Application of Vapor Compression System in Dehumidification

Based Drying Equipment

Made Ery Arsana

a

, Sudirman

b

, Achmad Wibolo

c

and I Nengah Ardita

d

Mechanical Departmen, Politeknik Negeri Bali, Jl. Kampus Bukit Jimbaran, Badung, Indonesia

Keywords: Vapor Compression, Drying, Dehumidification.

Abstract: The refrigeration system is not only used for domestic and commercial air conditioning, but it can also be

used to dry agricultural products. This article discusses drying using a dehumidification system that utilizes a

vapor compression system, which is better known as a refrigeration system. With this system, the compressor,

which is the heart of the refrigeration system, shows that it is safe to use for drying machines. The drying

machine was tested on gemitir flowers, which have multiple functions that will decrease if dried at

temperatures above 60 degrees Celsius. The machine was set at a temperature of 40 degrees Celsius and a

humidity level of 40 percent. Test results show that the average weight loss of gemitir flowers is 85 percent,

the product moisture content is 8 percent, and the energy consumed is 4.18 kWh/kg of gemitir flowers.

1 INTRODUCTION

Drying or dehydration is an ancient food processing

method that has the potential to preserve and reduce

packaging, storage, and transportation costs by

reducing the mass and volume of dry or dehydrated

products (Potisate et al., 2010). Dry or dehydrated

food is microbiologically stable because microbial

growth is controlled by low water activity. Protective

packaging and several dehydration methods may be

required to maintain product quality, including color,

taste, and structure (Kerr et al., 2013).

In the drying process, heat is required to evaporate

the moisture from the product and air flow to carry

the evaporated water vapor, making drying a high-

energy consuming operation (Jangam and Mujumdar,

2010). There are various heat sources available for

drying, and these have been well discussed in many

articles (Bailes, 2015). However, due to the increase

in fossil and electricity prices and CO2 emissions in

conventional drying methods, green energy-saving

and other heat recovery methods for processing and

drying products have become very important. Heat

pump technology has been successfully used to dry

agricultural products as well as for other domestic

a

https://orcid.org/0000-0002-6647-6621

b

https://orcid.org/0000-0002-5515-159X

c

https://orcid.org/0000-0002-7721-4037

d

https://orcid.org/0000-0003-3391-2404

dehumidification/heating applications. It has been

used for heating, ventilation, and air conditioning in

the domestic and industrial sectors in most developed

countries in the world, including Indonesia. However,

heat pump drying (HPD) of fruits and vegetables is

largely unexploited in Indonesia.

The purpose of this research is to develop a drying

machine with a low-temperature using a vapor

compression system, namely a refrigeration system.

The refrigeration system has four main components,

namely compressor, condenser, expansion valve, and

evaporator.

2 MATERIALS AND METHODS

2.1 Material

The Gemitir flower (Tagetes erecta Linn.) is a plant

that grows extensively in Central America and

countries in Asia, including Indonesia (Aristyanti et

al., 2017). Also known as the Marigold flower (Beti,

2020), it exhibits various pharmacological activities

such as antibacterial, antioxidant, hepatoprotective,

Arsana, M., Sudirman, ., Wibolo, A. and Ardita, I.

Application of Vapor Compression System in Dehumidification Based Drying Equipment.

DOI: 10.5220/0012068700003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 1089-1093

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1089

antiepileptic, antipyretic, carminative, and more

(Siddhu et al., 2017). The flower's color is produced

by two main pigments, namely a small number of

flavonoids and carotenoids (Aristyanti et al., 2017).

Gemitir flowers contain secondary metabolites in the

form of terpenoids, essential oils, phenols,

flavonoids, and carotenoids (Valvoya et al., 2012).

However, it's important to note that the flower's

usefulness decreases or is lost when heated to a

temperature above 60°C (Arun Kumar et al., 2010).

The Gemitir flowers used as experimental material in

this study were dried using a dehumidifier system

dryer.

