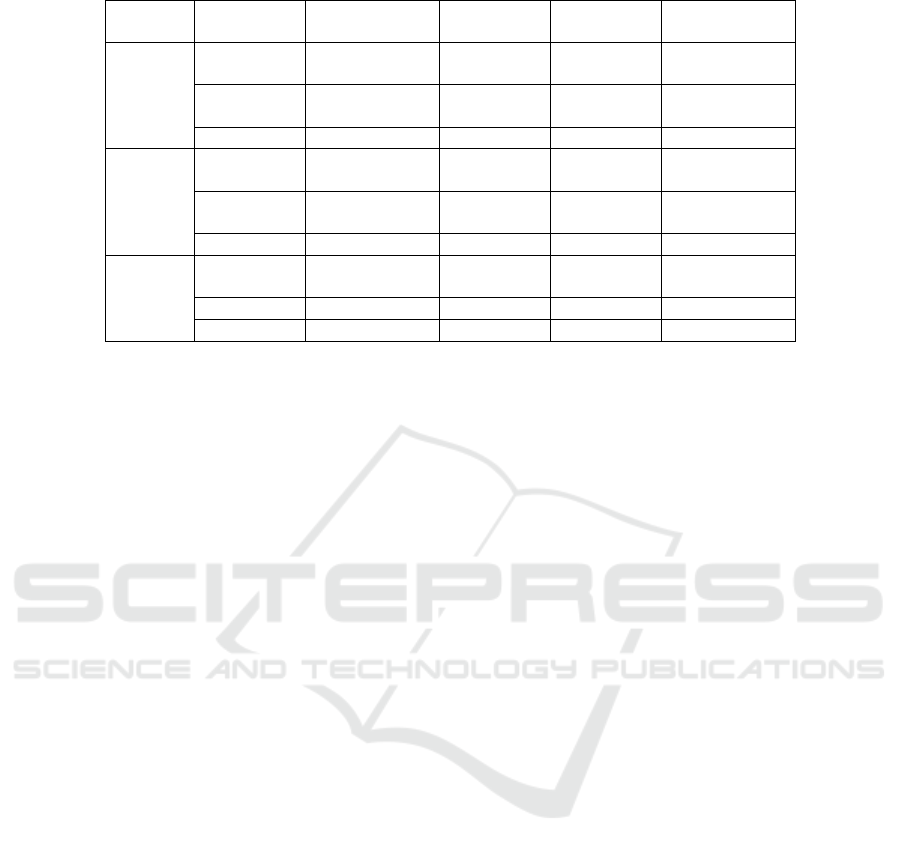

Table 1: Descriptive statistics.

