A Study on the Impact of Digitization and Service Level on the

High-Quality Development of Manufacturing Industry:

The Example of Beijing, Tianjin and Hebei

Jingyuan Han and Xiao Jing

*

School of Economics and Management, Hebei University of Science and Technology, Yuxiang Street, Hebei, China

Keywords: Digitalization, Servitization, Manufacturing Quality Development.

Abstract: The manufacturing industry influences the overall development of a country's economy, and the high-quality

development of the manufacturing industry is an implication of the high-quality development of the economy.

In order to explore the factors affecting the high-quality development of the manufacturing industry, the panel

data of the three provinces of Beijing-Tianjin-Hebei from 2012 to 2020 were selected, the input-output method

and fixed-effect model were used, and the data was processed by Stata14.0 computer data processing software,

and the impact on the high-quality development of the manufacturing industry was studied from the

perspectives of digitalization and servitization. It is found that: (1) the service level of manufacturing industry

has increased in the three provinces of Beijing, Tianjin and Hebei from 2012 to 2020, while the digitalization

level of manufacturing industry has decreased; (2) after the panel return, it is found that manufacturing

servitization can significantly and positively promote the high-quality development of the manufacturing

industry, and the digitalization of manufacturing cannot significantly promote the high-quality development

of the manufacturing industry, and investing in digitalization and servitization at the same time can more

effectively increase the output value of high-tech manufacturing and promote the high-quality development

of manufacturing.

1 INTRODUCTION

The manufacturing industry is the foundation of a

strong country and represents the productivity level

and strength of a country. In the context of the double

cycle, promoting the high-quality development of the

manufacturing sector is both a deepening of supply-

side reform and an inherent requirement for high-

quality economic development. In the era of digital

economy, promoting the integration of digital

economy development and manufacturing industry is

a hot issue in the two sessions in 2022. 5G, big data

and artificial intelligence represent the new

generation of digital technology to accelerate the

penetration and expansion of manufacturing industry,

smart design, smart factory and other development

new models to transform the growth momentum for

manufacturing industry and reshape the value growth

model of manufacturing industry. 2020 "The Central

Committee of the Communist Party of China on the

Formulation of the National Economic and Social

The "Proposal on the 14th Five-Year Plan for

National Economic and Social Development and the

Visionary Goals for 2035" clearly points out that

promoting the deep integration of service industry

and manufacturing industry can promote high-quality

economic development.

The digitalization of the manufacturing industry

and the service-oriented model are two important

strategies for the high-quality development of the

manufacturing industry. Some scholars have studied

the impact of digitalization on the high-quality

development of manufacturing, and some scholars

have studied the impact of servitization on the high-

quality development of manufacturing, but they have

not studied the impact of digitalization and

servitization together on the high-quality

development of manufacturing. This paper takes

Beijing, Tianjin and Hebei as an example. Taking the

Beijing-Tianjin-Hebei region as the research object,

this paper can study the digitalization and

servitization in the Beijing-Tianjin-Hebei region on

the one hand, and discuss the impact of digitalization

and servitization on the high-quality development of

Han, J. and Jing, X.

A Study on the Impact of Digitization and Service Level on the High-Quality Development of Manufacturing Industry: The Example of Beijing, Tianjin and Hebei.

DOI: 10.5220/0012034200003620

In Proceedings of the 4th International Conference on Economic Management and Model Engineering (ICEMME 2022), pages 433-438

ISBN: 978-989-758-636-1

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

433

manufacturing industry on the other hand, as a

reference for other regions.

2 REVIEWS OF THE

LITERATURE

2.1 Digitalization Levels and Service

Transformation

Digitalization can bring new technologies and

services to the manufacturing industry and promote

the transformation of the manufacturing industry into

a service industry. The new generation of digital

technology can expand the types of services for

manufacturing enterprises, provide data-based

services for enterprises' production processes,

products, suppliers and customers, achieve a value-

added model that matches supply and demand,

combine hardware and software, reduce transaction

costs and rapidly promote the development of

servitization in manufacturing (Li 2021). The data of

listed companies in the manufacturing industry can

verify that digital development can significantly

improve the servitization level of enterprises through

improving innovation capability and optimizing

human resource structure, and also verified that

digital development can improve enterprise

performance and promote high-quality development

through servitization transformation (Zhao 2021). At

the same time, servitization is a process by which

companies enhance their value chain and increase

user value through the digital technology (Cheng,

Zhu, Xie 2021).