2.2 Dehumidification Drying Machine

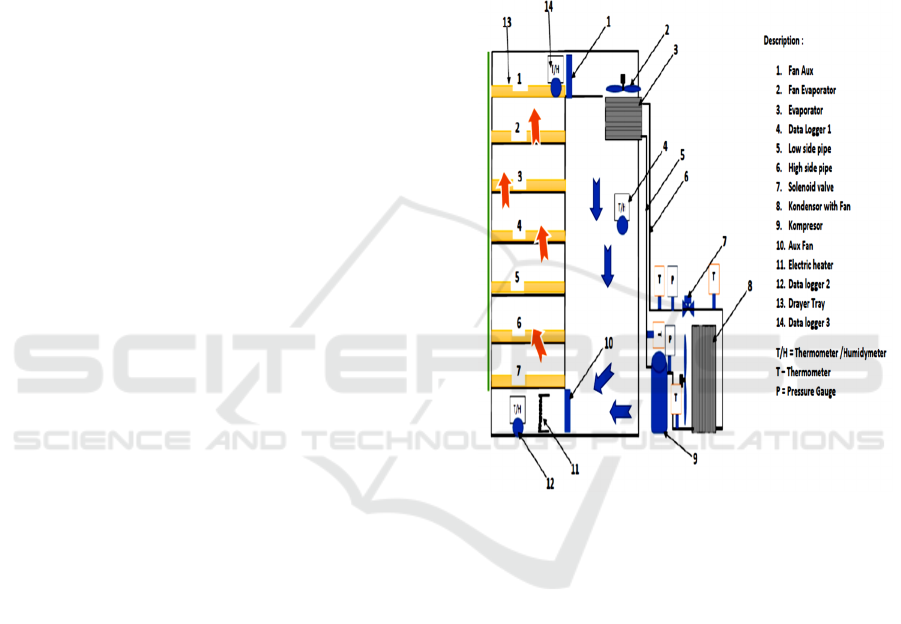

Figure 1 shows the schematic of the dehumidification

dryer used in this study. The dryer consists of a drying

chamber with 7 shelves for placing the bitter flowers,

an air circulation room with an evaporator, a fan, and

an electric heater. Four fans between the drying

chamber and air circulation room facilitate air

circulation. Outside the dryer, there is a compressor,

condenser, fan, and expansion valve.

The dehumidifier system drying machine works

by directing air from the drying chamber to the fan

and evaporator. The air in the evaporator is cooled,

causing water vapor from the air in the drying

chamber to turn into water, which is then discharged.

The cold and dry air then flows into the electric

heater, where it is heated before entering the drying

racks filled with bitter flowers. The heated air helps

to evaporate the water vapor from the gemitir flowers,

which then flows upwards. The humidity of the

drying air increases after passing through the bitter

flowers and moves towards the evaporator. In the

evaporator, the air is cooled, and the water vapor it

carries is condensed. This process is repeated until the

bitter flowers are dried to the desired level. The

temperature in the drying chamber is regulated using

a thermostat, while the humidity is controlled using a

humidistat, which turns on the compressor when

necessary.

2.3 Methode

This method assumes that the experiment is

conducted on a small scale, and that there is only one

batch of flowers being dried. If the experiment is

conducted on a larger scale or over multiple batches,

adjustments may need to be made to the method to

ensure accuracy and consistency.

2.3.1 Drying Process:

a) Place one portion of the fresh flowers onto each

shelf of the drying chamber, ensuring that each

shelf contains 500 grams of flowers.

b) Start the timer and begin the drying process.

c) Monitor the temperature and humidity levels at

point (4), point (12) and point (14) throughout

the drying process.

d) Record the time it takes for the flowers to dry

completely.

Figure 1: Drying machine dehumidification system.

2.3.2 Measurement:

a) Once the flowers are dry, remove them from the

drying chamber and weigh them.

b) Record the weight of the dried flowers.

c) Calculate the moisture content of the flowers

using the following formula: Moisture content

(%) = (Initial weight - Final weight) / Initial

weight x 100%

2.3.3 Analysis:

a) Analyze the data collected to determine the

effectiveness of the drying process.

b) Evaluate the temperature and humidity levels at

each monitoring point and their impact on the

drying process.

c) Assess the overall efficiency of the drying process

and determine any improvements that can be made.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