Variable N Average SD Min Max

Green 300 1.316 0.263 0.831 2.358

ER 300 1.226 1.437 0.041 8.163

INER 300 0.17 5 0.171 0.038 0.943

lnT 300 14.087 1.460 10.619 16.96

GOV 300 0.250 0.103 0.110 0.643

lnPGDP 300 10.841 0.436 9.705 12.013

HUM 300 0.360 0.254 0.135 1.716

ROAD 300 11.711 0.840 9.441 12.898

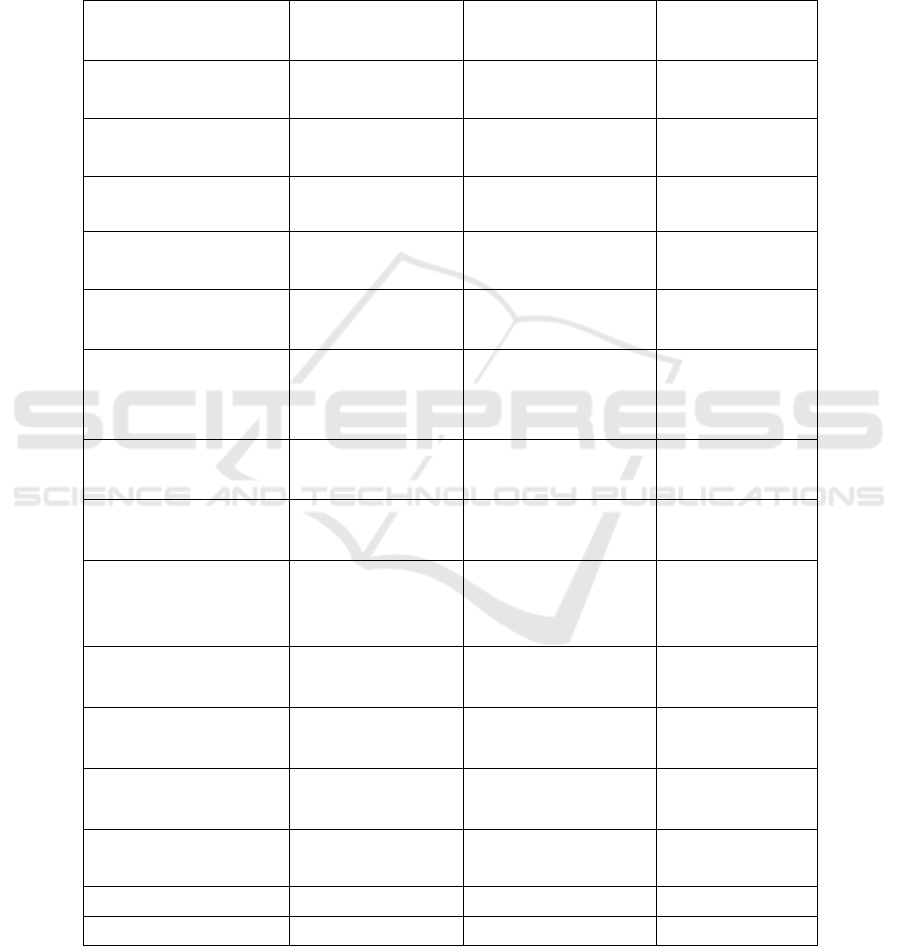

Table 2 reports the test results of repeated sampling

using the Bootstrap method for 1000 times. It can be

seen that when ER is used as the threshold variable,

the F values of the single threshold and the double

threshold have passed the 1% significance test,

indicating that with the increase of ER intensity ,

there is a double threshold effect with threshold

values of 0.8900 and 2.2261 between technological

innovation and manufacturing green transformation;

When INER is used as the threshold variable, the F

values of single threshold and double threshold have

passed the 5% significance test, indicating that with

the increase of INER, there is a double threshold

value of 0.0693 and 0.5255 between technological

innovation and manufacturing green transformation.

threshold effect; When CossER is used as the

threshold variable, only the F value of a single

threshold passes the 1% significance test, indicating

that as the intensity of CossER increases, there is a

single threshold effect with a threshold value of

0.0986 between technological innovation and

manufacturing green transformation.

ICEMME 2022 - The International Conference on Economic Management and Model Engineering

290

Table 2: Threshold effect test.

Variable Thresh-old

numbe

r

Threshold F value P value Confidence

interval

ER single 0.8900 30.71

***

0.004 [0.8345,

0.9268]

double 2.2261 22.64

**

0.013 [2.1774,

2.2486]

tri

p

le 0.2712 11.58 0.683

lnER

single 0.0693 33.54

**

0.025 [0.0686,

0.0699]

double 0.5255 32.79

**

0.012 [0.5225,

0.5308]

triple 0.5410 15.93 0.355

Coss

-ER

single 0.0986 54.12

***

0.000 [0.0975

,0.0988]

double 0.2668 9.60 0.189

triple 0.0337 7.06 0.651

Note: 1) The P value and confidence interval are the results obtained by the Bootstrap method repeated sampling 1000 times;

2) ***, *** and * indicate that the regression coefficients are significant at the 1%, 5% and 10% levels, respectively.

3 OUTCOME OF PRACTICE

From the threshold regression results, it can be seen

that there are significant differences in technological

innovation on the green transformation of

manufacturing under different environmental

regulation intensities.