2.2 Servitization and High-Quality

Manufacturing Development

Manufacturing servitization can promote high-quality

development of the manufacturing industry by

extending the manufacturing value chain and

increasing the added value of products. The use of

industry data can empirically verify that the degree of

servitization of enterprises can improve the

performance of servitization in the high-tech

manufacturing enterprises (Wei, Chen 2019). At the

same time, the servitization of manufacturing

industry can positively promote the transformation

and upgrading of industrial structure (Hu, Xia, Sun

2017). Furthermore, an empirical study from the

perspective of firm mark-up rate finds that the

servitization of manufacturing inputs can strengthen

the competitive advantage of enterprises (Luo, Duan,

Zhu 2021). Servitization of manufacturing is an

inevitable trend and potential requirement in the

process of achieving high-quality development of

manufacturing (Yu, Hu 2021).

2.3 Digitalisation and High-Quality

Development in Manufacturing

The key to achieving high-quality economic

development in China has become the question of

how to deeply integrate the digital economy with the

real economy. The data of listed companies in the

manufacturing industry can verify that digital

transformation of enterprises can improve the total

factor productivity of enterprises and promote high-

quality development of the manufacturing industry

and the economy (Tu, Yan 2022).

The integration of

digital technology and manufacturing can promote

the high-quality development of China's

manufacturing industry (Song, Zhong, Wen 2022).

An empirical study using provincial panel data and

found that the digital economy significantly

contributed to the high-quality development of the

manufacturing industry, with spatial variability (Wei,

Li, Wu 2021). An empirical study using inter-

provincial panel data verify that the development of

digital economy has a significant positive

contribution to the high-quality development of

manufacturing (Hui, Yang 2022).

3 MODEL DESIGN

3.1 Model Construction

In order to eliminate the effects of unobservable as

well as constant factors associated with the provinces.

The key explanatory variables for this study were

high technology manufacturing output, the level of

digitalisation of manufacturing and the level of

servitization of manufacturing and it was

hypothesised that unobservable individual

heterogeneity was associated with the key

explanatory variables and after passing the Hauseman

test, the test results rejected the original hypothesis

and therefore a fixed effects model was chosen.

Based on the above analysis of the relevant

literature, it is clear that the input of both servitization

and digitalisation factors in manufacturing can

transform the growth momentum of manufacturing

quality development. Therefore, the following

benchmark model was constructed to verify the level

of digitisation, the level of servitization and the

impact mechanism of both on manufacturing quality

ICEMME 2022 - The International Conference on Economic Management and Model Engineering

434

development. In addition, the data on the

manufacturing quality development variables in the

model are logarithmized to eliminate the effect of

heteroskedasticity. Where

it

hqd

is the explanatory

variable,

it

dig

and

it

ser

are the explanatory

variables.

01 2

ln

it it it i it

hqd dig ser u

αα α ε

=+ + ++

Table 1: Meaning of symbols used in the model.

3.2 Description of Variables

The level of high-quality development of the

manufacturing industry. To a certain extent, the

output value of high-tech industries reflects the level

of high-quality development of the manufacturing

industry, so the output value of high-tech industries

in the three provinces of Beijing, Tianjin and Hebei is

used to measure the level of high-quality

development of the manufacturing industry. Each

province has different categories for high-tech

industries. In this paper, we choose to use the

classification of high-tech industries in the China

Statistical Yearbook, that is, the sum of the output

value of five high-tech industries, namely

pharmaceutical manufacturing, aerospace

manufacturing, electronic and communication

equipment manufacturing, electronic computer and

office equipment manufacturing, medical equipment

and instrumentation manufacturing, to measure the

high-quality development of the manufacturing

industry (Chen 2020).