1090

3 RESULTS AND DISCUSSION

Based on the test results, weight measurements and

data obtained from the data logger were used to create

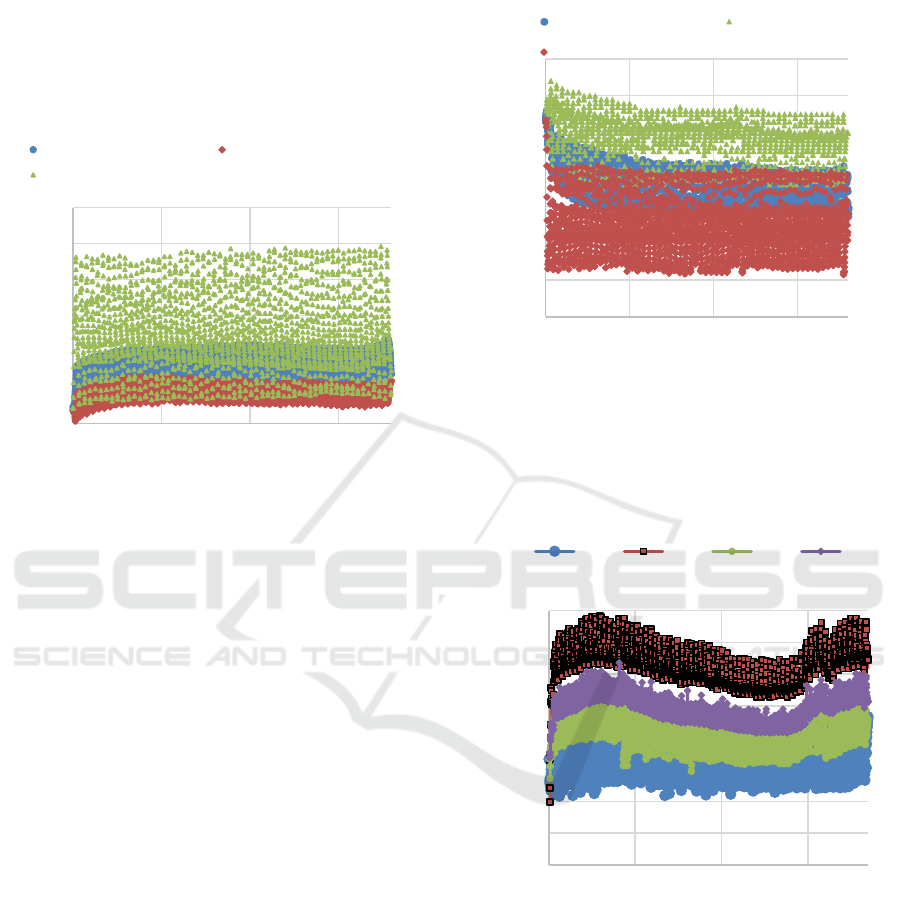

graphs and tables for easier analysis. Figure 2 shows

the graph of the drying chamber temperature

measured at three different points.

Figure 2: Graph of drying chamber temperature from 3

measurement points.

However, the measurements obtained from the

data logger show a wide range of values, indicating

that the airflow measured by the sensor is not laminar.

The temperature at measurement point (12) tends to

be higher than the others, as the air at that point has

passed through the heater. After passing through the

heater, the air then passes through the flower, which

causes a slight decrease in temperature, as seen at

point (14). Finally, the air reaches the evaporator and

measurement point (4), which records the lowest

drying air temperature.

To improve the accuracy of the measurements, it

may be necessary to ensure that the airflow is laminar

during the testing process. Additionally, future tests

could be conducted to compare the results obtained

from the data logger with those obtained from other

measuring devices, to confirm the accuracy of the

measurements.

Overall, the data obtained from the weight

measurements and data logger provide valuable

insights into the performance of the drying chamber,

and can be used to optimize its operation in order to

achieve more efficient and effective drying results.

The results of the drying chamber humidity

measurements are shown in Figure 3. The highest

humidity levels are recorded at point (12), as the air

However, the humidity tends to decrease as the air

passes through the load of bitter flowers, which

absorbs some of the moisture. passes through the

heater and its moisture content increases.

Figure 3: Drying chamber humidity graph from 3

measurement points.

Finally, the air passes through the evaporator and

its humidity level is the lowest at point (4), as the air

is condensed into liquid form.

Figure 4: Graph of measurement points on the refrigeration

system.

Figure 4 shows the measurements obtained from

the refrigeration system. Channel 1 records the lowest

temperature, as it is located at the point where the R32

refrigerant enters the compressor in its gaseous form.

Channel 2 records the temperature of the refrigerant

as it exits the compressor, having been pressurized

and heated. Channel 3 records the temperature of the

refrigerant as it passes through the condenser and its

heat is removed, causing the refrigerant to condense

25

30

35

40

45

50

55

0 500 1000 1500

Temperatur˚C

Time(second)

T°Catpoint(14) T˚Catpoint(4)

T°Catpoint(12)

25

35

45

55

65

75

85

95

0 500 1000 1500

Humidity(%)

Time(second)

H%atpoint(14) H%atpoint(12)

H%atpoint(4)

10

15

20

25

30

35

40

45

50

0 500 1000 1500

Temperature(

0

C)

Time(second)

1ch 2ch 3ch 4ch

Application of Vapor Compression System in Dehumidification Based Drying Equipment

1091

into a liquid form. Finally, channel 4 records the

temperature of the refrigerant as it passes through the

expansion valve, causing its pressure to decrease and

its temperature to remain relatively constant.