When ER is in the low-intensity range, the

regression coefficient of technological innovation to

the green transformation of the manufacturing

industry is 0.174; when ER is in the medium-intensity

range, the regression coefficient of technological

innovation to the green transformation of the

manufacturing industry is 0.164; when ER is in the

high-intensity range, the regression coefficient of

technological innovation on the green transformation

of manufacturing is 0.154. That is to say, as the

intensity of formal environmental regulation

continues to exceed the threshold, technological

innovation maintains a positive role in promoting the

green transformation of manufacturing, but this role

is also weakening. The reason may be that the

transformation and upgrading of my country's

manufacturing industry is still in the "pain period",

and the "following cost" effect produced by formal

environmental regulation still constrains the

development of manufacturing enterprises, and the

regulatory costs generated may lead to "negative

behavior" of enterprises. , that is, reducing pollutant

emissions by reducing production, thereby reducing

the profit margin of enterprises and weakening the

innovation power of enterprises, so the role of

technological innovation in promoting the

transformation and upgrading of the manufacturing

industry is further weakened.

When INER is in the low-intensity range, the

regression coefficient of technological innovation to

the green transformation of manufacturing is 0.217;

when INER is between 0.0693 and 0.5255, the

regression coefficient of technological innovation to

the green transformation of the manufacturing

industry is 0.236; When INER is greater than 0.5255,

the regression coefficient of technological innovation

on the green transformation of manufacturing is

0.200. This shows that with the increasing intensity of

informal environmental regulation, the positive effect

of technological innovation on the green

transformation of manufacturing industry shows a

trend of first increasing and then decreasing. The

reason may be that under informal environmental

regulation, the green consumer market has a good

development prospect. In order to meet the needs of

the green consumer market, enterprises will increase

green technology innovation and green product

development, but when informal environmental

regulation crosses the second threshold At the same

time, in order to deal with excessive public opinion

pressure, enterprises will occupy too much of their

own resources, which will reduce the investment in

technological innovation, and the role of

technological innovation in promoting the green

transformation of manufacturing industry will

decrease.

When CossER is in the low-intensity range, the

regression coefficient of technological innovation to

the green transformation of the manufacturing

industry is 0.218; when CossER intensity is greater

than 0.0986, the regression coefficient of

Dual Environmental Regulation, Technological Innovation and Green Total Factor Productivity of Manufacturing Industry: Based on the

Development Background of Information Technology

291

technological innovation to the green transformation

of the manufacturing industry is 0.206. This shows

that the intensity of dual environmental regulation

needs to be maintained within an appropriate

intensity, so that the role of technological innovation

in promoting the green transformation of

manufacturing can be at a high level. Manufacturing

enterprises are facing more and more stringent

government system constraints and public opinion

pressure. The focus of enterprises' resource allocation

will gradually shift, and the core competitiveness of

enterprises will be reduced, thus weakening the role

of technological innovation in promoting the green

transformation of manufacturing.