Servitization of manufacturing. Using the input-

output method commonly used by scholars, 42

sectors were combined into six categories for ease of

calculation, and the ratio of manufacturing

consumption of service sector inputs to total inputs

was calculated to measure the level of servitization of

manufacturing in each province (Hu 2017). The direct

consumption coefficient is the level of direct

consumption of all service industries per unit of

product produced in manufacturing. The specific

formula can be as shown in equation (1).

d

ij

ij

j

q

r

=

(1)

In equation (1)

ij

d

is the direct consumption

coefficient of manufacturing industry j on service

industry

i

, and

ij

q

refers to the production output of

the

j

industry of the manufacturing industry

j

r

consuming the services of the service industry

i

. In

addition to direct consumption there is also indirect

consumption, and the complete consumption

coefficient is the sum of the direct and indirect

consumption of the manufacturing industry to the

service industry, for which the formula for the

complete consumption coefficient can be shown in

equation (2) as follows.

111

m...

nnn

ij ij ik kj is ik kj

kkn

ddd ddd

===

=+ +∗ +

(2)

The first term in equation (2) is the direct

consumption coefficient of manufacturing industry

j

on service industry

i

. The second term is the first

round of indirect consumption of service industry

i

by manufacturing industry j through manufacturing

industry

k

, and so on for subsequent terms. In this

paper, the full consumption coefficient is chosen to

measure the level of servitization in manufacturing.

Digitisation of manufacturing. Using the direct

consumption coefficient of manufacturing for digital

economy factors in the input-output table was used to

measure the direct consumption coefficient of

manufacturing for digital economy factors (Song

2022). A direct dependency approach was also

created to measure the direct consumption coefficient

of digital economy factors in manufacturing as a

proportion of the sum of the direct consumption

coefficients of all other sectors, which enables an

indication of the relative importance of

manufacturing industries consuming digital economy

factors versus those consuming other industries.

Symbols Description

ln

it

hqd

the level of quality manufacturing

development in province

i

in year

t

it

dig

the level of manufacturing

digitalization in province

i

in year

t

it

ser

the level of manufacturing

servitization in province

i

in year

t

i

province

t

year

i

u

an individual fixed effect that does

not vary with province

it

ε

a random disturbance term

A Study on the Impact of Digitization and Service Level on the High-Quality Development of Manufacturing Industry: The Example of

Beijing, Tianjin and Hebei

435

4 DATA COLLECTION AND

MEASUREMENT

Indicators for the high-quality development of the

manufacturing industry were obtained from the 2012-

2020 Beijing Statistical Yearbook, Tianjin Statistical

Yearbook, Hebei Statistical Yearbook, Tianjin

Science and Technology Statistical Yearbook, Hebei

Science and Technology Statistical Yearbook and the

input-output tables of Beijing, Tianjin and Hebei for

2012 and 2017. The input-output tables of each

province in China are not continuous, so the

coefficient of complete consumption can only be

calculated in the input-output tables of 2012 and

2017, while for the intermediate years, the same

"equalization" approach is adopted as other scholars.

Since the digitalisation and manufacturing service

models only became widespread in China in 2013 and

2015 respectively, the article uses the input-output

tables of the Beijing-Tianjin-Hebei region in 2012

and 2017, and uses the complete consumption

coefficient of 2012 as the data for 2012-2016 and the

complete consumption coefficient of 2017 as the data

for 2017-2020(Du 2020,

Liu 2020, Chen 2014). The

results of the digitalization and servitization

coefficient of the Beijing-Tianjin-Hebei

manufacturing industry are shown in Table2 and

Table3.

Table 2: Beijing-Tianjin-Hebei manufacturing

servitization coefficient.

Yea

r

Beijing Tianjin Hebei

2012 0.7293 0.4229 0.3107

2017 0.9461 0.5755 0.3353

Table 3: Beijing-Tianjin-Hebei manufacturing

digitalization coefficient.

Yea

r

Beijing Tianjin Hebei

2012 0.5977 0.7033 0.5657

2017 0.4891 0.6986 0.4688

5 SOFTWARE COMMAND CODE

AND RESULT ANALYSIS

5.1 Program Code

Use stata14.0 computer software technology to write

software command code to statistically analyse the

collected data.

begin

rename var1 pro

rename var2 year

rename var3 dig

rename var4 ser

rename var5 hqd

gen lnhqd=log(hqd)

reg lnhqd dig

est store m1

reg lnhqd ser

est store m2

reg lnhqd dig ser

est store m3

esttab m1 m2 m3, replace

esttab m1 m2 m3, replace p ar2

esttab m1 m2 m3, replace b(%6.4f)

p(%6.4f) ar2(4)

esttab m1 m2 m3, replace b(%6.4f)

p(%6.4f) ar2(4)///

star(* 0.1 ** 0.05 *** 0.01)///

compress nogap///

mtitle ("model1""model2""model3")///

esttab m1 m2 m3 using reg1. rtf,

replace b(%6.4f) p(%6.4f) ar2(4)

compress nogap

mtitle ("model1""model2""model3")

End.