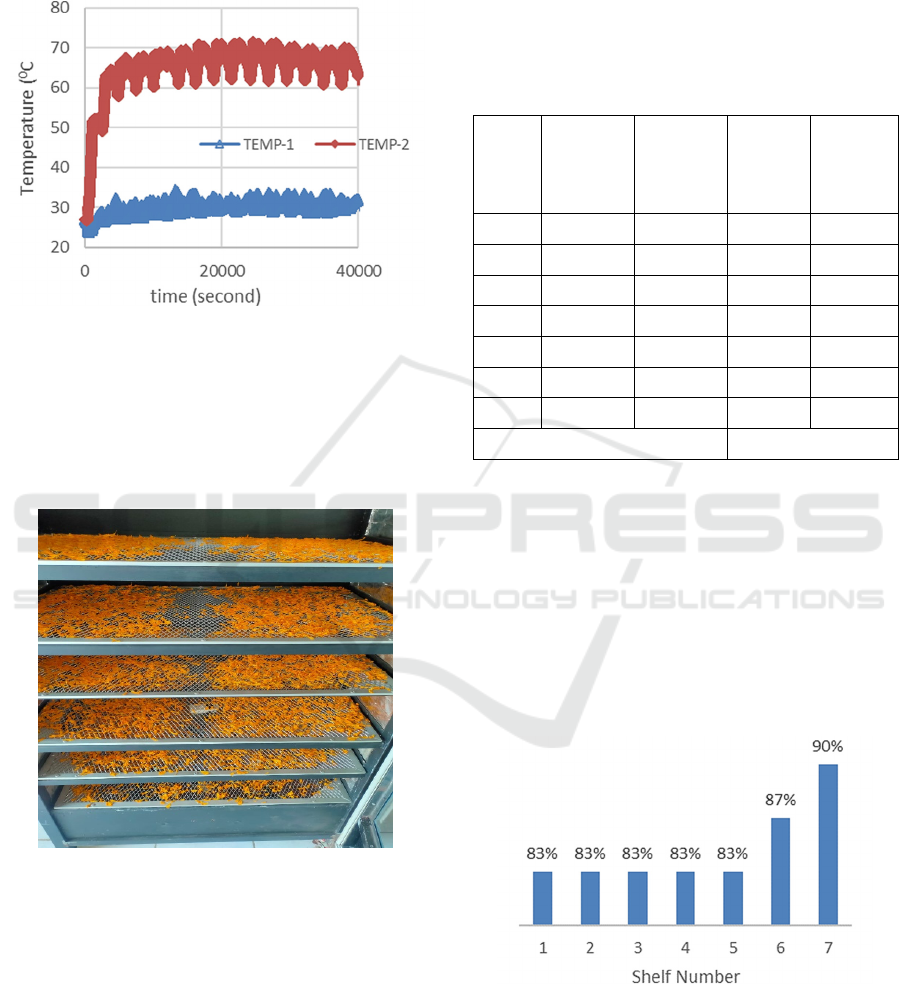

Figure 5: Graph of compressor casing temperature while

operating. (1.lower casing, 2.upper casing).

To ensure the safety of the refrigeration system, it

is important to monitor the temperature of the

compressor, which is the heart of the system. Figure

5 shows the graph of the compressor casing

temperature while the system is operating.

Figure 6: Gemitir flowers that have been dried for 24 hours

in a dehumidification system dryer.

The temperature of the compressor casing is a

good indicator of whether the system is operating

safely or not. If the temperature of the casing is close

to 100ºC, it indicates that the compressor is operating

in unsafe conditions and its coils may burn.

However, if the temperature is far below 100ºC,

then the system can be considered safe. In this

particular system, the compressor operating

temperature is around 70ºC, indicating that the system

is operating within safe parameters and the

compressor motor is not at risk of burning out.

Monitoring the compressor temperature is an

important part of ensuring the safe and efficient

operation of the refrigeration system.

After 24 hours the dryer is turned on, the results

of the dried gemitir flowers are as follows:

Table 1: Yield of dried gemitir flowers.

Shelf

Initial

Weight

(Grams)

Final

Weight

(Grams)

Weight

Loss

(%)

Moist

ure

content

(%)

1

150 25 83% 10,5

2

150 25 83% 9

3

150 25 83% 8,3

4

150 25 83% 8

5

150 25 83% 7,8

6

150 20 87% 7,5

7

150 15 90% 5

Total Energi 14,63 kWh

The drying process resulted in an average weight

loss of 85% for the gemitir flowers after 24 hours. The

largest weight loss was observed on rack number 7,

which is positioned directly above the electric heater

and receives the most heat. The average moisture

content of the dried flowers was measured at 8%.