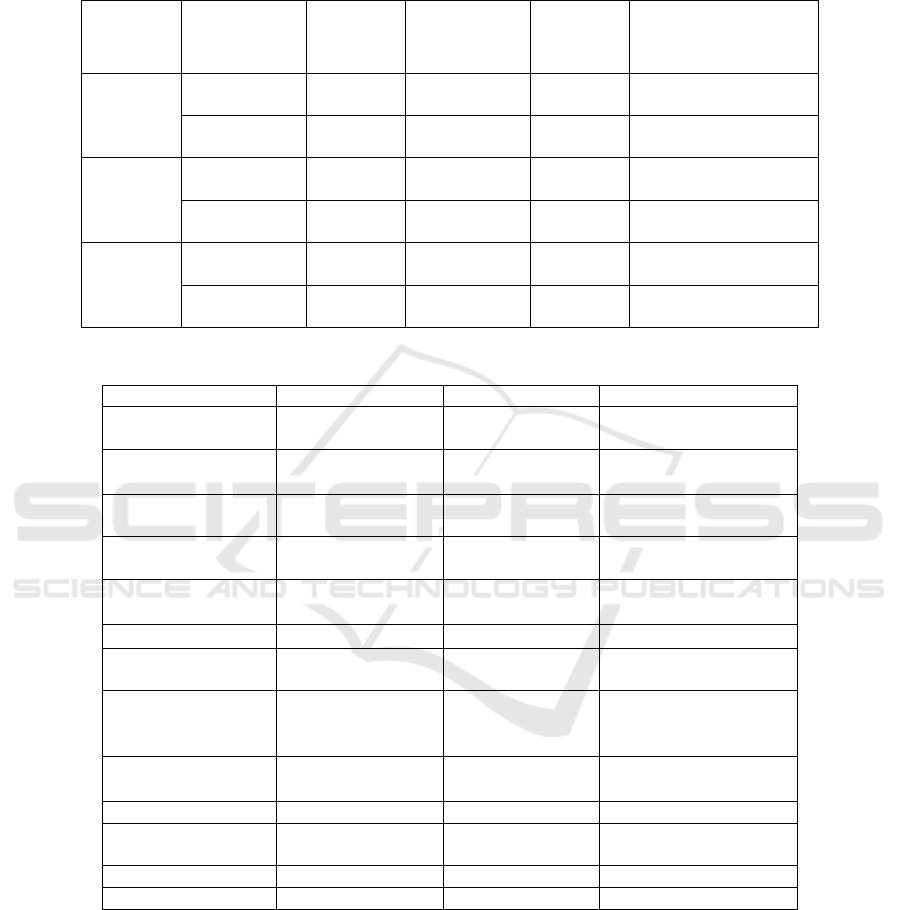

Table 3: Threshold model regression results.

Var iab le ER INER CossER

GOV 1.686

***

(4.32)

1.940

***

(5.13)

1.502

***

(3.82)

lnPGDP 0.575

***

(5.97)

0.352

***

(3.54)

0.521

***

(5.39)

HUM 2.476

***

(3.36)

3.356

***

(4.76)

2.389

***

(3.23)

ROAD -0.012

(-0.07)

0.288

(1.78)

0.098

(0.60)

lnT(ER≤0.8900)

0.174

***

(3.55)

lnT(0.8900<ER≤

2.2261)

0.164

***

(3.35)

lnT(ER>2.2261)

0.154

***

(3.11)

lnT(INER≤0.0693)

0.217

***

(4.46)

lnT(0.0693<INER≤

0.5255)

0.236

***

(4.86)

lnT(INER>0.5255)

0.200

***

(4.18)

lnT(CossER≤0.0986)

0.218

***

(4.47)

lnT(CossER>0.0986)

0.206

***

(4.22)

Constant -8.482

***

(-5.48)

-10.842

***

(-7.31)

-9.697

***

(-11.25)

N 300 300 300

F 74.76

***

79.43

***

86.93

***

In order to verify the robustness of the above

empirical results, this paper adopts the proxy variable

of replacing technological innovation, which is

different from the original index. Therefore, based on

the perspective of innovation output, the number of

manufacturing patents is selected as the proxy

ICEMME 2022 - The International Conference on Economic Management and Model Engineering

292

variable of technological innovation. Repeat the

above steps to obtain the estimation results in Table 4

and Table 5. It can be seen from the estimation results

in the observation table that they are basically

consistent with the previous ones, so the research

conclusions drawn are considered to be robust.

Table 4: Threshold effect test (robustness check).

Variab-le Threshold

Thres-

hold

F P

Confide

-nce

interval

ER

single 0.5315 36.44

***

0.000

[0.7888

,0.9268]

double 2.2261 23.86

**

0.004

[2.1774

,2.2486]

lnER

single 0.0693 34.35

**

0.011

[0.0686

,0.0699]

double 0.5396 32.79

*

0.094

[0.5307

,0.5410]

Coss

-ER

single 0.0986 51.80

***

0.000

[0.0975

,0.0988]

double 0.2668 11.55

*

0.080

[0.2386

,0.2681]

Table 5: Threshold model regression results (robustness check).

Var iab le ER INER CossER

lnT(ER≤

0.5315)

0.103

***

(2.78)

lnT(0.5315<

ER≤2.2261

)

0.092

***

(2.48)

lnT(ER>2.2261)

0.069

*

(

1.87

)

lnT(INER≤

0.0693)

0.046 (1.22)

lnT(0.0693<

INER≤0.5396

)

0.080

***

(2.13)

lnT(INER>0.5396)

0.031 (0.81)

lnT(CossER≤0.0986

)

0.125

***

(

3.34

)

lnT(0.0986<

CossER≤

0.2668

)

0.106

***

(2.85)

lnT(CossER

>0.2668)

0.095

**

(2.55)