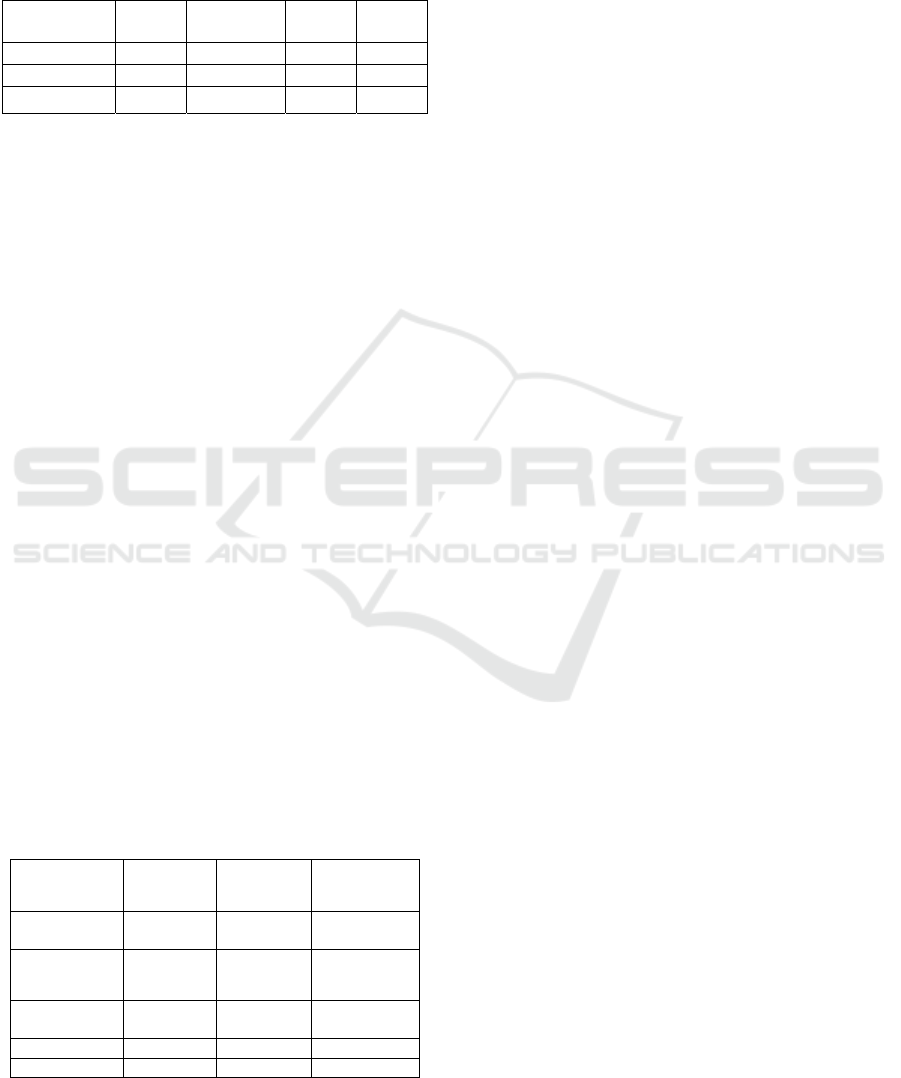

5.2 Descriptive Statistical Analysis

Results

The data were analysed descriptively using stata14.0.