To calculate the energy required to convert fresh

gemitir flowers into dried gemitir flowers, we divided

the total energy spent (14.63 kWh) by the total weight

of the dried flowers (3.5 kg). The resulting energy

consumption was 4.18 kWh/kg of gemitir flowers.

Figure 7: Loss of weight after drying.

This energy consumption value can be used to

optimize the drying process and minimize energy

waste. Additionally, the information about the weight

loss and moisture content of the dried flowers can

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

1092

help determine the appropriate storage conditions and

shelf life of the product.

Overall, the results of the drying process indicate

that the system is effective at removing moisture from

the gemitir flowers, with the largest weight loss

occurring on the rack positioned closest to the heat

source. The calculated energy consumption value can

be used to improve the efficiency of the process and

ensure optimal product quality.

4 CONCLUSIONS

In conclusion, the dehumidification system using a

refrigeration system was successful in drying gemitir

flowers, resulting in a weight loss of 85% and an

energy consumption of 4.18 kWh/kg. The system can

be optimized by monitoring weight loss and energy

consumption, allowing for adjustments to be made to

improve efficiency and reduce energy waste.

The results of this study can be used to improve

the overall effectiveness and cost-efficiency of the

drying process for gemitir flowers. With further

optimization, this system could potentially be used on

a larger scale for commercial drying applications.

ACKNOWLEDGEMENTS

I would like to thank PNB's P3M team who have

worked hard to create a reliable research and

community service system. and also thanks to the

Director of the Bali State Polytechnic for funding this

research.

REFERENCES

A. Bailes, “The Shocking Truth about Heat Pumps,” 2015,

http://www.energyvanguard.com/ blog-building-

science-HERSBPI/bid/69996/The-Shocking-Truth-

About-Heat-Pumps.

Arun Kumar Attkan, Nitin Kumar, Yogender Kumar Yadav,

“Performance Evaluation of a Dehumidifier Assisted

Low Temperature Based Food Drying System”, IOSR

Journal Of Environmental Science, Toxicology And

Food Technology (IOSR-JESTFT) e-ISSN: 2319-

2402,p- ISSN: 2319-2399. Volume 8, Issue 1 Ver. V

(Feb. 2014), PP 43-49

Aristyanti, N.M.P., Wartini, N.M., Gunam, I.B.W. 2017.

Rendemen dan Karakteristik Ekstrak Pewarna Bunga

Kenikir (Tagetes erecta L.) pada Perlakuan Jenis

Pelarut dan Lama Ekstraksi. Jurnal Rekayasa dan

Manajemen Agroindustri, 5(3): 13-23.

Beti, J. A. 2020. Marigold (Tagetes erceta L.) Tanaman

Hias Potensial Multiguna. Prosiding Seminar Nasional

Petanian Peternakan Terpadu Ke-3. Jawa Tengah:

158-166.

Kumar, R., Yu, W., Jiang, C., Shi, C., Zhao, Y. 2010.

Improvement of the Isolation and Purification of Lutein

from Marigold Flower (Tagetes erecta L.) and its

Antioxidant Activity. Journal of Food Process

Engineering, 33: 1065-1078.

Siddhu, N. dan Saxena, J. 2017. Quantification of Total

Phenolic and Total Flavonoid Content of Extracts of

Tagetes erecta Flower. Asian Journal of Pharmaceutical

and Clinical Research, 10(6): 328-330

S. V. Jangam and A. S. Mujumdar, “Classification and

selection of dryers for foods,” in Drying of Foods,

Vegetables and Fruits, S. V. Jangam, L. C. Lim, and A.

S. Mujumdar, Eds., vol. 1, pp. 59–82, Singapore, 2010.

W.L. Kerr. Food Drying and Evaporation Processing

Operations. In: Kutz M (ed.). Hand book of Farm, Dairy

and Food Machinery Engineering. 2nd ed. Academic

Press, San Diego (2013) 317-354.

Valvoya, M., Stoyanov, S., Markovska, Y., and Ganeva Y.

2012, Evaluation of in vitro antioxidant activity and

free radical scavenging potential of variety of Tagetes

erecta L. flowers growing in Bulgaria, International

Journal of Applied Research in Natural Products, 5(2):

19-25.

Y. Potisate, and S. Phoungchandang. Chlorophyll retention

and drying characteristics of ivy gourd leaf (Coccinia

grandis Voigt) using tray and heat pump-assisted

dehumidified air drying. Dry. Technol. 28 (2010) 786-

797.

Application of Vapor Compression System in Dehumidification Based Drying Equipment

1093