Controls Control Control Control

Constant term -7.107

***

(-3.60)

-9.381

***

(

-4.78

)

-6.433

***

(

-3.25

)

N

300 300 300

F

73.61

***

72.41

***

74.28

***

4 CONCLUSION AND

SUGGESTION

This study analyzes the impact of technological

innovation on green total factor productivity in

manufacturing from the perspective of environmental

regulation. According to the analysis of the above

results: The role of technological innovation in

promoting green transformation of manufacturing

industry will weaken as the intensity of formal

environmental regulation increases; As the intensity

of informal environmental regulation increases, the

impact of technological innovation on the green

transformation of the manufacturing industry has a

Dual Environmental Regulation, Technological Innovation and Green Total Factor Productivity of Manufacturing Industry: Based on the

Development Background of Information Technology

293

significant double threshold feature. When the

informal environmental regulation is in the optimal

range (0.0693 < INER ≤ 0.5255), technological

innovation has a significant impact on the

manufacturing industry. The promotion effect of

green transition is higher than the other two intervals.

Based on the above analysis conclusions and in

combination with the development background of

information technology in China, suggestions are

made for the green transformation of manufacturing

industry:

Give full play to the advantages of information

technology, formulate formal environmental

regulatory policies reasonably, and strengthen the

government's regulatory capacity while ensuring the

mandatory force of formal environmental regulation.

Through Internet information technology,

improve the public's awareness of environmental

protection, increase the public's participation in the

environmental supervision and governance system,

ensure that the government, the public and enterprises

cooperate with each other, and transform reasonable

public demand for environmental protection into a

driving force for enterprise technology innovation

and green transformation of the manufacturing

industry.

REFERENCES

Abramovitz, Moses. (1993). The Search for the Sources of

Growth: Areas of Ignorance, Old and New. J. The

Journal of Economic History. 53,217–243.

Gallego, Juan Miguel, et al. (2015). Innovation and

Productivity in the Colombian Service and

Manufacturing Industries. J. Emerging Markets

Finance and Trade. 51,612–634.

Gray, Wayne B, and Ronald J Shadbegian. (2003). Plant

Vintage, Technology, and Environmental Regulation. J.

Journal of Environmental Economics and Management.

46, 384–402.

Jaffe, Adam B., and Karen Palmer. (1997). Environmental

Regulation and Innovation: A Panel Data Study. J.

Review of Economics and Statistics. 79, 610–619.

Lei Yutao, Zhang Shuwen, Sun Jingjing. (2020). The impact

mechanism and empirical research of environmental

regulation on the green transformation of

manufacturing industry. J. Science and Technology

Progress and Countermeasures. 37, 63-70.

Moutinho, Victor, et al. (2020). Determinants of the

Environmental Kuznets Curve Considering Economic

Activity Sector Diversification in the OPEC Countries.

J. Journal of Cleaner Production. 271, 1226.

Porter, M E, and Linde C V D. (1995). Green and

Competitive: Ending the Stalemate. J. Long Range

Planning. 28, 128–129.

Peuckert, Jan. (2014). What Shapes the Impact of

Environmental Regulation on Competitiveness?

Evidence from Executive Opinion Surveys. J.

Environmental Innovation and Societal Transitions. 10,

77–94.

Porter, Michael E, and Claas van der Linde. (1995). Toward

a New Conception of the Environment-

Competitiveness Relationship. J. Journal of Economic

Perspectives. 9, 97–118.

Pargal, Sheoli, Wheeler, David. (1996). Informal

Regulation of Industrial Pollution in Developing

Countries: Evidence from Indonesia. J. Journal of

Political Economy, University of Chicago Press.

104(6), 1314-1327.

Tian, Ying, and Feng Chao. (2020). The Effects of Different

Types of Internal Controls on Self-Control. J. Journal of

Strategic Innovation and Sustainability. 14,30.

Zhang Youzhi, Qiao Yuhe. (2021). Research on the Impact

of Environmental Regulation on Green Total Factor

Productivity of Manufacturing: PSM-DID Test Based

on Carbon Emissions Trading Policy. J. Ecological

Economy. 37, 30-36.

ICEMME 2022 - The International Conference on Economic Management and Model Engineering

294