From Table4, it can be seen that the maximum

digitization level of the three provinces in Beijing-

Tianjin-Hebei is 0.703 and the minimum value is

0.469, while the maximum value of manufacturing

servitization level is 0.946 and the minimum value is

0.311, which shows that there is a large gap between

the level of manufacturing servitization and the

development of manufacturing digitalization level

between the three provinces, especially the gap

between the level of manufacturing service. At the

same time, the average value of manufacturing

digitalization in the three provinces of Beijing-

Tianjin-Hebei is 0.591, while the average value of

manufacturing service-oriented level is 0.546, which

is lower than the average of digitalization level,

indicating that the digitalization level of the Beijing-

Tianjin-Hebei region is better than the development

of service-oriented level. In addition, the standard

deviation of the level of digital development of

manufacturing is 0.091, and the standard deviation of

the level of manufacturing servitization is 0.227,

indicating that the gap between the level of

manufacturing digitalization in the three provinces of

Beijing-Tianjin-Hebei is smaller than that between

the level of manufacturing service. However, these

data show that there is a large gap between the high

level of service and low level of service in the

manufacturing industry and between the high level of

ICEMME 2022 - The International Conference on Economic Management and Model Engineering

436

digitalization and low digitalization level of the

manufacturing industry, indicating that there is a clear

difference in the level of manufacturing service in the

Beijing-Tianjin-Hebei region.

Table 4: Descriptive statistics of variables.

5.3 Regression Results

Model 1 is a complete model that includes only the

level of manufacturing digitisation, model 2 includes

only the level of manufacturing servitization, and

model 3 is a complete model that includes both

manufacturing digitisation variables and servitization

variables. The results are shown in Table 4, when

only the variables of the digitalization level of the

manufacturing industry are considered in model 1, the

correlation coefficient of the digitalization level on

the high-quality development of the manufacturing

industry is positive but not significant, which may be

because the digitalization level in the Beijing-Tianjin-

Hebei region is not high, which has insufficient

impact on the high-quality development of the

manufacturing industry. In Model 2, when the direct

effect of manufacturing servitization level on the

high-quality development of manufacturing is

verified, the servitization level is significantly

positively correlated with the high-quality

development of manufacturing. When two

explanatory variables are added to model 3 at the

same time, the level of servitization and digitalization

have a significant positive impact on the high-quality

development of the manufacturing industry, and the

correlation coefficient is higher than that of a single

variable.

Table 5: Regression analysis of the fixed effects model of

factors influencing quality development in manufacturing.

Variable

name

(1)

Model 1

(2)

Model 2

(3)

Model3

Level of

digitisation

1.2901

(0.0940)

1.7576

***

(0.0004)

Level of

servitization

1.1390

***

(0.0000)

1.2444

***

(0.0000)

constants

7.2018***

(0.0000)

7.3424

***

(0.0000)

6.2459***

(0.0000)

Sample size 27 27 27

R

2

values 0.0725 0.5091 0.7012

*

p < 0.05,

**

p < 0.01,

***

p < 0.001

6 CONCLUSIONS

For the level of manufacturing servitization, from

2012 to 2020, all three provinces of Beijing, Tianjin

and Hebei have increased their level of servitization,

with Beijing having the highest and fastest growing

level of manufacturing servitization, followed by

Tianjin. The level of manufacturing servitization in

Hebei province is relatively low and the development

rate is slow. However, the level of digitization of

manufacturing declined in all three provinces. In

response, the digital economy elements were further

divided into two aspects: digital infrastructure and

digital applications, and it was found that the three

provinces had a relatively high proportion of digital

infrastructure and a relatively low proportion of

digital applications. Such a result may be due to the

fact that building digital infrastructure is a large

capital investment, high technical barriers and long

construction time. The advancement of digitization

requires the building of digital infrastructure and the

improvement of digitization level; in the process of

digital infrastructure improvement, the development

in digital information services is slow due to the

existence of technical barriers, which makes the

overall digitization show a lower trend.

In the above regression results, it can be found that

the level of service in manufacturing can significantly

enhance the output value of high technology

industries and thus promote the high quality

development of manufacturing, the level of

digitalization of manufacturing alone cannot

significantly promote the high quality development of

manufacturing, but the simultaneous input of both

digitalization and service in manufacturing can

significantly promote the high quality development of

manufacturing and has a higher impact than either of

them on the output value of high technology.

Therefore, in the process of manufacturing

development, it is important to invest not only in

service-related elements, but also to focus on the

development of digital technology in manufacturing.

However, when provinces or enterprises have limited

resources, they can focus on investing more in service

factors, while building digital facilities that are

adapted to the development direction of the province

or enterprise. In the long run, digital technologies and

platforms can support the manufacturing industry to

provide more quality services and accelerate the

service-oriented transformation of the manufacturing

industry.

The article has certain limitations, because the

input-output data is released by the National Bureau

of Statistics every 5 years, and the input-output data

Variable

name

Avera

-ge

Standard

deviation

Mini-

mu

m

Maxi-

mu

m

digitisation 0.591 0.091 0.469 0.703

servitization 0.546 0.227 0.311 0.946

high-quality 7.964 0.356 7.362 8.543

A Study on the Impact of Digitization and Service Level on the High-Quality Development of Manufacturing Industry: The Example of

Beijing, Tianjin and Hebei

437

for 2022 has not yet been released, it is impossible to

accurately measure the level of manufacturing

digitalization and service-oriented in the Beijing-

Tianjin-Hebei region in 2022. Therefore, it can only

be replaced by the data of 2012 and 2017 and it can

be further studied after the subsequent release of the

input-output data in 2022.

ACKNOWLEDGEMENTS

This work was supported by the Hebei Social Science

Foundation Project: Research on the Measurement

and Evaluation of High-quality Development of

County Economy (approval number HB19JL005).

REFERENCES

Chen Q.F., Liu Z.B. (2014). An empirical analysis of the

import of productive services on the technological

progress of China's manufacturing industry. J.

Quantitative Economic and Technical Economics

Research, 31(03):74-88.

Cheng X.M., Zhu S.Q., Xie H. M. (2021). Digitalization,

service strategy and business model innovation. J.

Technology and Economy, 34(01):36-40.

Chen Q.P. (2020). Scientific and technological progress,

collaborative innovation and high-quality development

of manufacturing industry in Yangtze River Delta. J.

Jiang huai Forum, (02):103-112.

Du C.Z., Jin W.H. (2020). The employment scale effect of

manufacturing service transformation. J. Contemporary

Finance and Economics, (12):112-124.

Hu Z.L., Xia Q., Sun G.Y. (2017). Servitization of

manufacturing industry, technological innovation and

industrial structure transformation and upgrading-an

empirical study based on WIOD cross-country panel

data. J. International Economic and Trade Exploration,

33(12):4-21.

Hui N., Yang X. (2022). Digital economy drives the high-

quality development of China's manufacturing industry.

J. Journal of Shaanxi Normal University (Philosophy

and Social Science Edition), 51(01):133-147.

Li X.H. (2021). The development of service-oriented

manufacturing innovation driven by digital technology.

J. Reform, (10):72-83.

Liu Y.C., Luan W.X., Wan S.L. (2020). Does

manufacturing servitization match manufacturing

productivity--Empirical evidence of multiple mediating

effects based on joint cubic equations. J. Journal of

Shanxi University of Finance and Economics,

42(01):56-71.

Luo Y., Duan W.J., Zhu S.J. (2021). How servitization of

manufacturing affects firms' competitive advantage - a

study based on the perspective of firms' markup rate J.

Financial Theory and Practice, 42(01):125-132.

Song Q.H., Zhong Q.M., Wen H.W. (2022) Industrial

digitization and total factor productivity of firms -

Evidence from listed Chinese manufacturing

companies J/OL. Journal of Hainan University

(Humanities and Social Sciences Edition):1-11.

Tu X.Y., Yan X.L. (2022). Digital transformation,

knowledge spillover and total factor productivity of

firms - empirical evidence from listed manufacturing

firms. J. Industrial Economics Research, (02):43-56.

Wei L., Chen H.J. (2019). The impact of technological

innovation capability and servitization degree on the

servitization performance of high-tech manufacturing

enterprises-an empirical test from data of five major

industries. J. Science and Technology Progress and

Countermeasures, 36(13):97-104.

Wei Z.Y., Li Y.T., Wu K.D. (2021). Can the digital

economy promote high-quality manufacturing

development? -- An empirical analysis based on inter-

provincial panel data. J. Wuhan Finance, (03):37-45.

Yu D.H., Hu Y.N. (2021) Servitization of manufacturing,

technology path selection and high-quality

development. J. Economic and Management Studies,

42(09):28-41.

Zhao C.Y. (2021). Digital development and service

transformation-empirical evidence from listed

manufacturing companies. J. Nankai Management

Review, 24(02):149-163.

ICEMME 2022 - The International Conference on Economic Management and Model Engineering

438